Professional Documents

Culture Documents

Plan-Foldup Table PDF

Plan-Foldup Table PDF

Uploaded by

Carlos CostaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plan-Foldup Table PDF

Plan-Foldup Table PDF

Uploaded by

Carlos CostaCopyright:

Available Formats

Fold-out table

Get the extra table area you need to entertain

D o you need extra table space when guests drop by? And, what

do you do with it when it’s not needed? Our fold-out table

gives a 1465 x 850mm table area, but folds down to use only about

Item

WHAT YOU WILL NEED

Part Size Material

A Table legs (4) 42 x 42 x 730mm Pine

300 x 850mm floor space, small enough to store in a hallway. B Short rails (4) 42 x 19 x 160mm Pine

By Dieter Mylius C Long rails (4) 42 x 19 x 710mm Pine

D1 Gate-leg uprights (2) 42 x 19 x 726mm Pine

D2 Gate-leg uprights (2) 42 x 19 x 580mm Pine

Here’s how 4 Prepare the long rails (C) in the E Gate-leg rails (4) 42 x 19 x 623mm Pine

1 Measure legs (A), mark the cuts same way and dowel the two end F Tabletop 850 x 265 x 18mm Pine plywood

with a square and cut with a fine- assemblies together. Back of the G Flaps (2) 850 x 600 x 18mm Pine plywood

toothed tenon saw. On one face bottom rail must be flush with the H Piano hinges (2) 850mm Chrome

of each leg mark 10mm from top inside edge of the leg, leaving I Support stops (2) 42 x 19 x 47mm Pine

and 150mm from the bottom. Find room for the gate-leg. J Spacers (2) 65 x 65 x 4mm Scrap plywood

the centre and set the dowelling 5 For gate-legs, cut uprights and K Flush hinges (4) 50mm Chrome

jig to these marks using the rails (D, E) to length. From the

All joints are glued and dowelled unless otherwise indicated. Check

10mm sleeve. Place tape around bottom of the long upright mark

components against actual unit as it is being built. We used ordinary

a 10mm bit to drill to a depth of 130mm for the lower edge of the

furniture grade plywood. For neat and accurate dowelled joints it’s

25mm. Drill through the sleeve of bottom rail and 16mm from the worthwhile investing in a dowelling jig (from about $40).

the dowelling jig. top for the upper edge of the top

2 Keep legs in pairs. Starting with rail. This allows for 1mm clearance

their holes facing up, turn each leg under top rail and gives 4mm

in so drilled holes face each other. clearance for the piano hinge.

Mark the same distances from the Hold together and mark centre of tooth blade to cut. The tabletop width down on the bench, centre the table

ends, but for the bottom hole only all joints; use dowelling jig to drill lets the flaps hang clear of the legs in both directions and screw the

measure 10mm from the inside holes. Join with dowels and glue. hinges and supports when folded frame to the tabletop.

edge. Use dowelling jig to drill Screw to frame using 50mm flush down. Run the saw along a straight 10 Swing gate-legs out to where

holes. Repeat for other legs. hinges (K) spaced 70mm from the timber batten spaced and clamped they are 50mm from the edge of

3 Cut the short rails (B) and set top and bottom of short uprights. to allow for the distance between the the flap. Mark this spot along the

the dowelling jig to drill holes in 6 Close the gate-legs to mark saw blade and edge of the base underside of the flap. Cut the support

the centre of each end. Drill the the position of two notches to be plate of saw. While on the underside, stops (I) according to the dimensions

holes. Put a little PVA glue into the cut in the top rails of the table set the saw to cut a 4 x 15mm deep in the diagram; screw in place. Check

holes of the face without the offset to house the leg. Allow a little rebate for piano hinge. Use a batten the angled section faces the outside

hole, insert 10mm dowels and tap clearance, then saw and chisel to guide the saw, or use a router or of the flap and clears the bottom

on the short rails. The top rail is out neatly to a depth of 19mm. table saw. Cut two flaps (G) in the rail when the table is folded down.

installed flat and the bottom rail is 7 On the underside of a sheet of same way but without rebates. Adjust the position if necessary. As

on edge. Add the other leg; clamp plywood, measure the tabletop (F) 8 Cut piano hinge (H) to length with the support upright is 4mm short to

together until the glue dries. and use a circular saw with fine a hacksaw. Lay the flap with the face clear the piano hinge, add a spacer

side down and the tabletop with face (J) in front of the stop. The leading

side up, aligning edges. Mark screw edge of this spacer is sanded to a

holes from the piano hinge, pre-drill bevel so support does not catch.

and screw the hinge to the edges. 11 Sand unit carefully. Use several

9 Lay the tabletop and flaps face coats of Danish Oil to finish.

View A (plan)

http://www.bhg.com.au

You might also like

- MFTC Eng ImpDocument52 pagesMFTC Eng Imper3456df100% (5)

- Woodworking Plans - Box-Joint JigDocument8 pagesWoodworking Plans - Box-Joint Jig_Godfather100% (3)

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- Goat Milking Stand Plans PDFDocument6 pagesGoat Milking Stand Plans PDFcowboyNo ratings yet

- SN11536 Pull Saw Miter BoxDocument11 pagesSN11536 Pull Saw Miter BoxMrTabaco100% (3)

- TV Game Hideaway: Build A Nifty TV, Video and Games Storage UnitDocument2 pagesTV Game Hideaway: Build A Nifty TV, Video and Games Storage UnitEmilian BalutaNo ratings yet

- Adirondack ChairDocument2 pagesAdirondack ChairDenis Nantel100% (2)

- Tongue Drum: Tones-Of-FunDocument5 pagesTongue Drum: Tones-Of-FungeovarelaNo ratings yet

- Wheel in The Flowers: Better Homes and GardensDocument2 pagesWheel in The Flowers: Better Homes and GardensFe TusNo ratings yet

- Building A Rocking Horse 3Document2 pagesBuilding A Rocking Horse 3Donnette Davis100% (3)

- Treat Dispenser PDFDocument2 pagesTreat Dispenser PDFFe TusNo ratings yet

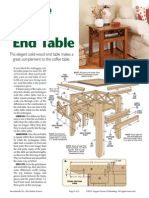

- End Table: MahoganyDocument3 pagesEnd Table: Mahoganyrherdez100% (1)

- Plant Stand: Build A Stand of Treated PineDocument1 pagePlant Stand: Build A Stand of Treated PineDaniel LourençoNo ratings yet

- Arched Aurora NightstandDocument7 pagesArched Aurora NightstandRoberto LandaNo ratings yet

- Dresser PlanDocument11 pagesDresser PlanGsmHelpNo ratings yet

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- Caballos TalladosDocument4 pagesCaballos TalladosJuanRodriguezNo ratings yet

- Cabinet Kitchen IslandDocument2 pagesCabinet Kitchen Islandsvsimo100% (1)

- Classy Cutting BoardsDocument6 pagesClassy Cutting Boardsgmand68No ratings yet

- Ingerie Resser LAN: PlansDocument10 pagesIngerie Resser LAN: PlansGsmHelpNo ratings yet

- How To Build A Toy TheatreDocument20 pagesHow To Build A Toy TheatreJeremy VinesNo ratings yet

- DIY Work Table v4Document6 pagesDIY Work Table v4sgenco.circlelineNo ratings yet

- Recycling Tower: Woodworks Projet Planner: 2015-2016 Intermediate ProjectDocument8 pagesRecycling Tower: Woodworks Projet Planner: 2015-2016 Intermediate ProjectarmaulanaaNo ratings yet

- Woodworks - 103-Blanket ChestDocument10 pagesWoodworks - 103-Blanket ChestzdejotaNo ratings yet

- Pholstered Vanity Seat: MaterialsDocument5 pagesPholstered Vanity Seat: MaterialsFe TusNo ratings yet

- 103 Tablesaw Sled PDFDocument3 pages103 Tablesaw Sled PDFMarvin Fernando Gomez100% (1)

- Plan Bed Heirloom Arts and CraftsDocument13 pagesPlan Bed Heirloom Arts and Craftspoimandres0% (1)

- Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is MoreDocument5 pagesSimple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is Moreanca mariaNo ratings yet

- With A Finger-Safe Hinge On The Roof, An Operabl em Exit and A Working Sign This Incredibly Cut S Busisasaf Bet For y Gift ListDocument6 pagesWith A Finger-Safe Hinge On The Roof, An Operabl em Exit and A Working Sign This Incredibly Cut S Busisasaf Bet For y Gift ListJuanRodriguezNo ratings yet

- Porch SwingDocument3 pagesPorch SwingManuel RomeroNo ratings yet

- RuterDocument7 pagesRuternokojNo ratings yet

- Veneered End Table: Project 17901EZDocument4 pagesVeneered End Table: Project 17901EZBSulliNo ratings yet

- How To Make A Meat SafeDocument5 pagesHow To Make A Meat SafeChristian Theriault100% (1)

- How To Build An Adirondack Chair: Introduction and Cutting ListDocument6 pagesHow To Build An Adirondack Chair: Introduction and Cutting ListSamir Joguncic100% (1)

- Figure #2: The Parts For The Drilling Jig After Cutting To SizeDocument7 pagesFigure #2: The Parts For The Drilling Jig After Cutting To SizeEricsNo ratings yet

- Mobile WorkbenchDocument5 pagesMobile Workbenchcfh666100% (3)

- Book Case (Mission Style)Document8 pagesBook Case (Mission Style)khunchaiyai100% (3)

- Curvy Coffee Table: Woodworks: Advanced ProjectDocument8 pagesCurvy Coffee Table: Woodworks: Advanced ProjectmarciliomeiraNo ratings yet

- WOOD Store: Thank You!Document12 pagesWOOD Store: Thank You!lacroitoruNo ratings yet

- EZStoolDocument4 pagesEZStoolBSulliNo ratings yet

- Panel JigDocument16 pagesPanel JigfasdfNo ratings yet

- Table Saw Cabinet PDFDocument11 pagesTable Saw Cabinet PDFEd Bozman100% (1)

- Wood PlanesDocument6 pagesWood Planeshenrybelanger100% (1)

- Planter Box PlansDocument10 pagesPlanter Box PlansMK Bye100% (2)

- Child: Adirondack / Muskoka Chair PlansDocument7 pagesChild: Adirondack / Muskoka Chair PlansVictor M GonzalezNo ratings yet

- Traditional Bookcase: Woodworks: Intermediate ProjectDocument6 pagesTraditional Bookcase: Woodworks: Intermediate ProjectDúctil De La Gran Raza de YithNo ratings yet

- WoodPlans Online - Drill Press TableDocument6 pagesWoodPlans Online - Drill Press TableЧедомир Арнаут100% (1)

- SIX-CANDLE CENTERPIECE - Woodsmith ShopDocument5 pagesSIX-CANDLE CENTERPIECE - Woodsmith ShopEricsNo ratings yet

- DPROJ02Document13 pagesDPROJ02VhomBoris75% (4)

- Brando Plans-Instr DigitalDocument21 pagesBrando Plans-Instr Digital劉書良100% (1)

- DP 00011Document14 pagesDP 00011Jason Weber100% (1)

- Utility Cart PDFDocument6 pagesUtility Cart PDFFe TusNo ratings yet

- Ultimate WorkbenchDocument8 pagesUltimate WorkbenchEric Gruff0% (1)

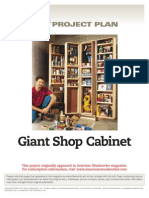

- American Woodworker - Giant Shop CabinetDocument9 pagesAmerican Woodworker - Giant Shop CabinetJosé Narcelio Sampaio Ferreira100% (1)

- Construct Your Own Living Room Cabinets - Step by Step Instructions to Build Cupboards, Bookshelves, Trays and TablesFrom EverandConstruct Your Own Living Room Cabinets - Step by Step Instructions to Build Cupboards, Bookshelves, Trays and TablesNo ratings yet

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- Build Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1From EverandBuild Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1No ratings yet

- Catalogo Paper Converting 2017Document5 pagesCatalogo Paper Converting 2017mmylitoNo ratings yet

- EnricoGalliDocument77 pagesEnricoGallimmylito100% (1)

- Table - AnniversaryDocument1 pageTable - AnniversarymmylitoNo ratings yet

- Table - 16 Drawer Apothecary PDFDocument2 pagesTable - 16 Drawer Apothecary PDFmmylito0% (1)