Professional Documents

Culture Documents

FAT2

Uploaded by

eva maniceCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAT2

Uploaded by

eva maniceCopyright:

Available Formats

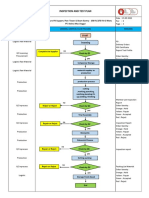

1.

Scope

Factory Acceptance Test is final inspection of tower /structure fabrication before doing

erection at site , starting from Inspection of Material, Inspection of Fabrication Output,

Inspection of Trial Assembly and Inspection of Galvanizing.

2. Inspection of Material

Material inspection is done by visual, random dimensional check and tensile test.

Visual material inspection and dimension check based on standart inspection applied i.e

JIS, ASTM,SNI or spesificaciton required by the Customer. Inspection can be done at

factory or workshop.

Yield and Tensile test ( steel material and bolt ) will done at the independent laboratory (

according to JIS /SNI/ASTM Standart ) by taking same material samples of steel angles and

plates, where it will be witnessed by Fabricator, Contractor and User / Client as per schedule

agreed.

3. Inspection of Welding Quality

Inspection of Welding Quality is done by random check use NDT method ( Penetrant Test ).

Dimension of welding is check based on standart AWS D1.1 by Welding Gauge.

4. Inspection of Fabrication Output.

Inspection of Fabrication Output consist of holes distance , hole’s diameter, visual

appearance and product marking or member based on drawing, this is done by random

check at the factory or workshop.

5. Inspection of Galvanizing

Inspection of Galvanizing consist to visual test and galvanizing thickness by random check

based on ASTM A123 standart or the specification required by Customer.

Inspection can be done at the factory or workshop.

6. All data collected from point number 2,3,4 & 5 will be crosscheked with TPG ( Tehnical

Particulare Guarantee )

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ITP1Document1 pageITP1eva maniceNo ratings yet

- Inspection and Test Plan: Start IncomingDocument1 pageInspection and Test Plan: Start Incomingeva maniceNo ratings yet

- Factory Acceptance Test ProcedureDocument1 pageFactory Acceptance Test Procedureeva maniceNo ratings yet

- A-12 - BRC - Rev 0Document1 pageA-12 - BRC - Rev 0eva maniceNo ratings yet

- A-39 - BRC - Rev 0Document1 pageA-39 - BRC - Rev 0eva maniceNo ratings yet

- A-42 - V.BRC - Rev 0Document1 pageA-42 - V.BRC - Rev 0eva maniceNo ratings yet

- A-41 - A-PLATE - Rev 0Document1 pageA-41 - A-PLATE - Rev 0eva maniceNo ratings yet

- A-10 - H.BRC - Rev 0Document1 pageA-10 - H.BRC - Rev 0eva maniceNo ratings yet

- A-40 - ASSY HOR - Rev 0Document1 pageA-40 - ASSY HOR - Rev 0eva maniceNo ratings yet

- A-9 - V.BRC - Rev 0Document1 pageA-9 - V.BRC - Rev 0eva maniceNo ratings yet

- ST-1 - ASSY STAIR - Rev 0Document1 pageST-1 - ASSY STAIR - Rev 0eva maniceNo ratings yet

- A-13 - HOR - Rev 0Document1 pageA-13 - HOR - Rev 0eva maniceNo ratings yet

- A-11 - BRC - Rev 0Document1 pageA-11 - BRC - Rev 0eva maniceNo ratings yet

- TS-SL-1 - POST - Rev 0Document1 pageTS-SL-1 - POST - Rev 0eva maniceNo ratings yet

- BD-3 - ASSY BORDES - Rev 0Document1 pageBD-3 - ASSY BORDES - Rev 0eva maniceNo ratings yet

- HR-3 - ASSY HANDRAIL - Rev 0Document1 pageHR-3 - ASSY HANDRAIL - Rev 0eva maniceNo ratings yet

- BD-2 - ASSY BORDES - Rev 0Document1 pageBD-2 - ASSY BORDES - Rev 0eva maniceNo ratings yet

- ST-2 - ASSY STAIR - Rev 0Document1 pageST-2 - ASSY STAIR - Rev 0eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- HR-2 - ASSY HANDRAIL - Rev 0Document1 pageHR-2 - ASSY HANDRAIL - Rev 0eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- BD-1 - ASSY BORDES - Rev 0Document1 pageBD-1 - ASSY BORDES - Rev 0eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet