Professional Documents

Culture Documents

Council Construction Specifications Part 266 PDF

Uploaded by

Tanmay Vegad0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

council-construction-specifications-Part-266.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageCouncil Construction Specifications Part 266 PDF

Uploaded by

Tanmay VegadCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Contract No.

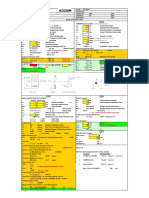

FLEXIBLE PAVEMENTS

6. Subbase materials shall comply with the requirements of Table 242.4 Subbase

Test Subbase Material Requirements

Method Description

DGS20 DGS40 GMS40 NGS20 NGS40

AS1289.3.6.1 Coarse Particle Size Distribution

% passing 75.0mm sieve - - - - -

% passing 53.0mm sieve - 100 100 - 100

% passing 37.5mm sieve - - - - 95-100

% passing 26.5mm sieve 100 - - 100 80-97

% passing 19.0mm sieve 95-100 50-85 50-75 96-100 -

% passing 13.2mm sieve - - - - -

% passing 9.5mm sieve - - - 65-89 48-85

% passing 6.7mm sieve 50-70 30-55 15-35 - -

% passing 4.75mm sieve - - - 47-80 35-73

% passing 2.36mm sieve 35-55 25-50 5-15 32-67 25-58

% passing 0.425mm sieve - - - 14-42 10-33

% passing 0.075mm sieve - - - 6-26 3-21

AS1289.3.6.3 Fine Particle Size Distribution

Ratios expressed as percentages

(for that portion of the material

passing 2.36mm sieve)

A. Pass 425µm sieve % 35-55 35-60 25-50 - -

B. Pass 75µm sieve % 35-55 35-60 25-50 - -

Pass 425µm sieve

C. Pass 13.5µm sieve % 35-60 35-65 - - -

Pass 75µm sieve

AS1289.3.1.1 Liquid Limit (if non plastic) max 23 max 23 - max 23 max 23

AS 1289.3.3.1 Plastic Limit (if plastic) max 20 max 20 - max 23 max 23

AS 1289.3.3.1 Plasticity Index max 12 max 12 max 12 max 12 max 12

T114 Maximum Dry Compressive min 1.0 MPa min 1.0 MPa - 1.0 MPa 1.0 MPa

Strength on fraction passing

19mm sieve

(only applies if Plasticity Index is

less than 1)

AS 1141.14 Particle Shape by Proportional

Calliper

% misshapen (2 : 1) max 35 max 35 max 35 - -

AS 1141.22 Aggregate Wet Strength min 50kN min 50kN min 130kN - -

AS 1141.22 Wet/Dry Strength Variation

Dry - Wet % max 60 max 60 max 30 - -

Dry

AS 1289.6.1.1 4 day Soaked CBR - - - 30 30

(98% Modified Compaction)

Table 242.4 - Unbound Subbase Material Properties

City of Greater Dandenong Page 266 of 538 Status REV-B

Approved By: Peter White © Copyright Date OCT-07

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Specification 243 - Bituminous Cold Mix Clause: Contract NoDocument1 pageSpecification 243 - Bituminous Cold Mix Clause: Contract NoTanmay VegadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Council Construction Specifications Part 291Document1 pageCouncil Construction Specifications Part 291Tanmay VegadNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Council Construction Specifications Part 289 PDFDocument1 pageCouncil Construction Specifications Part 289 PDFTanmay VegadNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Specification 244 - Sprayed Bituminous Surfacing Clause: Contract NoDocument1 pageSpecification 244 - Sprayed Bituminous Surfacing Clause: Contract NoTanmay VegadNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Council Construction Specifications Part 288 PDFDocument1 pageCouncil Construction Specifications Part 288 PDFTanmay VegadNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Council Construction Specifications Part 278Document1 pageCouncil Construction Specifications Part 278Tanmay VegadNo ratings yet

- Council Construction Specifications Part 285Document1 pageCouncil Construction Specifications Part 285Tanmay VegadNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Council Construction Specifications Part 287Document1 pageCouncil Construction Specifications Part 287Tanmay VegadNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Council Construction Specifications Part 277Document1 pageCouncil Construction Specifications Part 277Tanmay VegadNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Council Construction Specifications Part 267Document1 pageCouncil Construction Specifications Part 267Tanmay VegadNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Council Construction Specifications Part 279 PDFDocument1 pageCouncil Construction Specifications Part 279 PDFTanmay VegadNo ratings yet

- Council Construction Specifications Part 267Document1 pageCouncil Construction Specifications Part 267Tanmay VegadNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Contract No.: 242.10 Bound Base and Subbase MaterialsDocument1 pageContract No.: 242.10 Bound Base and Subbase MaterialsTanmay VegadNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- (C) NSW RTA Test Methods: Contract NoDocument1 page(C) NSW RTA Test Methods: Contract NoTanmay VegadNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Council Construction Specifications Part 263 PDFDocument1 pageCouncil Construction Specifications Part 263 PDFTanmay VegadNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Council Construction Specifications Part 262Document1 pageCouncil Construction Specifications Part 262Tanmay VegadNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Test Method Description Subbase Material RequirementsDocument1 pageTest Method Description Subbase Material RequirementsTanmay VegadNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Council Construction Specifications Part 235Document1 pageCouncil Construction Specifications Part 235Tanmay VegadNo ratings yet

- Contract No.: 242.10 Bound Base and Subbase MaterialsDocument1 pageContract No.: 242.10 Bound Base and Subbase MaterialsTanmay VegadNo ratings yet

- Council Construction Specifications Part 263Document1 pageCouncil Construction Specifications Part 263Tanmay VegadNo ratings yet

- Council Construction Specifications Part 262Document1 pageCouncil Construction Specifications Part 262Tanmay VegadNo ratings yet

- Notes On Table 242.3:: Contract NoDocument1 pageNotes On Table 242.3:: Contract NoTanmay VegadNo ratings yet

- Council Construction Specifications Part 236Document1 pageCouncil Construction Specifications Part 236Tanmay VegadNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Council Construction Specifications Part 264Document1 pageCouncil Construction Specifications Part 264Tanmay VegadNo ratings yet

- Specification 233 - Drainage Mats Clause: Contract NoDocument1 pageSpecification 233 - Drainage Mats Clause: Contract NoTanmay VegadNo ratings yet

- Council Construction Specifications Part 237Document1 pageCouncil Construction Specifications Part 237Tanmay VegadNo ratings yet

- Specification 233: Drainage Mats: Contract NoDocument1 pageSpecification 233: Drainage Mats: Contract NoTanmay VegadNo ratings yet

- Council Construction Specifications Part 230 PDFDocument1 pageCouncil Construction Specifications Part 230 PDFTanmay VegadNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Council Construction Specifications Part 234Document1 pageCouncil Construction Specifications Part 234Tanmay VegadNo ratings yet

- Fundamentals of Nuclear Engineering - (5.1 Choice of Coolant) PDFDocument1 pageFundamentals of Nuclear Engineering - (5.1 Choice of Coolant) PDFJagdeep SekhonNo ratings yet

- STEM Gen Chem 1 Q1 M2Document20 pagesSTEM Gen Chem 1 Q1 M2Roland AgraNo ratings yet

- SKF Economos SteelDocument22 pagesSKF Economos SteelJurun_BidanshiNo ratings yet

- Che Practice Questions: CPQ Set 1Document5 pagesChe Practice Questions: CPQ Set 1Jerome Javier0% (1)

- Surkhi 2Document7 pagesSurkhi 2Syed Showkath AliNo ratings yet

- In Depth Oil and Water SeparationDocument5 pagesIn Depth Oil and Water SeparationSerkan YukselNo ratings yet

- 5.1 Titremetric Analysis - Direct, Indirect and Residual TitrationDocument2 pages5.1 Titremetric Analysis - Direct, Indirect and Residual TitrationSister RislyNo ratings yet

- ASTM A262, CorrosietestenDocument2 pagesASTM A262, CorrosietestenSales HBS Solutions100% (1)

- Ma 0718806Document8 pagesMa 0718806Jalili KiyumarsNo ratings yet

- [Synthetic Metals 1985-oct vol. 11 iss. 6] Boehm, H.P._ Setton, R._ Stumpp, E. - Nomenclature and terminology of graphite intercalation compounds. Report by a subgroup of the international committee for charac (198Document9 pages[Synthetic Metals 1985-oct vol. 11 iss. 6] Boehm, H.P._ Setton, R._ Stumpp, E. - Nomenclature and terminology of graphite intercalation compounds. Report by a subgroup of the international committee for charac (198Ricardinho1987No ratings yet

- 01 FTK Chemical BiotechDocument47 pages01 FTK Chemical BiotechJessica PhillipsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Experiment CODDocument4 pagesExperiment CODHolyZikr100% (1)

- Pub Role Additives v4 LODocument20 pagesPub Role Additives v4 LOTudor RatiuNo ratings yet

- 9700 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesDocument11 pages9700 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesNerminNo ratings yet

- XADODocument2 pagesXADOGamalNo ratings yet

- 106 1 CompletedDocument323 pages106 1 CompletedAnonymous l5GLwMAE5No ratings yet

- Chem Sem 1 Q &A PDFDocument9 pagesChem Sem 1 Q &A PDFevacuate clashNo ratings yet

- Safe Storage of Ammonium NitrateDocument16 pagesSafe Storage of Ammonium Nitratepartha das sharma100% (1)

- Alubond Tech - Brochure PDFDocument8 pagesAlubond Tech - Brochure PDFLjubisa TopicNo ratings yet

- Brochure Nicomp n3000 Dynamic Light Scattering Particle Size Analyzer 10438Document6 pagesBrochure Nicomp n3000 Dynamic Light Scattering Particle Size Analyzer 10438Radha DeviNo ratings yet

- RapidDocument6 pagesRapidDewi SusantiNo ratings yet

- Flow BatteryDocument10 pagesFlow BatteryFatima AgNo ratings yet

- 2.1 Molecules To Metabolism: Molecular Biology Is The Chemistry of Living OrganismsDocument25 pages2.1 Molecules To Metabolism: Molecular Biology Is The Chemistry of Living OrganismsAbdul HalimNo ratings yet

- Essentials of Human Anatomy and Physiology 12th Edition Marieb Test BankDocument26 pagesEssentials of Human Anatomy and Physiology 12th Edition Marieb Test BankKevinRobertsbfak100% (46)

- MSDS Colafax PmeDocument2 pagesMSDS Colafax Pmemndmatt100% (2)

- Deep Drawing Process: A Brief Overview: September 2015Document6 pagesDeep Drawing Process: A Brief Overview: September 2015novkovic1984No ratings yet

- The Ways of Purifying Water Lesson PlanDocument3 pagesThe Ways of Purifying Water Lesson Planetwinning100% (1)

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Groundwater Ecology: Developing A Method For Anammox Determination Using Natural Isotope Signature (Stephanye Zarama Alvarado)Document83 pagesGroundwater Ecology: Developing A Method For Anammox Determination Using Natural Isotope Signature (Stephanye Zarama Alvarado)S. ZaramaNo ratings yet

![[Synthetic Metals 1985-oct vol. 11 iss. 6] Boehm, H.P._ Setton, R._ Stumpp, E. - Nomenclature and terminology of graphite intercalation compounds. Report by a subgroup of the international committee for charac (198](https://imgv2-1-f.scribdassets.com/img/document/613195716/149x198/cd1cc2775e/1710575975?v=1)