Professional Documents

Culture Documents

US3281186A

Uploaded by

AJ Prince0 ratings0% found this document useful (0 votes)

24 views5 pagesWheel project

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWheel project

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views5 pagesUS3281186A

Uploaded by

AJ PrinceWheel project

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

Oct. 25, 1966 M. F. DAVIS 3,281,186

CONVEREIBLE MULTI-PURPOSE VEHICLE

Filed Aug. 5, 1964 2 Sheots-Sheet 2

INVENTOR

MILTON F) DAVIS

™ Kae UW) Fleces

ATTORNEY

Oct. 25, 1966 M.F. DAVIS 3,281,186

convaRSTBLm MuL?-PURPOSE VanECLE

Filed Aug. 3, 1964 2 shoste-snoet 2

°

r INVENTOR

MILTON ¥? DAVIS

Kost W Frese

ATTORNEY

OS

f° oy

United States Patent Office

1

3,281,186

CONVERTIBLE MULTI-PURPOSE VEHICLE

Milton F. Davis, 3644 Miami Cove, Memphis, Tenn,

Filed Aug. 3, 1964, Ser. No. 387,148

8 Ciaims. (Cl, 298—2)

‘The present invention relates to a multi-purpase power

deiven vehicle that easily adapts to conversion for various

uses, and has particular reference to a vehicle that may

bbe used with a trough or a flat bed arrangement and may

be steered from behind or may be ridden by the operator

‘when a load is not being transported on the vehicle.

Accordingly, the present invention is directed to a

safe, inexpensive power vehicle for small hauling jobs

‘With a trough installed thereon the vehicle can be used

for hauling dist, concrete, sand, liquid, ete. With the

tough removed and the bracket holding the trough also

removed, the vehicle can be used 0 haul such items as

bricks, of any other items that may be conveniently hauled

‘on a fiat bed vehicle. Other conversion accessories may

be used for installation on the frame housing that will in-

crease the size of the flat bed and increase the hauling

‘capacity.

‘Also, itis an object of this invention to provide a haul-

ng vehicle which may conveniently damp its contents

forwardly or to either side of the vehicle as is most con-

venient for the operator and the use of said vehicle.

It is a further object of this invention to provide a

‘vehicle behind which the operator may walk while control

ling the vehicle and upon which the operator may ride

after disposing of the load on the vehicle and while re

turning for additional loads of material.

The above and other objects and advantages of the in-

vention will become apparent upon full consideration of

the following detailed description and accompanying draw-

ings of an embodiment of the invention in which:

FIG, 1 is a left side rear perspective view of the vebicle

of the present invention;

FIG. 2s a side elevation of the vehicle of FIG. 1;

FIG. 3 is a partially exploded view of the vehicle; and

FIGS. 4 and 5 are plan views of the vehicle showing

alternative dumping positions and handle positions for

steering the vehicle when ridden by the operator as in

FIG. 3.

‘Considering now the details of an embodiment of the

present invention, there is shown in FIGS. 1, 2 and 3 a

‘multi-purpose vehicle 10 having a frame 11 with a sub-

stantially flat horizontal top portion 12 and downward

extending sides 13. A pair Of fixed directional wheels

14 are mounted on axle 18 attached at the forward por-

tion of vehicle 10. In the particular embodiment illus-

‘rated, axle 15 is mounted through beatings 16 atiached

‘on inward extending lips 17 forming part of frame 11.

On the opposite end of frame 11 on its upper surface is

‘mounted a small engine 18. Extending below the frame

is a caster wheel 19 mounted oa forked member 21 at-

tached to a vertical arm 22, In a position forward of

‘vertical arm 22 and straddling engine 18 there is a bench

structure 23 attached to frame 11.

‘Any suitable type of engine 18 may be used on this

‘vehicle, of course, depending upon the size of the vehicle

tnd the loads which are to be transported thereon. In

‘engine 18 as illustrated, a dsiving pulley 25 is mounted

‘on motor shaft 26 and connected to a driven pulley 27 by

‘means of flexible belt 28, ‘The spacing between pulleys

25 and 27 is adjusted to be somewhat less than proper to

communicate drive directly through the belt 28. Because

of this slack the motor shaft 26 may turn free without

driving the pulley 27. Conventional throttle and clutch

‘controls, not shown, are mounted at a convenient posi-

tion near handle 29 to be always within convenient reach

10

20

25

30

0

45

50

5

0

0

3,281,186

Patented Oct. 25, 1966

2

of the operator of the vehicle and by means of this clutch

control the operator may control the movement of idler

pulley 31 which is moved so as to contact the belt between

pulleys 25 and 27 and thereby take up the slack as shown

in FIGS. 1 and 2, Asiillustrated in these flgures, the idler

‘pulley 31 is mounted on a rod 32 which is journaled to

rotate upon a bolt 33 connected to a member attached to

frame L1. The idler pulley 31 is therefore free 0 swing

arcuately, upwardly and downwardly about the pivot

point established by rod 32 and bolt 33. As the rod 32,

and therefore idler pulley 31, is pulled upward by means

‘of the clutch control, the idler pulley 31 engages the belt

28 so as t0 take up the slack therein and communicate the

rive from pulley 25 to pulley 27. Mounted on the

same shaft 34 is a sprocket 35 of smaller diameter than

driven pulley 27, thereby constituting a speed reduction

combination. A’ drive chain 36 drives the intermediate

sprocket 37 from driving sprocket 35. Intermediate

sprocket 37 is mounted on a shaft and beacing attached

to the overhanging side of frame 11, A final drive chain

38 supplies power from a smaller intermediate sprocl

377, on the same shaft with sprocket 37, t0 a larger front

Grive sprocket 39 for further speed reduction and greater

power. The embodiment of the vehicle illustrated uses

a three-wheel running gear with power applied to the

pair of directionally fixed wheels 14 for maximum trac-

tion purposes, since the greater weight of the loads car-

tied by the vehicle is applied nearer the front end of

this vehiole

Vehicle 19 may be steered by the swiveling of caster

whee! 19 through movement of handle 29 by the op-

erator of the vehicle. Vertical arm 22 which is attached

to fork member 21 through bearing 49 attached to frame

11 rotates with both fork member 24 and caster wheel

49, At the top end of vertical arm 22 there is located

a pivotal bearing arrangement 41 and a spring loaded

catch 42. Arm 45 is attached to vertical arm 22 at

this pivotal bearing arrangement 41 and has handle 29

also pivotally mounted at point 46 on its opposite end.

The two arrangements for handle 29 allowed by pivotal

attachment at 41 and 46 ate shown in FIGS. 1 and 3,

If the vehicle is carrying 2 heavy load and the operator

is following behind the vehicle and controlling it from

that position, then the handle 29 and associtaed con-

necting arm 48 are in the position shown in dashed out-

line in FIGS. 1 and 3. On the other hand, if the opera-

tor has disposed of the load and is riding the vehicle

as shown in FIG. 3, then the handle is in the forward

lowered position shown in full lines in FIGS. 1 and 3

and also in FIG. 2, In this forward lowered position the

handle 29 and arm 48 are in a locked position in rela-

tion to vertical arm 22 with spring loaded catch 42

locked in slots 43. For the position shown in dashed

outline the spring loaded catch 42 would lock in slots 46.

‘When it is required to change the position of handle 29

and attached arm 45 from its rear position to the lowered

forward position or vice versa, the seat board 47 is ro-

tated about hinge 48 to the dashed outline position shown,

in FIG. 1 thereby allowing movement of handle 29 and

connecting arm 48 through arc 50.

When in the forward lowered position with the op-

erator riding the vebicle as in FIG. 3, the handle 29 and

connecting arm 45 may be moved as shown in FIGS. 4

and 5 for right or Ieft turns respectively. This move-

ment of handle 29 and attached arm 48 causes the rota-

tion of vertical arm 22 thereby rotating caster wheel 19.

With turntable $8 and trough 36 removed from ve-

hicle 10 the vehicle may be used for hauling articles re-

‘quiting a flat bed arrangement, utilizing frame 11. On

the other hand, when such articles such as sand or liquid

are to be moved and it is required that a receptacle be

8,281,186

3

mounted on the vehicle for this purpose, a turntable 55

having a flat turntable base $7 with a vertical pin 58

‘mounted beneath its center may be mounted on the ve-

hicle by the insertion of the turntable pin $8 into a bush-

ing $9 mounted in the horizontal surface 12 near the

forward portion of frame 11,

On diametrically opposite sides of turntable base 57

there are mounted vertical side brackets 61 firmly at-

tached on their lower ends to turntable base 57 and hay-

ing forked beatings 62 on their upper ends. A tous

36 having pins 63 extending horizontally from its sides,

so placed as to easily drop into forked beatings 62 of

just as easily disengage from said fork beatings when

the trough is raised clear of turntable 85, is shown in the

‘exploded portion of FIG. 3. Trough pins 63 are placed

off center so that the center of gravity of a load caztied

by trough $6 will be toward the forward end of the

trough. “ Upon release of Tetch 64 the trough 36 will ip

forward automatically and dump its load as shown in

FIG. 2. “Latch 64 is merely a latch of the over center

type. It is pivotally mounted on inclined bar 65 which

is additionally supported by bracing member 66 attached

to side brackets 61 and partially encitcling trough $6,

Due to the pivotal mounting of latch 64 2 pull down-

wardly on handle 67 of said latch will raise hooked end

68 thereby moving the latch from the full line position

to the dashed outline position shown in FIG, 2 and there-

by release trough 56 to dump its contents as also shown

in the same figure,

While the contents of the trough may be dumped to-

ward the forward end of the vehicie as shown in FIG. 2,

these contents may also be dumped to either side of the

vehicle since the trough $6 may be rotated in either

direction because of the turntable arrangement of this

structure. Such rotation of trough 56 during its use is

illustrated in FIG. 5,

Other latching arrangements besides the type shown.

may be substituted, and for further convenience of the

operator, for instance, an additional pin on the trough

and a foot operated latch may be used instead of the

Tatch shown.

It will be obvious to those skilled in the att that vari-

fous changes may be made without departing from the

scope of the invention and therefore the invention is not

limited to what is shown in the drawings and deseribed

in the specification but only as indicated in the appended

claims.

What is claimed

LA vehicle comprising

a frame having a substantially uninterruptedly level

horizontal surface portion;

a pair of spaced wheels mounted at one end of said

frame with their topmost portion below the level of

the horizontal surface portion of said frame;

at least one wheel mounted at the opposite end of said

frame from said pair of spaced wheels;

seat mounted on said frame;

steering means adapted for steering said vehicle rom

‘a seated position on said vehicle or a walking posi-

tion rearwardly of said vebicle;

a removable turntable mounted on said frame including

‘a turntable base,

a pin depending from said turntable base,

‘and support means mounted on said turntable base:

‘means mounted in said frame to loosely receive said

pin whereby said turntable is easily detachable from

said frame leaving said substantially uninterruptedly

level horizontal surface portion for carrying pur-

poses;

and an engine mounted on said horizontal frame at the

‘opposite end from said turntable,

2. The vehicle of claim 1, further characterized by

4 receptacle mounted off its center of gravily on said

support means on said turntable base.

3. The vehicle of claim 1, further characterized by

10

6

25

30

35

0

55

65

0

%

4

said frame having depending sides and inward extend-

‘ng lips from the bottom of said depending sides;

an axle mounting said pair of spaced wheels which are

fixed directional wheels, with said axle attached to

said inward extending lips;

sprocket mounted oa a shaft journaled in said de-

pending sides of said frame and located between said

‘engine and said fixed directional wheels;

clutched drive means connecting said engine to said

sprocket;

‘an additional drive means from said sprocket to said

axle mounting fixed directional wheels,

4. A vehicle comprising

frame having a substantially horizontal surface por

tion;

8 removable turntable mounted on said frame includ-

ing

‘a turntable base,

a pin depending from said turntable base,

and vertical support members mounted on said

turntable base having forked receiving means on

the tops thereof;

‘bushing means mounted in said frame to loosely receive

said pin whereby said turntable is easily detachable

from said frame;

8 receptacle having sideward extending horizontal pins

located off-center from the center of gravity of the

receptacle when loaded;

Intching means attached fo said turntable to hold said

receptacle against tipping:

fan engine mounted on said ftame;

8 seating structure over said engine including

supporting vertical structure attached near op-

posite side edges of said frame,

and a seat board hingedly connected to support:

ing vertical structure near one side of said frame

and resting on supporting vertical structure near

the opposite side edge of ssid frame;

means driven by said engine to supply motive power for

the vehicle;

and means to steer the vehicle including

caster wheel mechanism mounted below said

frame and adjacent said engine,

4 vertical member attached to said caster wheel

mechanism for rotation therewith,

and a connecting member pivotally’ connected to

said vertical member at a height below that of

said seat board and above that of said engine,

8. A vehicle comprising

a frame having a substantially uninterruptedty level

horizontal surface portion;

4 removable turntable mounted on said frame includ-

ing

‘a turntable base,

a pin depending from said turntable base,

and support means mounted on said turntable

bases

‘means mounted in said frame to loosely receive sai

pin whereby said turntable is easily detachable from

said frame leaving said substantially uninterruptedly

level horizontal surface portion for carrying purposes;

‘an engine mounted on said frame on the opposite end

of the vehicle from said turntable;

‘means attached to said engine to move the vehicle;

a seating structure straddling said engine having a seat

board hinged at one end;

2 caster wheel mechanism mounted benesth sald frame

near said engine;

a vertical member attached to said caster wheel mecha-

nism and rotatable therewith;

and 2 connecting member pivotally attached to said

vertical member at a height below the level of said

seat board whereby when said connecting member

is in a substantially horizontal position it can extend

8,281,186

5

through said seating structure beneath said seat

board.

6. The vehicle of claim 5, further characterized by

means to lock said connecting member in one of at

Teast two different positions relative to said vertical

member.

7. The vehicle of claim 6 further characterized by

a substantially closed loop handle pivotally attached to

said connecting member.

8. A vehicle comprising

@ frame having a substantially uninterruptedly fevel

horizontal surface portion;

removable vertical support means mounted on said

frame;

a receptacle mounted off its center of gravity on said

removable vertical support means;

latching means attached to said support means to hold

said receptacle against tippings

an engine movinted on said frame on the opposite end

‘of the vehicle from said removable vertical support

means attached to suid engine to move the vehicle;

2 seating structure straddling said engine having a seat

‘board hinged at one end;

a caster wheel mechanism mounted beneath said frame

near said engines

6

fa vertical member attached to

nism and rotatable therewith;

and a connecting member pivotally attached to said

vertical member at a height below the level of said

5 seat board whereby when said connecting member

ig in a substantially horizontal position it can ex-

tend through said seating structure beneath said seat

id caster wheel mecha-

board.

" References Cited by the Examiner

UNITED STATES PATENTS

1,922,776 8/1933 Nichols - 254-166

2.207.447 7/1940 Viles.

ag 2192718 5/1957 Ellison — 18027

21987339 5/1957. Reid -. 298-17 X

FOREIGN PATENTS

26606 1913 Great Britain

2 544065 3/1942 Great Britain

630,518 10/1949 Great Britain,

BENJAMIN HERSH, Primary Examiner.

5 RB: JOHNSON, Assistant Examiner.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Emotion ListDocument1 pageEmotion ListAJ PrinceNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- National Portal For Rooftop Solar - Ministry of New and Renewable EnergyDocument2 pagesNational Portal For Rooftop Solar - Ministry of New and Renewable EnergyAJ PrinceNo ratings yet

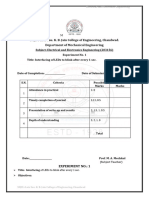

- 8th Sem SyllabusDocument25 pages8th Sem SyllabusAJ PrinceNo ratings yet

- National Portal For Rooftop Solar - Ministry of New and Renewable EnergyDocument46 pagesNational Portal For Rooftop Solar - Ministry of New and Renewable EnergyAJ PrinceNo ratings yet

- U 1 Energy AuditDocument9 pagesU 1 Energy AuditAJ PrinceNo ratings yet

- Share EXPT No 1 EEEDocument7 pagesShare EXPT No 1 EEEAJ PrinceNo ratings yet

- PythonTrainingPre RequitesDocument1 pagePythonTrainingPre RequitesAJ PrinceNo ratings yet

- Rahul Industrial Internship Training ReportDocument12 pagesRahul Industrial Internship Training ReportAJ PrinceNo ratings yet

- Dynamic BalancingDocument2 pagesDynamic BalancingAJ PrinceNo ratings yet