Professional Documents

Culture Documents

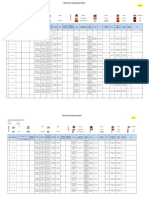

Chemical Storage Area Checklist

Uploaded by

Tyler RichardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Storage Area Checklist

Uploaded by

Tyler RichardCopyright:

Available Formats

Chemical Storage Area Checklist Done

1. Risk Assessment

Proper storage conditions have been identified for all chemicals (including potential

incompatibilities). □

A documented spill response plan is maintained and spill response equipment is provided

in areas where hazardous materials are used or stored. □

2. Hazard Communication

Safety Data Sheets (SDS) for every stored chemical is up-to-date, accurate, freely

accessible, and available in local language(s) for workers to review. □

All chemical containers have labels that indicate the chemical name, hazards, and GHS

pictogram(s). Labels are in the language of the employees and in good condition. □

Hazards of the stored chemicals used have been communicated to the workers who work

with or come into contact with stored chemicals. □

3. Controls

Warning signs and chemical handling procedures are posted in

chemical storage and use areas.

□

Hazardous chemicals storage areas have restricted access. □

Chemical storage areas have all required safety features including:

Area is secured and covered

Containers are stored on impervious surfaces

□

Secondary containment units are in place (Secondary containment should be at

least 110% of the volume of the largest container stored and/or greater than 10%

of the total volume of the stored substance(s).

Area has adequate ventilation.

Accessible safety shower/eye wash nearby (within 30 meters)

Restriction on drinking, eating, and smoking

Spill kits with materials for containment and absorption

Fire‐fighting equipment, fire hoses, and/or fire extinguishers

Signs indicating PPE required to work in area

Aisles and forklift routes are clearly marked (if applicable)

Incompatible materials are segregated

Flammable and combustible materials are stored away from ignition sources

Chemical containers should not be stacked higher than three (3) meters (10) feet

Chemical storage areas are inspected regularly.

□

You might also like

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsFrom EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsNo ratings yet

- Chemical Storage Checklist: Risk, Labels, ControlsDocument4 pagesChemical Storage Checklist: Risk, Labels, Controlsterzici13No ratings yet

- DIESEL STORAGE Guidelines in UAEDocument5 pagesDIESEL STORAGE Guidelines in UAEMuhammad Shiraz KhalidNo ratings yet

- Hazardous Material Management SopDocument6 pagesHazardous Material Management SopJim100% (2)

- Laboratory Inspection ChecklistDocument2 pagesLaboratory Inspection ChecklistTaarani AmbigavathyNo ratings yet

- Lab CHP Sop Entire-2Document66 pagesLab CHP Sop Entire-2Furqan ShabbirNo ratings yet

- Chemical Safety ProgramDocument8 pagesChemical Safety ProgramGerard M. EncarnacionNo ratings yet

- EHS Checklist-QCDocument7 pagesEHS Checklist-QCFarzana HossainNo ratings yet

- ToolboxDocument12 pagesToolboxHTNo ratings yet

- Control Hazardous MaterialsDocument6 pagesControl Hazardous MaterialsSheena Ann StonehillNo ratings yet

- Appropriate Storage For All ChemicalsDocument3 pagesAppropriate Storage For All ChemicalssixejoNo ratings yet

- Chemical Handling SOP GuideDocument7 pagesChemical Handling SOP Guideibnu wicaksonoNo ratings yet

- School Chemistry Laboratory - Chemical Storage Powerpoint PresentationDocument43 pagesSchool Chemistry Laboratory - Chemical Storage Powerpoint PresentationRodrigoNo ratings yet

- Safety: Linhas Aéreas InteligentesDocument30 pagesSafety: Linhas Aéreas InteligentesChristian OliveiraNo ratings yet

- Explosives SOPDocument8 pagesExplosives SOPAkaninyene mathiasNo ratings yet

- Assigment OSHMSDocument20 pagesAssigment OSHMSFaris MuhammadNo ratings yet

- Airs-Lm 2Document18 pagesAirs-Lm 2Jumar BaldrezNo ratings yet

- Hazardous WasteDocument16 pagesHazardous WasteJasonNo ratings yet

- SOP 5-Reactive Solids and LiquidsDocument4 pagesSOP 5-Reactive Solids and LiquidsGeorgeNo ratings yet

- Chapter II - Lab Safety and Regulations.Document29 pagesChapter II - Lab Safety and Regulations.Judy xoNo ratings yet

- Appendix E2 - Spill Contingency PlanDocument7 pagesAppendix E2 - Spill Contingency PlanBea MokNo ratings yet

- Sop Template Quenching Water Reactive MaterialsDocument9 pagesSop Template Quenching Water Reactive MaterialsjaneNo ratings yet

- EPB 261 - Chemical Use and Storage at WaterworksDocument3 pagesEPB 261 - Chemical Use and Storage at WaterworksKONSTANTINOS TOMAZISNo ratings yet

- Safety PolicyDocument21 pagesSafety Policythewhitebunny6789No ratings yet

- Chemical Spill Cleanup SWPDocument5 pagesChemical Spill Cleanup SWPSalman ShahzadNo ratings yet

- Unit-5 AMRDocument11 pagesUnit-5 AMRaerolab instructorNo ratings yet

- Standar WallMartDocument5 pagesStandar WallMartAndikaNo ratings yet

- E5 - Hazardous Materials and Contamination ControlDocument3 pagesE5 - Hazardous Materials and Contamination Controlkessery koivoguiNo ratings yet

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- On Safe ManagementDocument19 pagesOn Safe ManagementJenny PadsungayNo ratings yet

- FlammablesDocument12 pagesFlammablesSafety ManagerNo ratings yet

- Example-Self Safety Inspection Checklist - QADocument3 pagesExample-Self Safety Inspection Checklist - QAHehok Hehe100% (1)

- Chemical Storeroom ChecklistDocument5 pagesChemical Storeroom ChecklistEamonn Mc Conway100% (1)

- Spill Prevention, Response and Clean Up Procedures: Appendix DDocument5 pagesSpill Prevention, Response and Clean Up Procedures: Appendix DshameerNo ratings yet

- Emergency Chemical Spillages ProcedureDocument3 pagesEmergency Chemical Spillages ProcedureSkeeper GeminiNo ratings yet

- Safety Guidelines in Chemical Laboratories DISATDocument55 pagesSafety Guidelines in Chemical Laboratories DISATFloare de PrimavaraNo ratings yet

- SOP Flammable and Combustible Liquids: Doc: AAP/HR/EOHS/SP/FCL/00Document2 pagesSOP Flammable and Combustible Liquids: Doc: AAP/HR/EOHS/SP/FCL/00Neeraj TomerNo ratings yet

- Requirements Hazardous Waste Sep 05 Part 4Document18 pagesRequirements Hazardous Waste Sep 05 Part 4Andile NtuliNo ratings yet

- COSHH Essentials - G101 - General Storage of Solids and Liquids - G101Document4 pagesCOSHH Essentials - G101 - General Storage of Solids and Liquids - G101I LucianaNo ratings yet

- Lab Safety Check List PDFDocument2 pagesLab Safety Check List PDFalberto1954No ratings yet

- About Recycle: Oleh: Septian Teguh Akbar Novian Shafrial Eka P Muhammad ZulkarnainDocument7 pagesAbout Recycle: Oleh: Septian Teguh Akbar Novian Shafrial Eka P Muhammad ZulkarnainTeguh Akbar HarahapNo ratings yet

- Chemical Storage ProcedureDocument5 pagesChemical Storage ProceduresirajbooksNo ratings yet

- Handling and Storing ChemicalsDocument6 pagesHandling and Storing Chemicalsqccendo nonsterilNo ratings yet

- P AF 4.1.2-1 Health and SafetyDocument1 pageP AF 4.1.2-1 Health and SafetyTanjaMitevaNo ratings yet

- Laboratory Safety EssentialsDocument34 pagesLaboratory Safety EssentialsEmmylou MurilloNo ratings yet

- 5.3 Working With Substances Hazardous To Your HealthDocument3 pages5.3 Working With Substances Hazardous To Your HealthPrécieux BabiNo ratings yet

- Chemical Safety: CHY76ADocument7 pagesChemical Safety: CHY76ARoxanne Mae VillacoraNo ratings yet

- CHEMICAL MANAGEMENT INSPECTION CHECKLISTDocument11 pagesCHEMICAL MANAGEMENT INSPECTION CHECKLISTLi QiNo ratings yet

- Harper College 26 HOUSEKEEPING PROCEDURESDocument3 pagesHarper College 26 HOUSEKEEPING PROCEDURESLammiifan JemalNo ratings yet

- 7a. Specific Requirements For Diagnostics Centres Xray V1.3Document8 pages7a. Specific Requirements For Diagnostics Centres Xray V1.3godsway.dzikunuNo ratings yet

- Standard Operating Procedure For Laboratory and Chemical SafetyDocument4 pagesStandard Operating Procedure For Laboratory and Chemical Safetyahmed alghrablyNo ratings yet

- T3 Lab Safety and RegulationsDocument3 pagesT3 Lab Safety and RegulationsZeian Jacob BaylaNo ratings yet

- Cleaning, Disinfection & Sterilization ProceduresDocument9 pagesCleaning, Disinfection & Sterilization ProceduresAgiel X-friendNo ratings yet

- Cleaning, Disinfection, & Sterilization Policy & ProcedureDocument9 pagesCleaning, Disinfection, & Sterilization Policy & ProcedureHasni Abdul RahimNo ratings yet

- Xyzklm 6789 JKJKJKDocument1 pageXyzklm 6789 JKJKJKnguyenthinhvinhkhaNo ratings yet

- 3.safe Handling and Storage of ChemicalsDocument3 pages3.safe Handling and Storage of Chemicalsjacobpm2010100% (1)

- Storage of Hazardous Chemicals in Warehouses and Drum StoresDocument4 pagesStorage of Hazardous Chemicals in Warehouses and Drum Storessjmpak100% (1)

- Corrosives IrritantsDocument11 pagesCorrosives IrritantsSafety ManagerNo ratings yet

- Laboratory HouskeepingDocument3 pagesLaboratory HouskeepingTanvir SiddikiNo ratings yet

- Housekeeping Safety Program Material StorageDocument3 pagesHousekeeping Safety Program Material StorageSkeeper GeminiNo ratings yet

- Incident EventDocument1,022 pagesIncident EventTyler RichardNo ratings yet

- Worker Safety Form - Competency EvaluationDocument1 pageWorker Safety Form - Competency EvaluationTyler RichardNo ratings yet

- Combustible Dust ProgramDocument9 pagesCombustible Dust ProgramTyler RichardNo ratings yet

- Safety ControllerDocument32 pagesSafety ControllerTyler RichardNo ratings yet

- Epa Hazwoper 40 HR Manual Epw-09-006 HZTDocument406 pagesEpa Hazwoper 40 HR Manual Epw-09-006 HZTTyler Richard100% (1)

- Fluid-Resistant Full Face Protector KitDocument1 pageFluid-Resistant Full Face Protector KitTyler RichardNo ratings yet

- Safety Data Sheet for Molykote DX PasteDocument10 pagesSafety Data Sheet for Molykote DX PasteshareavNo ratings yet

- Safety Data Sheet SummaryDocument7 pagesSafety Data Sheet SummaryDumitru MoldovanNo ratings yet

- Safety Data Sheet for Diesel Gas OilDocument8 pagesSafety Data Sheet for Diesel Gas OilMaza LufiasNo ratings yet

- OLIN - Curing Agent Easy-Fit ADocument9 pagesOLIN - Curing Agent Easy-Fit ABoyet BaldeNo ratings yet

- S-Felt Vs 140 PDS Sika SarnafilDocument4 pagesS-Felt Vs 140 PDS Sika SarnafilAndrei PantuNo ratings yet

- Brayco MSDS 2916907Document16 pagesBrayco MSDS 2916907RNo ratings yet

- Uvitex Edb MSDSDocument10 pagesUvitex Edb MSDSraju_hosssenNo ratings yet

- WHMIS in Your WorkplaceDocument4 pagesWHMIS in Your WorkplaceAllexes DuncombeNo ratings yet

- CD-0054-V.6.0 Diab Group MSDS - Divinycell PVC FamilyDocument4 pagesCD-0054-V.6.0 Diab Group MSDS - Divinycell PVC FamilyThaís SilvaNo ratings yet

- MSDS-TS TSS Dan TDSDocument2 pagesMSDS-TS TSS Dan TDSArdhy LazuardyNo ratings yet

- Shell Omala S4 WE 320: Safety Data SheetDocument19 pagesShell Omala S4 WE 320: Safety Data SheetKhaledNo ratings yet

- HP 60XL Black PDFDocument7 pagesHP 60XL Black PDFRafael De los SantosNo ratings yet

- Chemical Inventory Sheet Version 1Document4 pagesChemical Inventory Sheet Version 1Nur E Alam NuruNo ratings yet

- MSDS Sysmex Hematology EIGHTCHECK-3WP - 30jun12-3Document4 pagesMSDS Sysmex Hematology EIGHTCHECK-3WP - 30jun12-3Laboratorium RswkNo ratings yet

- Deadfast Sulphur CandleDocument4 pagesDeadfast Sulphur CandleKewal N MishraNo ratings yet

- 2227 - LuminolDocument3 pages2227 - LuminolLucas BrasilianoNo ratings yet

- SF6 Sulfur Hexafluoride PDFDocument12 pagesSF6 Sulfur Hexafluoride PDFSujit Kumar pahiNo ratings yet

- AlbatrossDocument5 pagesAlbatrossJuan David Ospina GonzalezNo ratings yet

- Distilled WaterDocument6 pagesDistilled WaterandriNo ratings yet

- Vinac XX Series EmulsionsDocument2 pagesVinac XX Series EmulsionselgendawyNo ratings yet

- Ben Nye Bond-Off MsdsDocument3 pagesBen Nye Bond-Off MsdsZsuzsanna KuruczNo ratings yet

- MSDS Cl2Document3 pagesMSDS Cl2akhil1231No ratings yet

- Msds Polysugaquat L-1010p (16 Section)Document5 pagesMsds Polysugaquat L-1010p (16 Section)mndmattNo ratings yet

- Acumer5000 PDFDocument13 pagesAcumer5000 PDFdalton2003No ratings yet

- Buffer Solution PH 1001 - GHS - en - 2016 10 18 PDFDocument20 pagesBuffer Solution PH 1001 - GHS - en - 2016 10 18 PDFReza Hendy DjoerkaeffNo ratings yet

- BSCI Self Assessment English 2009Document26 pagesBSCI Self Assessment English 2009Ranjit RoyNo ratings yet

- Caustic Neutraliser SDS Safety Data SheetDocument7 pagesCaustic Neutraliser SDS Safety Data SheetAsadNo ratings yet

- Safety Data Sheet - Salt: Section I - Product and Company IdentificationDocument5 pagesSafety Data Sheet - Salt: Section I - Product and Company IdentificationMudhofar AdeNo ratings yet

- Safety Data SheetDocument14 pagesSafety Data SheetPEng. Tech. Alvince KoreroNo ratings yet

- Intergard 269 DatasheetDocument4 pagesIntergard 269 DatasheetBalasubramanian AnanthNo ratings yet