Professional Documents

Culture Documents

Fact Sheet: Hazards Associated With Spray Painting in Shipyard Employment

Uploaded by

carlo cuevas100%(1)100% found this document useful (1 vote)

45 views3 pagesOriginal Title

OSHA3897

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

45 views3 pagesFact Sheet: Hazards Associated With Spray Painting in Shipyard Employment

Uploaded by

carlo cuevasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Shipyard

Employment

Fact Sheet

Hazards Associated with Spray

Painting in Shipyard Employment

The construction and maintenance of vessels often involves spray painting, which can pose serious

hazards to workers. The primary dangers include fires and explosions from flammable paints and coatings,

as well as exposures to chemical hazards and toxic substances. The work is frequently conducted in

confined spaces that, if not properly ventilated, can cause sickness or death for workers. Employers must

take the necessary precautions to safeguard workers.

Exposure to Hazardous Substances

During spray painting operations, workers are at a greater risk of remain enforceable. However, the agency recommends that

exposure to hazardous substances than when they are painting employers use the most protective occupational exposure limits to

with a brush or roller. Paint particles are released into the better protect their workers.

atmosphere through the spray nozzle, which increases the release

of hazardous vapors. While safer methods have been developed, Fires or Explosions

such as using less volatile and less toxic paints and coatings, and Spray painting releases significant amounts of flammable and

low-flow airless spray nozzles, shipyard employers still need to combustible vapors into the atmosphere, which increases the

take precautions to avoid hazardous exposures to workers. This is potential for fires or explosions. A spark from electrical equipment or

especially true in confined spaces. static discharge can be enough to ignite volatile vapors. Employers

Shipyard employers are responsible for identifying, evaluating, must follow the safety precautions provided in 29 CFR 1915.36

and protecting workers from exposure to respiratory and other and 1915.35(b) when spray

hazards in the workplace. Where appropriate, employers must painting activities are capable

ensure chemical labels and safety data sheets are made available of producing a flammable or

to exposed workers, and train them on the hazards and measures combustible atmosphere.

necessary to protect themselves.

Control Measures

For more information on hazard communication requirements Exposure to dangerous

specific to work performed in the maritime industry, see OSHA compounds can be prevented

Fact Sheet — Hazard Communication in the Maritime Industry. by using engineering controls

and personal protective

equipment (PPE). However,

OSHA’s maritime standards specify permissible exposure limits

Photo: OSHA

the use of engineering

(PELs) and other controls to protect workers from chemical hazards

controls should be evaluated

(29 CFR Part 1915, Subpart Z). However, based on more recent

and implemented before

science, lower and more protective exposure limits have been A worker involved in spray

relying exclusively on PPE for

recommended by many technical, professional, industrial, and painting applications.

protection. Always review the

government organizations, both inside and outside the United States.

manufacturer’s safety data sheet (SDS) for all paints and coatings

Details can be found at www.osha.gov under Permissible Exposure

to determine flash points and if other volatile, toxic, or flammable

Limits — Annotated Tables. OSHA’s mandatory PELs in the Z-Tables

substances are in the mixtures.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

Engineering Controls • Check that all power and lighting cables are inspected regularly by

Engineering controls, such as ventilation, are used to prevent a competent person to verify that the insulation is free of cracks and

worker exposure to hazardous atmospheric conditions and fires or worn spots, lines are not overloaded, and that cables are suspended

explosions. During the spray application of paints or coatings where with sufficient slack to prevent undue stress or chafing.

the potential for such hazards exists, a shipyard competent person • Prohibit the use of objects or equipment that produce open

must conduct frequent tests to verify that solvent vapors are at a flames or sparks, such as matches, lit cigarettes, cigars or pipes,

concentration below 10% of the lower explosive limit (LEL). Additionally, cartridge-type stud guns, and tools used for hot work. Use only

when using paint mixtures containing highly toxic, flammable, and non-sparking paint buckets, spray guns, and tools.

explosive solvents with flash points below 80°F, employers must: • Keep electrical connections at least 50 feet or more from paint

and tank coating operations.1

• Stop painting operations and immediately evacuate exposed

workers when atmospheric testing indicates that the concentration Each connection within 50 feet of painting operations must be

of solvent vapors reaches or exceeds 10% of the LEL. evaluated based on the class of the location in which they are

• Use exhaust ventilation that is discharged away from working intended to be used, in addition to the ignitable or combustible

areas and potential ignition sources to keep concentrations of properties of the specific gas or vapor present (29 CFR 1910.307(c)

flammable vapors below 10% of the lower explosive limit and (2)). The National Electrical Code, NFPA 70, which defines hazardous

prevent fires or explosions. gases, vapors, and dusts by their ignitable or combustible properties,

• Continue using ventilation after the completion of paint or also contains guidelines for determining the type and design of

coating applications to dissipate excess vapor concentrations, equipment and installations approved for a specific hazardous

keeping the compartment or space gas free. (classified) location. Examples of such design principles and

equipment characteristics may include the use of positive pressure

• Retest the atmosphere 10 minutes after ventilation has been

ventilation, as well as explosion-proof, non-incendiary, intrinsically

discontinued to confirm that atmospheric conditions remain at

safe, and purged and pressurized equipment.

an acceptable level.

Personal Protective Equipment

For additional information on the selection, installation and use of

ventilation equipment, see OSHA guidance document 3639 — Employers must assess work activities at their facility to determine

Ventilation in Shipyard Employment. if hazards are present or likely to be present that require worker

use of PPE. 29 CFR Part 1915, Subpart

I, specifies employer responsibilities to

Tools and Equipment provide workers with and ensure the use

Tools and equipment have the potential to be an ignition source of PPE that will adequately protect them

in flammable and combustible atmospheres through an electrical from the hazards identified. To protect

spark or static discharge. Employers must: workers from hazards associated with

spray painting operations, employers

• Confirm that, where paints or coatings in use have flash points must make sure workers use:

below 80°F, all tools, equipment, and associated metallic parts

(e.g., spray guns, paint pots, motors, fans, ventilators, and duct • Airline respirators with auxiliary self-

work) are electrically bonded and/or grounded to the vessel to contained air supply for emergency

prevent static discharge. Fan blades and portable air ducts must escape when paint mixed with toxic

solvents is being applied through

Photo: OSHA

be made of nonferrous material, no ferrous materials may be

taken into work areas, and all staging and scaffolds must be spray application in confined spaces.

erected in a manner that ensures they are non-sparking. During exterior spray painting

operations, use of filter cartridge Airline respirator with

• Make sure that where paints or coatings in use have flash points personal protective

below 80°F, all motors and control equipment are classified as type respirators is required.

equipment (PPE) to

explosion-proof and are properly maintained and grounded. • The appropriate PPE, such as prevent skin contact.

• Ensure that the metallic parts of air moving devices, such as protective clothing, gloves, goggles,

fans, blowers, and jet-type air movers, and all duct work are and face shields, that prevent air sprayed coatings from

bonded to the vessel’s structure where paints or coatings in use contacting the worker’s face, eyes, head, hands, feet and other

are mixed with toxic vehicles or solvents. exposed skin.

• Only permit explosion-proof lighting in work areas, approved by a

Nationally Recognized Testing Laboratory for use in Class I, Group 1. On vessels, 29 CFR Part 1910, Subpart S is applied when shore-based electrical

D atmospheres, or approved as permissible by the Mine Safety installations provide power for onboard use (e.g., the power from the electrical system

and Health Administration or the U.S. Coast Guard. comes from shore or from portable electrical generators), but does not apply to

permanently installed electrical systems on vessels.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

• Non-sparking footwear and gloves to prevent static electricity, State Plans

as well as coveralls or outer clothing made of cotton, and rubber There are 28 OSHA-approved occupational safety and health state

gloves, rather than plastic, where paints or coatings in use have plans. State plans are required to have standards and enforcement

flash points below 80°F. programs that are at least as effective as Federal OSHA standards,

which may be different or more stringent. More information is

For additional information on other hazards associated with available at: www.osha.gov/dcsp/osp.

surface preparation and preservation activities, including

the application of paint and other protective coatings, see OSHA’s On-site Consultation Program

Safety and Health Injury Prevention Sheet (SHIPS) on Surface OSHA’s On-site Consultation Program offers free and confidential

Preparation and Preservation. advice to small and medium-sized businesses in all states, with priority

given to high-hazard worksites. On-site consultation services are

Disposal separate from enforcement and do not result in penalties or citations.

• Employers must provide covered metal containers at worksites For more information or to find the local On-site Consultation office

for the disposal of scrapings and rags soaked with flammable in your state, visit www.osha.gov/consultation, or call 1-800-321-

compounds. OSHA (6742).

Emergency Response Workers’ Rights

In case of a fire, response time is crucial. Employers must: Under federal law, workers are entitled to working conditions that

• Provide suitable fire extinguishing equipment for each work area do not pose a risk of serious harm.

that is immediately available in a state of readiness for instant use. For more information on how to assure a safe and healthful

• Train workers to recognize unsafe conditions, including workplace, see OSHA’s Workers page.

significant fire hazards, and procedures to follow in the event

a fire occurs as outlined in the facility’s fire safety plan. How to Contact OSHA

• Ensure workers designated as fire watches are trained in For questions or to get information or advice, to report an

accordance with 29 CFR 1915.508(c). emergency, fatality, inpatient hospitalization, amputation, or loss

of an eye, or to file a confidential complaint, contact your nearest

OSHA office, visit www.osha.gov or call OSHA at 1-800-321-

OSHA (6742), TTY 1-877-889-5627.

This is one in a series of informational fact sheets highlighting OSHA programs, policies or standards. It does not impose any

new compliance requirements. For a comprehensive list of compliance requirements of OSHA standards or regulations, refer

DSG FS-3897 06/2017

to Title 29 of the Code of Federal Regulations. This information will be made available to sensory-impaired individuals upon

request. The voice phone is (202) 693-1999; teletypewriter (TTY) number: 1-877-889-5627.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

You might also like

- CASE IH MAXXUM 130 TRACTOR Service Repair Manual PDFDocument120 pagesCASE IH MAXXUM 130 TRACTOR Service Repair Manual PDFjfjksekdmeik0% (2)

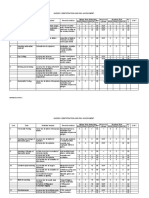

- EHS Training Matrix - Rev2finalDocument1 pageEHS Training Matrix - Rev2finalMalik Khuram ShazadNo ratings yet

- 11work Xone Traffic SafetyDocument2 pages11work Xone Traffic SafetysolidrepNo ratings yet

- Noise and Hearing Conservation TrainingDocument1 pageNoise and Hearing Conservation TrainingRabialtu SulihahNo ratings yet

- Lightning Brochure18Document2 pagesLightning Brochure18Matt GunnNo ratings yet

- Shipyard Safety Hand BookDocument144 pagesShipyard Safety Hand BookRahul ShandilyaNo ratings yet

- Shipyard Safety PDFDocument174 pagesShipyard Safety PDFequalizer12345100% (1)

- Awareness On Working at HeightDocument3 pagesAwareness On Working at Heightsubhadipmanna8100% (1)

- Procedure For OffloadingDocument10 pagesProcedure For OffloadingStansilous Tatenda Nyagomo100% (1)

- 1.daily Work PermitDocument1 page1.daily Work PermitIndraNo ratings yet

- DBI Sala Catalog - Capital Safety EquipmentDocument192 pagesDBI Sala Catalog - Capital Safety Equipmentiossales100% (1)

- OSHA Fire Safety Requirements - Protecting Life and PropertyDocument8 pagesOSHA Fire Safety Requirements - Protecting Life and PropertyhjsdgfnNo ratings yet

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- Working From Heights Wooden PolesDocument31 pagesWorking From Heights Wooden PolesJose OrtegaNo ratings yet

- 101 SafetyTalk Topics ZetekyDocument21 pages101 SafetyTalk Topics ZetekyMu'az ObadakiNo ratings yet

- Hot WorkDocument4 pagesHot WorkNat Flores100% (1)

- UTA AST-Fall Protection SafetyDocument72 pagesUTA AST-Fall Protection SafetyNyoman SaktiNo ratings yet

- Workers Seriously Injured in Conveyor AccidentsDocument2 pagesWorkers Seriously Injured in Conveyor AccidentsGissmoNo ratings yet

- Load Combinations of Concrete DesignDocument7 pagesLoad Combinations of Concrete Designcarlo cuevasNo ratings yet

- 3 Hazard CommunicationDocument9 pages3 Hazard CommunicationAlaa AllamNo ratings yet

- Hazard Communication ProgramDocument3 pagesHazard Communication ProgramindheatingNo ratings yet

- F HSE 008 Job Safety AnalysisDocument27 pagesF HSE 008 Job Safety AnalysisBoy100% (1)

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Safety Harness Monthly Checklist-Register JAN23Document1 pageSafety Harness Monthly Checklist-Register JAN23Iqbal HossainNo ratings yet

- Questions of HSE Competency AssessmentDocument16 pagesQuestions of HSE Competency AssessmentekoimampNo ratings yet

- Sample Training MatrixDocument5 pagesSample Training MatrixJack PNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Chemical Management PlanDocument64 pagesChemical Management PlanyahyaNo ratings yet

- Hazard Communication Program 1Document4 pagesHazard Communication Program 1myo lwinNo ratings yet

- Uk Hse Gas CylindersDocument20 pagesUk Hse Gas Cylindersfredu3No ratings yet

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouNo ratings yet

- Standard Operating Procedure: Vehicle FuelingDocument1 pageStandard Operating Procedure: Vehicle FuelingAnees EkNo ratings yet

- Lifting & Hoisting PracticesDocument40 pagesLifting & Hoisting PracticesInternational Certification100% (1)

- Entry Into Enclosed Spaces - Part 1 AwarenessDocument20 pagesEntry Into Enclosed Spaces - Part 1 AwarenessDaniel RolandiNo ratings yet

- Confined Space JSADocument1 pageConfined Space JSADILAL B P100% (16)

- Confined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramDocument7 pagesConfined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramAnge JuanNo ratings yet

- WW ALL S 05 002 - PETRONAS Carigali Permit To Work Procedure Rev 4 July 2013Document145 pagesWW ALL S 05 002 - PETRONAS Carigali Permit To Work Procedure Rev 4 July 2013Muhammad Izzad Othman100% (3)

- Hazards in Port and Dock OperationsDocument5 pagesHazards in Port and Dock Operationsven1959No ratings yet

- Fork Lift Daily Check: (Only For FL Operated by Batery)Document1 pageFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloNo ratings yet

- Aircraft Purging System and ProcessDocument186 pagesAircraft Purging System and ProcessNaveen Kumar100% (1)

- Confined Spaces CardsDocument1 pageConfined Spaces CardsJafar KhanNo ratings yet

- Hot Work Activity RemindersDocument24 pagesHot Work Activity RemindersKristine Danielle RamirezNo ratings yet

- Risk Assessment For Heaven. INC Short FilmDocument2 pagesRisk Assessment For Heaven. INC Short FilmHarryGeorgePrestonNo ratings yet

- SST CompanyName EHS ProgramsDocument9 pagesSST CompanyName EHS ProgramsTimothy DimaanoNo ratings yet

- Chemical SpillagesDocument1 pageChemical SpillagesMuhammad ZaffanNo ratings yet

- CartridgeSelectionPoster English HRDocument1 pageCartridgeSelectionPoster English HRTg TarroNo ratings yet

- Doe STD 1 090 96 Hoisting and RiggingDocument326 pagesDoe STD 1 090 96 Hoisting and RiggingIngenieros Prevención100% (1)

- Oil and Gas Well Drilling and Servicing Etool - General Safety and Health - Hot Work - Occupational Safety and Health AdministrationDocument4 pagesOil and Gas Well Drilling and Servicing Etool - General Safety and Health - Hot Work - Occupational Safety and Health AdministrationIne Nurista100% (1)

- Bcga Code of Practice 36 Cryogenic Liquid Storage at Users' PremisesDocument52 pagesBcga Code of Practice 36 Cryogenic Liquid Storage at Users' PremisesAlexander Quebra Madeira NemchinovNo ratings yet

- Fire Extinguisher Training: Health, Safety & Environment DeptDocument33 pagesFire Extinguisher Training: Health, Safety & Environment DeptRosano D. ManamtamNo ratings yet

- Safety Questions For ExaminationDocument1 pageSafety Questions For ExaminationAkeem Dwayne Ralph NoelNo ratings yet

- Lead Safety in ConstructionDocument27 pagesLead Safety in ConstructionalimarhoonNo ratings yet

- REGDOC2 1 2 Safety Culture Final EngDocument31 pagesREGDOC2 1 2 Safety Culture Final Engnagatopein6No ratings yet

- Confined SpacesDocument25 pagesConfined Spaceshi2lathaNo ratings yet

- Health and Safety & TOPdesk: A Safe CombinationDocument2 pagesHealth and Safety & TOPdesk: A Safe CombinationTOPdeskNo ratings yet

- Eye WashDocument21 pagesEye Washapi-273019508100% (1)

- Genie-Making Sense of MEWPSDocument11 pagesGenie-Making Sense of MEWPSd. donlonNo ratings yet

- 1926 Table of ContentsDocument18 pages1926 Table of ContentsRizwan AkramNo ratings yet

- University of Nevada, Reno: Crane & Hoist Safety ProgramDocument31 pagesUniversity of Nevada, Reno: Crane & Hoist Safety ProgramSs SelvanNo ratings yet

- F-018-Weekly Safety Inspection ChecklistDocument2 pagesF-018-Weekly Safety Inspection Checklistalvhyan anandolakiNo ratings yet

- Scaffolder Erector Medical ExaminationDocument6 pagesScaffolder Erector Medical ExaminationZulqarnain RamliNo ratings yet

- Jotun Thinner No.17 MsdsDocument9 pagesJotun Thinner No.17 Msdssudeesh kumarNo ratings yet

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- Risk - Assessment - Form 14th Oct 2017Document2 pagesRisk - Assessment - Form 14th Oct 2017hunstreteNo ratings yet

- 0001 - Environmental ControlDocument2 pages0001 - Environmental ControlJohn Vem BansagNo ratings yet

- Power FloatDocument6 pagesPower FloatAditi BazajNo ratings yet

- Breathe Right!Document44 pagesBreathe Right!Safety and Health magazineNo ratings yet

- Lab Design Guide ChecklistDocument9 pagesLab Design Guide ChecklistTanveer AzizNo ratings yet

- Generic Mechanical Workshop Risk AssessmentDocument6 pagesGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqNo ratings yet

- IUMI Webinar Flat RacksDocument35 pagesIUMI Webinar Flat RacksJackNo ratings yet

- Hse Check List For Arc Welding Machine: Contractor Name Machine No Document No DateDocument2 pagesHse Check List For Arc Welding Machine: Contractor Name Machine No Document No DateRaynus ArhinNo ratings yet

- Sfty AUDIT FormDocument17 pagesSfty AUDIT Formahmad adliNo ratings yet

- ABC's of Fall Protection: Murray State University Susan MillerDocument24 pagesABC's of Fall Protection: Murray State University Susan MillerSam SalesNo ratings yet

- FUNCTIONALISMDocument16 pagesFUNCTIONALISMcarlo cuevasNo ratings yet

- Grade 8 TleDocument6 pagesGrade 8 Tlecarlo cuevasNo ratings yet

- Grade 8 TleDocument6 pagesGrade 8 Tlecarlo cuevasNo ratings yet

- 1 Air Quality 1.8 National Air Quality Status Report 2008 2015 PDFDocument52 pages1 Air Quality 1.8 National Air Quality Status Report 2008 2015 PDFPaolo Q. Sangalang100% (1)

- Numbered Tasks Costing January FebruaryDocument6 pagesNumbered Tasks Costing January Februarycarlo cuevasNo ratings yet

- Soil Sampling TechniquesDocument34 pagesSoil Sampling TechniquesJishanthAAravindakshanNo ratings yet

- EPA - Standard Operating Procedures - Soil SamplingDocument13 pagesEPA - Standard Operating Procedures - Soil SamplingrealchicNo ratings yet

- Experiment No. 3 Wet Preparation of Disturbed Soil Samples 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)Document6 pagesExperiment No. 3 Wet Preparation of Disturbed Soil Samples 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)MewnEProwtNo ratings yet

- Curriculum Vitae Triwahyu RubiantoDocument5 pagesCurriculum Vitae Triwahyu RubiantoWahyu Sunday100% (1)

- Providing & Laying of 750mm Dia MS. Pipe Line From GMDC Sump To Plant Reservoir at KLTPSDocument4 pagesProviding & Laying of 750mm Dia MS. Pipe Line From GMDC Sump To Plant Reservoir at KLTPSkalpana_89128965No ratings yet

- Non Gas Free Tank EntryDocument15 pagesNon Gas Free Tank EntryJan KubišNo ratings yet

- Hazard Identification and Risk Assessment: 503708245.xls-Sheet1Document7 pagesHazard Identification and Risk Assessment: 503708245.xls-Sheet1nashwan mustafaNo ratings yet

- Confined Space Entry: Environmental, Health & SafetyDocument56 pagesConfined Space Entry: Environmental, Health & SafetyZhu Chen ChuanNo ratings yet

- Material Safety Data Sheet (MSDS) Helium) : (Please Ensure That This MSDS Is Received by An Appropriate PersonDocument3 pagesMaterial Safety Data Sheet (MSDS) Helium) : (Please Ensure That This MSDS Is Received by An Appropriate PersonsafaniaNo ratings yet

- MR XXX - Modified CVDocument2 pagesMR XXX - Modified CVAryful YahdiNo ratings yet

- Rescue Plan: Hot Oil Drain DrumDocument3 pagesRescue Plan: Hot Oil Drain DrumNaveed AhmedNo ratings yet

- Hach-Sigma 900 Composite Sampler Users ManualDocument52 pagesHach-Sigma 900 Composite Sampler Users ManualaquachemNo ratings yet

- KPRL HandbookDocument52 pagesKPRL HandbookAhsani TaqwimNo ratings yet

- C04 Kelloway MOHS8e FinalDocument47 pagesC04 Kelloway MOHS8e FinalPritom DuttaNo ratings yet

- Haseeb H2S Technician ..Document3 pagesHaseeb H2S Technician ..sohailmumtaz987No ratings yet

- Dhi-Ehs-Hsm-031 Permit To Work Rev0Document21 pagesDhi-Ehs-Hsm-031 Permit To Work Rev0khoahuyen_89No ratings yet

- SIGMA 910 & 920 Flow Meters Instrument ManualDocument48 pagesSIGMA 910 & 920 Flow Meters Instrument ManualdtalaveraNo ratings yet

- OSHA 501 Subpart J Confined SpacesDocument109 pagesOSHA 501 Subpart J Confined Spacesdroffilcz27No ratings yet

- Concept & Importance of TrainingDocument16 pagesConcept & Importance of TrainingJasmine SuriNo ratings yet

- MSH TB ElectricalHazardAwarenessDocument54 pagesMSH TB ElectricalHazardAwarenesstuNo ratings yet