Professional Documents

Culture Documents

FCM 4000 Flyer FCMNA 29-Mar-19 PDF

Uploaded by

cristianbrandauOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FCM 4000 Flyer FCMNA 29-Mar-19 PDF

Uploaded by

cristianbrandauCopyright:

Available Formats

FCM 4000

High-volume Aqueous Cleaning for Aftertreatment Systems

Advanced cleaning for higher volumes

More units mean more service revenue for your business

Our high-volume Flash Cleaner Machine (FCM 4000) safely

and effectively combines water and vacuum to clean deposits

from diesel particulate filters (DPFs), diesel oxidation catalysts

(DOCs) and selective catalyst reduction (SCR) units.

However, unlike conventional machines, our design cleans

units from all diesel classes – broadening your potential

customer base far beyond conventional, segment-limited

Supports Two Cleaning Cabins

cleaning machines.

High-volume aqueous cleaning with clear advantages Cleans in as little as:

Proven methods combine with efficiencies for your operations

In addition to cleaning different types of units, FCM’s process uses both water

pressure and vacuum, combining the force of both to quickly clean DPF, DOC and

5

Minutes

SCR units – often in only 5 minutes. If you are a high-volume (20+ units per day)

cleaning operation, the FCM 4000 is likely the right machine for you. With our automatic cycle.

This distinct combination maximizes cleaning throughput, while minimizing costs

related to shop footprint, utilities and time needed to service your customers’

aftertreatment systems to get their equipment back in service.

• Services all DPF, DOC & SCR units (passenger cars thru Class 8 equipment*)

• FCM’s automatic cycle can clean DPF units in as little 5 minutes

• Most effective process for removing compacted soot, ash & other residue

• Technology recognized by major OEMs & substrate manufacturers

• Separate dryer units available for even faster unit turnaround

During its brief cleaning, FCM’s advanced processes provide greater recovery of

unit efficiency compared to other cleaning methods, which will help keep your

customers’ equipment working for longer periods.

Upon cycle completion, FCM’s integrated printer gives you verifiable results –

providing backpressure tests pre- and post-cleaning that you can share with your

customers for their service records.

Turn our cleaning benefits to your advantage

Find out how our advanced methods can improve your competitiveness

We can help broaden your business and streamline your operations. To learn Combines Vacuum and

more, contact your authorized FCM distributor. They will be happy to talk with you Liquid Cleaning

and provide more detailed information based on your specific operation.

* With optional universal cleaning cabin

For FCM sales, customer service and post-sales support, contact:

Contact: Greg Borden Email: info@fcmna.com

20190329

Phone: 708-937-3895 Website: www.fcmna.com

FCM 4000

High-volume Aqueous Cleaning for Aftertreatment Systems

FCM-4000 BAKE & BLOW

(Aqueous Flow) (Heat & Compressed Air)

Process Overview & Performance Comparison

Place units in oven and gradually heat

Connect units to machine using

to 1100-1300°F for specified time.

Process cleaning solution, water flow

After cooling, transfer units to

Description and vacuum to remove deposits

machines that use compressed

and residues. On-road Heavy Duty

air to "blow-out" residual ash.

Flow Restoration 97 - 98% 74 - 94%

Soot Removal Varies dramatically

High effectiveness

(PM-10) (based on operator and machine type)

Oil Residual & Cerium

High effectiveness Low effectiveness

Removal

Risk of Unit Damage Minimal risk Moderate risk

5 – 60 Minutes 12-24 Hours

Cleaning Time

(same-day service) (next day service) Off-road Heavy Duty

Applications All dieselsA Heavy Trucks Only

Cost & Operational Considerations

Backpressure tester and/or scale

FCM-4000 and

Required Machinery Thermal oven

Air compressor

Air-blast machine and compressor

Shop Footprint Minimal Significant

Utility Hook-ups Electrical only Electrical only

Labor Required Low (automated process) Medium - High

Other Advantages & Disadvantages Light & Medium Duty

FCM machines do not need a

Advantages Most commonly-recognized method

constant water supply, only

for aftertreatment cleaning

topping-off as it evaporates

Use of water to clean virtually

eliminates airborne soot and

dust in service facility

Risk of thermal shock during baking

Disadvantages Method sometimes confused Passenger Car

can damage noble metals and

with using a pressure washer

catalyst performance

Air-cleaning machines often increase

airborne dust - exposing personnel to

carcinogenic soot particles

Technical Specifications

External Dimensions 3-phase: +T (L3) + N (Neutral)

50L x 32W x 53H Inches Power Supply

(control body) 380/400V, 60HzB

Ext. Dimensions (cabin) 59L x 40W x 79H Inches Power Consumption Kw 8 / 8.5 kW

Inside Washing Capacity 39L x 24W x 71H Inches Machine Weight (cabin + control) 1,786 Pounds

Floor Load Capacity 440 Pounds (cabin) Cleaning Enclosure Material Stainless Steel

Water Tank Capacity 79.25 US Gallons Air Compressor (not included) 120 PSI | 14.5 CFM | >27 US Gal.

Included Equipment & Equipment: Pressure controller, filter restraint system, touch screen controls, printer and user manual

Accessories Accessories: T8 TAN (20 liters), adapter disk for heavy-duty truck units

A With optional universal cleaning cabin

B Other voltages are available. please contact your authorized FCM distributor for more information.

For FCM sales, customer service and post-sales support, contact:

Contact: Greg Borden Email: info@fcmna.com

20190329

Phone: 708-937-3895 Website: www.fcmna.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- FCM 4000 Flyer FCMNA 29-Mar-19 PDFDocument2 pagesFCM 4000 Flyer FCMNA 29-Mar-19 PDFcristianbrandauNo ratings yet

- FCM 4000 Flyer FCMNA 29-Mar-19 PDFDocument2 pagesFCM 4000 Flyer FCMNA 29-Mar-19 PDFcristianbrandauNo ratings yet

- Manual de Servicio Geely mr479q Mr479qa Mr481qa jl481q PDFDocument198 pagesManual de Servicio Geely mr479q Mr479qa Mr481qa jl481q PDFJose Aguero Pomachagua100% (1)

- SSP 325 - Audi A6 - 05 AssembliesDocument92 pagesSSP 325 - Audi A6 - 05 AssembliesMcGiver990No ratings yet

- Jaguar X TypeDocument124 pagesJaguar X TypecristianbrandauNo ratings yet

- 1999corvette PDFDocument376 pages1999corvette PDFcristianbrandauNo ratings yet

- Control Units MaseratiDocument48 pagesControl Units Maseraticristianbrandau100% (1)

- 1998corvette PDFDocument378 pages1998corvette PDFcristianbrandauNo ratings yet

- AL4 TransmissionDocument59 pagesAL4 Transmissionericsolver97% (62)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 050 Vacuum Pump Systems 2021Document190 pages050 Vacuum Pump Systems 2021Balamurugan ArumugamNo ratings yet

- HPE Reference Architecture For Microsoft SQL Server 2019 On HPE SimpliVity 380 Gen10 Node-A50003635enwDocument21 pagesHPE Reference Architecture For Microsoft SQL Server 2019 On HPE SimpliVity 380 Gen10 Node-A50003635enwYeraldo MarinNo ratings yet

- Lecture 10: A Design Example - Traffic Lights: The ProblemDocument6 pagesLecture 10: A Design Example - Traffic Lights: The ProblemrinobiNo ratings yet

- Indira Gandhi National Open University: Course Re-Registration Form For BTCM, 2 Year (Module-II), January 2017Document9 pagesIndira Gandhi National Open University: Course Re-Registration Form For BTCM, 2 Year (Module-II), January 2017IghfigufifiNo ratings yet

- Lubricator L26 Economist™ L27 Atomist™: Specifi CationsDocument2 pagesLubricator L26 Economist™ L27 Atomist™: Specifi CationsJacobo SuarezNo ratings yet

- ParkinsonsDocument22 pagesParkinsonsHrudhay LuckyNo ratings yet

- Parts Shutter CompletoDocument158 pagesParts Shutter CompletofaelofNo ratings yet

- EFDP Symbiosis Brochure-June 2023Document2 pagesEFDP Symbiosis Brochure-June 2023Sandeep GaikwadNo ratings yet

- ESBWR Natural Circulation Fact SheetDocument1 pageESBWR Natural Circulation Fact SheetmanuvildaNo ratings yet

- Mathematical Modeling Performance Evaluation of Electro Hydraulic Servo ActuatorsDocument24 pagesMathematical Modeling Performance Evaluation of Electro Hydraulic Servo ActuatorsZyad KaramNo ratings yet

- History of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasDocument41 pagesHistory of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasMary Ianne Therese GumabongNo ratings yet

- User-Manual-1587358 Tenda W303Document66 pagesUser-Manual-1587358 Tenda W303wasiuddinNo ratings yet

- Bharti Enterprises: Masters of Business AdministrationDocument40 pagesBharti Enterprises: Masters of Business AdministrationNaman JainNo ratings yet

- 3000 LR NSK Double - Row - Ball - BearingDocument40 pages3000 LR NSK Double - Row - Ball - BearingÇağlar AYKUTALPNo ratings yet

- Integer Linear Programming Chapter 3 OverviewDocument133 pagesInteger Linear Programming Chapter 3 OverviewNguyễnXuânAnhQuânNo ratings yet

- JP Sr. Sec. School Half Yearly Exam 2019 – 20 Class III MathsDocument2 pagesJP Sr. Sec. School Half Yearly Exam 2019 – 20 Class III MathsanandNo ratings yet

- Project Proposal: Smart Health CardDocument7 pagesProject Proposal: Smart Health CardEngr. Madeeha SaeedNo ratings yet

- SSV 2019 - Wiring Diagram - 219100978 - WD91Y019S10 - enDocument9 pagesSSV 2019 - Wiring Diagram - 219100978 - WD91Y019S10 - enAlex CachuNo ratings yet

- Working With Time - Lab Solutions Guide: Index Type Sourcetype Interesting FieldsDocument10 pagesWorking With Time - Lab Solutions Guide: Index Type Sourcetype Interesting FieldsPreet GadhiyaNo ratings yet

- 1810 (W 100 CFi - W 120 CFi - W 130 CFi) PDFDocument1 page1810 (W 100 CFi - W 120 CFi - W 130 CFi) PDFadrianNo ratings yet

- English 5 Video Script - FinalDocument12 pagesEnglish 5 Video Script - FinalEspie CosteloNo ratings yet

- ICT AssignmentDocument8 pagesICT Assignmentlij yoNo ratings yet

- DH-HAC-B2A21: 2MP HDCVI IR Bullet CameraDocument3 pagesDH-HAC-B2A21: 2MP HDCVI IR Bullet CameraDenis RodriguezNo ratings yet

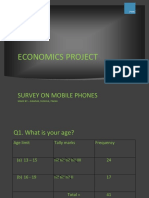

- Economics Project: Survey On Mobile PhonesDocument16 pagesEconomics Project: Survey On Mobile PhonesmanikNo ratings yet

- Star Computer Systems Limited: Internship Report ONDocument46 pagesStar Computer Systems Limited: Internship Report ONMilion NugusieNo ratings yet

- Investor Customer'S Option To Receive Payments Through: No/Ledger Folio NoDocument3 pagesInvestor Customer'S Option To Receive Payments Through: No/Ledger Folio NoAnkur Bharat VermaNo ratings yet

- Decision Support Systems: Mcgraw-Hill/IrwinDocument67 pagesDecision Support Systems: Mcgraw-Hill/IrwinAlexNo ratings yet

- AbstractDocument22 pagesAbstractSangeeta JamadarNo ratings yet

- EBS 122 Cum RCD HCMDocument187 pagesEBS 122 Cum RCD HCMmohammed akbar aliNo ratings yet

- Translation Quality Assessment of Google Translate From English To KinyarwandaDocument64 pagesTranslation Quality Assessment of Google Translate From English To Kinyarwandanelmushimiyimana77No ratings yet