Professional Documents

Culture Documents

Solid Modeling and Additive Manufacturing

Solid Modeling and Additive Manufacturing

Uploaded by

Firoz Amin0 ratings0% found this document useful (0 votes)

403 views8 pagesOriginal Title

22041 - Solid Modeling and Additive Manufacturing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

403 views8 pagesSolid Modeling and Additive Manufacturing

Solid Modeling and Additive Manufacturing

Uploaded by

Firoz AminCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Soi Maing 2nd Ade Mami Couse Coe 22081

Program Name = Diploma in Automo

Program Code: AE

Semester : Fourth

Course Title : Solid Modelling and Additive Manufacturing

Course Code :

1. R ONALE

Mechanical, Plastic, Automobile and allied Industries need to build model based applications

which are being developed using “solid modeling software”. This course deals with concepts

of solid modeling to enhance solid modeling skills of diploma students. This course will

enable the students to inculeate solid modeling and additive manufacturing concepts and

methodology to solve engineering problems.

2. COMPETENCY

The aim of this course is to help the student to attain the following industry identified

competency through various teaching learning experienc

‘* Develop ‘Solid Models' of given machine components using any parametric CAD

software,

3. COURSE OUTCOMES (COs)

The theory, practical experiences and relevant soft skills associated with this course are to be

taught and implemented, so that the student demonstrates the following industry oriented

COs associated with the above mentioned competency

a. Prepare 2D Drawing using sketcher workbench of any parametric CAD software.

b. Generate 3D Solid models from 2D sketch using Part workbench of any parametric

CAD software.

c. Prepare assembly of part models using Assembly workbench of any parametric CAD

sofiware,

d. Generate orthographic views of 3D solid models/assemblies using drafting workbench

of any parametric CAD software.

©. Plot a drawing for given part model/assembly,

f. Print components using 3D Printer/Rapid prototyping machine.

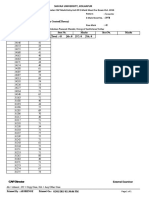

4, TEACHING AND EXAMINATION SCHEME

Teaching | oO

Scheme

Credit

Theor Practical

aster) >

Toul ESE PA

Min | Max | tin] max | tin | Max

2s@ | 10 | 25~

ESE

[Max [Min

10

(*): Under the theory PA, Out of 30 marks, 10 marks are for micro-project assessment to

facilitate integration of COs and the remaining 20 marks is the average of 2 tests 10 be taken

during the semester for the assessment of the cognitive domain UOs required for the

attainment of the COs.

Legends: L-Lecture; T— Tutorial/Teacher Guided Theory Practice; P - Practical; C

ESE - End Semester Examination; PA - Progressive Assessment

1 Copy Dt. 20.04.2018 Page 1of 8

Solid Modeling ad Addive No

couse Code: 22041,

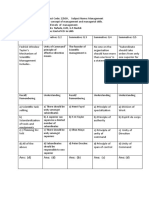

8. COURSE MAP (with sample COs, PrOs, UOs, ADOs and topics)

This course map illustrates an overview of the flow and linkages of the topics at various levels

of outcomes (details in subsequent sections) to be attained by the student by the end of the

course, in all domains of learning in terms of the industry/employer identified competency

depicted at the centre of this map.

7 GR

clita, Worsley

ye —

6 W4y- posit . ‘

1 arenes

SA Seer

ae

Competency

aon nha

esa

ioincagive” >. 097A Amine

"> oe © Batts)

is ek r

Figure 1 - Course Map

6. SUGGESTED PRACTICALS/ EXERCISES

‘The practicals in this section are PrOs (i.e. sub-components of the COs) to be developes

assessed in the student for the attainment of the competency:

MSBTE — Final Copy Dt. 20.04.2018 Page 2 of 8

ons C2208

] ] Approx. |

| ° Practical Outcomes (PrOs) unite

L No. No. :

- - | Required

1 Prepare drawing template consisting of Name plate boundary lines. 1 02

and projeetion symbol, _

2. _| Draw and print two simple 2D geometries using sketcher Lv 0

commands oe |

3. _ | Draw and print twe complex 2D geometries using sketcher LV) 0

commands oe

4, | Draw and print the given two simple 3-D drawings using 3D HV 0

modeling commands | i

3. | Draw and print the production drawing of the 3D part models of || LV | 02

individual components of Bench viee / Drill Jig / Serew Jack / Too!

Post / any assembly consisting of at least five parts.(Problem-1) 7

6. | Draw and print the production drawing of the 3D part models of || IV | 02

individual components of Bench viee / Drill ig / Serew Jack ‘Too!

Post / any assembly consisting of at least five parts. (Problem -I

continued) _ a

7. | Draw and print the production drawing ofthe 3D part models of || U,V | 02

individual components of Bench vice / Drill Jig / Screw Jack / Tool

Post / any assembly consisting of at least five parts. (Problem -1

continued) _

8. | Draw and print the production drawing of the 3D part models of || IW | 02

individual components of Bench vice / Drill Jig / Serew Jack / Tool

Post / any assembly consisting of at least five parts. (Problem -1

continued)

9. | Assemble and print the orthographic views of the assembly, bill of | II, | 02

materials of Bench viee / Drill Jig / Screw Jack / Tool Post /any | IV,

assembly consisting of at least five parts. (Problem - I) v |

10. | Assemble and print the orthographic views of the assembly, bill of | II, | 02

materials of Bench vice / Drill Jig / Serew Jack /Tool Post /any | IV,

|__| assembly consisting of at least five parts. (Problem—Tcontinued) | Vo |

TI. | Draw and print the production drawing of the 3D part models of | IV | 02

individual components of Bench vice / Drill Jig / Serew Jack / Tool

|__| Post / any assembly consisting of at least five parts.(Problem - I!)

12, | Draw and print the production drawing of the 3D part models of | 1. V | 02

individual components of Bench vice / Drill Jig / Serew Jack / Tool

Post / any assembly consisting of at least five parts. (Problem - II

|__| continued) |

13. | Draw and print the production drawing ofthe 3D part models of [ 1,V | 02

individual components of Bench vice / Drill Jig / Screw Jack / Too!

Post / any assembly consisting of at least five parts, (Problem - Il

continued) -

74, | Draw and print the production drawing of the 3D part models of [IV | 02

individual components of Bench vice / Drill Jig / Serew Jack / Too!

Post / any assembly consisting of at least five parts. (Problem - Il

continued) — J

15. | Assemble and print the orthographic views of the assembly, bill of | III, | 02

|_| materials of Bench vice / Drill Jig / Serew Jack / Tool Post /any | 1V. |.

MSBYE — Final Copy Dt. 20.04.2018 Page 3 0f 8 Bos

ows Code: 22011

= . Approx.

In Practical Outcomes (PrOs) wut on |

peep a 8% | required

| assembly consisting of at least five parts. (Problem - II) lv _

| 16._| Assemble and print the orthographic views of the assembly, bill of | HI 02

|_| materials of Bench vice / Drill Jig / Screw Jack / foo! Post /any | 1V

+: mbly consisting of at least five parts. (Problem ~ I continued) | v _

17. | Print simple component using 3D printer / Rapid prototyping vi 02

| machine. _ |

18. | Printa complex component using 3D printer / Rapid prototyping VI 02

| {wachin (Problem - 1)

‘Total _ | 86

Note

1A suggestive list of PrOs is given in the above table. More such PrOs can be added to

attain the COs and competency. A judicial mix of minimum 24 or more practical need to be

performed, out of which, the practical marked as “*” are compulsory, so that the student

reaches the Precision Level’ of Dave's ‘Psychomotor Domain Taxonomy’ as generally

required by the industry

4, The ‘Process’ and ‘Product’ related skills associated with each PrO is to be assessed

according to a suggested sample given below:

S.No. | Performance Indicators Weightage

in%

1 Use of proper commands - er)

2 Completion of drawing with minimum size of model tree | 20

3 | Generation and printing of drawing views, tables, tc, and their 20

arrangement on different sheet sizes _ |

4 Able to answer oral questions. i [ 10

5 Completion of work in time. - 10

Total 100

The above PrOs also comprise of the following social skills/attitudes which are Affective

Domain Outcomes (ADOs) that are best developed through the laboratory/field based

experiences:

Follow safety practices.

Practice good housekeeping,

Practice energy conservation.

Handle solid modeling software carefully.

Plan for creation of solid model

Demonstrate working as a leader / a team member.

Maintain software tools and equipment.

Follow ethical practices.

Boseege

The ADOs are not specific to any one PrO, but are embedded in many PrOs. Hence, the

acquisition of the ADOs takes place gradually in the student when s/he undertakes a series of

practical experiences over a period of time. Moreover, the level of achievement of the ADOs

according to Krathwohl’s ‘Affective Domain Taxonom:

below:

* ‘Valuing Level’ in I" year

MSBTE — Final Copy Dt. 20.04.2018, Page 4 of 8

|

7

year and

year,

“Organising Level’ in 2™

“Characterising Level’ in 3"

MAJOR EQUIPMENT) INS

Gane Cae 22081

UMENTS REQUIRED

‘The major equipment with broad specification mentioned here will

sher in uniformity in

conduct of experiments, as well as aid to procure equipment by authorities concerned

3_| Software: Any parametric solid modeling soltware.

4

8.

Equipment Name with Broad Sp.

Hardware: Personal computer. (13/ 15 or higher). RAM minimum 4

play-wide Screen preferably.

2 | Operating system: Windows XP/Windows 7/ Windows 8/Windows 10_|

GB, A3/.A4 size printer / plotter.

or higher.

3D printer rototyping Machine.

Expt. Sr.

No.

For all

Experiments

tions

UNDERPINNING THEORY COMPONENTS

The following topics/subtopics should be taught and assessed in order to develop UOs for

achieving the COs to attain the identified competency.

Major Learning Outcomes

(in cognitive domain)

Unit—1 fla, Describe the given sketcher

Working commands.

in2D — |Ib, Demonstrate the given modity

environm | commands.

ent. lic. Apply dimensioning and

Constraints

Unit- 11 | 2a, Prepare 3D models for the parts

Developm | of the given assembly using

ent of different commands with

Solid minimum tree.

Models. | 2b.Describe intersection of the given

Solid.

2c, Prepare production drawing for

the given 3D part model /

assembly.

Unit- IIT a. Use of assembly tools to prepare

Computer | assembly using given 3D solid

aided models.

MSBTE — Final Copy Dt. 20.04.2018

Topies and Sub-topies

Drawing tool: Line, Rectangle, Circle,

Are, Ellipse, Spline, ete,

Editing tool: Trim, Extend, Erase,

Mirror, etc.

Modify tool: Chamfer, Fillet, Copy,

Move. ete.

Linear, angular dimensions.

Dimensioning constraint and

Geometrical constraint,

Drawing template: prepare drawing

template consisting of Name plate

‘boundary lines and projection symbol.

Working in 3D environment: Creating

3D Solid Models of simple machine

parts.

Part tool: Extrude, Hole, Revolve, Rib,

Sweep, Swept blend, Pattern, etc

Part Editing tool: Trim, Extend, Erase,

Mirror,

Part Modify tool: Chamfer. Round,

Copy. Move, Draft, etc.

Intersect 2 solid components by inserting,

new body option. Boolean operations:

Union, subtract, intersection.

‘Assembly Drawing: Preparation of

assembly drawing by using assé@jily

command,

Page Sof 8

Sod Metin ni Manic Conse Ce: 22048

Major Learning Outcomes | “Topics and Sub-topies

| | __ lin cognitive domain) - - -

| Assembly [3b. Use of explode command forthe 32 Exploded view Explode the assembly

| | given assembly

Unit

Unit-IV a. Use drawing module to create Orthographic projections: Generate |

| Drafting | orthographie views for the given | orthographie projections of the |

of 3D assembly. |, assembly. |

assembly tb. Generate Bill of material for 11.2. Bill of material: Propare part list table |

given assembly Drawing. |

| |

Use different settings for plotting, (5.1 Printer selection, paper size, orientation |

Use printer to plot drawing on A3 [5.2 Page sei up, |

or Ad size sheet, -

Describe the process of Additive

6.1 Additive manufacturing: 3D printing,

‘manufacturing, Rapid prototyping, |

Study construction and working | 6.2 File format: STL (Stereo

of 3D printer / Rapid Lithography),

prototyping machine, 6.3 3D printer software: part import,

Describe materials use for 3D orientation, processing and printing,

printer / Rapid prototyping

machine | a a”

Note: To attain the COs and competency, above listed UOs need to be undertaken to achieve

the ‘Application Level’ and above of Bloom's ‘Cognitive Domain Taxonomy’

9. SUGGESTED SPECIFICATION TABLE FOR QUESTION PAPER

(INTERNAL) DESIGN

Unit Title [Practical

Hours

_ a _ : | Level

1 | Working in 2D environment 04 ol

| 1 _| Development of Solid Models 4 | 02 | o1

IIL_[ Assembly Drawing 04 - fo 0.

IV_| Drafting of 3D assembly 04 - [2 |02 [04

V_| Plott 02 : oor |

VI_| Additive Manufacturing 04 : or | 02 | 03

Pe Total 32 03_|_o7 | 15 | 25

Legends: Remember. U=Understand, A~Apply and above (Bloom's Revised taxonomy)

Note: This specification table provides general guidelines to assist studenn for thet learning

and 19 teachers to teach and assess students with respect to attainment of UOs. The ant

distribution of marks at differem taxonomy levels (of R. ( and A) in the question paper may

vary fram above table.

10. SUGGESTED STUDENT ACTIVITIES

Other than the classroom and laboratory learning, following are the suggested student-related 55>

; SLT

co-curricular activities which can be undertaken to accelerate the attainment of the varios %

outcomes in this course: Students should conduct following activities in group and prepare. SQ 3,

my, A

Final Copy Di. 20.04.2018 Page 6of

Sold Maing and Addhive Manet Cause Code: 2204

reports of about 5 pages for each activity, also collect/record physical evidences for their

(student’s) portfolio which will be useful for their placement interviews

a. Prepare journals based on practical performed in laboratory.

b. Give seminar on relevant topic.

¢. Library/E-Book survey regarding ‘Solid modeling’ used in manufacturing industries.

d. Prepare power point presentation or animation for __drafting/solid

modeling/assembly/exploded view/3D printing

ist applications of 3D printing.

t to institute/industry having 3D printer/Rapid Prototyping machine.

ll. SUGGESTED SPECIAL INSTRUCTIONAL STRATEGIES (if any)

‘These are sample strategies, which the teacher can use to accelerate the attainment of the

various outcomes in this course:

a. Massive open online courses (MOOCs) may be used to teach various topies/sub

topics.

b. ‘L’ in item No. 4 does not mean only the traditional lecture method, but different

types of teaching methods and media that are to be employed to develop the outcomes.

©. About 15-20% of the topics/sub-topics which is relatively simpler or descriptive in

nature is to be given to the students for self-directed learning and assess the

development of the COs through classroom presentations (see implementation

guideline for details).

d. With respect to item No.10, teachers need to ensure to create opportunities and

provisions for co-curricular activities

Guide student(s) in undertaking micro-projects.

Correlate subtopics with actual design and additive manufacturing.

Use proper equivalent analogy to explain different concepts.

Use Flash/Animations to explain 3D printing and Rapid prototyping manufacturing

methods,

12. SUGGESTED MICRO-PROJ

Only one micro-project is planned to be undertaken by a student that needs to be assigned to

him/her in the beginning of the semester. In the first four semesters, the micro-project are

group-based, However, in the fifth and sixth semesters, it should be preferably be individually

undertaken to build up the skill and confidence in every student to become problem solver so

that s/he contributes to the projects of the industry. In special situations where groups have to

be formed for micro-projecis, the number of students in the group should not exceed three.

The micro-project could be industry application based, intemet-based, workshop

based, laboratory-based or field-based. Each micro-project should encompass two or more

COs which are in fact, an integration of PrOs, UOs and ADOs. Each student will have to

maintain dated work diary consisting of individual contribution in the project work and give a

seminar presentation of it before submission. The total duration of the micro-project should not

be less than 16 (sixteen) student engagement hours during the course. The student ought to

submit micro-project by the end of the semester to develop the industry oriented COs.

A suggestive list of micro-projects are given here. Similar micro-projects could be

added by the concerned faculty:

a. 2D drawing: Each student will collect one or two drawings from the nearby

industry/workshop and prepare a 2D drawing from it,

b. 3D model: Each student will identify a small assembly from th

workshop/laboratory. Measure the dimensions of each part and prepare

MSBTE — Final Copy Dt. 20.04.2018 Page 7 of 8

Sol Maing al Adve Mating Conse Cok: 22081

Using sketches prepared 3D model of parts and assembly. Plot the assembly und detail

drawings. (eg. Bench vice, Machine vice, Tool post, Couplings, Joints, Bearings etc.)

©. 3D. printing/RPT: Each student will visit a nearby institute/industry. Collect

information regarding troubleshooting of 3D printer/Rapid prototyping machine and

prepare a report

13. SUGGESTED LEARNING RESOURCES

Title of Book Author Publication

1 |CATIAVSRI7 for | Sham Tickoo Softcover, Cadcim Technologies

Designers

Pro/Engineer Wildfire | Sham Tickoo

for

Designers

Solid Works For Sham Tickoo

Designers

| Release 2006

4 | Autodesk Inventor for | Sham Tickoo

Designers: Release 10

5 |NX4 for Designers | Sham Tickoo,

Softcover, Cadcim Technologies

Softcover, Cadcim Technologies

Softcover, Cadcim Technologies

Deepak Maini

6 | Solid Edge V19 for | Sham Tickoo, Softcover, Cadcim Technologies

Designers | Deepak Maini

Soficover, Cadcim Technologies |

|

|

14, SOFTWARE/LEARNING WEBSITES

hup://www.solidworks.in/sw/products/3d-cad/3d-solid-modeling htm

hutp://web. itd ac.in/~hegde/cad/lecture/L30_solidmod_basics.pdf

. hitps://en.wikipedia org/wiki/Solid_modeling

hitp://npkauto.com/solid-modeling/

Intps://www.youtube.com/watch?v=yjX4PDIcFOL

htips://www-youtube.com/watch?v-SBDHS4FN2-

htps://www-youtube,com/wateh?v=JjKs-lePIPY

mone se

©

MSBTE ~ Final Copy Dt. 20.04.2018 Page 8 of 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Theory of Machines PDFDocument10 pagesTheory of Machines PDFFiroz AminNo ratings yet

- ILASS-Americas 24th Annual Conference On Liquid Atomization and Spray Systems, San Antonio, TX, May 2012Document9 pagesILASS-Americas 24th Annual Conference On Liquid Atomization and Spray Systems, San Antonio, TX, May 2012Firoz AminNo ratings yet

- Confirmed CAP Mark Entry List of E-Mark Sheet For Exam Oct. 2014Document2 pagesConfirmed CAP Mark Entry List of E-Mark Sheet For Exam Oct. 2014Firoz AminNo ratings yet

- 4593-Article Text-16536-2-10-20181221Document10 pages4593-Article Text-16536-2-10-20181221Firoz AminNo ratings yet

- Fundamentals of Digital Communications and Data TransmissionDocument114 pagesFundamentals of Digital Communications and Data TransmissionFiroz AminNo ratings yet

- Confirmed Moderator CAP Mark Entry List of E-Mark Sheet For Exam Oct. 2014Document1 pageConfirmed Moderator CAP Mark Entry List of E-Mark Sheet For Exam Oct. 2014Firoz AminNo ratings yet

- 1076-Article Text-6019-1-10-20201003Document13 pages1076-Article Text-6019-1-10-20201003Firoz AminNo ratings yet

- Two-Wheeler Safety System For Accident Prevention, Detection and ReportingDocument3 pagesTwo-Wheeler Safety System For Accident Prevention, Detection and ReportingFiroz AminNo ratings yet

- Marks: (Autonomous)Document30 pagesMarks: (Autonomous)Firoz AminNo ratings yet

- Automobile EnginesDocument42 pagesAutomobile EnginesFiroz AminNo ratings yet

- Automobile Sem 5 PDFDocument49 pagesAutomobile Sem 5 PDFFiroz AminNo ratings yet

- Interview Venue Candidate Id Name Mobile EmailDocument2 pagesInterview Venue Candidate Id Name Mobile EmailFiroz AminNo ratings yet

- Hitesh R. Kadave: Career ObjectiveDocument2 pagesHitesh R. Kadave: Career ObjectiveFiroz AminNo ratings yet

- Selection of Dip Aprrentices For Adani EletricityDocument3 pagesSelection of Dip Aprrentices For Adani EletricityFiroz AminNo ratings yet

- Resume:-: MAHESH ANIL POWAR. Production-Machining-About 2yrsDocument3 pagesResume:-: MAHESH ANIL POWAR. Production-Machining-About 2yrsFiroz AminNo ratings yet

- HR Heads All India 16170Document2,026 pagesHR Heads All India 16170Tinku Chowdary Malempati0% (2)

- Form 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Document4 pagesForm 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Firoz AminNo ratings yet

- Suspension & Brakes System: N. S. Surner SRES College of Engineering, KoprgaonDocument59 pagesSuspension & Brakes System: N. S. Surner SRES College of Engineering, KoprgaonFiroz AminNo ratings yet

- Master HRDocument1,030 pagesMaster HRshekharNo ratings yet

- Management - CO1 - LO1 - Study MaterialDocument143 pagesManagement - CO1 - LO1 - Study MaterialFiroz AminNo ratings yet

- Rubicon Training Outline: Sr. No. Topic Learning Objectives DurationDocument1 pageRubicon Training Outline: Sr. No. Topic Learning Objectives DurationFiroz AminNo ratings yet

- Classes Spring 2017Document292 pagesClasses Spring 2017Firoz AminNo ratings yet

- Assessment Type: Summative: End of CO: in LMS: Ans: (D) Ans: (D) Ans: (B) Ans: (C) Ans: (D)Document2 pagesAssessment Type: Summative: End of CO: in LMS: Ans: (D) Ans: (D) Ans: (B) Ans: (C) Ans: (D)Firoz AminNo ratings yet