Professional Documents

Culture Documents

TE Studs

Uploaded by

Ravi Chaitanya Velamarthy0 ratings0% found this document useful (0 votes)

9 views1 pageAPI Spec mat'l trim

Original Title

TE studs

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI Spec mat'l trim

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageTE Studs

Uploaded by

Ravi Chaitanya VelamarthyAPI Spec mat'l trim

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

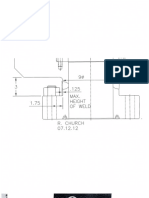

Today most tap end studs used are in the oilfield, and there are appropriate (API and

other)

standards for their design. The following is taken from the American Machinists' Handbook by

Colvin and Stanley, Seventh Edition (1940). The parameters given in this reference are similar to

the oilfield specs, but not identical.

Dimensions

D = nominal thread size (O.D.) of stud

L = overall length of stud

A = length of thread on tap end = D + 1/8", and is measured from the end of the stud to

the end of the imperfect thread

S = length of the unthreaded portion or shoulder = D, except when L < 4D + 3/8", in

which case S may be decreased or eliminated entirely so that B > 2D + 1/4".

B = length of thread on the nut end = L - (A + S) > 2D + 1/4", and is measured from the

end of the stud to the end of the imperfect thread

C = length of the imperfect threads < 2 1/2 threads

For short studs where S = 0, B can be less than 2D + 1/4", but A > D + 1/8".

If L > 4D + 3/8", B = L - (A + S), or otherwise put, "the balance of the stud not consumed by A,

the tap end threading (A = D + 1/8") and S, the shoulder length (S = D)."

Note the convention of chamfering the tap end and rounding the nut end of the stud.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- RAL Color Chart 1Document10 pagesRAL Color Chart 1Ravi Chaitanya VelamarthyNo ratings yet

- FE Analysis of FlangesDocument65 pagesFE Analysis of FlangesRavi Chaitanya Velamarthy0% (1)

- Eng FormulasDocument21 pagesEng FormulaszingalalaNo ratings yet

- BETE NF-metricDocument1 pageBETE NF-metricRavi Chaitanya VelamarthyNo ratings yet

- Bete NFDocument1 pageBete NFRavi Chaitanya VelamarthyNo ratings yet

- Pneumatic Driven Liquid PumpsDocument28 pagesPneumatic Driven Liquid PumpsRavi Chaitanya VelamarthyNo ratings yet

- Is Stainless Steel MagneticDocument1 pageIs Stainless Steel MagneticRavi Chaitanya VelamarthyNo ratings yet

- SDX Connector System PDFDocument8 pagesSDX Connector System PDFRavi Chaitanya VelamarthyNo ratings yet

- Catalogo JuntasDocument49 pagesCatalogo Juntasdavidmn19100% (1)

- .75 Taper Dry Seal PDFDocument1 page.75 Taper Dry Seal PDFRavi Chaitanya VelamarthyNo ratings yet

- A Glossary of Forging TermsDocument22 pagesA Glossary of Forging TermsSiva Subramaniam M BNo ratings yet

- Xylan 1424 Color ChartDocument1 pageXylan 1424 Color ChartRavi Chaitanya Velamarthy100% (1)

- Accumulators Basically Comprise of Two CompartmentsDocument2 pagesAccumulators Basically Comprise of Two CompartmentsRavi Chaitanya VelamarthyNo ratings yet

- 999 Industrial Guide 2010Document42 pages999 Industrial Guide 2010kasosei100% (1)

- ATEX Certified: Shown: ZA4208MX, ZA4420MXDocument2 pagesATEX Certified: Shown: ZA4208MX, ZA4420MXRavi Chaitanya VelamarthyNo ratings yet

- API Spec Mat'l TrimDocument1 pageAPI Spec Mat'l TrimRavi Chaitanya VelamarthyNo ratings yet

- Wireline CatalogueDocument17 pagesWireline CatalogueRavi Chaitanya VelamarthyNo ratings yet

- API Spec Mat'l TrimDocument1 pageAPI Spec Mat'l TrimRavi Chaitanya VelamarthyNo ratings yet

- Wrench Clearnace 51 Bop Flange 7.06 5MDocument3 pagesWrench Clearnace 51 Bop Flange 7.06 5MRavi Chaitanya VelamarthyNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Ravi Chaitanya VelamarthyNo ratings yet

- Parker Cylinder PDFDocument84 pagesParker Cylinder PDFRavi Chaitanya VelamarthyNo ratings yet

- American Standard Acme Screw Thread DimensionsDocument1 pageAmerican Standard Acme Screw Thread DimensionsIvan RuizNo ratings yet

- DFSDFSDFSDFSDFDFDDocument1 pageDFSDFSDFSDFSDFDFDRavi Chaitanya VelamarthyNo ratings yet

- HP Auto Clave FittingsDocument1 pageHP Auto Clave FittingsRavi Chaitanya VelamarthyNo ratings yet

- D 12234 FGFDF 3 DFDDocument1 pageD 12234 FGFDF 3 DFDRavi Chaitanya VelamarthyNo ratings yet

- DFSDFDDocument1 pageDFSDFDRavi Chaitanya VelamarthyNo ratings yet

- DFSDFDDocument1 pageDFSDFDRavi Chaitanya VelamarthyNo ratings yet