CALCULATION FOR WALL ANCHOR BRACKET

PROJECT‐PHASE‐1A &1B

Data – 08‐11‐2020

REV‐00

DOCUMENT NUMBER: STS‐P1A‐GEN‐SDW‐BMU‐GEN‐0005

�

1. OBJECTIVE

Objective of the calculation is to check whether the wall anchor bracket is

safe under the applied load.

2. CODES USED

BS 7985

3. INPUT DATA

Ultimate load on the anchor Fb= 15 kN (As per BS 7985: Clause [Link])

4. LOAD

1

�PROJECT : PHASE-1A Engineer : VIVEK___________

PROJECT NO. Verified : ASHWIN__________

Revision: 00 | Date : 08-11-2020

[Link] FOR WALL ANCHOR BRACKET IN PUT OUT PUT

Steel materials safety factor

FOS : νE1 1.5

LOADS ACTING ON THE WALL ANCHOR BRACKET

Load acting on the bracket Fb 15kN (Refer page-1)

MATERIAL PROPERTIES

1)Mild Steel

Grade S275JR

Tensile strength, yield : σEA 275MPa

Tensile strength, ultimate : σUA 430MPa

Modulus of elastisity : EA 200GPa

Max allowable stress σEA

σA1 σA1 183.333 MPa

νE1

2)Weld Electrode

Grade E35

N

Design strength of the electrode σAE 220

2

mm

2

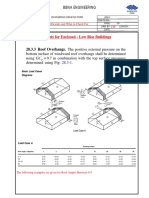

�5.1 CHECK FOR HORZONTAL SHS

Selected SHS 75x75x6

Effective length of SHS L1 283mm

4

Moment of inertia Ix 1264300mm

Distance from nutal axis Yx 35.7mm

2

Area of cross section ASHS 1617mm

Moment on SHS M 1 Fb L1 M 1 4.245 kN m

Bending stress on SHS M 1 Yx

σ1 σ1 119.866 MPa

Ix

Shear stress on SHS Fb

τ1

ASHS τ1 9.276 MPa

Equivalent stress on SHS 2 2

σ1eq σ1 3 τ1 σ1eq 120.938 MPa

Max allowable stress σA1 183.333 MPa

stress_status_1 if σ1eq σA1 "OK" "NOT OK"

stress_status_1 "OK"

5.2 CHECK FOR WELD

Weld thickness : thw 6mm

Weld throat thickness : thwt 0.707thw thwt 4.242 mm

2

Weld area Aw 2248mm

4

Moment of inertial of weld Ixw 4020000mm

Yw 43.16mm

Bending stress on the weld

σ2

M1 Yw σ2 45.576 MPa

Ixw

Fb

Shear stress on the weld due to Fh τ2 τ2 6.673 MPa

Aw

Equivalent stress on weld 2 2

σ2eq σ2 3 τ2 σ2eq 47.018 MPa

3

�Design strength of weld elctrode σAE 220 MPa

stress_status_2 if σ2eq σAE "OK" "NOT OK"

stress_status_2 "OK"

5.3 CHECK FOR BASE PLATE

Length of base plate Lp 195mm

Plate width b P 105mm

Plate thickness t P 20mm

Ls 135mm

Bolt spacing

C1 30mm

Bending over hang

b t 2

Section modulus of plate

Z2

P P Z2 7000 mm

3

6

Area of cross section of plate

A2 b P tP 2

A2 2100 mm

Tensile force on anchors M1

Pb

Ls Pb 31.444 kN

4

�Bending stress on the plate

σ3

Pb C1 σ3 134.762 MPa

Z2

Shear stres on the plate Pb

τ3 τ3 14.974 MPa

A2

τ3 14.974 MPa

Equivalent stress on plate 2 2

σ3eq σ3 3 τ3 σ3eq 137.235 MPa

Max allowable stress as per EN 1808 case-1 σA1 183.333 MPa

stress_status_3 if σ3eq σA1 "OK" "NOT OK"

stress_status_3 "OK"

5.4 SLECTION OF ANCHORS

M b M 1 4.245 kN m

Moment acting on base plate

Shear load

Fs Fb 15 kN

Refer attachd hilti report

5

� C-FIX [Link]

Database version

2020.[Link]

Date

08/11/2020

fischer FZE

Jebel Ali Free Zone Warehouse No XB

P.O. Box 261738 Dubai

Enquiry@[Link]

[Link]

Design Specifications

Anchor

Anchor system fischer Bolt anchor FAZ II

Anchor Bolt anchor FAZ II 16/25 R, stainless steel,

Property Class ≥ 70

Calculated anchorage 74 mm

depth

Design Data Anchor design in Concrete according European Technical

Assessment ETA-05/0069, Option 1,

Issued 24/04/2020

Geometry / Loads / Scale units

mm, kN, kNm

Value of design actions (including

partial safety factor for the load) Static

Not drawn to scale

The input values and the design results should be checked against local valid standards and approvals. Please respect the disclaimer of warranty in

the license agreement of the Software.

Page 1

� C-FIX [Link]

Database version

2020.[Link]

Date

08/11/2020

Input data

Design method TR055/ETAG 001, Annex C, Method A

Base material Normal weight concrete, C35/45, EN 206

Concrete condition Non-cracked, dry hole

Reinforcement Normal or no reinforcement. No edge reinforcement

Drilling method hammer drilling

Installation type Push-through installation

Annular gap Annular gap not filled

Type of loading Static or quasi-static

Base plate location Base plate flush installed on base material

Base plate geometry 195 mm x 105 mm x 20 mm

Profile type Customized profile

Design actions *⁾

# NSd VSd,x VSd,y MSd,x MSd,y MT,Sd Type of loading

kN kN kN kNm kNm kNm

1 0.00 15.00 0.00 0.00 4.25 0.00 Static or quasi-static

*⁾ The required partial safety factors for actions are included

Resulting anchor forces

Tensile action Shear Action Shear Action x Shear Action y

Anchor no. kN kN kN kN

1 28.44 7.50 7.50 0.00

2 0.00 7.50 7.50 0.00

max. concrete compressive strain : 0.34 ‰

max. concrete compressive stress : 11.6 N/mm²

Resulting tensile actions : 28.44 kN , X/Y position ( -68 / 0 )

Resulting compression actions : 28.44 kN , X/Y position ( 82 / 0 )

Resistance to combined tensile and shear loads

Eq. (5.8a)

Proof successful Eq. (5.8b)

Eq. (5.8c)

Remarks

The general and technical remarks you will find in the complete printout.

The input values and the design results should be checked against local valid standards and approvals. Please respect the disclaimer of warranty in

the license agreement of the Software.

Page 2