Professional Documents

Culture Documents

14b8d1f1b344aeBARRIERTA L 55 1 2 3

Uploaded by

Shaleh AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14b8d1f1b344aeBARRIERTA L 55 1 2 3

Uploaded by

Shaleh AhmadCopyright:

Available Formats

BARRIERTA L 55/0; L 55/1; L 55/2; L 55/3

High-temperature and long-term lubricants

Description: Application notes:

BARRIERTA L 55/0; L 55/1;

BARRIERTA L 55/0/1/2/3 make up a To ensure long service life, bearings

L 55/2; L 55/3

synthetic high-temperature lubricating should be equipped with seals or caps.

grease series based on perfluorinated For an optimal lubricating effect, we

recommend cleaning the friction point

• Lubricants for rolling and plain

polyether oil and PTFE. It can be used bearings, slideways

for temperatures up to 260 °C. The low with Klüberalfa XZ 3-1 or white spirit

evaporation rate ensures a long service 180/210 prior to first-time lubrication • Wide service temperature range

life and long relubrication intervals. by BARRIERTA. • Low evaporation rate

Due to special additives the BARRIERTA To remove lubricants based on per-

fluorinated polyether oil, such as

• Neutral towards most

L 55 products are almost neutral towards elastomers and plastics

most elastomers and plastics and parti- BARRIERTA, use the solvent and

cularly compatible with FKM materials. cleaning agent Klüberalfa XZ 3-1. • Resistant to chemicals and

aggressive media

BARRIERTA L 55 lubricants are resis-

tant to chemicals and aggressive media Minimum shelf life: • Free of sodium nitrite

such as concentrated acids, alkaline The minimum shelf life is approx. • USDA H2 registration

solutions and organic solvents (except 60 months if the product is stored in the

for fluorinated hydrocarbon solvents, original closed container in a dry place.

strong bases, earth/alkali metals and Pack sizes:

Lewis acids). This product series is

approved by the FDA (Food and Drug 10 kg bucket

Administration) as a USDA H2 lubricant 1 kg tin

for the food processing industry. 800 g cartridge

200 g glass can

(only BARRIERTA L 55/2 and L 55/3)

Application: Product data:

BARRIERTA L 55/0 and BARRIERTA BARRIERTA BARRIERTA BARRIERTA BARRIERTA

L 55/1 are especially suitable for re- L 55/0 L 55/1 L 55/2 L 55/3

lubrication of load rollers, turn rollers Base perfluorinated polyether oil, PTFE

and chain wheel bearings in conveyors

Colour white

and rolling bearings subject to high

loads which were initially lubricated with Service temperature range*,

°C, approx. – 45 to 260 – 40 to 260 – 40 to 260 – 30 to 260

BARRIERTA L 55/2 or BARRIERTA

L 55/3. Furthermore, BARRIERTA Drop point, DIN ISO 2176;

L 55/1 can also be used for the relubri- °C not measurable

cation of grease-lubricated fabric Worked penetration,

conveyor chains in textile machinery. DIN ISO 2137, at 25 °C;

0.1 mm 355 to 385 310 to 340 265 to 295 220 to 250

BARRIERTA L 55/1 and BARRIERTA Consistency, DIN 51 818;

L 55/2 are also suitable for the lubrica- NLGI grade 0 1 2 3

tion of contacts in high-voltage switches. Density, DIN 51 757,

at 20 °C; g/cm3, approx. 1.95 1.96

BARRIERTA L 55/2 or BARRIERTA

L 55/3 should be used for long-term or Base oil viscosity,

lifetime lubrication of rolling and plain DIN 51 562

at 40 °C, mm2/s, approx. 390 to 440

bearings subject to high temperatures, at 100 °C, mm2/s, approx. 35 to 45

and for slideways in

Speed factor** for deep

– electric motors groove ball bearings,

(n 3 dm), mm 3 min–1,

– driers

approx. 300.000

– calenders

– kiln carts Apparent dynamic viscosity,

Klüber viscosity grade*** M S

– tyre moulds

– fans Four ball tester welding

load, DIN 51 350 pt. 4; N > 6000 > 7000 > 8000

– baking machinery

– continuous particle board and FAG-FE 9 test run,

DIN 51 821 pt. 1/pt 2,

laminate presses n = 3000 min–1, Fa = 1500 N,

– vacuum pumps 240 °C, L50 running time, h – – 450 533

– fabric conveyor chains in textile * Service temperatures are guide values which depend on the lubricant’s composition, the intended use and the applica-

finishing machines or film stretching tion method. Lubricants change their consistency, apparent dynamic viscosity or viscosity depending on the mechano-

machinery dynamical loads, time, pressure and temperature. These changes in product characteristics may affect the function of a

component.

** Speed factors are guide values which depend on the type and size of the rolling bearing type and the local operating

conditions, which is why they have to be confirmed in tests carried out by the user in each individual case.

*** Klüber viscosity grades: EL = extra light lubricating grease; L = light lubricating grease; M = medium lubricating grease;

S = heavy lubricating grease; ES = extra heavy lubricating grease

Product information 5.386 e Edition 03.00

TVD/MST

BARRIERTA L 55/0; L 55/1; L 55/2; L 55/3

Safety Data Sheet

1.1 Product name: BARRIERTA a) L 55/0; b) L55/1; c) L 55/2; d) L 55/3 9. Physical and chemical properties

Code-No.: a) 090 035; b) 090 042; c) 090 013; d) 090 014 Form paste

30.04.1999 Colour white

Odour none

Drop point not melting, °C, DIN ISO 2176

1.2 Klüber Lubrication München KG Emergency telephone no.: Flash point none, °C (base oil)

Geisenhausenerstraße 7 ++49 - 89 7876 - 0

Flammability not applicable

D-81379 München

Tel. ++49 - 89 78 76 - 0 telephone exchange Ignition temperature not applicable

Fax: ++49 - 89 78 76 - 333 Autoflammability not applicable

Lower explosion limit not applicable

Upper explosion limit not applicable

2. Composition / information on ingredients Vapour pressure-first not applicable

Chemical characterization (preparation): Fluorinated polyether oil, PTFE Density a), b) approx. 1.95 g/cm3, 20 °C

Additional information: No hazardous ingredients c), d) approx. 1.96 g/cm3, 20 °C

Water solubility insoluble

pH value not applicable

3. Hazards identification Kinematic viscosity not applicable

No particular hazards known Further information none

10. Stability and reactivity

4. First aid measures

Conditions to avoid: None

After inhalation: Not applicable

Materials to avoid: Strong bases, alkali metals, alkaline earth metals,

After contact with skin: Wash off with soap and plenty of water Lewis acids

After contact with eyes: Rinse with plenty of water Hazardous decomposition products: > 260 °C traces of fluorinated

After ingestion: Do not induce vomiting. Obtain medical attention products

Advice to doctor: Treat symptomatically Additional information: Some materials (e.g. titanium, aluminium or

alloys of these materials) may cause lower decomposition temperatures

5. Fire-fighting measures

Suitable extinguishing media: The product itself does not burn. Use 11. Toxicological information

extinguishing measures that are appropriate to the environment The toxicological data has been taken from products of similar

Special Hazards: In case of fire the following can be released: Traces of composition

fluorinated products Acute toxicity: LD50/oral/rat = > 2 g/kg (literature data)

Special protective equipment for firefighters: Standard procedure for Chronic toxicity: None

chemical fires Human experience: Prolonged skin contact may cause skin irritation

Additional information: Water mist may be used to cool closed and/or dermatitis

containers. In the event of fire and/or explosion do not breathe fumes

12. Ecological information

6. Accidental release measures Information on elimination (persistence and degradability): Product is

insoluble in water. May be separated out mechanically in purification

Personal precautions: Not required

plants

Environmental precautions: Do not flush into surface water or sanitary

Behaviour in environmental compartments: Ecological injuries are not

sewer system

known or expected under normal use

Methods for cleaning up / taking up: Use mechanical handling equip-

Ecotoxic effects: Aquatic toxicity is unlikely due to low solubility

ment. Dispose of absorbed material in accordance with the regulations

Additional information: None Additional information: Should not be released into the environment

13. Advice on Disposal

7. Handling and storage Disposal: Can be incinerated when in compliance with local, state and

Advice on safe handling: No special handling advice required federal regulations. Contains halogene

Advice on protection against fire and explosion: No special precautions Dispose of contaminated packaging and recommended cleaning: Offer

required rinsed packaging material to local recycling facilities

Requirements on storage rooms and vessels: No special storage

conditions required

Incompatible materials: Do not store together with food 14. Transport information

GGVS / GGVE: not applicable

Further information on storage conditions: Store at room temperature in

ADN / ADNR: not applicable

the original container IMDG-Code: not applicable

ICAO / IATA-DGR: not applicable

Further information: Not classified as dangerous in the meaning of

8. Exposure controls / personal protection transport regulations

Additional advice on system design: Not applicable

Ingredients and specific control parameters: None

Respiratory protection: No special protective equipment required 15. Regulatory information

Hand protection: No special protective equipment required Labelling according to EU-guidelines: The product does not require a

hazard warning label in accordance with EC-directives/German

Eye protection: No special protective equipment required regulations on dangerous substances

Body protection: No special protective equipment required National regulations

Other protection measures: No special protective equipment required

General protection and hygiene measures: Avoid prolonged and/or

repeated contact with skin. Remove soiled or soaked clothing im- 16. Other information

mediately. Clean skin thoroughly after work; apply skin cream. Keep Issue-department of Safety Data Sheet: Chemical Documentation,

away from tobacco products Tel.: ++49 - 89 7876 - 564

The data in this product information is based on our general experience and knowledge at the time of printing and is intended to give information of possible applications to a

reader with technical experience. It constitutes neither an assurance of product properties nor does it release the user from the obligation of performing preliminary tests with the

selected product. We recommend contacting our Technical Consulting Staff to discuss your specific application. If required and possible we will be pleased to provide a sample

for testing. Klüber products are continually improved. Therefore, Klüber Lubrication reserves the right to change all the technical data in this product information at any time

without notice.

Klüber Lubrication München KG, a member of the Freudenberg group

Publisher and Copyright: Reprints, total or in part, are permitted if source Klüber Lubrication München KG

Klüber Lubrication München KG is indicated and voucher copy is forwarded. Postfach 70 10 47, D-81310 München

Tel. (0 89) 78 76-0, Telefax (0 89) 78 76-333

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Alpha Series Workshop Manual: Lpa, LPW, LPWT, Lpws and LPWGDocument109 pagesAlpha Series Workshop Manual: Lpa, LPW, LPWT, Lpws and LPWGAndres Huertas100% (1)

- Process Design in Impression Die Forging: T. Altan and M. Shirgaokar, ERC/NSM, NSM Laboratory, Ohio State UniversityDocument12 pagesProcess Design in Impression Die Forging: T. Altan and M. Shirgaokar, ERC/NSM, NSM Laboratory, Ohio State Universitypzd5ngNo ratings yet

- Tamrotor E3 and E6 Manual Book 2016Document20 pagesTamrotor E3 and E6 Manual Book 2016adrianNo ratings yet

- API Flange Bolting Torque ChartDocument8 pagesAPI Flange Bolting Torque ChartCristian Alfredo OyarzunNo ratings yet

- Session B1 Preventive, Predictive, and Corrective MaintenanceDocument38 pagesSession B1 Preventive, Predictive, and Corrective MaintenancejuneNo ratings yet

- Psa B15 3320 B enDocument13 pagesPsa B15 3320 B enhkatzerNo ratings yet

- Operations Operations Operations Operations Manual Manual Manual ManualDocument6 pagesOperations Operations Operations Operations Manual Manual Manual ManualSarah BautistaNo ratings yet

- O&M Manual For New D Series CPCB-II Diesel EngiDocument71 pagesO&M Manual For New D Series CPCB-II Diesel EngiGOPAL DIXIT67% (3)

- Cong Nghe San Xuat Dau Boi Tron PDFDocument239 pagesCong Nghe San Xuat Dau Boi Tron PDFMinh Hai RungNo ratings yet

- Grease Cross ReferenceDocument1 pageGrease Cross ReferenceJuan Perez100% (3)

- 2011 Guide To Additives & CleanersDocument14 pages2011 Guide To Additives & CleanersOilLubeNewsNo ratings yet

- 2954 3190 01 - XA (M, T, H, V) S 307-407 CD, XA (M, T, H, V) S 650-850 - ENDocument90 pages2954 3190 01 - XA (M, T, H, V) S 307-407 CD, XA (M, T, H, V) S 650-850 - ENАнтон КонновNo ratings yet

- Gadus GreaseDocument25 pagesGadus GreaseGian TeryNo ratings yet

- Astm, Sae and Iso Bolting MaterialDocument7 pagesAstm, Sae and Iso Bolting MaterialSds Mani SNo ratings yet

- National Crane 500E2 Operators ManualDocument94 pagesNational Crane 500E2 Operators ManualRoamir Alayon MalaveNo ratings yet

- Operation Manual Se5-15 PDFDocument42 pagesOperation Manual Se5-15 PDFSousaFV100% (1)

- Concept Mill 155 en Beschr ADocument74 pagesConcept Mill 155 en Beschr ATânNguyễn100% (2)

- Friction in IC EnginesDocument27 pagesFriction in IC EnginesRobinson Prabu100% (1)

- SHB 38z3 en 1000160891 2 1Document226 pagesSHB 38z3 en 1000160891 2 1Alberto100% (1)

- As-T-T014 SQR372 Engine MechanicalDocument37 pagesAs-T-T014 SQR372 Engine MechanicalJunior Edder Aguilar ApolayaNo ratings yet

- Annual Report CPIN 2019 UnlockedDocument197 pagesAnnual Report CPIN 2019 UnlockedShaleh AhmadNo ratings yet

- Engines For Stationary Generator in Normal Service in Domestic MarketDocument7 pagesEngines For Stationary Generator in Normal Service in Domestic MarketRoland sNo ratings yet

- Annual Report Cpin 2011Document172 pagesAnnual Report Cpin 2011Shaleh AhmadNo ratings yet

- Diesel Generator Sets: Cat Diesel Engines Engine SpecificationsDocument4 pagesDiesel Generator Sets: Cat Diesel Engines Engine Specificationsbankchoo 27No ratings yet

- Cpi 2017 PDFDocument196 pagesCpi 2017 PDFalvin gunadiNo ratings yet

- Understanding Apprenticeship Basics: Youth With Disabilities Entering The Workplace Through ApprenticeshipDocument4 pagesUnderstanding Apprenticeship Basics: Youth With Disabilities Entering The Workplace Through ApprenticeshipShaleh AhmadNo ratings yet

- M0743-109000 Barrierta L55 2Document4 pagesM0743-109000 Barrierta L55 2Moustafa HelmyNo ratings yet

- Trafoindo Catalogue Oil Immersed Transformers PDFDocument2 pagesTrafoindo Catalogue Oil Immersed Transformers PDFShaleh AhmadNo ratings yet

- (English) SDS Grease Pertamina WR-NLDocument13 pages(English) SDS Grease Pertamina WR-NLShaleh AhmadNo ratings yet

- Foa Eta 18 08Document80 pagesFoa Eta 18 08Shaleh AhmadNo ratings yet

- Installation and Maintenance of V Belt DrivesDocument28 pagesInstallation and Maintenance of V Belt DrivesGurdeep Sungh AroraNo ratings yet

- Instruction & Maintenance Manual: (Pearl Is A Brand Name of SHOW GIKEN INDUSTRIAL CO., LTD.)Document6 pagesInstruction & Maintenance Manual: (Pearl Is A Brand Name of SHOW GIKEN INDUSTRIAL CO., LTD.)Shaleh AhmadNo ratings yet

- Foa Eta 19 09Document80 pagesFoa Eta 19 09Shaleh AhmadNo ratings yet

- 539 Grease Interchange Feb10Document1 page539 Grease Interchange Feb10nata siagianNo ratings yet

- Bolt TableDocument1 pageBolt TableErebert C. CaracasNo ratings yet

- Shell Gadus S2 V220 2 (En) TDS GreaseDocument2 pagesShell Gadus S2 V220 2 (En) TDS Greasekevin_lim90No ratings yet

- mx-dc1 c7 PDFDocument10 pagesmx-dc1 c7 PDFShaleh AhmadNo ratings yet

- Staburags N 12 MF GrasaDocument2 pagesStaburags N 12 MF GrasaSergio MancillaNo ratings yet

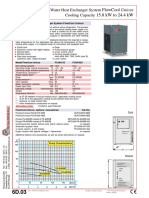

- National Lab: Water-to-Water Heat Exchanger System Cooling CapacityDocument1 pageNational Lab: Water-to-Water Heat Exchanger System Cooling CapacityShaleh AhmadNo ratings yet

- Excel Spreadsheet in Mechanical EngineeringDocument11 pagesExcel Spreadsheet in Mechanical EngineeringShaleh AhmadNo ratings yet

- Excel Spreadsheet in Mechanical EngineeringDocument11 pagesExcel Spreadsheet in Mechanical EngineeringShaleh AhmadNo ratings yet

- Excel Spreadsheet in Mechanical EngineeringDocument11 pagesExcel Spreadsheet in Mechanical EngineeringShaleh AhmadNo ratings yet

- 6743 12784 1 SMDocument13 pages6743 12784 1 SMAdduchanNo ratings yet

- Excel Spreadsheet in Mechanical EngineeringDocument11 pagesExcel Spreadsheet in Mechanical EngineeringShaleh AhmadNo ratings yet

- Nadella - Rodamientos CombinadosDocument22 pagesNadella - Rodamientos CombinadosDj ́s Mix LiveNo ratings yet

- MACDEMIDDocument55 pagesMACDEMIDSetyohdWNo ratings yet

- Influence of Tribology On Global Energy Consumption, Costs and EmissionsDocument22 pagesInfluence of Tribology On Global Energy Consumption, Costs and EmissionsAlejandro Caceres HumireNo ratings yet

- Hyd Oil Nuto 68 MobilDocument4 pagesHyd Oil Nuto 68 MobilHaytham RedaNo ratings yet

- COGELSA Food Industry Catalogue LDDocument9 pagesCOGELSA Food Industry Catalogue LDandriyanto.wisnuNo ratings yet

- Si No Company NameDocument261 pagesSi No Company NamesalesNo ratings yet

- SIL99-2C: Service Information LetterDocument22 pagesSIL99-2C: Service Information LettersandyNo ratings yet

- Heavy Duty CatalogDocument27 pagesHeavy Duty Catalogocto widodoNo ratings yet

- Effect of Extracting Method of Coconut Oils On Tribological Properties As Bio-Based LubricantDocument10 pagesEffect of Extracting Method of Coconut Oils On Tribological Properties As Bio-Based LubricantRio Muhammad NurNo ratings yet

- LYX100 ManualDocument12 pagesLYX100 ManualEMMANo ratings yet

- SMC Rotary Union JointDocument4 pagesSMC Rotary Union JointDhairyasheel BhutkarNo ratings yet

- Rocker 400 Introduction Manual en - V2016.03 enDocument5 pagesRocker 400 Introduction Manual en - V2016.03 endayanara886No ratings yet

- Introduciton of MTM Mill and MTW Mill: We Pursue The Zenith of Technology and QualityDocument9 pagesIntroduciton of MTM Mill and MTW Mill: We Pursue The Zenith of Technology and QualityArdi NalNo ratings yet

- MODULE 7 - Helical GearDocument12 pagesMODULE 7 - Helical GearBoris PalaoNo ratings yet

- Me Lab DieselDocument13 pagesMe Lab DieselXharlene HernandezNo ratings yet