Professional Documents

Culture Documents

473 Series, PICO II, Slo-Blo Fuse

Uploaded by

RomanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

473 Series, PICO II, Slo-Blo Fuse

Uploaded by

RomanCopyright:

Available Formats

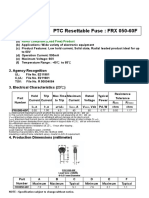

Axial Lead & Cartridge Fuses

PICO® ll > Slo-Blo® > 473 Series

473 Series, PICO® II, Slo-Blo® Fuse PS

E

Description

The PICO® II Slo-Blo® Fuse combines time-delay

performance characteristics with the proven reliability of

a PICO® Fuse.

Features

• Enhanced inrush • RoHS compliant

withstand • Wide operating

• Small size temperature range

• Wide range of current • Low temperature

ratings (375mA - 7A) de-rating)

Agency Approvals

Applications

Agency Agency File Number Ampere Range

• Flat–panel Display TV • Medical equipment

E10480 375mA - 7A

• LCD monitor • Industrial equipment

LR 29862 375mA - 7A • Lighting system

PS

E JET 1896-31007-1001 1A - 5A Electrical Characteristics

% of Ampere

Opening Time

Rating

Additional Information

100% 4 Hours, Min.

200% 1 Sec., Min.; 60 Sec., Max.

300% 0.2 Sec., Min.; 3 Sec., Max.

Datasheet Resources Samples 800% 0.02 Sec., Min.; 0.1 Sec., Max.

Electrical Characteristics

Max Agency Approvals

Ampere Nominal Cold Nominal Nom

Amp Voltage Interrupting

Rating Resistance Melting Voltage Drop

Code Rating Rating PS

(A) (Ohms) I2t (A2 sec) (mV) E

(V)

0.375 .375 125 1.7400 0.085 0.840 X X

0.500 .500 125 1.1300 0.210 0.775 X X

0.750 .750 125 0.4600 0.760 0.429 X X

1.00 001. 125 0.3000 2.010 0.353 X X X

1.50 01.5 125 0.1160 3.940 0.208 X X X

2.00 002. 125 0.0712 7.600 0.180 X X X

50 amperes at 125 VDC/

2.25 2.25 125 0.0630 9.280 0.164 X X X

VAC

2.50 02.5 125 0.0520 13.00 0.153 X X X

3.00 003. 125 0.0380 21.00 0.140 X X X

3.50 03.5 125 0.0240 26.80 0.094 X X X

4.00 004. 125 0.0194 35.00 0.086 X X X

5.00 005. 125 0.0133 54.80 0.074 X X X

7.00 007. 125 0.0092 105.00 0.070 X X

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Axial Lead & Cartridge Fuses

PICO® ll > Slo-Blo® > 473 Series

Temperature Rerating Curve Average Time Current Curves

.375A

.50A

.75A

1.0A

1.5A

2.0A

2.5A

3.0A

3.5A

4.0A

5.0A

7.0A

1000

100

TIME IN SECONDS

10

Note:

1. Derating depicted in this curve is in addition to the standard derating of 25% for 0.1

continuous operation.

Soldering Parameters

0.01

0.1 1 10 100 1000

Recommended Process Parameters: CURRENT IN AMPERES

Wave Parameter Lead-Free Recommendation

Preheat:

(Depends on Flux Activation Temperature) (Typical Industry Recommendation)

Temperature Minimum: 100° C

Temperature Maximum: 150° C

Preheat Time: 60-180 seconds

Solder Pot Temperature: 260° C Maximum

Solder Dwell Time: 2-5 seconds

Recommended Hand-Solder Parameters:

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Note: These devices are not recommended for IR or

Convection Reflow process.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Axial Lead & Cartridge Fuses

PICO® ll > Slo-Blo® > 473 Series

Product Characteristics

Encapsulated, Epoxy-Coated Body; MIL-STD-202, Method 201 (10–55

Solder Coated Copper wire leads; Hz); MIL-STD-202, Method 204, Test

Materials Vibration

RoHS compliant Product: Pure Tin-coated Condition C (55–2000 Hz at 10 G’s

Copper wire leads Peak)

Solderability MIL-STD-202, Method 208 MIL-STD-202, Method 101, Test

Salt Spray

Condition B

MIL-STD-202, Method 211, Test Condition

Lead Pull Force Insulation Resistance MIL-STD-202, Method 302, (10,000

A (will withstand 7 lbs. axial pull test)

(After Opening): ohms minimum at 100 volts)

Operating

–55ºC to +125ºC Resistance to Soldering MIL-STD-202, Method 210, Test

Temperature

Heat Condition C (20 sec at 260ºC)

MIL-STD-202, Method 213, Test Condition

Shock MIL-STD-202, Method 107, Test

I (100 G’s peak for 6 milliseconds) Thermal Shock

Condition B (–65ºC to 125ºC)

MIL-STD-202, Method 106 (90–98%

Moisture Resistance

RH), Heat (65ºC)

Dimensions Part Numbering System

62.7 (2.468") 0473 xxxx Y R T1 L

52.4 (2.062")*

27.78 27.78

(1.094") 7.11 (.280") (1.094") Series

3.43 (.135")

0.64 (.025") MAX Current Rating

1A L

F

Refer to Amp Code column of

Electrical Characteristics Table

6.35 (.25") 5.0 (.197") 6.35 (.25")

tape tape Quantity

1A L

F Y = 4000

P = 2000

M = 1000

473 series markings

Type of Packaging

R = Reel

A = Ammo Pack

X = Loose Pack

Lead Length

T1: 52.4mm (2.062”)*

RoHS + HF

Packaging

Quantity &

Packaging Option Packaging Specification

Packaging Code

Please refer to available quantities

*T1: 52.4mm (2.062") Tape and Reel EIA 296

above in "Part Numbering System”

Notes: * T1 dimension is defined as the length of the component between the two tapes. The full component length is 62.7mm (2.468").

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

You might also like

- Littlefuse Fast Action FuseDocument2 pagesLittlefuse Fast Action FuseCarlosDíazPeñaNo ratings yet

- Manufacturer Data: Job # Humidity Test Status Asset Id Date °FDocument3 pagesManufacturer Data: Job # Humidity Test Status Asset Id Date °FCorey PorterNo ratings yet

- TE5 Time-Lag 392 SeriesDocument3 pagesTE5 Time-Lag 392 Seriesanand shekhawatNo ratings yet

- Surface Mount 2920L SeriesDocument6 pagesSurface Mount 2920L SeriesAfonso MoutinhoNo ratings yet

- 1 N 56Document4 pages1 N 56Ankadi Sikari ReddyNo ratings yet

- Low Profile Bending Beam Low Profile Bending Beam: Model 60040Document3 pagesLow Profile Bending Beam Low Profile Bending Beam: Model 60040Alec Hernandez GomezNo ratings yet

- NMG Catalog 9AKK2017-109096 RevB EN 05-2019 LowresDocument20 pagesNMG Catalog 9AKK2017-109096 RevB EN 05-2019 Lowresvogid38712No ratings yet

- 700HR52TA17 2304 DatasheetDocument3 pages700HR52TA17 2304 DatasheetLeobardo GascaNo ratings yet

- 1101-808-1 Datasheets USDocument4 pages1101-808-1 Datasheets USJOSE BNo ratings yet

- Miniature Fuse, 5 X 20 MM, Time-Lag T, H, 250 VAC, UL: 115 V - 300 VDCDocument3 pagesMiniature Fuse, 5 X 20 MM, Time-Lag T, H, 250 VAC, UL: 115 V - 300 VDCSatish KumarNo ratings yet

- Fast Recovery Diodes VS-SD303C25S20CDocument9 pagesFast Recovery Diodes VS-SD303C25S20CFay AgodoloNo ratings yet

- 58mm Rotary Encoder for Cost-Effective Industrial Automation SystemsDocument2 pages58mm Rotary Encoder for Cost-Effective Industrial Automation Systemskanhav joshiNo ratings yet

- High Frequency Capacitor SpecsDocument2 pagesHigh Frequency Capacitor SpecsАндрей ПоляковNo ratings yet

- P6KE Series: Silicon Avalanche DiodesDocument5 pagesP6KE Series: Silicon Avalanche Diodesrafael quiaroNo ratings yet

- 433 Series Fuse: Thin Film 1206 Size Very Fast Acting 433 SeriesDocument4 pages433 Series Fuse: Thin Film 1206 Size Very Fast Acting 433 SeriesCristobalzqNo ratings yet

- Littelfuse PTC 30R Datasheet PDFDocument7 pagesLittelfuse PTC 30R Datasheet PDFKilmer Galindo VarillasNo ratings yet

- AMB-45 Insulation Resistance TesterDocument2 pagesAMB-45 Insulation Resistance TesterDaniel PinheiroNo ratings yet

- Vega Lite Specification PDFDocument6 pagesVega Lite Specification PDFJinju P KunjhappanNo ratings yet

- Apex Iv X5 240 SM: AC Surge Protector SPD APEX Panel 240 Vac Single-Phase SASD, MOV 30 Ka, UL 94-5VDocument3 pagesApex Iv X5 240 SM: AC Surge Protector SPD APEX Panel 240 Vac Single-Phase SASD, MOV 30 Ka, UL 94-5VJulio Cesar Huachaca RodriguezNo ratings yet

- 22 AMB-45-specDocument2 pages22 AMB-45-specJim GuzmanNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- A12fa 10a 500V Schurter FuseDocument2 pagesA12fa 10a 500V Schurter FuseGustavo MaiaNo ratings yet

- Axial Leaded High Frequency Pulse CapacitorsDocument3 pagesAxial Leaded High Frequency Pulse Capacitorsgrasia77No ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- VSB SeriesDocument3 pagesVSB SeriesCubix AutomationNo ratings yet

- SA5.0 (C) A - SA170 (C) A: 500 Watt Transient Voltage SuppressorsDocument5 pagesSA5.0 (C) A - SA170 (C) A: 500 Watt Transient Voltage SuppressorsSero StivNo ratings yet

- Data Sheet: Low VF High-Speed Switching DiodeDocument3 pagesData Sheet: Low VF High-Speed Switching DiodeSanthosh Kumar JNo ratings yet

- Sdurf2040cta N1636 Rev.a PDFDocument4 pagesSdurf2040cta N1636 Rev.a PDFcesarNo ratings yet

- Eocr FMZ2 H1duwDocument2 pagesEocr FMZ2 H1duwSwarup Kumar MaitiNo ratings yet

- Radial Leaded 3PTC Resettable Fuse: FRX 050-60F: 1. SummaryDocument7 pagesRadial Leaded 3PTC Resettable Fuse: FRX 050-60F: 1. SummaryАнатолий ДонецкNo ratings yet

- Copia de PSE105-600-70 ABB Softstarter PDFDocument4 pagesCopia de PSE105-600-70 ABB Softstarter PDFJUAN DAVID BENAVIDES VALLEJOS100% (1)

- Moc3023m DDocument12 pagesMoc3023m Diet mitNo ratings yet

- Eaton 10858691 NZMN4 AE1000 en - GBDocument4 pagesEaton 10858691 NZMN4 AE1000 en - GBPeter UhuleNo ratings yet

- Ram 3000 enDocument2 pagesRam 3000 enprjktxNo ratings yet

- Moc3072m DDocument13 pagesMoc3072m DhiperdyniaNo ratings yet

- GRM155R71E104KE14Document32 pagesGRM155R71E104KE14rakeeNo ratings yet

- Luker Lflsl200 200w Sleek FloodlightDocument1 pageLuker Lflsl200 200w Sleek FloodlightHanvika Projects OPC Private Limited HanvikaNo ratings yet

- 1SFA894015R7000 pstb370 600 70Document4 pages1SFA894015R7000 pstb370 600 70pifehic372No ratings yet

- Product Data Sheet 3RV2011-0HA10Document4 pagesProduct Data Sheet 3RV2011-0HA10M Alejandro CoronelNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- A82-00-0109 Datasheets USDocument3 pagesA82-00-0109 Datasheets UScarrei JohnNo ratings yet

- Crydom HD4850 10 DatasheetDocument4 pagesCrydom HD4850 10 DatasheetOscar PelcastreNo ratings yet

- Littelfuse Fuse KLK DatasheetDocument3 pagesLittelfuse Fuse KLK Datasheetagus2kNo ratings yet

- Electronic Over Current Relay (EOCR)Document2 pagesElectronic Over Current Relay (EOCR)BambangsNo ratings yet

- Load CellDocument3 pagesLoad Celllmriose94No ratings yet

- 8AMG5903670 A en 0Document8 pages8AMG5903670 A en 0MOHAMED BOUDENNo ratings yet

- PSE72-600-70 Softstarter: Product-DetailsDocument4 pagesPSE72-600-70 Softstarter: Product-DetailsMd Mustafijur Rahman TusharNo ratings yet

- Fast Recovery Rectifiers Diodes: High-Reliability Discrete Products and Engineering Services Since 1977Document3 pagesFast Recovery Rectifiers Diodes: High-Reliability Discrete Products and Engineering Services Since 1977Mahtab HassanzadehNo ratings yet

- Catalogue 170M1417Document1 pageCatalogue 170M1417Huỳnh Trung ChinhNo ratings yet

- Digital AC DC TRMS Clamp Meter KM2754ATDocument1 pageDigital AC DC TRMS Clamp Meter KM2754ATindustrialindiaNo ratings yet

- 700HRM12TA17Document3 pages700HRM12TA17ittg ittgNo ratings yet

- 1SFA898217R7000 pstx570 690 70Document4 pages1SFA898217R7000 pstx570 690 70ener paul jacobo ortegaNo ratings yet

- HDW6 2000acbDocument19 pagesHDW6 2000acbRoxanneNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogJuan Francisco Sanchez MassadiNo ratings yet

- Simplitz HighbayDocument4 pagesSimplitz Highbaysinar automationNo ratings yet

- Nano Very Fast-Acting Fuse 451/453 SeriesDocument4 pagesNano Very Fast-Acting Fuse 451/453 Seriesm3y54mNo ratings yet

- Arka Series: WSM-400 TO WSM-415Document2 pagesArka Series: WSM-400 TO WSM-415PradeepRathiNo ratings yet

- FR-4.0 Conventional FR-4 and Bonding Prepreg FeaturesDocument2 pagesFR-4.0 Conventional FR-4 and Bonding Prepreg FeaturesNOUREDDINE ELHAMRINo ratings yet

- Special Power of Attorney for Overseas EmploymentDocument2 pagesSpecial Power of Attorney for Overseas EmploymentJakeLeonciniNo ratings yet

- Sand Patch TestDocument5 pagesSand Patch TestgreatpicNo ratings yet

- 200 NsDocument63 pages200 NsSam SamiNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- The Threat Landscape Quiz ResultsDocument5 pagesThe Threat Landscape Quiz ResultsKaskusemail88 EmailNo ratings yet

- Nitro2 User Manual v2.24 PDFDocument29 pagesNitro2 User Manual v2.24 PDFReifesxd ProNo ratings yet

- Electrical design for proposed residential buildingDocument24 pagesElectrical design for proposed residential buildingMALABIKA MONDALNo ratings yet

- Tall VarietiesDocument23 pagesTall VarietiessakthivelNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Ahmed KhedrNo ratings yet

- Quiz II - Company MissionDocument4 pagesQuiz II - Company MissionSuraj SapkotaNo ratings yet

- SANS10162-4 Design of Cold Formed Stainless SteelDocument83 pagesSANS10162-4 Design of Cold Formed Stainless SteelhenvaswegeNo ratings yet

- 78ac PDFDocument7 pages78ac PDFvhgiaoNo ratings yet

- PPM Advance Android Application - User ManualDocument22 pagesPPM Advance Android Application - User ManualmayckerNo ratings yet

- Extracting Data From GpsDocument7 pagesExtracting Data From GpsRidhima KhajuriaNo ratings yet

- Power Semiconductor Devices ClassificationDocument9 pagesPower Semiconductor Devices ClassificationdevchandarNo ratings yet

- ODMP Hydrology and Water Resources Inception ReportDocument68 pagesODMP Hydrology and Water Resources Inception ReportAse JohannessenNo ratings yet

- Coal PDFDocument36 pagesCoal PDFurjanagarNo ratings yet

- Madras University Time TableDocument19 pagesMadras University Time TablearvindNo ratings yet

- Understanding Data GovernanceDocument28 pagesUnderstanding Data GovernanceJoe leninja100% (1)

- Nfpa Codes PDFDocument12 pagesNfpa Codes PDFphe zenNo ratings yet

- Training and Development in Consumer IndustriesDocument31 pagesTraining and Development in Consumer IndustriesKiran kumar SahuNo ratings yet

- Quy Trình AgencyDocument4 pagesQuy Trình Agencyson nguyenNo ratings yet

- Akd 736103113213Document1 pageAkd 736103113213May'Axel RomaricNo ratings yet

- Judicial Watch Vs State Dept Stephen Mull DepositionDocument415 pagesJudicial Watch Vs State Dept Stephen Mull DepositionThe Conservative Treehouse100% (1)

- ACR - Grolier Turn Over of Online ResourcesDocument4 pagesACR - Grolier Turn Over of Online ResourcesIreneo Aposacas Jr.No ratings yet

- 10 Days 7 NightsDocument5 pages10 Days 7 NightsSisca SetiawatyNo ratings yet

- Assignment For LawDocument9 pagesAssignment For LawFeroze IshtiaqueNo ratings yet

- 11.30 Imran Akram IA CementDocument12 pages11.30 Imran Akram IA CementParamananda SinghNo ratings yet

- Allison - Dp-8000 - Manual de Servicio - Pag-390Document390 pagesAllison - Dp-8000 - Manual de Servicio - Pag-390Manuales De Maquinaria Jersoncat100% (1)

- Assignment Number 2Document4 pagesAssignment Number 2Elson TalotaloNo ratings yet