Professional Documents

Culture Documents

Introduction: - Electro Rheological (ER) Fluids Basically Consist of Particles That Are

Introduction: - Electro Rheological (ER) Fluids Basically Consist of Particles That Are

Uploaded by

sukanto bagchiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction: - Electro Rheological (ER) Fluids Basically Consist of Particles That Are

Introduction: - Electro Rheological (ER) Fluids Basically Consist of Particles That Are

Uploaded by

sukanto bagchiCopyright:

Available Formats

Introduction: - Electro rheological (ER) fluids basically consist of particles that are

held in suspension by a non- conducting fluid. The suspending liquid which should

have a high electrical resistivity is typically low viscosity hydrocarbon or silicone oil.

The particles dispersed in this liquid are commonly metal oxides, alumino silicates,

silica, organics or polymers. In particular, the particles are very small and have

sufficiently low concentration to allow the fluid to maintain a relatively low viscosity

in the absence of an applied electric field. ER fluids are suspensions consisting of

dielectric particles of size 0.1-100 micro meter (µm.) and dielectric fluid. In their

liquid like state, they exhibit fluid like properties. In their activated conditions, they

exhibit solid like state.

Types of ER fluids

Positive ER fluids: - The property of increase in the viscosity by applying the

electric field to the ER fluid induced is termed the positive ER fluid. Many particle-

fluid combinations have been tried in order to find an increment in viscosity.

Negative ER fluids:- The property of decrease in the viscosity by applying the

electric field to the ER fluid induced is termed the negative ER fluid.

Electro Rheological Material Behavior

The electrorheologicaleffect occurs in electro rheological fluids when an electric field

is applied causing the uniform dispersed solid

particles to become polarized. Once polarized, they begins to interact with each other,

and form chain like structure, parallel to electrical field direction, connecting the two

electrode. Upon further intensification of the electrical field, chains begin to form

thicker column.

A change in the suspension’s rheological properties is associated with this

change in its structure. The columnar particles structure give the fluid a greater yields

stress. Upon removing the electrical field, the particles lose their polarization and

return to their freely roaming state. The period of time over which these events occurs

is on the order of milliseconds.The operational mode can be classified as

a) Flow mode: - In flow mode, two electrodes are fixed and vibrational control is

obtained by controlling the flow motion between two fixed electrodes.

b) Shear Mode: - In shear mode, one electrode is free to rotate relative to another

electrode so vibration control is obtained by controlling shear force.

c) Squeeze Mode: - In squeeze mode, the electrode gap is varied and electro

rheological fluid squeezed by normal force.

Electro Rheological Fluids & Its Properties

Electro rheological fluids belong to a class of colloidal suspensions which exhibit

large reversible changes in their rheological behavior when subjected to external

electrical fields. Many researchers presently have been actively studying the

mechanism and application of electro rheological fluid. One silent property of the

electro rheological fluid itself is that it has a very fast response characteristic to

electric field and hence wide control bandwidth. This inherent feature has

triggered tremendous research activities in the development of various engineering

application. These include shock absorbers, engine mount, machine mount and smart

structure. Electro rheological fluid is known as a functional fluid, whose yield shear

stress can be varied by the applied electric field strength. This unique fluid was

known to world through the patent obtained by W. Winslow [1]. This special fluid has

recently gathered greater attention due to scope for their commercial

success in state of art automobile. Willis M. Winslow [1] discovered the effect of

electro rheological effect in 1942, and since then there has been much struggle first to

completely understand the effect, and second to develop electro rheological fluid with

properties that meet the design requirement for practical applications. Some of the

properties of electro rheological fluids that have hindered them from performing

sufficiently for many applicationsare yield stress, temperature stability, and

power consumption. The properties of electro rheological fluids depend on particle

size, density, carrier fluid properties, additives and temperature. A higher

concentration of volume fraction of the dispersed particulates phase can give the fluid

a much higher electro rheological effect, but at the same time can cause problems.

Sedimentation is a major factor, since higher concentration of solid particles increase

the amount of settling that will occur. The other potential problem is an increase in the

zero field’s viscosity. The most obvious property

affected by temperature is viscosity, which

decrease as temperature increases. The

dynamic yield strength also decreases with

increase in temperature. The more extensive

change in dynamic yield strength for electro

rheological fluids is primarily due to change in

conductivity and relative permittivity of the

particle and oil components of the fluid over

the temperature. The voltage required to

include rheological changes through a given

thickness of electro rheological fluid is

relatively small (Approximately 1 to 4

KV/mm). Typically, the current densities of

electro rheological fluid are between 10-6 to 10-

3 amp/cm2 . Current density measurements are

used to predict the power consumption of

particular electro rheological fluids. One of the

most important properties of an electro

rheological fluid is its dynamic yield stress,

which is the minimum stress required to cause

You might also like

- Esas Preboard ObjectivesDocument236 pagesEsas Preboard ObjectivesVen Jay Madriaga Tabago89% (18)

- General Wave Properties 1 QPDocument13 pagesGeneral Wave Properties 1 QPMELODY CHENNo ratings yet

- Urinalysis Sample Report With Notes - 0Document1 pageUrinalysis Sample Report With Notes - 0sukanto bagchiNo ratings yet

- Helical Gears ProblemsDocument29 pagesHelical Gears Problemsa17e100% (1)

- Seryice Mant) AlDocument11 pagesSeryice Mant) Alloupapi3350% (2)

- Modern Applications of Electrorheological (ER) Fluids: January 2014Document8 pagesModern Applications of Electrorheological (ER) Fluids: January 2014Maya GlamourstickesNo ratings yet

- Electrorheological Fluid - Wikipedia, The Free EncyclopediaDocument4 pagesElectrorheological Fluid - Wikipedia, The Free EncyclopediaSundae bgramNo ratings yet

- LiquidsDocument32 pagesLiquidsMudassirAliNo ratings yet

- Advance High Voltage EngineeringDocument44 pagesAdvance High Voltage EngineeringDipesh ChaudharyNo ratings yet

- Jawaban Soal Liquid Dielectric Santos EdunDocument8 pagesJawaban Soal Liquid Dielectric Santos EdunLuthfi Arif Fadillah100% (1)

- Lecture 6 (AHVE)Document24 pagesLecture 6 (AHVE)SAJEEDNo ratings yet

- Chapter 31: Principles of Active Vibration Control: Electrorheological FluidsDocument12 pagesChapter 31: Principles of Active Vibration Control: Electrorheological FluidsNagarajan PitchandiNo ratings yet

- Lecture 5 (AHVE)Document32 pagesLecture 5 (AHVE)SAJEEDNo ratings yet

- Chemical EffectDocument12 pagesChemical EffectMohan LalNo ratings yet

- 2004 - RehdenDocument7 pages2004 - RehdensajbberNo ratings yet

- Bef45203 HV Chapter 2 - Breakdown in LiquidDocument24 pagesBef45203 HV Chapter 2 - Breakdown in LiquidNUR AQILAH MOHD AZMANNo ratings yet

- Electrochemistry and Water TreatmentDocument16 pagesElectrochemistry and Water TreatmentSarkuvi ProdNo ratings yet

- Electrolyzer Modules A) Unipolar and B) Bipolar Cell ConfigurationsDocument8 pagesElectrolyzer Modules A) Unipolar and B) Bipolar Cell ConfigurationsAnuj ShahiNo ratings yet

- Reduction Potential Oxidation Potential and Cell PotentialDocument19 pagesReduction Potential Oxidation Potential and Cell PotentialKeanne QuicoyNo ratings yet

- Breakdown in Liquid DielectricsDocument5 pagesBreakdown in Liquid DielectricskrishnandrkNo ratings yet

- Seminar On Electro Active Polymers: Submitted To: Submitted byDocument10 pagesSeminar On Electro Active Polymers: Submitted To: Submitted bytanveershariff13No ratings yet

- ER FluidsDocument14 pagesER FluidsKashyap MkNo ratings yet

- Lec 13 BD in LiquidsDocument24 pagesLec 13 BD in LiquidsNimra JavedNo ratings yet

- General Electrochemistry For Chlorine GenerationDocument9 pagesGeneral Electrochemistry For Chlorine GenerationTS WongNo ratings yet

- Liquid BreakdownDocument24 pagesLiquid BreakdownKokila ChezianNo ratings yet

- Experimental Investigation of The Operating Parameters AffectingDocument4 pagesExperimental Investigation of The Operating Parameters AffectingJonas Drumond Alves SoaresNo ratings yet

- Proj - Electrolytic CellDocument19 pagesProj - Electrolytic CellGeetanjali YadavNo ratings yet

- Refresher AssignmenrDocument9 pagesRefresher AssignmenrKulasekara PandianNo ratings yet

- ElectrochemistryDocument30 pagesElectrochemistryPankaj Jindam100% (1)

- Electro Active PolymersDocument40 pagesElectro Active PolymersPratik TankNo ratings yet

- Electrolysis LessonDocument25 pagesElectrolysis LessonAbigail MedinaNo ratings yet

- Unit IiDocument22 pagesUnit IiMagambo Sahiil MorisNo ratings yet

- Breakdown in LiquidsDocument17 pagesBreakdown in LiquidsMuhd Nur RidzwanNo ratings yet

- Seminar On: Electro Rheological, Magneto Rheological Fluids & Piezoelectric MaterialsDocument12 pagesSeminar On: Electro Rheological, Magneto Rheological Fluids & Piezoelectric MaterialsMainakMitraNo ratings yet

- Lecture 3, High Voltage LIQUID INSULATORS 2023Document32 pagesLecture 3, High Voltage LIQUID INSULATORS 2023katjinomasa kavetuNo ratings yet

- Kinetic Molecular ModelDocument83 pagesKinetic Molecular ModelMonch LacedaNo ratings yet

- Materials Chemistry and Physics: 2 Chin-Shen Lim, K.H. Teoh, Chiam-Wen Liew, S. RameshDocument7 pagesMaterials Chemistry and Physics: 2 Chin-Shen Lim, K.H. Teoh, Chiam-Wen Liew, S. Rameshkhellouf940101No ratings yet

- UEE & T Notes (1) (6th Semester Electrical) - MergedDocument199 pagesUEE & T Notes (1) (6th Semester Electrical) - MergedAmit HansdaNo ratings yet

- Wa0007.Document6 pagesWa0007.SRS status kingNo ratings yet

- Lab Assignment Submitted To: MIRPUR University OF SCIENCE and TechnologyDocument2 pagesLab Assignment Submitted To: MIRPUR University OF SCIENCE and TechnologyMir Junaid Ul HaqNo ratings yet

- A Review of The Theory of Osmotic Damp Proofing - PDF 20042010-1543-41Document15 pagesA Review of The Theory of Osmotic Damp Proofing - PDF 20042010-1543-41kalpna_n3No ratings yet

- Chemical Effets of El NVS TeachersDocument12 pagesChemical Effets of El NVS Teachersaashna shirbhateNo ratings yet

- ElectrogravimetryDocument15 pagesElectrogravimetryMigs Bernal100% (1)

- An Experimental Study of The Electrohydrodynamic Characteristics of Sedimenting Drops Under Uniform Alternating Electric FieldsDocument7 pagesAn Experimental Study of The Electrohydrodynamic Characteristics of Sedimenting Drops Under Uniform Alternating Electric Fieldskushal bosuNo ratings yet

- LPDocument4 pagesLPChandan SahuNo ratings yet

- Electrolysis PresentationDocument24 pagesElectrolysis PresentationsaeikipNo ratings yet

- ElectrochemistryDocument13 pagesElectrochemistrymochimochikoNo ratings yet

- Electroplating and Surface Modification: Dr. Surender KumarDocument51 pagesElectroplating and Surface Modification: Dr. Surender KumarMonika SinghNo ratings yet

- Electrolysis: Amy Jewel, Rob Larkin and Todd HaurinDocument24 pagesElectrolysis: Amy Jewel, Rob Larkin and Todd Haurinlove_puezied4793No ratings yet

- Electro CoagulationDocument20 pagesElectro CoagulationBrahmanto Anggoro Laksono100% (2)

- Electrophoretic DepositionDocument7 pagesElectrophoretic Depositionpuneetchawla9No ratings yet

- Introduction To ElectrochemistryDocument40 pagesIntroduction To ElectrochemistryAngates1100% (2)

- Lec# 17 Breakdown Theories For Liquid DielectricsDocument13 pagesLec# 17 Breakdown Theories For Liquid DielectricsVishal MeghwarNo ratings yet

- What Is Conductivity and How Is It Measured?Document24 pagesWhat Is Conductivity and How Is It Measured?iptNo ratings yet

- Throwing Power and Covering Power of An Electrochemical ReactionsDocument14 pagesThrowing Power and Covering Power of An Electrochemical ReactionsDevashish JoshiNo ratings yet

- Eizreen Binti Eizuddin (D20182085830) ElectrochemistryDocument7 pagesEizreen Binti Eizuddin (D20182085830) ElectrochemistryEizreenNo ratings yet

- Mse Final TestDocument9 pagesMse Final TestJennifer HansonNo ratings yet

- 3-Electrochemistry NotesDocument20 pages3-Electrochemistry NotesTech BusterNo ratings yet

- Electrochemistry DMDNDocument4 pagesElectrochemistry DMDNYdyfr FsytNo ratings yet

- Smart FluidsDocument3 pagesSmart FluidsKrishna AgarwalNo ratings yet

- Trident PaperDocument6 pagesTrident PaperniceseshaNo ratings yet

- Unit-3Electrochemistry 88896Document37 pagesUnit-3Electrochemistry 88896Dhatri SriramNo ratings yet

- Bscpe Sci1 SLM 5Document25 pagesBscpe Sci1 SLM 5April Joy GonzalesNo ratings yet

- Me 401 Mechanical Lab - Ii Assignment - 2 Submittedby:-Santobagchi Roll Number: - 171me112 Submitted To: - DR Arumuga Perumal D Mechanical DepartmentDocument1 pageMe 401 Mechanical Lab - Ii Assignment - 2 Submittedby:-Santobagchi Roll Number: - 171me112 Submitted To: - DR Arumuga Perumal D Mechanical Departmentsukanto bagchiNo ratings yet

- Mmi 2Document9 pagesMmi 2sukanto bagchiNo ratings yet

- Indiana University Mathematics Department Journal of Mathematics and MechanicsDocument19 pagesIndiana University Mathematics Department Journal of Mathematics and Mechanicssukanto bagchiNo ratings yet

- Rheological Properties of FerrofluidsDocument1 pageRheological Properties of Ferrofluidssukanto bagchiNo ratings yet

- ME351MDV Jan2014 2DOF Tutorial Ver01Document4 pagesME351MDV Jan2014 2DOF Tutorial Ver01sukanto bagchiNo ratings yet

- Chapter 2Document34 pagesChapter 2Aditya MachirajuNo ratings yet

- 152lecture 1 1 Static Force Analysis of Planar MechanismDocument29 pages152lecture 1 1 Static Force Analysis of Planar Mechanismsukanto bagchiNo ratings yet

- Sequences (Part 1)Document51 pagesSequences (Part 1)sukanto bagchiNo ratings yet

- Module 4Document164 pagesModule 4Vimal SankarNo ratings yet

- General Conduction Equation - Cartesian CoordinatesDocument17 pagesGeneral Conduction Equation - Cartesian Coordinatesnimish_nirmaNo ratings yet

- Power Point Anti Blocking 1Document26 pagesPower Point Anti Blocking 1Octo Goldwin TambaNo ratings yet

- DC Machines 3Document24 pagesDC Machines 3Janaka Chathuranga AbeywardenaNo ratings yet

- Large-Scale Direct Shear Testing of Geocell Reinforced SoilDocument6 pagesLarge-Scale Direct Shear Testing of Geocell Reinforced SoilnarutowhatsupNo ratings yet

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- 6-Request AC - Ventilation Work Inspection 01 - 02Document4 pages6-Request AC - Ventilation Work Inspection 01 - 02Construction UpdatePHNo ratings yet

- Datsun 1200 1973 Service ManualDocument20 pagesDatsun 1200 1973 Service Manualdelores100% (62)

- Cummins ISX CM571 & Signature 600 Fault CodesDocument15 pagesCummins ISX CM571 & Signature 600 Fault CodesOlivaresM.Emanuel100% (2)

- FM Lab 6Document6 pagesFM Lab 6Kamil Rasheed SiddiquiNo ratings yet

- Physics - Syllabus - Grade 10 PDFDocument42 pagesPhysics - Syllabus - Grade 10 PDFAbi Kasahun75% (4)

- Advantages of Traction Machine of ElevatorDocument6 pagesAdvantages of Traction Machine of ElevatorMzimasi MjanyelwaNo ratings yet

- H09095 - SuperFill Surge Reduction EquipDocument4 pagesH09095 - SuperFill Surge Reduction EquipAQUILES CARRERANo ratings yet

- Laboratory Soils Testing: Engineer Manual E M 1110-2-1906Document407 pagesLaboratory Soils Testing: Engineer Manual E M 1110-2-1906Nicolas Fuentes Von KieslingNo ratings yet

- FIR 001 - Rev.06 12Document12 pagesFIR 001 - Rev.06 12SteveYobsNo ratings yet

- Lab 8 Full ReportDocument31 pagesLab 8 Full ReportCham Amirruddin77% (13)

- Transmission 5800 - 16800 8-Speed ManualDocument65 pagesTransmission 5800 - 16800 8-Speed ManualMauro Perez100% (1)

- Daily Monitoring BD (DMBD) - BKL R0Document1 pageDaily Monitoring BD (DMBD) - BKL R0Theo AnggaraNo ratings yet

- Eaton Clutch - PDF AUTODocument4 pagesEaton Clutch - PDF AUTODiego Gomez Navarro100% (2)

- Quick Review Is 6403Document2 pagesQuick Review Is 6403Kanaiyalal N. ShethNo ratings yet

- Reboiler Selection CriteriaDocument5 pagesReboiler Selection CriteriamineralgroupstmfiNo ratings yet

- Ch1 ThermochemistryDocument9 pagesCh1 ThermochemistryRonnel ClarinNo ratings yet

- CH 13Document32 pagesCH 13hirenpatel_universalNo ratings yet

- C4 C44 C51 Cryogenic Service Valves PDFDocument12 pagesC4 C44 C51 Cryogenic Service Valves PDFTaylor RamirezNo ratings yet

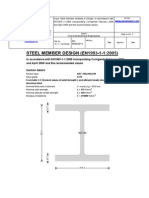

- Sachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Document6 pagesSachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Costas SachpazisNo ratings yet

- Procedimiento para Reparar La Bomba de AguaDocument4 pagesProcedimiento para Reparar La Bomba de AguaJose A. Basanta H.No ratings yet