Professional Documents

Culture Documents

Technical Data Sheet: High Performance Rail Lubricant

Uploaded by

varunchOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet: High Performance Rail Lubricant

Uploaded by

varunchCopyright:

Available Formats

TECHNICAL DATA SHEET

BioRail®

HIGH PERFORMANCE RAIL LUBRICANT

BioRail® is first and foremost a high performance rail curve grease. BENEFITS:

It is also based on oils from vegetable sources that are 100% • BIODEGRADABLE – all grades of BioRail® are classified as

biodegradable. “Readily Biodegradable”.

In wayside systems BioRail® forms a vertical bead that is easily • NO HAZARDOUS COMPONENTS - the non-oil components

picked up. It carries through multiple curves and forms a coating are partially biodegradable and non hazardous.

on the gage face that is clearly visible for ease of inspection. In

many cases the use of BioRail® will result in reduced grease • NOISE REDUCTION - especially valuable in urban areas.

consumption.

• ADHESIVE AND COHESIVE - excellent track carry down,

BioRail® empties evenly from the holding tank, without slumping reducing the number of wayside lubricators.

down to form a “V”. This minimizes pump cavitation. Unlike some

vegetable based products, BioRail® will not gel over time. It • WIDE TEMPERATURE RANGE – the need for seasonal

remains pumpable and does not plug ports. product grade changes is eliminated in many areas.

BioRail® has been extensively tested on Class 1 freight railroads in APPLICATIONS:

the United States, which represent the most severely loaded

conditions anywhere in the world. Field experience has shown that BioRail® is suitable for lubrication of rail curves where it protects

the carry down, coating of the rail, and level of wear protection are the gage face and wheel flanges. It can also be used in bearings

equal to Whitmore’s non-biodegradable rail curve greases. and to lubricate wire ropes, particularly in ecologically sensitive

areas.

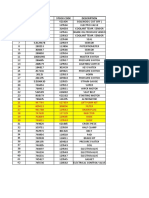

ASTM # TYPICAL CHARACTERISTICS

Grade BioRail® EP 0 BioRail® EP 1 BioRail® EP 1.5 BioRail® EP 2

D-217 Penetration (Worked) 355-385 305-335 285-315 265-295

D-2265 Dropping Point, °F (°C) >500 (260) >500 (260) >500 (260) >500 (260)

D-445 Base Oil Viscosity

cSt @ 40°C 45.0 45.0 118.2 55.6

cSt @ 100°C 9.9 9.9 19.9 12.8

D-2270 Viscosity Index of Base Oil 215 215 192 238

Gardener Density, lb/gal @ 60°F (15.5°C) 8.43 8.43 8.72 8.72

Method Specific Gravity, g/cc @ 60°F (15.5°C) 1.0120 1.0120 1.044 1.0470

D-2596 Four Ball EP, Weld Point, kg 500 500 500 500

D-2266 Four Ball Wear, Wear Scar, mm 0.60 0.60 0.68 0.68

Coefficient of Friction Not Tested 0.065 Not Tested Not Tested

Ambient Temperature Range, Trackside applicator

°F NA -10 to 80 0 to 113 32 to >130

°C NA -23 to 27 -18 to 45 0 to >54

Operational temperature range on the rail

°F -33 to 165 -25 to 175 -27 to 185 -22 to 195

°C -36 to 74 -32 to 80 -33 to 85 -30 to 90

Thickener Type Calcium Calcium Calcium Calcium

Sulfonate Sulfonate Sulfonate Sulfonate

FTM 321.2 Screen Bleed, % -- 4.46 4.10 3.14

MITI Test OECD 301B Pass Pass Pass Pass

The above are average values. Minor variations which do not affect product performance are to be expected in normal manufacturing.

PACKAGING

Nonreturnable

Shuttle Tanks Drums Kegs Pails w/Liners

Totes

For warranty information, scan the QR code.

930 Whitmore Drive • Rockwall, Texas 75087 • USA • (972) 771-1000 • 800-699-6318

An ISO 9001 and ISO 14001 registered company • www.whitmores.com

TDS-4044 6-26-19 tm/kc

You might also like

- Fortune500 CIO DatabaseDocument120 pagesFortune500 CIO Databasegomzy_45650% (2)

- Discrepancy Switches - Control Discrepancy Switches Standard Electrical DiagramsDocument20 pagesDiscrepancy Switches - Control Discrepancy Switches Standard Electrical DiagramsAnonymous XS9jAhY1pENo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Rock Mass Classification SystemsDocument33 pagesRock Mass Classification Systemsmortaza7094No ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Vintage Airplane - May 1990Document36 pagesVintage Airplane - May 1990Aviation/Space History Library100% (1)

- Print: 2Zr-Fe Engine Control Sfi System System DiagramDocument10 pagesPrint: 2Zr-Fe Engine Control Sfi System System DiagramAlfredo MedinaNo ratings yet

- Earthkeeper Hydraulic Oil TDS 9005Document1 pageEarthkeeper Hydraulic Oil TDS 9005Jose Luis Ramirez RamirezNo ratings yet

- Synthetic TBI ISO 32 46 Biodegradable Hydraulic OilDocument2 pagesSynthetic TBI ISO 32 46 Biodegradable Hydraulic Oilbrian5786No ratings yet

- Hyperion TDS 1034Document1 pageHyperion TDS 1034varunchNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- Caliber 460 M TDS 2081Document1 pageCaliber 460 M TDS 2081Jose Luis Ramirez RamirezNo ratings yet

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- Whitmore GF-Series Synthetic Blend Gear OilDocument1 pageWhitmore GF-Series Synthetic Blend Gear OilDon HowardNo ratings yet

- Meropa ISO 320 Technical DatasheetDocument5 pagesMeropa ISO 320 Technical DatasheetaskodidcNo ratings yet

- Technical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDocument1 pageTechnical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDon HowardNo ratings yet

- Chevron Meropa EP PDSDocument2 pagesChevron Meropa EP PDSArie'f Armand ArsyatNo ratings yet

- 1.envirolube TDS EnglishDocument1 page1.envirolube TDS EnglishThắng Phạm NguyênNo ratings yet

- Syncon R&o Oil (Iso - VG - 32-68)Document2 pagesSyncon R&o Oil (Iso - VG - 32-68)Roberto Carlos H. AguilarNo ratings yet

- SurStik 800 TDS 3034Document1 pageSurStik 800 TDS 3034Don HowardNo ratings yet

- SurStik 800 TDS 3034 PDFDocument1 pageSurStik 800 TDS 3034 PDFDon HowardNo ratings yet

- Technical Data Sheet: Leak Control Gear OilDocument1 pageTechnical Data Sheet: Leak Control Gear OilDon HowardNo ratings yet

- Lubricants: AAR 963 OilDocument2 pagesLubricants: AAR 963 OilArslan ILServicesNo ratings yet

- Multifak EP - Data SheetDocument2 pagesMultifak EP - Data SheetJeremias UtreraNo ratings yet

- Caliber M TDS 2051Document1 pageCaliber M TDS 2051dhowardjNo ratings yet

- Technical Data Sheet: Astm # Typical CharacteristicsDocument1 pageTechnical Data Sheet: Astm # Typical CharacteristicsDon HowardNo ratings yet

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanNo ratings yet

- TDS Monte Gear OilDocument1 pageTDS Monte Gear OilPT.TANESHA INDUSTRINo ratings yet

- 27e9f1d3-c2a9-443a-b033-5cecf47738caDocument3 pages27e9f1d3-c2a9-443a-b033-5cecf47738caahmetNo ratings yet

- Envirolube Xe Extreme: Technical Data SheetDocument1 pageEnvirolube Xe Extreme: Technical Data SheetDon HowardNo ratings yet

- Mobilgear SHC 3200 6800 PdsDocument2 pagesMobilgear SHC 3200 6800 PdsMohamed SalemNo ratings yet

- THE LAST TURBINE OIL YOU'LL EVER NEEDDocument4 pagesTHE LAST TURBINE OIL YOU'LL EVER NEEDAhmad ButtNo ratings yet

- Lubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDocument2 pagesLubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDixo FernandezNo ratings yet

- Technical Data Sheet: Wire Rope OilDocument1 pageTechnical Data Sheet: Wire Rope OilDon HowardNo ratings yet

- Pureblu Hydraulic Oil: With Leak Detection FormulationDocument2 pagesPureblu Hydraulic Oil: With Leak Detection FormulationDavid RamosNo ratings yet

- Technical Data Sheet: High Performance Rail Grease With GraphiteDocument1 pageTechnical Data Sheet: High Performance Rail Grease With GraphiteDon HowardNo ratings yet

- TDS Naffcool GO SeriesDocument1 pageTDS Naffcool GO SeriesEmpy SumardiNo ratings yet

- JBT Foodtech H1 Food Grade GreaseDocument6 pagesJBT Foodtech H1 Food Grade Greaseandri putrantoNo ratings yet

- Bel-Ray No-Tox Syntra Food Grade Synthetic OilDocument4 pagesBel-Ray No-Tox Syntra Food Grade Synthetic OilGiovanny MosqueraNo ratings yet

- Servo Product Data - Industrial GradesDocument23 pagesServo Product Data - Industrial GradesUtkarsh100% (1)

- Castrol Biobar Range: DescriptionDocument4 pagesCastrol Biobar Range: Descriptionnauta007No ratings yet

- Chevron Aries TDSDocument2 pagesChevron Aries TDSprimmughalNo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- 76 Grasa Megaplex XD3Document2 pages76 Grasa Megaplex XD3Gustavo De Haro GonzálezNo ratings yet

- Whitmore Decathlon Gold Open Gear LubricantDocument1 pageWhitmore Decathlon Gold Open Gear LubricantDon HowardNo ratings yet

- Technical Data Sheet: Heavy Duty GreaseDocument1 pageTechnical Data Sheet: Heavy Duty GreaseDon HowardNo ratings yet

- Technical Data Sheet: Biodegradable Switch Plate LubricantDocument1 pageTechnical Data Sheet: Biodegradable Switch Plate LubricantvarunchNo ratings yet

- MSDS - Magna-Plate-19263 19264 19265-TDDocument2 pagesMSDS - Magna-Plate-19263 19264 19265-TDMohamad HudhaNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- Triton 5005 EXDDocument3 pagesTriton 5005 EXDCarlosNo ratings yet

- Envirolube XE Extreme TDS 190828 203810Document1 pageEnvirolube XE Extreme TDS 190828 203810Don HowardNo ratings yet

- Chevron Open Gear NC PDFDocument2 pagesChevron Open Gear NC PDFDavid Hinostroza IbarraNo ratings yet

- Technical Data Sheet: Priming LubricantDocument1 pageTechnical Data Sheet: Priming LubricantDon HowardNo ratings yet

- Chevron Open Gear LubricantDocument2 pagesChevron Open Gear LubricantJeremias Utrera100% (1)

- Hoja Tecnica - OmnilithDocument1 pageHoja Tecnica - OmnilithJhosbrield Pacheco ZegarraNo ratings yet

- C H O AW: Hevron Ydraulic ILDocument2 pagesC H O AW: Hevron Ydraulic ILAmir Reza RashidfarokhiNo ratings yet

- Chevron SRI Nov'07 润滑脂Document2 pagesChevron SRI Nov'07 润滑脂khurramNo ratings yet

- Operation ManualDocument4 pagesOperation Manualphucdc095041No ratings yet

- Whitslide HV TDS 3030 PDFDocument1 pageWhitslide HV TDS 3030 PDFDon HowardNo ratings yet

- 2186 - Pc-Abs Pulse gx70Document3 pages2186 - Pc-Abs Pulse gx70mikeburnsthrowaccNo ratings yet

- L-CKC Medium Duty Industrial Gear OilDocument3 pagesL-CKC Medium Duty Industrial Gear OilYoong TanNo ratings yet

- Marfak 00, 0, 1Document2 pagesMarfak 00, 0, 1Hector IbarraNo ratings yet

- Gearmate 1000 ICT PDFDocument1 pageGearmate 1000 ICT PDFvarunchNo ratings yet

- Silicone Compound Dm-2: Moisture Proofing Sealant & LubricantDocument1 pageSilicone Compound Dm-2: Moisture Proofing Sealant & LubricantvarunchNo ratings yet

- Silicone Compound Dm-3: Moisture Proofing Sealant & LubricantDocument1 pageSilicone Compound Dm-3: Moisture Proofing Sealant & LubricantvarunchNo ratings yet

- Technical Data Sheet: Biodegradable Switch Plate LubricantDocument1 pageTechnical Data Sheet: Biodegradable Switch Plate LubricantvarunchNo ratings yet

- Whitmore EZ-Switch LubricantDocument1 pageWhitmore EZ-Switch LubricantDon HowardNo ratings yet

- Technical Data Sheet: Biodegradable Switch Plate LubricantDocument1 pageTechnical Data Sheet: Biodegradable Switch Plate LubricantvarunchNo ratings yet

- Technical Data Sheet: Flange Stick LubricantDocument1 pageTechnical Data Sheet: Flange Stick LubricantvarunchNo ratings yet

- Moly-Mist™: Mos Dry Film LubricantDocument1 pageMoly-Mist™: Mos Dry Film LubricantvarunchNo ratings yet

- HSC Time 2011Document10 pagesHSC Time 2011varunchNo ratings yet

- Jet-Lube 769 Lubricant and PenetrantDocument1 pageJet-Lube 769 Lubricant and PenetrantDon HowardNo ratings yet

- OXIDATIONDocument36 pagesOXIDATIONMansab AliNo ratings yet

- Galaxy Y S5360 Android 2.3.6 Gingerbread Official FirmwareDocument23 pagesGalaxy Y S5360 Android 2.3.6 Gingerbread Official Firmwarekharishkhan0% (1)

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document8 pages400 Bad Request 400 Bad Request Nginx/1.2.9bahramhooNo ratings yet

- Enerflex Rocsole Presentation 051220 - 1033 - v.2Document28 pagesEnerflex Rocsole Presentation 051220 - 1033 - v.2Monsivais AntonioNo ratings yet

- TMP 727Document40 pagesTMP 727FrontiersNo ratings yet

- OJT Lob LODocument29 pagesOJT Lob LOEsa Ghanim0% (1)

- Philips MDK 900Document2 pagesPhilips MDK 900Heri MunirNo ratings yet

- Cycle of Copper Reactions LabDocument6 pagesCycle of Copper Reactions LabbigfoottedNo ratings yet

- Field Engineer ResumeDocument3 pagesField Engineer ResumesambhuNo ratings yet

- Isis Manual Vol. 2Document168 pagesIsis Manual Vol. 2Νίκος ΚατριβέσηςNo ratings yet

- BO Consultant Resume Summary Role SAPDocument5 pagesBO Consultant Resume Summary Role SAPsundeep2kumgmailcomNo ratings yet

- Industrial Electrical or Maintenance RepairDocument2 pagesIndustrial Electrical or Maintenance Repairapi-78929944No ratings yet

- Oracle BOM Mass Changes - Oracle Functionality - ManojDocument29 pagesOracle BOM Mass Changes - Oracle Functionality - ManojVijay PawarNo ratings yet

- Torre Sauter 4 PosiçõesDocument22 pagesTorre Sauter 4 PosiçõesPaulo Henrique ValérioNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- General notes and location planDocument1 pageGeneral notes and location planRamith De SilvaNo ratings yet

- NI Camera Link IO BoardDocument20 pagesNI Camera Link IO BoardelmoandcookieNo ratings yet

- Frame Generator PDFDocument13 pagesFrame Generator PDFWilly PeralesNo ratings yet

- Kodak X-Omat Multiloader 300 Film Feeder - User ManualDocument10 pagesKodak X-Omat Multiloader 300 Film Feeder - User ManualNikolay PenevNo ratings yet

- MAE Courses For PHDDocument8 pagesMAE Courses For PHDNho Do ThanhNo ratings yet

- 2017+Module+1+Term+Test+ SolutionsDocument13 pages2017+Module+1+Term+Test+ Solutionszubair ahmedNo ratings yet

- 318D L Series 2: Hydraulic ExcavatorDocument32 pages318D L Series 2: Hydraulic ExcavatorFelipe Pisklevits LaubeNo ratings yet

- Melab1 Exp3Document11 pagesMelab1 Exp3John Ferben Sallena DepnagNo ratings yet

- Modified o and G Slides 2Document21 pagesModified o and G Slides 2Salam FaithNo ratings yet

- Notifier Compatible EquipmentDocument2 pagesNotifier Compatible EquipmentHesams EnamoradoNo ratings yet