Professional Documents

Culture Documents

Wahan Engineering Corporation Catlouge

Wahan Engineering Corporation Catlouge

Uploaded by

patelchiragis0 ratings0% found this document useful (0 votes)

18 views16 pagesOriginal Title

WAHAN_ENGINEERING_CORPORATION_CATLOUGE(1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views16 pagesWahan Engineering Corporation Catlouge

Wahan Engineering Corporation Catlouge

Uploaded by

patelchiragisCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

Excellence in

CARDAN SHAFT

UNIVERSAL JOINTS

WAKAN'

ENGINEERING CORPORATION

ENGINEERING MEETS

TECHNOLOGY

DRIVE SHAFTS FOR A SMOOTHER WAY AHEAD

Web: yornwahanengineeing in

Table of Contents

+ Conventional Cardan Shaft Application layouts:

eee ener en tore

SUR RE ee RCC CUR UCU U Eo c Cy

+ Torque calculation technique for The Paper & Pulp Industry ..

+ Varied Cardan shaft Designs with Standard Flange Options

+ Universal Joint Cross Service Kits Design and Dimension

re UT ee OE ea acne UT See

eer Een ee ca eee

ee Ee OO eae acd

+ Procurement Made Easy: Ref. Cardan shaft Drawing illustrations

+ Recommendations for Installation and Maintenance of Cardan Shaft

+ Important Guidelines prior to generating a purchase Order for Cardan Shafts

emer ity

PNR Oe

10

TT

7

3

4

5

16

acre fsrnerne}ijarreref

Conventional Cardan Shaft

Application layouts.

=

Diverse Industrial &

Automotive Applications

Heavy Shock Load

Pulp & Paper Industry

Steel Roling & Tube Mis,

Comugated Box Mg, Co

Sewage Pumping Stations,

Conveyer Primary Dives,

Cement industries

Tube Statering Machines

Medium Shock Load

TMT Manufactures

Vibrating Sreens|

Self Loading Transit Mixer

DTH Water Well Dring Rigs

Road Construction Equip. Machinery

Ausliary Orves

Transfer Tole Roller Tales

Light Shock Load

T0-Pump Drive Propeler Shafts

Pring & Packaging Industry

Tele Machinery

Rip Saw Wood Working machines

Balancing Machines

Diamond Wire Saw Machines

Farm Equipment &TractorLoaders

About us!

Waban Engineering Corporation from Ahmedabad in Gujarat is located in the western part of India and is primarily engaged in the

design, development of precise and rugged manufacturing of Stee! Forged Industrial Cardan Shafts since last 4:5 decades in India,

Our enormous experience has awfully helped us to create propitious products and adapt designs for meeting the provisions to the

ever challenging needs of our customers from varied industrial backgrounds.

Who we are !

‘We at “Wahan” comprise of a team of young and ethical entrepreneurs who are passionate about finding an antidote to some of the

breakdown issues that a production house may encounter due to premature failure of Cardan Shafts leading to huge opportunity and

down time losses, ut at "Wahan" we pledge that we won' allow this to happen to you.

Our mission statement

We strive to work on our quintessential principle of providing our customers such products which are optimally designed to suit the

precise application and objectives at an affordable price (it's not going to work if itis too expensive)

‘And you bet, Everyone knows that for sure, But actually, attaining its fun for us, As we love doing what we are doing!

To accomplish this, we austerely follow the golden rule and continuously work towards ths selfembedded truth for survival

in today's fiercely Competitive world - That is - INNOVATE or EVAPORATE!

Emulating Customers Expectations

Citing adaption of new manufacturing techniques and mechanism is justin fact not the only reason for our company’s instantaneous

growth & development, However, the real crux lies in the correct interpretation of the consumer's needs and serving them with @

Suitable & customized product which not only caters tothe technical needs and performance but, also emulates them on the economic

front as well

‘An ear for the customer

“"Wahan” not only enviches in catering to the above supplements, but, aso supports new ideas and advancement techniques from

casting and new customers as well so as to resolute targets and promote innovative ideas from each ofits client to improvise upon

previously supplied products and services. The core fcus however lies in giving our customers Contentment & peace of mind through

our trouble fre producs.

Our unique competitive edge

Many often, the markets debate about having many medium & large sized player in the market as thelr Immediate & the mast fierce

competitors | But, we have always contemplated that we ourselves at "WAHAN" are in fact "Wahan’s” biggest competitor as we have

always stowed our complete focus inthe process of improvisation and development of new customized and coherent designs. In fac,

we have been looking at all other small & big players as a perpetual and sanguine source of inspiration for betterment and innovation.

Quality Assurance

We have perused the custom to continue the heritage as being known as a quality, committed and a competitive supplier for Cardan

Shafts forthe hugely growing market in Transmission & Driveline products for varied industrial applications. Staring as a modest

debutant, we have now maneuvered and provide products and services as a connoisseur in Cardan Shafts, Propeller Shaft & Driveline

‘components to the Heavy Commercial Automotive After Market as well

Our Core Strength is our People

Customers shall find that our workforce consists of qualified and trained individuals who are adept in their particular fields, Every

member of our workforce is devoted to serving the needs of customers in their particular area of concern and to the best of their ability.

Quality Customer Service

In commerce, we understand that customers rightfully expect nothing but the best from their counterparts and therefore we work

ethically to not only meet ther righteous expectations from us them, but to exceed them, We have implemented various training

programs to ensure our workforce continues to be proficient in all aspects, and be able enough to ensure delivery of the highest quality

& service to our customers

How Do | Select A Suitable Cardan Shaft ?

Understanding the Mechanism of Cardan Shafts and the Growth in its Application!

Cardan Shafts defined asa motorized machine that an vans torque between the diven andthe diving torque or otatona motion fom one shat to

another at ited and vated angles of intersection onthe shaft ax. They are principally categorized by tet torque indicators when used a single joint while

operating at angles greater than 0° which may be non-uniform or nifarm coning to their necessary applications

Thouah, itis conventionally known tha the one of the most unigue and prominent feature ofa Cardan Stats nat only of handing misalignment capabilites

‘upto 15" or greater which evdentii quit higher than the 6” potential of gar couplings and spindles, but Also fr applying it for high ses torque load

applations and aimost continuous operation in various mls oda, is surely onthe ise As a consequence the requisitions for Cardan Shafts have increased

Significantly where high torque load varsmision is mandatory

‘We are presenting for you a relatively simpli and universally approved torque determining technique which has been employed over the years by many

Drive Shaft Manufacturing Companies that have been perusing a similar procedure while nominating to authorize a techicaly and ecient design of Cardan

Shat which would best suit your requirements. On the Cardan Shaft elecion, its necessary to assure thatthe ating speed which in uncon ofthe

‘working angle is not too much hgh.

Torque Transmission in Nm = 7025 * (p) in motor-hp )/ rpm x safety factor ( where ever applicable )

CARDAN SHAFT - SERIES SELECTION CHART

Treen Penn eri

4 = ge

i bs Bs

Pibiigig? fife “ii

. fae bebaad Piedad

— a =

Note: Although major elements for determining the Torque levels have been ensured, we woul stil ecommend a discussion with our technical

team before the final selection of Cardan Shaft

Torque Calculation Technique

Suitable For The Paper & Pulp Mills Applications.

1, Basic Parameters required

(A) mpm - meters per minute, (B) rd - Roll Dia in mm, (C) p -Motor-HP

Determining the Circular Movement = (cm) of the Roll by using the following technique. cm = rd* (3.1416)

Method for calculating the RPM = mpm/cm* 1000

Nominal Torque ( Nm ) Rating Calculation method : Nm = 7,025 x hp/rpm

Closed and Expansion Length Measurement Observations must be drawn from the actual working conditions.

Safety Factors to be considered where applicable.

Please refer the below illustration for a better understanding

Basic parameters observed and received are : mpm = 200 , Roll dia - 950.mm and the motor HP = 220

Finding out the cm = circular dia = 950 x3.1416 = 2984.5,

Step — 2 — Finding out the RPM = mpm / cm = 200 / 2984.5 x 1000 = 67

Step

Step —3 Finding Nominal - Torque = 7025 x 220 / 67 = 23067 - Safety Factors may we considered where necessary.

Note: Athough major elements for determining the Torque levels have been ensured, we would stil recommend a discussion with our technical

team before the final selection of Cardan Shaft

Varied Cardan With Standard

Shaft Designs Flange Options

aay

Ta

Length Expansion

gs)

iurris 4 BOLT FLANGE 6 BOLT FLANGE

Percy

Nas

nad

eo ea

TYPED SBOLTFLANGE 8 BOLT FLANGE DRIVE KEY

Double Flange Yoke

ey

na

Secu ey

12 BOLT FLANGE 16 BOLT FLANGE

ra

ra

UNIVERSAL JOINT SERVICE KITS

Ovo woe

LO || 5]

©

OU (2

i ©

‘outer Clamp Lock

Weld Plate Lock

vasennce a] arora unr Dr rao) baa

PART CODE PART CODE

wes.ui01

wes.ean

wesu-03

westus08

wes.ui0s

wes.u06

wes.u-07

wesu-08

wesu08

WesuHt0

wesuett

wesust2

wesunt3

wesut4

Wests

Wests

wes.unt7

west

Wosunt9

wes.u.20

wesi21

wesu-22

wesui23

000

95.00

33.00

7490

55.00

53.00

57.00

57.00

52.00

52.00

48.00

48.00

2188

ans

20

2.00

2.00

a8

33.00

3895

3495

32.00

30.00

245,00

718.00

2800

21800

1.00

16700

152.00

148.00

18150

3.00

154.00

135.00

135.00

3490

29.00

122.00

11980

2600

11500

12600

106.00

5300

106.00

wesui24

wies.25

wesui26

wesui27

wes 28

wies.us29

wiesu30

wesuiat

wes.i32

wies.ui33

wesui34

wesui35

wes.ui36

wesui37

30.00

30.00

270

20

23.00

2.00

16.00

38.00

2380

7400

7490

33.00

53.00

13.00

9290

aia0

a1a0

7300

6180

5500

e200

5700

3525

090

244.00

280.00

17.00

15500

CARDAN SHAFT - TORQUE RANGE:

Mt.350.Nm up to 4000.Nm

SHORT DURATION TORQUE 150

A FLANGE BASE 0D mm 65 5 Sa I 36 en ae A

A FLANGE THICRNESS mm 6 8 52 52 6a 7 18 5

‘FLANGE SPIcoT—o0 mm 35) a2 0 0 60 37 8 2

‘A FLANGE SPIGOTHEIGAT mm 15 15 16 16 16 2 16 16

A CLOFJONTTORLANGE FACE mm == S05 60S 0 3 a 30 30 80

A NO.OF HOLES ms 4 4 4 4 4 6 4 68

‘A BOITHOLE Peo mm 2 os 98 m3 at 95/100 1015

‘A DIAMETER OF BOLT HOLE mm 52 62 82 82 8 as m2jn2 106

A ROTATINGDIA mm 10 8 0 6 95 mm. 20

A JOURNAL CAP DIA mm 2 2 2 BE oN sogi 30,0586

ATURE DIA om 0 0 6 5 65 6 6 en

‘A SUP MOVEMENT mm 100 sayz toortso 40 0 50/100 50 8

A OPERATING ANGLE éegree 20" Fo ww 1 ww 1 a

AMIN LENGTH = tz mm 300) 325 s2sj400 255 sages 35010 as

© COMPACTDESIGNMin-z mm == 20050 250075 25080 180030 21580 2eB;s20 320, 3107360

Note: Although major elements for determining the Torque levels have been ensured, we woul stl ecommend a discussion with our technical

team before the final selection of Cardan Shaft

CARDAN SHAFT - TORQUE RANGE:

Mt.5000.Nm up to 9500.Nm

Dee a

co

Lite itll) aaa

SHORT DURATION TORQUE

A FLANGEBASE-o mm

A FLANGE THICKNESS om

‘FLANGE spIcoT-oD mm

‘A FLANGESPIGOT HEIGHT mm

A CLOFJOWNTTOFLANGE FACE mm

A NO.OF HOLES ras

‘A BOITHOLE Peo mm

‘A DIAMETER OF BOLT HOLE mm

‘A FLANGE ROTATING DIA rm

A JOURNAL CAP DIA mm

‘SUP MOVEMENT mm

A ANGULAR MOVEMENT egiee

A MINLENGTH tz mm

© COMPACTDESINLENGTH: tz mm

a

°

2

2

0

68

1015112

105

us

46

5

0

as

500/530

250

146

an

95

2

64/70

0

9

150

38

o

2»

485

300/380

ro

cia

RECTANGULAR

108

95

2

s1/80

4

0

9

150

35/41

o

wea

65/500

450/495

155

2,

907100

2

80/85

68

130

m2

150

35/41

60/75

18/20"

550

0/470

us

10

168

18

m7

8

1552

98/102

180

anya7se

50

wo

600/575,

4701465

1cS-MD | WeS-MD ] WCS-MD

riss | Ras 5

20075009500

208

oa) 14

196/198

2

1065

en

140/184

102/122

20

~

65/85

1

620/590

550 485,

Noe: Athough major elements for determining the Torque levels have been ensured, we would stil commend a discussion with our technical

team before the inal selection of Cardan Shaft

CARDAN SHAFT - TORQUE RANGE:

Mt.9500.Nm up to 85000.Nm

eS Rae Ae ttc

SHORT DURATION TORQUE 16000 55000 5000

A FLANGEBASE- oD mm 208 ns 250 285 315 350

A FLANGE THIOOUESS| mm 22/14 ar t8 18/20 3/8 28/30 2

‘A FLANGE sPicor-0D mm PAN/196 180 Puan ran PAN Pan

‘A FLANGESPIGOT-HEIGHT/ DEPTH mm HZ 4 6 3 10 2

‘A CLOFJOINTTORLANGE FACE mm 105 no 15 0 140 150

A NOLOFHOLES mos 8 8 5 8 8 2

‘A BOITHOLE Peo mm 184 196 no 250 230 295

‘A DIAMETER OF BOLT HOLE mm 22/14A 144168 164188 RBA 28/25, 231

A JOURNAL CAP DIA mm 52/37 31/58 59765 65/74 83/95 95/110

A Keyway mmm OPTIONAL OPTIONAL “OPTIONAL ~—=—OPTIONAL—=—“OPTIONAL OPTIONAL

A REVINAY (TDA TAICQNESS) mm 12°86 20*20 25*25 25°25 30°30 3

A TUBE-OUTERDIA mm 101 vaio 16/128 t2ay30 155/175 175/190,

A SUP MOVEMENT mm 58 6 1 0 100 10

A OPTIMAL ANGULAR MOVEMENT degree 20 ie 1s 1 1% 1%

A MIN LENGTH AVAILABLE mm 700 750 80/700 725/760 850/900 950/ 1000,

8 MNLLENGTH- te

© COMPACTDESIGNLENGIN: Lz mm 525/560 80/620 620/680 680/750 750/820 820/950

Note: Although major elements for determining the Torque levels have been ensured, we woul stl ecommend a discussion with our technical

team before the final selection of Cardan Shaft

We are pleased to share illustrated drawings to ease your effort in sharing accurate dimensional information before

sharing data of your existing or new requisitions for Cardan Shafts.

3

FE

A

EB

rs

z

Ff

z

EB

F

2

Installation Manual

+ Installing the Cardan Shafts requires skilled use of man power and we highly recommend that the responsible applicator should

ideally be a skilled one. ll traces of dirt, rust inhibitor and grease must be removed from the surface of the old flange to preserve the

coefficient of friction whichis vital for the torque transmission.

+ Prior tothe installation, it must be properly checked that they are assembled correctly which means that the ¢ ——» marking rays

‘on the spline shaft and the spline hub must face each other at the same angle.

+ The necessary bolting hardware used should be equal in length, strength and should be suitable as per the holes ofthe Spline

Companion Hub, Also, please ensure that play between the Flange Hole and Bolts used to fasten the Cardan Shafts should be

within the permissible limits.

Re-Lubricating Instructions

+ The Cardan Shafts are normally provided with grease points, one on the Grease cup and the other one on the spline shaft.

‘+ We highly recommend you to provide fora periodical lubrication both on the Bearing Caps and the Spline graoves, at an interval of

1-2 months , However in case of Medium and Heavy Duty shafts, we recommend that the greasing process be carried out every 4-6

‘weeks for obtaining a longer life span of the universal joint cross bearings.

“+ Pumping of the grease on the bearings should ideally be carted out up to its emission from the bearings cap seals with a maximum

pressure 15 bar. Further, after the greasing process is completed, excess grease must be wiped off from the bearing sides and it may

attract dust from the environment. a

Ideal Bolts Tightening .

Procedure lh a,

Reference Notes

Guidelines prior to placing a Purchase Order.

Special technical requests must be stated clearly in your valued Purchase Order forms and approval for the same is

mandatory from our end.

Reference drawing incase ofthe existing Cardan Shafts (if available) may be submitted along with your requirement.

‘Any specific or Preferred Packaging Details - Wooden / Corrugated Boxes / Poly Bags - etc. may be updated tous.

Color Preferences (f any) must be mentioned separately

Request for Anti-cortosion coating in case required must be stated in your order,

Room Temperature and working area conditions may be mentioned fora better understanding of the requirement.

The Lead Time must be clearly stated in your order form, so that any kind of delay is avoided.

Lubrication procedures may be well understood for obtaining a mature lifecycle ofthe product.

Reference fr use of High Tensile Fasteners are recommended, however, it may be consulted incase required.

9. Mode of material transit may be stated precisely along with your prefered dispatch destination

10. Billing Name & Address, GST No, Any particular correspondence address should be precisely indicated

10. Any preferred mode of Courier services may be mentioned clearly.

11. Your company’s E-Mailing addresses with mandatory cc-bec address.

12, Name and contact details of the Technical & Commercially concerned persons may be shared for prompt communication

SS GAUL Mae eae

PAPERA PULPNILL COUCHROLL —WCSH0-250 1100 2SKNm

Uae ms T4112 WesMp.204 so 2S 1OKNm 10

VIBRATING SCREEN VB-MACHINE ——WCS-MD155 50950 SKN 15

SEWAGE PUMPS PUMP—NO- 1-6, WSHD-165 A 10001075 15K

A TRIBUTE TO THE INVENTION OF CARDAN SHAFTS

In 1676, Robert Hooke revisited Italian Cardano’s idea to make use of an

instrument that would allow them a safer way to study the sun .This unique

instrument used a new type of joint that allowed a twisting motion in one shaft

to be passed on to another, no matter how the two shafts were oriented,

However, it took another 240 years for Clarence W, Spicer to come along and

apply this idea to the automotive and industrial industries. Spicer received a

patent for the universal joint in 1903 and demonstrated his new patent in a self-

designed car, which did not have a troublesome chain & sprocket nor did it have

chain and geared adaptions. However, the company eventually began the complete manufacturing in 1904. Since then,

it has been innovation & development all the way from the automotive to the industrial sector as well

Contact Us:

WAHAN uae

ENGINEERING CORPORATION

WAHAN HOUSE.

Plot No. 1-2-3, Auto Friends Ind. Estate, Before Sanathal Over Bridge,

Sarkhej, Ahmedabad - 382 210. Gujarat, India,

Office No. : +91-79-29794175/76 + +91-79-26891847

Email: sales@wahan.in « Web: www.wahanengineering.in

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- Vib Screen 16X5X4.5 Deck G.A.Document1 pageVib Screen 16X5X4.5 Deck G.A.patelchiragisNo ratings yet

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet

- DTJC 3009-02 G.A. (Double Wheel)Document1 pageDTJC 3009-02 G.A. (Double Wheel)patelchiragisNo ratings yet

- Returning Wall: Maxwell CrushtechDocument1 pageReturning Wall: Maxwell CrushtechpatelchiragisNo ratings yet

- Job Card ReportDocument1 pageJob Card ReportpatelchiragisNo ratings yet

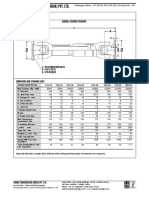

- Universal Joint Drawing - 1Document2 pagesUniversal Joint Drawing - 1patelchiragisNo ratings yet

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet

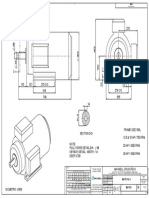

- Model Vibro MotorDocument1 pageModel Vibro MotorpatelchiragisNo ratings yet

- Thermal Systems: Innovation. AvailabilityDocument16 pagesThermal Systems: Innovation. AvailabilitypatelchiragisNo ratings yet

- SR - No Part - No PTC Common Name: Maxwell CrushtechDocument1 pageSR - No Part - No PTC Common Name: Maxwell CrushtechpatelchiragisNo ratings yet

- 1 2c2sjj SB 00 00 001 24 07 20 SHEET 7 R1Document1 page1 2c2sjj SB 00 00 001 24 07 20 SHEET 7 R1patelchiragisNo ratings yet

- Safety Data Sheet: Product Name: MOBILITH SHC 220Document9 pagesSafety Data Sheet: Product Name: MOBILITH SHC 220patelchiragisNo ratings yet

- Ambaji Stone Decor PVT LTD-R1-16-09-20 PDFDocument1 pageAmbaji Stone Decor PVT LTD-R1-16-09-20 PDFpatelchiragisNo ratings yet

- Maxwell Crushtech: Raw Material SizeDocument1 pageMaxwell Crushtech: Raw Material SizepatelchiragisNo ratings yet

- VS Screen 18X5X4.5 Deck G.a-1Document1 pageVS Screen 18X5X4.5 Deck G.a-1patelchiragisNo ratings yet

- 1 2c2sjj SB 00 00 001 24 07 20 SHEET 7 R1Document1 page1 2c2sjj SB 00 00 001 24 07 20 SHEET 7 R1patelchiragisNo ratings yet

- Plant Layout Jayntilal and co-OP-2Document1 pagePlant Layout Jayntilal and co-OP-2patelchiragisNo ratings yet

- Sanjaybhai Conv FDN PDFDocument1 pageSanjaybhai Conv FDN PDFpatelchiragisNo ratings yet

- Grease Detail VSI PDFDocument1 pageGrease Detail VSI PDFpatelchiragisNo ratings yet

- Day-1 POI ANSKEYDocument4 pagesDay-1 POI ANSKEYpatelchiragisNo ratings yet

- Grease Detail VSI PDFDocument1 pageGrease Detail VSI PDFpatelchiragisNo ratings yet

- Look Within: Pre-Assessment Worksheet QuestionsDocument4 pagesLook Within: Pre-Assessment Worksheet QuestionspatelchiragisNo ratings yet

- Look Within Day-3 Composition of AirDocument3 pagesLook Within Day-3 Composition of AirpatelchiragisNo ratings yet

- Class - IV: Mon Tue Wed Thu FriDocument1 pageClass - IV: Mon Tue Wed Thu FripatelchiragisNo ratings yet

- Design A Poster On "How ToDocument2 pagesDesign A Poster On "How TopatelchiragisNo ratings yet