Professional Documents

Culture Documents

XV-3900 FOR Gas Injection Datasheet

XV-3900 FOR Gas Injection Datasheet

Uploaded by

Raj0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

XV-3900 FOR Gas Injection datasheet.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageXV-3900 FOR Gas Injection Datasheet

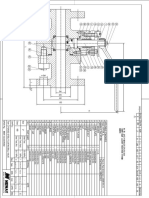

XV-3900 FOR Gas Injection Datasheet

Uploaded by

RajCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

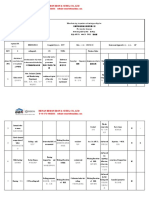

PROJECT

MANHATTAN

TITLE : DATA SHEET FOR HYDRAULIC ON-OFF VALVE PAGE NO.

S.No DESCRIPTION

1 Tag No. XV-3900

2 Line No. 8"-HG-G1-38007

3 Quantity 1 No.s

4 Line Size(ID & OD) & Line Sch. 8'' / SCH 120

General

5 Line Material CS

6 Location Gas Injection Compressor Header

7 Fluid HC GAS

8 P & ID SEPA15003-EPFD-PS-PID-001-001 ( 2 of 2)

Units Max Normal Min

9 Flow Rate MMSCFD 150 100 50

10 Design Pressure PSIG 5165

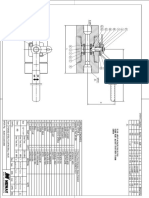

0

11 Operating Temperature F 130

12 Shut Off Pressure PSIG 5165

PROCESS

CONDITIONS 13 Density Kg/m3 & Mol. Wt. 250 &19.72

14 Viscosity cP 0.0156

15 Pressure drop (∆p) PSIG 0

16 Vapour Pressure Pv PSIG -

17 Critical Pressure Pc PSIG 671

18 Max. Allowable Sound Level(dBA) dB <85

Pipe Line Matl./Size In ASTM A106Gr C / 8" ZONE 60 Hazardous Area Classification Zone 0, Gas Group IIA, T1

19

LINE Out ASTM A106Gr C / 8" 61 Type Rotar SA Single Acting Cylinder

20 Line Insulation / Thickness NA 62 Size *

Valve Body 63 Effective Area *

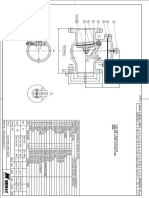

21 Type Ball 64 On/Off or Modulating ON-OFF (As per EN-14382)

22 Valve Size / Port Size 8" 65 Valve Action Fail to Close

23 Body Material ASTM A216 WCB ACTUATOR 66 Max. Allowable Pressure *

24 End Connection Flanged 67 Min. Pressure Required *

25 Flange Face Finish ASME B16.5,8 INCH / 2500 / RTJ 68 Actuator Orientation *

VALVE BODY /

BONNET / Bonnet 69 Hand wheel Not Required

WETTED PARTS

26 Type of Bonnet * 70 Make & Model No. *

27 Bonnet Material * 71 Field Indication ( Open / Close) Required

Wetted Parts 72 Type 3/2 Way Direct operated

28 Ball Material SS 316/* 73 Power Supply 24 VDC

29 Stem Material SS 316/* 74 Material Body / Internals SS316

30 Make & Model No. * 75 Pnumatic Connection 1/2'' NPT(F)

31 Rated Travel * 76 Output Signal *

32 Characteristic ON - OFF 77 Available Air Pressure Max 12 Bar

33 Balanced / Unbalanced * 78 Available Air Pressure Min 4 Bar

34 Rated CV * 79 Pnumatic Connection 1/2'' NPT(F)

35 Cv at Min / Norm / Max * 80 Tube Size & Material 1/2'' OD SS316, Swagelock

36 % Open Min / Norm / Max * SOV 81 Tube Fitting Material Swagelock

TRIM 37 Trim Material SS316 82 Cable Entry M20 x 1.5

38 Seat Material SS 316 83 Coil Insulation Class *

39 Plug Material SS 316 84 Manual Override Required

40 Stem Material SS 316 85 Enclosure Class IP 66

41 Cage / Guide Material SS 316 86 Explosion Protection Ex d (Flame Proof)

42 Valve body test As per 2500# ANSI std. 87 Housing & Mounting Dicast Aluminium , Side Mounted

43 ANSI Leakage Class ANSI/FCI 70.2,Class IV 88 Manufacturer *

44 Type Mechanical Limit Switch 89 Fusible Plug Required

45 Quantity, Open / Close 2 No's For Close / Open 90 Model No *

46 Contact Rating 24 VDC, 5A ESD 91 Make *

LIMIT SWITCHES

47 Enclosure Class & Protection IP 67, Ex d

48 Cable Entry 2 No's, M20 x 1.5

49 Manufacturer & Model No *

51 Quantity 1 No's

52 Filter & Specification Required / 5 Micron Size

53 Gauges 2'' Dial Size

54 Inlet Connection 1/2'' NPT(F)

AIR FILTER 55 Inlet Pressure 4-12 bar

REGULATOR

56 Drain Manual

57 Tubing SS 316

58 Manufacturer *

59 Model *

Notes: * Vendor To Specify

1 Emergency shutdown valve shall be provided with SS316 identification tag, permanently attached.

2 Ball Valve shall be firesafe .

3 Tag Plates provided should be of SS 304

4 Tubing to be 3I6 stainless steel.

5 Valve and actuator design must be suitable for installation in any direction.

6 Vendor to furnish Sizing calculations ,Valve opening atMin/Nor/Max,Possibilityof Flashing & Cavitation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bit Hydraulic e CD CalculatorDocument1 pageBit Hydraulic e CD CalculatorJeffrey HoNo ratings yet

- PW610 PWM BB3 PDFDocument6 pagesPW610 PWM BB3 PDFRajNo ratings yet

- Price. Bid: Ce For Pump S Sub.: Pri Pare and PartsDocument2 pagesPrice. Bid: Ce For Pump S Sub.: Pri Pare and PartsRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-02Document2 pagesJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-02RajNo ratings yet

- Alacrity Production Systems Limited, Nigeria: Doc No: Rev: R0 Page: 1 of 2Document2 pagesAlacrity Production Systems Limited, Nigeria: Doc No: Rev: R0 Page: 1 of 2RajNo ratings yet

- Saturn Home Appliances: 271b Ajose Adeogun Street, Victoria IslandDocument1 pageSaturn Home Appliances: 271b Ajose Adeogun Street, Victoria IslandRajNo ratings yet

- Product Certificate (Registered) : Standards Organisation of Nigeria Conformity Assessment ProgrammeDocument1 pageProduct Certificate (Registered) : Standards Organisation of Nigeria Conformity Assessment ProgrammeRajNo ratings yet

- S/N QTY Description Cost /unit Total: 2NR 2NR 2NR 3NR 3NRDocument1 pageS/N QTY Description Cost /unit Total: 2NR 2NR 2NR 3NR 3NRRajNo ratings yet

- Technical Specifications: Zoomlion Ztc800V Truck CraneDocument27 pagesTechnical Specifications: Zoomlion Ztc800V Truck CraneRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-03Document1 pageJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-03RajNo ratings yet

- WETGFDZSR 27Y英文技术规格书Document28 pagesWETGFDZSR 27Y英文技术规格书RajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-01Document2 pagesJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-01RajNo ratings yet

- 200 2BB6R V3 C40 3N662-Model PDFDocument1 page200 2BB6R V3 C40 3N662-Model PDFRajNo ratings yet

- QWETWEFEWDocument1 pageQWETWEFEWRajNo ratings yet

- Air Intake System: Systems DataDocument2 pagesAir Intake System: Systems DataRajNo ratings yet

- RWHRESFHGGRVDocument1 pageRWHRESFHGGRVRajNo ratings yet

- ZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书Document17 pagesZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书RajNo ratings yet

- Luoyang Runcheng Petrochemical Equipment Co., Ltd. Painting ProcedureDocument10 pagesLuoyang Runcheng Petrochemical Equipment Co., Ltd. Painting ProcedureRajNo ratings yet

- NO. Document No. Title of Document / DrawingDocument15 pagesNO. Document No. Title of Document / DrawingRajNo ratings yet

- 360 6S3R, C00 8 (-NRD3-VY1,) - ModelDocument1 page360 6S3R, C00 8 (-NRD3-VY1,) - ModelRajNo ratings yet

- QCP of Api5lgr.b PDFDocument8 pagesQCP of Api5lgr.b PDFRajNo ratings yet

- Valve / Actuator Sizing Summary: Quotation No: FEQ-20-60010-A-1 Customer: 纽威 Project Name: 尼日利亚项目Document6 pagesValve / Actuator Sizing Summary: Quotation No: FEQ-20-60010-A-1 Customer: 纽威 Project Name: 尼日利亚项目RajNo ratings yet

- THW444DRTFGHDocument1 pageTHW444DRTFGHRajNo ratings yet

- Henan Bebon Iron & Steel Co., LTDDocument6 pagesHenan Bebon Iron & Steel Co., LTDRajNo ratings yet

- QCP of Q235B Steel Structural PDFDocument2 pagesQCP of Q235B Steel Structural PDFRajNo ratings yet

- 02 - Calosi Surge Exploration Tests and Second Quadrant Characteristic Dynamic Modeling On High Pressure Ratio CompDocument14 pages02 - Calosi Surge Exploration Tests and Second Quadrant Characteristic Dynamic Modeling On High Pressure Ratio CompseniabenicarloNo ratings yet

- Hydraulic Power Units Vertical Mount Fixed DisplacementDocument32 pagesHydraulic Power Units Vertical Mount Fixed DisplacementSujata Roy100% (1)

- Flow of Gas in PipelinesDocument11 pagesFlow of Gas in PipelineskamelkolsiNo ratings yet

- Abrasive Perforator Rev2Document1 pageAbrasive Perforator Rev2JasonNo ratings yet

- Catálogo Técnico: Technical CatalogDocument56 pagesCatálogo Técnico: Technical CatalogBezares SANo ratings yet

- Tosaca: ENTRAC International S.A. Att. Ala BelhassenDocument3 pagesTosaca: ENTRAC International S.A. Att. Ala Belhassenichi ezzahraNo ratings yet

- Copt Manual PDFDocument79 pagesCopt Manual PDFSriram RamaswamiNo ratings yet

- Hydraulics Refersher Module PDFDocument4 pagesHydraulics Refersher Module PDFKim SomeraNo ratings yet

- Accumulator AccessoriesDocument10 pagesAccumulator AccessoriesHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Pfp-2Hphnd-M: Honda Powered PumpDocument1 pagePfp-2Hphnd-M: Honda Powered PumpFiretex Protective Technologies Pvt Ltd FiretexNo ratings yet

- Fittings Catalog 2010Document97 pagesFittings Catalog 2010aredkaNo ratings yet

- 21.FM MCQ - (SK Model) PDFDocument254 pages21.FM MCQ - (SK Model) PDFRam kumarNo ratings yet

- Manual HydraulicVentValveDocument4 pagesManual HydraulicVentValvebentsopoNo ratings yet

- Using The 9U5383 Vacuum Tester (1105) : Special InstructionDocument4 pagesUsing The 9U5383 Vacuum Tester (1105) : Special InstructionЕвгений АбрамовNo ratings yet

- Air and Gas Compressors 2 PDH PDFDocument15 pagesAir and Gas Compressors 2 PDH PDFJohn barry CorpuzNo ratings yet

- CompressorDocument35 pagesCompressoriqmalNo ratings yet

- Daily Air Compressor Inspection ChecklistDocument1 pageDaily Air Compressor Inspection Checklistarunjith rNo ratings yet

- 2acaterpillar Tamir Takimlari 2022 02 PDF - 1655288802Document10 pages2acaterpillar Tamir Takimlari 2022 02 PDF - 1655288802Rakhitha Waragoda0% (1)

- Components of Water Distribution SystemDocument4 pagesComponents of Water Distribution SystemTRISHIA JOYCENo ratings yet

- Ship Departure Checklist For Engine DepartmentDocument23 pagesShip Departure Checklist For Engine Departmentshin deiru100% (1)

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Air Compressor LubricantsDocument1 pageAir Compressor LubricantsRifki AndriyanNo ratings yet

- 6.0 Powerstroke Fuel Pressure Testing and Tips 1webDocument19 pages6.0 Powerstroke Fuel Pressure Testing and Tips 1webDavid Fuentes100% (6)

- Daf. Harga PipaDocument5 pagesDaf. Harga PipaIhwan Ukhrawi Ali50% (2)

- Orifice Plate Design - v1 - CurrentDocument8 pagesOrifice Plate Design - v1 - Currentnastyn-1No ratings yet

- Huong Dan Lap Dat Va Su Dung Van Chong Va PDFDocument4 pagesHuong Dan Lap Dat Va Su Dung Van Chong Va PDFDONGTA123No ratings yet

- Converging Nozzles & Converging-Diverging NozzlesDocument4 pagesConverging Nozzles & Converging-Diverging NozzlesSaiful ZakwanNo ratings yet

- Training Report: The Open Univeersity of Sri LankaDocument61 pagesTraining Report: The Open Univeersity of Sri LankaJanaka ChathurangaNo ratings yet

- Product Catalogue 2021/22: Your Solution Partner 1978Document12 pagesProduct Catalogue 2021/22: Your Solution Partner 1978BaselNo ratings yet