Professional Documents

Culture Documents

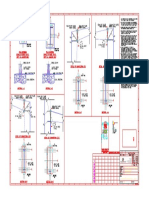

101 NAV SAOI VYARA-Model

Uploaded by

kavin patel0 ratings0% found this document useful (0 votes)

12 views1 pageOriginal Title

101_NAV_SAOI_VYARA-Model

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 page101 NAV SAOI VYARA-Model

Uploaded by

kavin patelCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

TRIMS FOR PE-1000 PANELS

(SELECT FROM DROP DOWN)

1. ALL DIMENSIONS ARE IN MILLIMETERS AND ALL LEVELS

ARE IN METERS UNLESS NOTED OTHERWISE.

2. THE STRUCTURE UNDER THIS CONTRACT IS DESIGNED AND

DETAILED FOR THE LOADS STIPULATED AND SHOWN ON THESE

DRAWINGS. ANY ALTERATIONS TO THE STRUCTURAL SYSTEM OR

REMOVAL OR ADDITION OF OTHER CONSTRUCTION MATERIALS OR

LOADS MUST NOT BE DONE WITHOUT PRIOR CONSENT OF ----

3. ALL STEEL FRAMING MEMBERS EXCEPT BOLTS AND FASTENERS

SHALL RECEIVE ONE COAT OF 25MICRON SHOP PRIMER

COMPARABLE TO THE PERFORMANCE REQUIREMENT OF THE U.S.

FEDERAL SPECIFICATION TT-P-636C WHICH PROVIDES TEMPORARY

PROTECTION FOR THE MEMBERS DURING TRANSPORTATION AND

ERECTION ONLY. ADDITIONAL PAINT PROTECTION SUITABLE FOR

BUILDING USAGE AND ENVIRONMENT MUST BE ADDED BY THE

CUSTOMER/OWNER

4. HIGH STRENGTH BOLTS HAVE YELLOW DI-CHROMATED COLOR

WHILE MACHINE BOLTS ARE ELECTRO-GALVANIZED

5. HIGH STRENGTH BOLTS TO BE LUBRICATED AND FREE KEPT FROM

DUST AND DEBRIS. NUTS WITH LUBRICANT MUST BE ROTATED

FROM THE SNUG TIGHT CONDITION REQUIRED FOR FULL

TENSIONING OF BOLTS WITHOUT STRIPPING. IF THE ERECTOR

NOTICED ANY LACK OF SUCH LUBRICATION HE IS REQUIRED TO

LUBRICATE THEM AT SITE, BEFORE TIGHTENING.

6. ALL SECONDARY CONNECTIONS REQUIRE 12MM DIA

ELECTRO-PLATED MACHINE BOLTS CONFORMING TO ASTM A-307

U.N.O

7. THE CORRECT TYPE OF BOLTS MUST BE USED AS CALLED FOR ON

THE DETAILS. USING WRONG TYPE OF BOLTS MAY CAUSED BUILDING

FAILURE AT ERECTOR'S RESPONSIBILITY

8. CONTINUOUS MACHINE SUBMERGED ARC WELDING (S.A.W) MEET

THE APPLICABLE REQUIREMENTS OF THE AMERICAN WELDING

SOCIETY (A.W.S) D1.1-1996.

9. WEB TO FLANGE WELDS ARE SINGLE SIDE FILLET WELDS IN

ACCORDANCE WITH THE NINTH EDITION OF THE AISC TABLE J2.4

PAGE 5-67 U.N.O

10. WEB BUTT WELDS ARE COMPLETE PENETRATION USING

FLUX BACK-UP (16MM PLATE MAXIMUM)

11. FLANGE BUTT WELDS ARE ON BOTH SIDES WITH

COPPER BACK-UP. FLANGES 19MM OR HIGHER ARE

BEVELED PRIOR TO ASSEMBLY

12. BUILT-UP SECTIONS ARE MADE FROM HOT ROLLED

PLATES CONFORMING TO ASTM A-36 WITH A MINIMUM

YIELD STRENGTH OF 250MPa

13. ALL SECONDARIES i.e., PURLINS AND GIRTS ARE MADE

FROM COILS CONFORMING TO GRADE-50 WITH A

MINIMUM YIELD STRENGTH OF 345MPa

RAFTER

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Palanpur Design 16-ModelDocument1 pagePalanpur Design 16-Modelkavin patelNo ratings yet

- Arsh Consultants: Mission & VisionDocument4 pagesArsh Consultants: Mission & Visionkavin patelNo ratings yet

- 004 MTFB (20-21) 16.83x20.77Document1 page004 MTFB (20-21) 16.83x20.77kavin patelNo ratings yet

- Palanpur Design SectionsDocument1 pagePalanpur Design Sectionskavin patelNo ratings yet

- 101 - NAV - SAOI - Maflipur 24-05AS PER ARCHI COMMENTS18-09-ModelDocument1 page101 - NAV - SAOI - Maflipur 24-05AS PER ARCHI COMMENTS18-09-Modelkavin patelNo ratings yet

- 2-Nov-2020 GB DETAILS-ModelDocument1 page2-Nov-2020 GB DETAILS-Modelkavin patelNo ratings yet

- 07.01.2021 Ground Floor Slab Layout and Details (1) - ModelDocument1 page07.01.2021 Ground Floor Slab Layout and Details (1) - Modelkavin patelNo ratings yet

- Gov. - Dholka Sport Authority-ModelDocument1 pageGov. - Dholka Sport Authority-Modelkavin patelNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument12 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing Balancekavin patelNo ratings yet

- STR 237Document144 pagesSTR 237kavin patel100% (1)

- Gov. - Dholka Sport Authority-Model PDFDocument1 pageGov. - Dholka Sport Authority-Model PDFkavin patelNo ratings yet

- LaodcombinationDocument1 pageLaodcombinationkavin patelNo ratings yet

- G+2 Pranavbhai's bunglow-ModelFFSLABDocument1 pageG+2 Pranavbhai's bunglow-ModelFFSLABkavin patelNo ratings yet

- Design of PergolasDocument3 pagesDesign of Pergolaskavin patelNo ratings yet

- That Is GreatDocument5 pagesThat Is Greatkavin patelNo ratings yet

- Paper Title (Use Style: Paper Title) : Subtitle As Needed (Paper Subtitle)Document3 pagesPaper Title (Use Style: Paper Title) : Subtitle As Needed (Paper Subtitle)kavin patelNo ratings yet

- Literature ReviewDocument8 pagesLiterature Reviewkavin patelNo ratings yet

- Ship ToDocument1 pageShip Tokavin patelNo ratings yet

- EstimateDocument3 pagesEstimatekavin patelNo ratings yet

- Ship ToDocument1 pageShip Tokavin patelNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Go Go Go Go.......................................................................Document53 pagesGo Go Go Go.......................................................................kavin patelNo ratings yet

- Moment of Inertia (Graphics)Document32 pagesMoment of Inertia (Graphics)NanowordNo ratings yet

- Passport Rushin PDFDocument1 pagePassport Rushin PDFkavin patelNo ratings yet

- Education: Degree Branch Year of Passing College/School University/Board ScoreDocument2 pagesEducation: Degree Branch Year of Passing College/School University/Board Scorekavin patelNo ratings yet

- High Rise BuildingDocument41 pagesHigh Rise BuildingweeteoNo ratings yet

- AbstractDocument1 pageAbstractkavin patelNo ratings yet

- Resume - : Nikunj R. Patadia AddressDocument6 pagesResume - : Nikunj R. Patadia Addresskavin patelNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Inspection Release NoteDocument69 pagesInspection Release NotebigurijunnataNo ratings yet

- Project Engineer First Aider ForemanDocument1 pageProject Engineer First Aider ForemanInathan GarciaNo ratings yet

- Fab Separator Coal Miil PT SEMEN TONASADocument27 pagesFab Separator Coal Miil PT SEMEN TONASAmoddysNo ratings yet

- ISO 2768-mk EN ISO 13920-BF: Tanasa C. Tanasa CDocument1 pageISO 2768-mk EN ISO 13920-BF: Tanasa C. Tanasa CDaniel ProncoschiNo ratings yet

- WorkOrder 10 06 2020 PDFDocument2 pagesWorkOrder 10 06 2020 PDFJay CuaNo ratings yet

- CUBO Homebuyer's Guide 2021 - 01.01.21Document44 pagesCUBO Homebuyer's Guide 2021 - 01.01.21ANNLNo ratings yet

- Guide 01300Document2 pagesGuide 01300djukalNo ratings yet

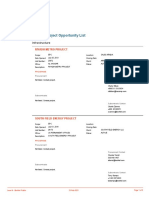

- Bechtel Project Opportunity List: InfrastructureDocument9 pagesBechtel Project Opportunity List: InfrastructureDhanu NikkuNo ratings yet

- Method Statement Demolition & Removal of Courtyard Flooring, Asphalt, Curb Stones, Block Wall & SeatsDocument26 pagesMethod Statement Demolition & Removal of Courtyard Flooring, Asphalt, Curb Stones, Block Wall & SeatsIrfan AliNo ratings yet

- 1CP01 MDS CR Con SS08 000008 (C01)Document15 pages1CP01 MDS CR Con SS08 000008 (C01)Pavlos InglesisNo ratings yet

- Supply and Delivery of Panelboards: (ABB CIRCUIT-Breakers)Document3 pagesSupply and Delivery of Panelboards: (ABB CIRCUIT-Breakers)Interfield Const CorpNo ratings yet

- Cuplock EngineeringDocument14 pagesCuplock Engineeringkauffmanj09No ratings yet

- Nuvoco Vistas IPO AnalysisDocument5 pagesNuvoco Vistas IPO AnalysisDaksh MaruNo ratings yet

- Sika Watertight Concrete System - CAD GuidanceDocument4 pagesSika Watertight Concrete System - CAD GuidancePaulo Garcia0% (1)

- Prefabricated Structures PDFDocument51 pagesPrefabricated Structures PDFAlex Christopher64% (14)

- 110 - Technical Specification 220kV Moose + Zebra WB - 10-ADocument255 pages110 - Technical Specification 220kV Moose + Zebra WB - 10-AwaniasimNo ratings yet

- Small Construction Company ProfileDocument17 pagesSmall Construction Company ProfileMajaya JonasiNo ratings yet

- Prada TransformerDocument23 pagesPrada TransformerPablo García PettersNo ratings yet

- MS For Trial Hole Excavation.Document4 pagesMS For Trial Hole Excavation.TamilananthNo ratings yet

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 005Document2 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 005Anonymous sLRlLluNo ratings yet

- Example Method Statement For The Installation of Roof TrussesDocument8 pagesExample Method Statement For The Installation of Roof TrussesSai Shankar LakshminarayananNo ratings yet

- Mep Spec 3Document80 pagesMep Spec 3loc khaNo ratings yet

- Cement Testing ServicesDocument18 pagesCement Testing Servicessiddhi jadhavNo ratings yet

- Inspection and Test Plan - Wooden Wall Panel InstallationDocument2 pagesInspection and Test Plan - Wooden Wall Panel Installationexia1992No ratings yet

- Variation Order ProcedureDocument30 pagesVariation Order ProcedureMoinuddin Ansari75% (4)

- Abdala AgreementDocument5 pagesAbdala AgreementEMINAT PRINCENo ratings yet

- Saso 145Document8 pagesSaso 145Ayman EwaisNo ratings yet

- API 650 ENOC Spec. - Rev.3 - Dated 22-09-2005Document21 pagesAPI 650 ENOC Spec. - Rev.3 - Dated 22-09-2005Elias EliasNo ratings yet

- Specifications: I. General ProvisionsDocument4 pagesSpecifications: I. General Provisionsemem CatzNo ratings yet

- Scope of Works Proposed 6-Storey Mixed-Used Commercial and Residential Building With Roof DeckDocument8 pagesScope of Works Proposed 6-Storey Mixed-Used Commercial and Residential Building With Roof DeckAngel RondillaNo ratings yet