Professional Documents

Culture Documents

Technical Properties of 30khgsa Steel Rods (Gost 4543-71 / 2590-88)

Uploaded by

rakesh0 ratings0% found this document useful (0 votes)

356 views2 pagesThe document provides technical specifications for 30KhGSA steel rods, including their chemical composition, mechanical properties, and surface condition requirements. It specifies the allowable ranges for elements like carbon, silicon, manganese, and impurities. It also outlines minimum requirements for properties like yield strength, tensile strength, elongation percentage, and hardness. Surface conditions must meet GOST 4543-71 standards, with an allowable number and size of marks, dents, and cracks depending on the intended use of cold or hot working.

Original Description:

Original Title

30KhGSA1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides technical specifications for 30KhGSA steel rods, including their chemical composition, mechanical properties, and surface condition requirements. It specifies the allowable ranges for elements like carbon, silicon, manganese, and impurities. It also outlines minimum requirements for properties like yield strength, tensile strength, elongation percentage, and hardness. Surface conditions must meet GOST 4543-71 standards, with an allowable number and size of marks, dents, and cracks depending on the intended use of cold or hot working.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

356 views2 pagesTechnical Properties of 30khgsa Steel Rods (Gost 4543-71 / 2590-88)

Uploaded by

rakeshThe document provides technical specifications for 30KhGSA steel rods, including their chemical composition, mechanical properties, and surface condition requirements. It specifies the allowable ranges for elements like carbon, silicon, manganese, and impurities. It also outlines minimum requirements for properties like yield strength, tensile strength, elongation percentage, and hardness. Surface conditions must meet GOST 4543-71 standards, with an allowable number and size of marks, dents, and cracks depending on the intended use of cold or hot working.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

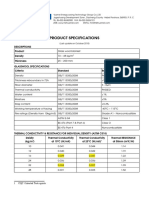

TECHNICAL PROPERTIES OF 30KhGSA STEEL RODS (GOST 4543-71 / 2590-88)

CHEMICAL COMPOSITION

CARBON : 0.28-0.34

SILICON : 0.90 – 1.10

MANGANESE : 0.80- 1.10

CHROMIUM : 0.80 – 1.10

COPPER : 0.30 Max.

NICKEL : 0.30 Max.

SULPHUR : 0.025 Max.

PHOSPHORUS : 0.025 Max.

MECHANICAL PROPERTIES

CONDITION Of Test Specimen : HARDENED AND TEMPERED

YEILD STERNGTH (Kgf/mm2) (Min.) : 85

ULTIMATE TENSILE STRENGTH (Kgf/mm2 )(Min.) : 110

ELONGATION % (Min.) : 10

REDUCTION IN AREA % (Min.) : 45

IMPACT STRENGTH Kgm / cm2 (Min.) : 5

HARDNESS BHN (Max.) : 229( in Annealed condition)

Specifications for surface conditions:

30KhGSA - Surface conditions as per GOST 4543-71

1) Surface Condition (GOST 1051-74):

Surface of sized bar should be clean, smooth, bright or dull, without cracks, blisters, laps

and seals. On the surface of rods isolated marks, dents, pitted surface within half of the tolerance

and small hair line cracks not exceeding ¼ of tolerance in depth but not exceeding 0.2mm are

allowed for rods used for hot working. Regional defects exceeding the negative tolerance on size

are not allowed for materials used for cold machining.

2) Macrostructure:

Macrostructure of steel shall be checked on etched specimen or on fracture.

Macrostructure of steel should be free from shrinkage, porosity, bubbles, cracks,

seams, slag inclusions and flakes. Inner crystalline cracks, sub-surface bubbles are not allowed.

Central porosity, point homogeneity, square segregation should not be more than point 3 for quality

steel and more than point 2 for high quality steel patch segregation & edge segregation is not

allowed in high quality steel and should not be more than point 1 for quality steel.

You might also like

- My FileDocument2 pagesMy FileSyed Umair RizviNo ratings yet

- Netway Rg-59 CCSDocument1 pageNetway Rg-59 CCSVikneswaran MuniandyNo ratings yet

- C63020 Nickel Aluminum Bronze - ConcastDocument3 pagesC63020 Nickel Aluminum Bronze - ConcastBruno FaveroNo ratings yet

- Material Data Sheet: Ref: HIL826M40 Issue: 1.0 Title: 826M40 - 2.5% Nickel-Chromium-Molybdenum Through Hardening SteelDocument1 pageMaterial Data Sheet: Ref: HIL826M40 Issue: 1.0 Title: 826M40 - 2.5% Nickel-Chromium-Molybdenum Through Hardening SteelRaghav GoelNo ratings yet

- Alloy Steels: GMTC GMTCDocument2 pagesAlloy Steels: GMTC GMTCpvdangNo ratings yet

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDocument1 pageNon-Alloy Structural Steels: Mechanical Properties Available Dimensionssorin robertNo ratings yet

- 300 SeriesDocument33 pages300 Seriesvikram jainNo ratings yet

- Sekisui Thermobreak Thermaloc 2017 Brochure - OptDocument4 pagesSekisui Thermobreak Thermaloc 2017 Brochure - OptengineerhamzehNo ratings yet

- FR 151 ZD Data SheetDocument1 pageFR 151 ZD Data SheetZahid RafiqNo ratings yet

- 310 Data SheetDocument10 pages310 Data SheetAbdullrahman AlzahraniNo ratings yet

- How To Get High Quality Boiler TubesDocument7 pagesHow To Get High Quality Boiler TubesYaneYangNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Cw008a EnglishDocument1 pageCw008a EnglishJorge VasquezNo ratings yet

- Surface Finish Tensile TestsDocument6 pagesSurface Finish Tensile TestsPaldexNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General Informationcarlos lolaNo ratings yet

- Siare Technologies - Test ReportDocument1 pageSiare Technologies - Test ReportnikhilbhorNo ratings yet

- SM 8234 10-675Document5 pagesSM 8234 10-675Remco Van Den BergNo ratings yet

- 7124 - LND - Nuclear Radiation DetectorsDocument2 pages7124 - LND - Nuclear Radiation DetectorszigobasNo ratings yet

- Technical Datasheet: Co2 (High Pressure) 2 KG Fire ExtinguisherDocument1 pageTechnical Datasheet: Co2 (High Pressure) 2 KG Fire Extinguishershashi ranjanNo ratings yet

- T, RTFF ": Technical DataDocument1 pageT, RTFF ": Technical DataNirmit GandhiNo ratings yet

- Alambron CHQDocument4 pagesAlambron CHQJavier GranadosNo ratings yet

- Normas de Acero - Grupo 3Document11 pagesNormas de Acero - Grupo 3JoseAndresAANo ratings yet

- Tungum Tubes & Their SpecificationsDocument9 pagesTungum Tubes & Their SpecificationsASPERA2No ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- Iscor RailsDocument3 pagesIscor Railsmgeorgiadis7No ratings yet

- Specifiaction - PROKDocument5 pagesSpecifiaction - PROKAjit AgrawalNo ratings yet

- LPCB Fire Resistant CableDocument2 pagesLPCB Fire Resistant CableArjunNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- 60munice ANDocument5 pages60munice ANbā wārNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- Technical Delivery Condition: LBST Specification Code: LB 304Document2 pagesTechnical Delivery Condition: LBST Specification Code: LB 304Prasenjit PuriNo ratings yet

- Hot Rolled Coils For Large Diameter Pipes L360NBDocument2 pagesHot Rolled Coils For Large Diameter Pipes L360NBvayo99No ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDocument3 pagesYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNo ratings yet

- 2.2.4 Elgard 85 Ribbon MeshDocument1 page2.2.4 Elgard 85 Ribbon MeshSoltani AliNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- KAMAX - Bolt and Screw CompendiumDocument60 pagesKAMAX - Bolt and Screw Compendiumjzaw65No ratings yet

- C89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006Document1 pageC89520 (Sebiloy Ii (Envirobrass Ii) ) : Last Updated: Jan 27, 2006박준용No ratings yet

- HDD Calculation - CH 15Document23 pagesHDD Calculation - CH 15Binay Kumar100% (1)

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- Mat 07000-07149 200411Document5 pagesMat 07000-07149 200411Ronaldo Bandeira RodriguesNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- C63020 Nickel Aluminum Bronze - Concast 2Document2 pagesC63020 Nickel Aluminum Bronze - Concast 2Bruno FaveroNo ratings yet

- Schott Borofloat Technical Data Sheet EnglishDocument1 pageSchott Borofloat Technical Data Sheet Englishlilian.agenaisNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- TDS Turbonycoil TN160 1E9Document2 pagesTDS Turbonycoil TN160 1E9HimalayaNo ratings yet

- Spike BeltDocument2 pagesSpike BeltgalateaciclesNo ratings yet

- Corning ULEDocument4 pagesCorning ULECương Nguyễn ĐìnhNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Steel Grades Gost PDFDocument5 pagesSteel Grades Gost PDFrakeshNo ratings yet

- Product Information: Tectyl™ 506-EHDocument2 pagesProduct Information: Tectyl™ 506-EHrakeshNo ratings yet

- ICF MD Spec 297Document8 pagesICF MD Spec 297rakeshNo ratings yet

- Steel Grades Gost PDFDocument5 pagesSteel Grades Gost PDFrakeshNo ratings yet

- Sig N 027 101 Q3 PDFDocument13 pagesSig N 027 101 Q3 PDFrakesh100% (1)

- BS3100 CastingDocument1 pageBS3100 Castingrakesh100% (1)

- Material Specification Sheet Saarstahl - 27Mncrb5-2Document1 pageMaterial Specification Sheet Saarstahl - 27Mncrb5-2rakeshNo ratings yet