Professional Documents

Culture Documents

Folding Deck: Project 17737EZ

Folding Deck: Project 17737EZ

Uploaded by

Rafael LeònOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Folding Deck: Project 17737EZ

Folding Deck: Project 17737EZ

Uploaded by

Rafael LeònCopyright:

Available Formats

Project 17737EZ:

Folding Deck

Table

The design of this deck table is based on an

idea that’s been used for everything from

stools to small tables. As a side table for

your barbecue grill, an extra serving table

in the dining room, or in some other capac-

ity, this little fold-away table will find many

uses.

But beyond its functional side this table is fun to build. The way the table col-

lapses will probably have you setting it up and breaking it down just to see how

cleverly everything nests together.

All the board stock for the table is 3/4" thick. Our table was constructed of ash,

but almost any hardwood can be used.

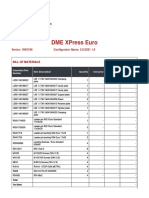

Folding Deck Table Materials List

Part Description Size No. Req’d

A Slat 3/4" x 3-1/2" x 20" 4

B Half Slat 3/4" x 1-3/4" x 20" 2

C Cleat 3/4" x 1-1/2" x 17-1/4" 4

D Leg 3/4" x 1-1/2" x 30-1/4" 4

E Stretcher 3/4" x 1-3/4" x 20" 2

F Handle 1/2" dia. x 16-1/2" long 1

Folding Deck Table Complete Schematic

Folding Deck Table Step-by-Step Instruc-

tions

1. Refer to the cutting diagram to lay out all parts so they can be cut from a 3/

4" thick by 8" wide by 9' long board.

2. Make an initial rip cut as shown. NOTE: The 9' length only includes an

allowance of 1/8" for each of the four crosscuts, so you’ll need to be

accurate if you want to get all your parts from a board this long.

3. Rip and crosscut to separate the parts. NOTE: Don’t worry if you’ve lost a

little length after sanding; it won’t make any difference come assembly.

4. NOTE the table construction: The top consists of four slats (A) and two

half slats (B); the slats mount to the cleats (C), which are then attached to

the legs (D); and the four cleats are identical, as are the four legs, but when

the table is assembled one set of legs and cleats is assembled so it fits in-

board of the other set. This is the secret to the table folding flat.

5. Lay out the 1/2" diameter dowel holes at the ends of the cleats, 3/4" on

center and 3/4" from the end.

6. Use a drill press and set up a jig to speed the work and insure accuracy.

NOTE the location of the dowel holes at the point the legs cross, 14-1/4"

from the top end.

7. Finish drilling all the dowel holes.

8. Scribe pencil lines to serve as your guide for the 3/4" radii on the ends of

the legs, the dowel ends of the cleats, and the lower corner on the opposite

end of the cleats.

9. Use a disk sander to round these radii.

10. Start assembly on the outside and work your way in. NOTE: It’s a good

idea to just lay the parts in their correct orientation — as they would be

with the table folded up-to check alignment.

11. NOTE that the dimensions on the front elevation allow 1/8" for each

washer separating the sections, which works out just right if you buy

the 1/8" thick washers we used. The 1-3/8" diameter washers are a little

smaller than the stock width so they won’t show at the edge.

12. Start by mounting two slats and one of the half slats to the two outer cleats.

13. Position the slats so the ends are flush with the outside edges of the cleats.

14. Use oval-head 1-1/2" long brass screws and countersink so the screw heads

are slightly recessed.

15. Add the two outermost legs, with a washer at each joint between the cleats

and legs.

16. Use glue and a 1-1/4" long brad to anchor the pivot dowel and cleat connec-

tion, but be careful not to get any glue on the leg end of the dowel, as the

leg must be free to pivot.

17. Add the two inside legs, again with a washer between the adjoining parts.

18. Glue and reinforce the outside half of the joint with a brad as shown, but

leave the inside section free to pivot.

19. Mount the remaining slats and half slat to the two inside cleats.

20. Join the previous assembly to the rest of the table with the long dowel

handle (F), being sure to allow for the washers that will separate the cleats

and legs when mounting the slats to the cleats. NOTE: The washers pro-

vide much needed insurance against too tight a fit, but it’s important to

check everything to be sure.

21. Screw the slats in place and then add the handle. NOTE: A brad and glue

anchors the ends of the handle where it fits into the legs, but that the cleats

must be allowed to pivot freely.

22. Take care not to make too tight a fit of the dowels through the parts that

must pivot, or you’ll find the joints binding in humid weather.

23. Mount the stretchers (E) with the table folded flat, so you can be sure the

leg position is accurate.

24. Maintain the 1/8" washer space along the full length of the legs in the

nested position to prevent binding.

25. Flip the table over to mount the other stretcher.

26. Align the locking pins by opening the table up and scribing index lines

across the half-cleats with a T-Square.

27. Unscrew the cleats.

28. Use a drill press to establish the pin holes.

29. Chamfer the inside edge of the holes with a countersink.

30. Taper the exposed ends of the pins to help ease their entry during setup.

31. Set up the table from the folded position by lifting the slat and cleat sec-

tions, then sliding the two sections together on a horizontal plane, scissoring

open the legs (see Setup Diagram).

32. Anchor the table in the open position with the locking pins.

33. Finish the table with three light coats of spar varnish, allowing each coat to

dry overnight.

These plans were originally published in Volume 14, Issue 4 of The Woodworker’s

Journal (July/Aug. 1990, pages 37-39).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Eeyore Rattle Crochet Pattern in ENG - LulupetitedollDocument11 pagesThe Eeyore Rattle Crochet Pattern in ENG - LulupetitedollMAPI CRASH100% (16)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- ShopNotes No. 121 FullDocument52 pagesShopNotes No. 121 FullKen Lock100% (13)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Scraps The DogDocument6 pagesScraps The Dogtatianateixeira325100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rope Whipping SheetDocument6 pagesRope Whipping SheetBSulliNo ratings yet

- Project 18732EZDocument4 pagesProject 18732EZBSulliNo ratings yet

- Writing Desk: Project 13586EZDocument7 pagesWriting Desk: Project 13586EZBSulliNo ratings yet

- Ez Shaker WashstandDocument7 pagesEz Shaker WashstandBrian-Patty SullivanNo ratings yet

- EZVeneer BraceletDocument3 pagesEZVeneer BraceletBSulliNo ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Shaker Single Drop Leaf TableDocument6 pagesShaker Single Drop Leaf TableLory Dena HeathNo ratings yet

- Veneered End Table: Project 17901EZDocument4 pagesVeneered End Table: Project 17901EZBSulliNo ratings yet

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliNo ratings yet

- Wooden Combs: Project 16483EZDocument3 pagesWooden Combs: Project 16483EZBSulliNo ratings yet

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Weather Station: Project 14445EZDocument4 pagesWeather Station: Project 14445EZBSulliNo ratings yet

- Workshop Tote Box: Project 20466EZDocument3 pagesWorkshop Tote Box: Project 20466EZBSulli100% (1)

- Workbench Helper: Project 20518EZDocument3 pagesWorkbench Helper: Project 20518EZBSulliNo ratings yet

- Stacking Desk Tray: Project 19874EZDocument4 pagesStacking Desk Tray: Project 19874EZBSulliNo ratings yet

- EZStoolDocument4 pagesEZStoolBSulliNo ratings yet

- Wooden Coat Hanger: Project 16474EZDocument3 pagesWooden Coat Hanger: Project 16474EZBSulliNo ratings yet

- EZTenon JigDocument3 pagesEZTenon JigBSulliNo ratings yet

- Carved Walking Stick: Project 16695EZDocument3 pagesCarved Walking Stick: Project 16695EZBSulli100% (2)

- Valentine Box: Project 10766EZDocument5 pagesValentine Box: Project 10766EZBSulliNo ratings yet

- EZTowelbar W Glass ShelfDocument2 pagesEZTowelbar W Glass ShelfBSulliNo ratings yet

- Rolling Toy: Project 19376EZDocument3 pagesRolling Toy: Project 19376EZBSulliNo ratings yet

- Shop Workstation: Project 20569EZDocument3 pagesShop Workstation: Project 20569EZBSulliNo ratings yet

- Box of Shapes Toy: Project 18618EZDocument5 pagesBox of Shapes Toy: Project 18618EZBSulliNo ratings yet

- EZRouted BookendsDocument3 pagesEZRouted BookendsBSulliNo ratings yet

- Shaker Sewing TableDocument21 pagesShaker Sewing TableFeng Shu jiNo ratings yet

- EZSalad TongsDocument3 pagesEZSalad TongsBSulliNo ratings yet

- Recipe Box: Project 15193EZDocument5 pagesRecipe Box: Project 15193EZBSulli100% (1)

- Router Bit Box: Project 20261EZDocument6 pagesRouter Bit Box: Project 20261EZBSulliNo ratings yet

- Porch Swing: Project 16258EZDocument5 pagesPorch Swing: Project 16258EZBSulli100% (1)

- Boxes. Bowls and BasketsDocument116 pagesBoxes. Bowls and BasketsPatricia Arias G100% (4)

- Aljusa Shawl by Sanne KalmbacherDocument5 pagesAljusa Shawl by Sanne KalmbacherMarina ASNo ratings yet

- ABrasive FormulasDocument3 pagesABrasive FormulasjakimlmNo ratings yet

- LiloDocument15 pagesLiloSusana Garces de Arias100% (2)

- Sept TestDocument14 pagesSept Testinfo1040No ratings yet

- 5 Little Monsters: Bead Stitch Crochet HatDocument10 pages5 Little Monsters: Bead Stitch Crochet HatElaine AlonsoNo ratings yet

- Top 10 Sewing TechniquesDocument12 pagesTop 10 Sewing TechniquesAlbert Yong100% (1)

- Workshop PracticeDocument2 pagesWorkshop PracticeSachi MensiNo ratings yet

- CNC Machine ToolsDocument64 pagesCNC Machine ToolsArun PrasadNo ratings yet

- Cutting Tool Brochure GCT SectionDocument3 pagesCutting Tool Brochure GCT SectionVojkan DamjanovićNo ratings yet

- Duende de Los Hilos - Mickey MouseDocument8 pagesDuende de Los Hilos - Mickey MouseBarbaraHidalgoOlaveNo ratings yet

- DiesDocument80 pagesDiesRajyalakshmi.G50% (2)

- Stitch Diva Studios: Bustle SkirtDocument2 pagesStitch Diva Studios: Bustle SkirtputmyemailhereNo ratings yet

- BusyBeeTools - Ca FlyerDocument32 pagesBusyBeeTools - Ca FlyercaveratNo ratings yet

- Toota's Tractor: Before You StartDocument15 pagesToota's Tractor: Before You StartlussiduNo ratings yet

- Fitter: Syllabus of Semester System For The Trade ofDocument24 pagesFitter: Syllabus of Semester System For The Trade ofkumarNo ratings yet

- Art Journal 12Document3 pagesArt Journal 12Mafe Nenia MejiasNo ratings yet

- Parallel ClampsDocument19 pagesParallel ClampsMartin MartinezNo ratings yet

- Dme Xpress Euro: Series: 196X196 Configurator Name: 5/2/2021 1.0Document3 pagesDme Xpress Euro: Series: 196X196 Configurator Name: 5/2/2021 1.0Ahmed SamirNo ratings yet

- No.14 Study GuideDocument10 pagesNo.14 Study GuideJessa Mae SisonNo ratings yet

- Foundary Technology Questions With AnswersDocument2 pagesFoundary Technology Questions With Answerskaluagrawa100% (1)

- Safety Procedure in Needle CraftDocument3 pagesSafety Procedure in Needle CraftRoanne Francisco0% (1)

- Aluminum Mk8 Extruder PlansDocument6 pagesAluminum Mk8 Extruder PlansPato AcevedoNo ratings yet

- Measured Tools:: Machining. The Process of Using A Scriber Is Called Scribing and Is Just Part of The Process ofDocument9 pagesMeasured Tools:: Machining. The Process of Using A Scriber Is Called Scribing and Is Just Part of The Process ofTamil passang songNo ratings yet

- Module 6-Lathe Machine (Topics) PDFDocument1 pageModule 6-Lathe Machine (Topics) PDFFayyaz NadeemNo ratings yet

- Die Clearance Chart and Metal Gages CardDocument2 pagesDie Clearance Chart and Metal Gages CardNaukowyDrp100% (1)

- Jenniedolly LenaDocument15 pagesJenniedolly LenaÁnh Sương Bùi100% (7)