0% found this document useful (0 votes)

239 views1 pageStructural Glass Design Analysis

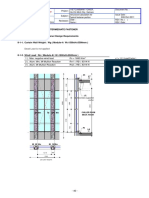

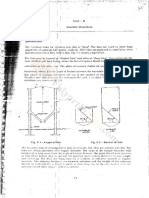

The document summarizes the structural glass design of a glass panel that is 1.5 feet by 5 feet and 0.787 inches thick, based on finite element analysis. It provides the allowable glass strength, deflection, loads, and analysis of joint deflections, reactions, section forces, bending capacity, and deflection. The design was found to be adequate with maximum deflection of 0.21 inches and bending moment of 0.42 ft-k/ft, both within allowable limits.

Uploaded by

Er Chandra BoseCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

239 views1 pageStructural Glass Design Analysis

The document summarizes the structural glass design of a glass panel that is 1.5 feet by 5 feet and 0.787 inches thick, based on finite element analysis. It provides the allowable glass strength, deflection, loads, and analysis of joint deflections, reactions, section forces, bending capacity, and deflection. The design was found to be adequate with maximum deflection of 0.21 inches and bending moment of 0.42 ft-k/ft, both within allowable limits.

Uploaded by

Er Chandra BoseCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd