Professional Documents

Culture Documents

Control: Sliding Door System 20

Uploaded by

derbalijalelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control: Sliding Door System 20

Uploaded by

derbalijalelCopyright:

Available Formats

Control

Sliding door system 20

© Copyright agtatec AG 2011

Manufacturer Service-Hotline Distributer

agtatec ag

Allmendstrasse 24

CH-8320 Fehraltorf

Art. Nr. 102-020401135

Downloaded from www.Manualslib.com manuals search engine

Table of contents / Index

Table of contents

1. General.................................................................................................................. 5

1.1. Document identification ...................................................................................................... 5

1.2. Structure of the documentation .......................................................................................... 5

1.2.1. Overview of each chapter................................................................................................... 5

1.3. Instruction manual .............................................................................................................. 6

2. Control module STM 20 ....................................................................................... 7

2.1. Controlling elements on STM 20 ........................................................................................ 7

2.2. Type plate STM 20 ............................................................................................................. 8

2.3. Wiring diagram control module STM 20 ........................................................................... 10

3. Control module STM 20 RED/DUO.................................................................... 12

3.1. Controlling elements on STM 20 RED/DUO..................................................................... 12

3.2. Applications ...................................................................................................................... 12

3.2.1. Escape and rescue routes as RED installation ................................................................ 13

3.2.2. Heavy door leafs as DUO installation............................................................................... 13

3.3. Type plate STM 20 RED/DUO.......................................................................................... 13

3.4. Wiring diagram control module STM 20 RED/DUO.......................................................... 16

3.5. Components RED/DUO system ....................................................................................... 18

3.5.1. Overview of the additional components............................................................................ 18

4. Control module STM 21 ..................................................................................... 19

4.1. Controlling elements on STM 21 ...................................................................................... 19

4.2. Application field of control module STM 21 ...................................................................... 20

4.2.1. Typical range of applications ............................................................................................ 20

4.2.2. Unavailable applications................................................................................................... 20

4.3. Type plate STM 21 ........................................................................................................... 20

4.4. Wiring diagram control module STM 21 ........................................................................... 22

5. Control module STM 21 RED ............................................................................ 24

5.1. Controlling elements on STM 21 RED.............................................................................. 24

5.2. Applications ...................................................................................................................... 24

5.2.1. Escape and rescue routes as RED installation ................................................................ 25

5.3. Type plate STM 21 RED................................................................................................... 25

5.4. Wiring diagram control module STM 21 RED................................................................... 27

5.5. Components RED system ................................................................................................ 29

5.5.1. Overview of the additional components............................................................................ 29

6. Control module STM 22 RED/DUO.................................................................... 30

6.1. Controls on STM 22 RED/DUO ........................................................................................ 30

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 2 / 36

Downloaded from www.Manualslib.com manuals search engine

Table of contents / Index

6.2. Applications ...................................................................................................................... 31

6.2.1. Escape and rescue routes as RED installation ................................................................ 31

6.2.2. Heavy door leafs as DUO installation............................................................................... 31

6.3. Type plate STM 22 RED/DUO.......................................................................................... 31

6.4. Wiring diagram control module STM 22 DUO/RED.......................................................... 34

6.5. Components RED/DUO installations................................................................................ 36

6.5.1. Overview of the additional components............................................................................ 36

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 3 / 36

Downloaded from www.Manualslib.com manuals search engine

Table of contents / Index

Index

A I

Application field of control module STM 21 ...................... 20 Instruction manual .................................................................6

Applications ............................................................ 12, 24, 31

O

C Overview of each chapter ......................................................5

Components RED system.................................................... 29 Overview of the additional components .................. 18, 29, 36

Components RED/DUO installations.................................. 36

Components RED/DUO system .......................................... 18

Control module STM 20 ....................................................... 7 S

Control module STM 20 RED/DUO ................................... 12 Structure of the documentation..............................................5

Control module STM 21 ..................................................... 19

Control module STM 21 RED............................................. 24

Control module STM 22 RED/DUO ................................... 30 T

Controlling elements on STM 20 .......................................... 7

Controlling elements on STM 20 RED/DUO...................... 12 Type plate STM 20 ................................................................8

Controlling elements on STM 21 ........................................ 19 Type plate STM 20 RED/DUO............................................13

Controlling elements on STM 21 RED ............................... 24 Type plate STM 21 ..............................................................20

Controls on STM 22 RED/DUO ......................................... 30 Type plate STM 21 RED .....................................................25

Type plate STM 22 RED/DUO............................................31

Typical range of applications...............................................20

D

Document identification........................................................ 5 U

Unavailable applications......................................................20

E

Escape and rescue routes as RED installation ......... 13, 25, 31 W

Wiring diagram control module STM 20.............................10

G Wiring diagram control module STM 20 RED/DUO ..........16

Wiring diagram control module STM 21.............................22

General.................................................................................. 5 Wiring diagram control module STM 21 RED....................27

Wiring diagram control module STM 22 DUO/RED ..........34

H

Heavy door leafs as DUO installation ........................... 13, 31

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 4 / 36

Downloaded from www.Manualslib.com manuals search engine

Table of contents / Index

1. General

1.1. Document identification

Name: B6_Control_SYS20_EN_V1.3.doc

Version: V1.3

Serial no.: 102-020401135

1.2. Structure of the documentation

The documentation of the system 20 is divided into different manuals, in order to reduce file size

and to simplify the handling.

The structure of the document is as follows (B1 =book 1):

B1_General

B2_Assembly STA

B3_Assembly TSA

B4_Assembly TOS

B5_Options

B6_Control

B7_Commissioning

B8_Annex

B9_Assembly and Start-Up FTA/FBO

1.2.1. Overview of each chapter

Chapter Content

B1_General General

Safety instructions

Preparations

Technical data

General plans

B2_Assembly STA General

Installation drive module D-STA/E-STA

Installing running gear D-STA/E-STA

Installing door leale D-STA/E-STA

Installation of the drive unit D-STA/E-STA

B3_Assembly TSA General

Floor tracks / Door leaf guides

Profile system D-TSA/E-TSA – Overview

Attaching and adjusting carriages

Installing slow running plane D-TSA / E-TSA

Installing fast running plane D-TSA / E-TSA

Attaching drive unit set D-TSA / E-TSA

Profile system D-TSA/E-TSA – Overview

Installing fast running plane D-TSA / E-TSA

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 5 / 36

Downloaded from www.Manualslib.com manuals search engine

General 1

B4_Assembly TOS General

TOS installations – for escape and rescue routes

Mounting profile and tracks

Mounting and setting the side leaves

Locking

Electrical connections

B5_Options General

Locking

Installation of CO48

Extended function module

Battery / Accumulator

Operator casing

Fanlight

Protective screen

B6_Control General

Control module STM 20

Control module STM 20 RED / DUO

Control module STM 21

Control module STM 21 RED

Control module STM 22 RED / DUO

B7_Commissioning General

Principles for commissioning

The CAN-bus

BDE-D Operating unit

Operating instructions Easy-Programmer EPC 903

Start-Up

Commissioning of systems

Parameter explanations

B8_Annex General

Module types cladding height 200 mm

Drive module

Drawings

Article list

B9_Assembly and Start- General

Up FTA/FBO Technical Data

Elevation/drawing of header FTA/FBO

Installation FTA/FBO 20

Parameter

Options

1.3. Instruction manual

After the system installation, the instructions have to be stored in an accessible and dry place.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 6 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 2

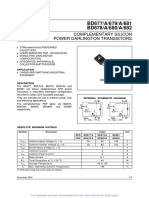

2. Control module STM 20

2.1. Controlling elements on STM 20

Control module STM 20 works with an active HIGH level. That means that a minimum of +24V is

required to activate a function. Safety functions of inputs are activated in case of interruption. 0V is

connected to the ground. This connection can be interrupted for test reasons by use of the ground

screw, located next to terminal 12. LED 2 (red) comes on.

Control module and power supply

Control module Fused power

STM 20 supply

DANGER ELECTRIC SHOCK

Electric shock, combustion, death when touching the power supply without

protection cover

Before opening the metallic cover of the power supply unit, disconnect it

from the mains

The installation may only be connected to the mains again, after the protec-

tion cover has been closed again

NOTE

The STM 20 control module has been tested after ISO standard 13849-1:2006,

category 2 PLc.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 7 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 2

2.2. Type plate STM 20

STM20

Jumper Change of function

Allows emergency stop and HEA to be connected in series:

JP1 Jumper on HEA HEA 3-2

Emergency stop 2-1

Influences motor-driven braking function in case of power

JP2 Standard / CO48 failure

(weaker with CO48)

JP3 Syst.-conditioned, internal Not visible – reserved for future applications

Change plugging to reverse rotational direction (EST-R)

JP4 Standard D-ST & EST L

– The resetting of the control is required

JP5 Standard master mode Slave – only in case of two STM

Light-emitting diode Meaning

LD1 Red control-LED For MF button S1 – blinking, when button is pressed

Ground – Red control- Must light up, if protective earth screw is withdrawn

LD2

LED Otherwise grounding is on

LD3 green + 24 V Is on, if 24 volt circuit is OK

Comes off in case of short-circuit in 24 volt

LD4 green + 32 V Is on, if system connected to mains voltage

Multifunctional key Function, after impulses have been given

1 pulse Releases an opening movement (AKI)

2 pulses Calibrating ELS

3 pulses Calibrating door parameters

4 pulses Entering programming level

5 pulses Battery emergency reaction, as long as system is discon-

nected from mains

Battery test in case of mains connection

8 pulses Loads default values of door type selected

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 8 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 2

9 pulses Back to factory settings

(afterwards an emergency stop or a reset must be actuated

within 10 seconds) The function emergency-stop with reset

can only be actuated if the INPUT/OUTPUT parameter

Emergency-Stop with Reset is active!!

14 pulses Hardware-Reset will be done after approx 12 sec.

Connector designation Connections

J1 Mains plug

J2 Terminals 25 - 28 for BDE-D

J3 Terminals 1 - 12:

Functions according to wiring diagram 102-020109934

J4 Locking device

J5 Battery

J6 Motor brake

J7 ATE motor

J8 CAN bus

J9 CAN bus plug for FPC-servicing

J10 Encoder motor

J11 Extra printed circuit board ELS (ZLP ELS)

J12-14 Reserved for future modules

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 9 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 2

2.3. Wiring diagram control module STM 20

102-020109935

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 10 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 2

102-020109935

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 11 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

3. Control module STM 20 RED/DUO

3.1. Controlling elements on STM 20 RED/DUO

Control module STM 20 RED/DUO works with an active HIGH level. That means that a minimum

of +24V is required to activate a function. Protective inputs are activated in case of interruption.

OV is connected to the ground. This connection can be interrupted for test reasons by use of the

ground screw, located next to terminal 12. LED 1 (red) comes on.

Control module and power supply

Control module Fused power

STM 20 RED/DUO supply

DANGER ELEKTRIC SHOCK

Electric shock, combustion, death when touching the power supply without

protection cover

Before opening the metallic cover of the power supply unit, disconnect it

from the mains

The installation may only be connected to the mains again, after the protec-

tion cover has been closed again.

3.2. Applications

Control module STM 20 RED/DUO is – according to the software implemented and the appropri-

ate authorization – used for the installations below.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 12 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

3.2.1. Escape and rescue routes as RED installation

NOTE

Control module STM 20 RED/DUO with RED software has been tested according

EN 13849-1:2006, category 3 PLd.

3.2.2. Heavy door leafs as DUO installation

NOTE

Control module STM 20 RED/DUO with DUO software has been tested according

EN 13849-1:2006, category 2 PLc.

ATTENTION

STM 20 RED/DUO is usually delivered with a RED software!

In the event of applications as DUO-operators (heavy doors), the appropriate

DUO-software must be installed on CPU 1 and CPU 2!

FPC flash manual installation (both CPU’s!)

3.3. Type plate STM 20 RED/DUO

STM 20 RED/DUO

Jumper Change of function

Allows emergency stop and HEA to be connected in series

JP1 Jumper on HEA HEA 3-2

Emergency stop 2-1

JP2 Not printed

JP3 Syst.-conditioned, internal Not visible – required for VRR2 (MPV 16)

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 13 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

JP4 On RED and DUO installation

D-ST & EST-R Factory setting

Fixing connecting clamp to upper part of toothed belt - Shunt

EST-L

position remains unchanged !

Standard Master opera-

JP5 Slave – only in case of two STM

tion mode

Light-emitting diodes Meaning

Ground – must light up, if protective earth screw is with-

LD1 Ground – red control-LED drawn

Otherwise grounding is on

LD2 green + 24 V Is on, if 24 volt circuit OK

Comes off in case of by-pass in 24 volt circuit

LD3 green + 32 V Is on, if system connected to mains voltage

LD4 red control-LED For MF key S1 – is blinking, if button is pressed

Multifunctional key Function, after pulses have been given

1 pulse Releases an opening movement (AKI)

2 pulses Calibrating ELS

3 pulses Calibrating door parameters

4 pulses Entering programming level

5 pulses RED

Redundancy test, if system connected to mains voltage

DUO

Battery emergency reaction, as long as system discon-

nected from mains

Battery test in case of mains connection

8 pulses Loads default values of door type selected

9 pulses Back to factory settings (afterwards emergency stop must be

actuated within 10 seconds)

14 pulses Hardware reset is performed after approx. 12 seconds

Connector designation Connections

J1 Terminals 25 – 28 for BDE-D

J2 Terminals 1 – 12:

Functions according to wiring diagram 102-020110534

J3 Terminals 13 – 17 (only used with RED applications):

With DUO-applications the terminals 13 – 17 are used as

additional inputs

Functions according to wiring diagram 102-020110534

J4 Battery 1 (used for DUO and RED applications)

J5 Battery 2 (only used for RED applications)

J6 Locking

J7 Motor brake

J8 ATE motor 1 (The DUO-application can be driven with 1 mo-

tor only)

J9 ATE motor 2

J10 CAN bus / CAN sensors

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 14 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

J11 Extra printed circuit board ELS (ZLP-ELS)

J12 Extra printed circuit board AKI (ZLP-AKI)

J13 CAN bus plug for FPC-servicing

J14 Reserved for future modules

J15 Encoder motor 1

J16 Encoder motor 2 (not necessary for DUO-applications)

J17 Reserved for future modules

J18 Reserved for future modules

NOTE Emergency stop:

Cuts the motor off the amplifier

Door can be moved manually

Only for DUO-applications

Inapplicable for RED-applications

NOTE

Emergency open:

Opens the door if not locked

Only for RED-applications

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 15 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

3.4. Wiring diagram control module STM 20 RED/DUO

102-020110534

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 16 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

102-020110534

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 17 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 20 RED/DUO 3

3.5. Components RED/DUO system

MS Power set DUO 102-020808749

Control module STM 20 RED/DUO

2 pc. ATE 20

Socket

Cable and installation material

BAT 20 RED 102-020808835

In the two above mentioned assembly kits, there are all the necessary components included for a

standard complying RED installation.

Mechanically there is no difference between a pure DUO system and a RED system (with certifica-

tion for escape and rescue routes). On a RED installation there is a special RED-software for

CPU1 and CPU2 loaded on the control module STM 20 RED/DUO. This software complies with

the standard: EN 13849-1:2006 Category 3 PLd.

NOTE

On RED system the Encoder cable must be also connected on the 2nd Motor.

3.5.1. Overview of the additional components

Basically, the components will mounted and wired analogue to a normal sliding door.

Below we refer to the necessary additional components for a RED system.

Mot 1 STM 20 RED/DUO BAT 20 RED Mot 2

NOTE

Note that STM 20 RED/DUO will be positioned next to MOT 1

(short Encorder connection cable)

The BDE – V for the night closure must be procured locally. There are 2 closing

contacts necessary.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 18 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 4

4. Control module STM 21

4.1. Controlling elements on STM 21

Control module STM 21 works with an active HIGH level. That means that a minimum of +24V is

required to activate a function. Protective inputs are activated in case of interruption. OV is con-

nected to the ground. This connection can be interrupted for test reasons by use of the ground

screw, located next to terminal 12. LED 2 (red) comes on.

Control module and power supply

Control module Fused power

STM 21 supply

DANGER ELECTRIC SHOCK

Electric shock, combustion, death if touching the power supply without protec-

tion cover

Before opening the metallic cover of the power supply unit, disconnect it

from the mains

The installation may only be connected to the mains again, after the protec-

tion cover has been closed again

NOTE

The STM 21 control module has been tested after ISO standard 13849-1:2006,

category 2 PLc.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 19 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 4

4.2. Application field of control module STM 21

NOTE

Control module STM 21 is exclusively used in combination with a weaker drive unit

featuring restricted functional requirements and limited door weight.

4.2.1. Typical range of applications

Low-cost door installations with limited possibilities of upgradability

Inside and outside applications

4.2.2. Unavailable applications

The following applications are not available with control module STM 21:

No RED installation (redundant for escape and rescue routes)

No DUO installation (heavy doors)

No TOS installation (sliding/swivelling doors)

No MPV (multipoint locking device)

No FEM1 application (interlock function)

4.3. Type plate STM 21

STM 21 DUO

Jumper Change of function

Allows emergency stop and HEA to be connected in series::

JP1 Jumper on HEA HEA 3-2

Emergency stop 2-1

Influences motor-driven braking function in case of power

JP2 Standard / CO48

failure (weaker with CO48)

JP3 Syst.-conditioned, internal Not visible – reserved for future applications

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 20 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 4

Re-plugging for monitoring devices EST R

JP4 Standard D-ST & EST L

– subsequently reboot of control necessary

Light-emitting diode Meaning

LD1 Red control-LED For multifunctional key S1 – blinks when key is pressed

LD2 Red Change plugging to reverse rotational direction (EST-R)

Then resetting STM is required

LD3 Green + 24 V Is on, if 24 volt circuit OK

Comes off in case of by-pass in 24 volt circuit

LD4 Green + 32 V Is on, if system connected to mains voltage

Multifunctional key Function, after impulses have been given

1 puls Activates an opening function (AKI)

2 pulses Calibrating ELS

3 pulses Calibrating door parameters

4 pulses Entering programming level

5 pulses Battery emergency reaction, as long as system is dis-

connected from mains

Battery test in case of mains connection

8 pulses Loads default values of door type selected

9 pulses Back to factory settings

(afterwards an emergency stop or a reset must be actuated

within 10 seconds) The function emergency-stop with reset

can only be actuated if the INPUT/OUTPUT parameter

Emergency-Stop with Reset is active!!

14 pulses Hardware reset is performed within ca. 12 seconds

Connector designation Connections

J1 Mains plug

J2 Terminals 25 – 28 für BDE-D

J3 Terminals 1 - 12:

Functions according to wiring diagram 021.110.649_D

J4 Locking device

J5 Battery

J6 Motor brake

J7 ATE Motor

J8 CAN-bus

J9 CAN bus plug for FPC-servicing

J10 Encoder motor

J11 Extra printed circuit board ELS (ZLP-ELS)

J12 - 13 Reserved for future modules

J15 Extra printed circuit board BAT (ZLP-BAT) for lead-acid bat-

tery

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 21 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 4

4.4. Wiring diagram control module STM 21

102-021110650

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 22 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 4

102-021110650

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 23 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 RED 5

5. Control module STM 21 RED

5.1. Controlling elements on STM 21 RED

Control module STM 21 RED works with an active HIGH level. That means that a minimum of

+24V is required to activate a function. Protective inputs are activated in case of interruption. OV is

connected to the ground. This connection can be interrupted for test reasons by use of the ground

screw, located next to terminal 12. LED 1 (red) comes on.

Control module and power supply

Control module Fused power

STM 21 RED supply

DANGER ELEKTRIC SHOCK

Electric shock, combustion, death when touching the power supply without

protection cover

Before opening the metallic cover of the power supply unit, disconnect it

from the mains

The installation may only be connected to the mains again, after the protec-

tion cover has been closed again.

5.2. Applications

Control module STM 21 RED is – according to the software implemented and the appropriate au-

thorization – used for the installations below.

NOTE

The installations with the control module STM 21 RED work with a reduced func-

tionality

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 24 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 RED 5

5.2.1. Escape and rescue routes as RED installation

NOTE

Control module STM 21 RED with RED software has been tested according

EN 13849-1:2006, category 3 PLd.

5.3. Type plate STM 21 RED

STM 21 RED

Jumper Change of function

Allows emergency stop and HEA to be connected in series

JP1 Jumper on HEA HEA 3-2

Emergency stop 2-1

JP2 Not printed

JP3 Syst.-conditioned, internal Not visible – required for VRR2 (MPV 16)

JP4 On RED and DUO installation

D-ST & EST-R Factory setting

Fixing connecting clamp to upper part of toothed belt - Shunt

EST-L

position remains unchanged !

Standard Master opera-

JP5 Slave – only in case of two STM

tion mode

Light-emitting diodes Meaning

Ground – must light up, if protective earth screw is with-

LD1 Ground – red control-LED drawn

Otherwise grounding is on

LD2 green + 24 V Is on, if 24 volt circuit OK

Comes off in case of by-pass in 24 volt circuit

LD3 green + 32 V Is on, if system connected to mains voltage

LD4 red control-LED For MF key S1 – is blinking, if button is pressed

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 25 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 RED 5

Multifunctional key Function, after pulses have been given

1 pulse Releases an opening movement (AKI)

2 pulses Calibrating ELS

3 pulses Calibrating door parameters

4 pulses Entering programming level

5 pulses RED

Redundancy test, if system connected to mains voltage

DUO

Battery emergency reaction, as long as system discon-

nected from mains

Battery test in case of mains connection

8 pulses Loads default values of door type selected

9 pulses Back to factory settings (afterwards emergency stop must be

actuated within 10 seconds)

14 pulses Hardware reset is performed after approx. 12 seconds

Connector designation Connections

J1 Terminals 25 – 28 for BDE-D

J2 Terminals 1 – 12:

Functions according to wiring diagram 102-020110534

J3 Terminals 13 – 17 (only used with RED applications):

Functions according to wiring diagram 102-020110534

J4 Battery 1 (used for DUO and RED applications)

J5 Battery 2 (only used for RED applications)

J6 Locking

J7 Motor brake

J8 ATE motor 1

J9 ATE motor 2

J10 CAN bus / CAN sensors

J11 Extra printed circuit board ELS (ZLP-ELS)

J12 Extra printed circuit board AKI (ZLP-AKI)

J13 CAN bus plug for FPC-servicing

J14 Reserved for future modules

J15 Encoder motor 1

J16 Encoder motor 2

J17 Reserved for future modules

J18 Reserved for future modules

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 26 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 RED 5

5.4. Wiring diagram control module STM 21 RED

102-020110534

Control module 21 RED

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 27 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 RED 5

Control module 21 RED

102-020110534

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 28 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 21 RED 5

5.5. Components RED system

MS Power set STM 21 RED 102-021808964

Control module STM 21 RED

1 pc. ATE 21 (Linix)

1 pc. ATE 21

Socket

Cable and installation material

BAT 20 RED 102-020808835

In the two above mentioned assembly kits, there are all the necessary components included for a

standard complying RED installation.

Mechanically there is no difference between a pure DUO system and a RED system (with certifica-

tion for escape and rescue routes). On a RED installation there is a special RED-software for

CPU1 and CPU2 loaded on the control module STM 21 RED. This software complies with the

standard: EN 13849-1:2006 Category 3 PLd.

NOTE

On RED system the Encoder cable must be also connected on the 2nd Motor.

5.5.1. Overview of the additional components

Basically, the components will be mounted and wired analogue to a normal sliding door.

Below we refer to the necessary additional components for a RED system.

Mot 1 STM 21 RED BAT 20 RED Mot 2

NOTE

Note that STM 21 RED will be positioned next to MOT 1

(short Encorder connection cable)

The BDE – V for the night closure must be procured locally. There are 2 closing

contacts necessary.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 29 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

6. Control module STM 22 RED/DUO

6.1. Controls on STM 22 RED/DUO

The control module STM 22 RED/DUO works with an active HIGH level. To activate the function

+24V must be present. Safety inputs will be activated by an interruption. The basic signal 0V is

connected to the protective earth. This compound could be separated with ground screw for test-

ing – LED1 (red) light.

Control module and power supply

Power supply

Control module STM 22 and mains fuse

RED/DUO

DANGER ELECTRIC SHOCK

Electrical shock, burns, death if you touch the power supply without protective

cover.

Before removing the metal cover disconnect the drive from the main.

Installation only reconnects to the network after the protection cover is

closed.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 30 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

6.2. Applications

The control module STM 22 RED/DUO will be – depending on the implemented software and cor-

responding admissions – used for the following installations.

6.2.1. Escape and rescue routes as RED installation

NOTE

The STM 22 RED/DUO control module with RED Software complies with EN

13849-1:2006, Category 3 PLd.

6.2.2. Heavy door leafs as DUO installation

NOTE

The STM 22 RED/DUO control module with RED Software complies with EN

13849-1:2006, Category 2 PLc.

ATTENTION

The STM 22 RED/DUO is usually delivered with RED soft ware!

For applications as DUO drive (heavy doors) the corresponding DUO software

on CPU1 and CPU2 need to be installed!

FPC menu Flash-programmer update manual (both CPU’s!)

6.3. Type plate STM 22 RED/DUO

STM 22 RED/DUO

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 31 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

Jumper Change of function

Allows emergency stop and HEA to be connected in series::

JP1 Jumper on HEA HEA 3-2

Emergency stop 2-1

JP2 Not equipped

JP3 Syst.-conditioned, internal Not visible – reserved for future applications

JP4 If used as RED+DUO-installation

D-ST & EST-R Factory setting

Mounting of the belt clamp at the upper belt torsion – the

EST-L

jumper-position remains unchanged!

JP5 Standard master mode Slave – only used with two STM

Light-emitting diode Meaning

Ground – Red control- Must light with distant ground screw

LD1

LED Otherwise, there is ground present

LD2 green + 24 V Is on, if 24 volt circuit OK

Comes off in case of by-pass in 24 volt circuit

LD3 green + 32 V Is on, if system connected to mains voltage

LD4 Red control-LED For multifunctional key S1 – blinks when key is pressed

Multi function key Function, after impulses have been given

1 puls Triggering the opening movement (AKI)

2 pulses Calibrating ELS

3 pulses Calibrating door parameters

4 pulses Entering programming level

5 pulses RED

Redundancy test with existing mains power

DUO

Battery emergency reaction, if no mains power available

Battery test with existing mains power

8 pulses Loads default values of door type selected

9 pulses Back to factory settings

(afterwards an emergency stop or a reset must be actuated

within 10 seconds) The function emergency-stop with reset

can only be actuated if the INPUT/OUTPUT parameter

Emergency-Stop with Reset is active!!

14 pulses Hardware reset is performed within ca. 12 seconds

Connector designation Connections

J1 Terminals 25 – 28 for BDE-D

J2 Terminals 1 - 12:

Functions according to wiring diagram 102-020110533

J3 Terminals 13 – 17 (only used with RED applications):

With DUO-applications the terminals 13 – 17 are used as

additional inputs

Functions according to wiring diagram 102-020110534

J4 Battery 1 (use for DUO- and RED-applications)

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 32 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

J5 Battery 2 (just use for RED-applications)

J6 Locking

J7 Motor brake

J8 ATE motor 1 (The DUO-application can be driven with 1 mo-

tor only)

J9 ATE Motor 2

J10 CAN-Bus / CAN Sensors

J11 Additional printed circuit board ELS (ZLP-ELS)

J12 Additional printed circuit board AKI (ZLP AKI)

J13 CAN-Bus service plug for FPC

J14 Reserved for future modules

J15 Encoder Motor 1

J16 Encoder motor 2 (not necessary for DUO-applications)

J17 Reserved for future modules

J18 Reserved for future modules

NOTE Emergency stop:

Cuts the motor off the amplifier

Door can be moved manually

Only for DUO-applications

Inapplicable for RED-applications

NOTE

Emergency open:

Opens the door if not locked

Only for RED-applications

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 33 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

6.4. Wiring diagram control module STM 22 DUO/RED

102-020110534

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 34 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

102-020110534

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 35 / 36

Downloaded from www.Manualslib.com manuals search engine

Control module STM 22 RED/DUO 6

6.5. Components RED/DUO installations

MS Power set STM22 RED/DUO 102-020401204

Control module STM 22 RED/DUO

2 pc. ATE

Cable and installation material

BAT 20 RED 102-020808835

Basically, all the components for a RED-system installation are included in both above listed as-

sembly kits.

Mechanically there is no difference between a pure DUO system and a RED system (with certifica-

tion for escape and rescue routes). On a RED installation, a special RED-software for CPU1 and

CPU2 is installed on the control module STM 22 RED/DUO. This software complies with the stan-

dards: EN 13849-1:2006 Category 3 PLd.

NOTE

On RED system the Encoder cable must be also connected on the 2. Motor.

6.5.1. Overview of the additional components

Basically, the components will be mounted and wired analogue to a normal sliding door.

Below we refer to the necessary additional components for a RED installation.

Mot 1 STM 20 RED/DUO BAT 20 RED Mot 2

NOTE

Note that STM 22 RED/DUO will be positioned next to MOT 1

(short Encorder connection cable)

The BDE – V for the night closure must be supplied locally. There are 2 closing

contacts necessary.

B6_Control_SYS20_EN_V1.3.doc Art. Nr. 102-020401135 36 / 36

Downloaded from www.Manualslib.com manuals search engine

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BD681Document6 pagesBD681derbalijalelNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- MPDFDocument10 pagesMPDFderbalijalelNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Planning Guide Sherpa Escorta 20210329 LUK - 01Document22 pagesPlanning Guide Sherpa Escorta 20210329 LUK - 01derbalijalelNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Mod. PDG-2/EV: Demonstration Panel For The Electric Testing Carried Out in Industrial BuildingsDocument2 pagesMod. PDG-2/EV: Demonstration Panel For The Electric Testing Carried Out in Industrial BuildingsderbalijalelNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Addendum To Manual SPIDO Addendum Al Manuale SPIDO Apéndice A El Manual SPIDODocument4 pagesAddendum To Manual SPIDO Addendum Al Manuale SPIDO Apéndice A El Manual SPIDOderbalijalelNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Design of Single Phase To Three Phase Static Power ConverterDocument7 pagesDesign of Single Phase To Three Phase Static Power Converterderbalijalel100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- CoreDocument7 pagesCorederbalijalelNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Certificate Matrix ISO 9001 ENDocument2 pagesCertificate Matrix ISO 9001 ENderbalijalelNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- LCDv3 33-Rev1ADocument338 pagesLCDv3 33-Rev1AderbalijalelNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- ILC Ricambi Spare Parts ITA ENG 2021Document66 pagesILC Ricambi Spare Parts ITA ENG 2021derbalijalelNo ratings yet

- GPWPLC MCDocument874 pagesGPWPLC MCderbalijalelNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 00 F 5 Meak 320Document388 pages00 F 5 Meak 320derbalijalelNo ratings yet

- Inbound 2597999576819586269Document2 pagesInbound 2597999576819586269derbalijalelNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Warning: To Prevent DamageDocument10 pagesWarning: To Prevent DamagederbalijalelNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Automatic Sliding Door: DescriptionDocument41 pagesAutomatic Sliding Door: DescriptionderbalijalelNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- AC Servo Motor & D2 Drive: Technical InformationDocument41 pagesAC Servo Motor & D2 Drive: Technical InformationHữu Thịnh ĐỗNo ratings yet

- ADV-Series Manual ENDocument406 pagesADV-Series Manual ENderbalijalel100% (1)

- Centroid Acorn CNC ControllerDocument1 pageCentroid Acorn CNC ControllerderbalijalelNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 32 Bit Risc Cpu Power: User Interface PanelsDocument28 pages32 Bit Risc Cpu Power: User Interface PanelsderbalijalelNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- IKonMac. Marking Our Way in The World The Product Range. May 2012 Log On ToDocument23 pagesIKonMac. Marking Our Way in The World The Product Range. May 2012 Log On ToderbalijalelNo ratings yet

- Sirio 3 12/24: Electronic Control Unit For Two 12/24 VDC MotorDocument16 pagesSirio 3 12/24: Electronic Control Unit For Two 12/24 VDC MotorderbalijalelNo ratings yet

- ST-IIIB User ManualDocument46 pagesST-IIIB User ManualderbalijalelNo ratings yet

- Open Source Rover: Electrical Assembly Instructions: Authors: Michael Cox, Eric Junkins, Olivia LofaroDocument17 pagesOpen Source Rover: Electrical Assembly Instructions: Authors: Michael Cox, Eric Junkins, Olivia LofaroPruthvi NinganurNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- JFET Biasing: Unit IiDocument39 pagesJFET Biasing: Unit IiAnonymous F4pTL0No ratings yet

- Audiometro 229 BDocument193 pagesAudiometro 229 BMatias Ivan Toloza MoraNo ratings yet

- STM32F429 User ManualDocument38 pagesSTM32F429 User ManualrsudjianNo ratings yet

- Hydranm2 Gea 12934a HRDocument2 pagesHydranm2 Gea 12934a HRMarcus SiaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- LESCO Test 2019Document16 pagesLESCO Test 2019Ubaid Ur Rahman QureshiNo ratings yet

- Unit 4 Input Output Devices: Structure Page NoDocument29 pagesUnit 4 Input Output Devices: Structure Page NoViraj KumarNo ratings yet

- Scheps Omni Channel PDFDocument41 pagesScheps Omni Channel PDFaaronweNo ratings yet

- Era ND6460 - SW2.7xDocument295 pagesEra ND6460 - SW2.7xjames_hayekNo ratings yet

- CCL-S / CCT / CCL-P: Programming AND Installation ManualDocument5 pagesCCL-S / CCT / CCL-P: Programming AND Installation ManualyounesNo ratings yet

- Introduction To Power QualityDocument13 pagesIntroduction To Power QualityShantanu gargNo ratings yet

- Silicon Variable Capacitance Diodes: BB639/BB659..Document8 pagesSilicon Variable Capacitance Diodes: BB639/BB659..Denis BohushNo ratings yet

- CPLD / FPGA Programming and With E-Blocks: MatrixDocument21 pagesCPLD / FPGA Programming and With E-Blocks: MatrixVahid PooreftekhariNo ratings yet

- Micro Mag PowerDocument10 pagesMicro Mag Powerjahan69No ratings yet

- High-Speed Switching Operation For A Sic Cmos and Power ModuleDocument5 pagesHigh-Speed Switching Operation For A Sic Cmos and Power ModuleDivia PercetakanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Service Manual FE-2: KV-29LS40B KV-29LS40E KV-29LS40KDocument49 pagesService Manual FE-2: KV-29LS40B KV-29LS40E KV-29LS40KGabi StrejtNo ratings yet

- Mewevig Sony Led TV Repair Guide PigowukexDocument4 pagesMewevig Sony Led TV Repair Guide PigowukexImonkNo ratings yet

- HEF4521B: 1. General DescriptionDocument17 pagesHEF4521B: 1. General DescriptionpaulpuscasuNo ratings yet

- Chapter 5 FETDocument48 pagesChapter 5 FETNeha Verma100% (1)

- Technical Reference Manual: Protect Line Distance Protection Terminal REL 521 2.5Document426 pagesTechnical Reference Manual: Protect Line Distance Protection Terminal REL 521 2.5george_cpp2No ratings yet

- P 1315389322 Audison SR2 Advanced Manual PDFDocument13 pagesP 1315389322 Audison SR2 Advanced Manual PDFSergei BaikovNo ratings yet

- HL15 Module-1 Radio Optimization Guideline, KPI OverviewDocument70 pagesHL15 Module-1 Radio Optimization Guideline, KPI OverviewprakashbaranwalNo ratings yet

- Unit Iii Vlsi Circuit Design Processes: MOS Circuits Are Formed On Four Basic LayersDocument21 pagesUnit Iii Vlsi Circuit Design Processes: MOS Circuits Are Formed On Four Basic Layers121910401008 PRATIK ADHIKARYNo ratings yet

- Plugin-Exhibitorlist 2Document12 pagesPlugin-Exhibitorlist 2bbharaniprasad0% (1)

- 2013.03.20 - Wiring - Stylea - BrochureDocument12 pages2013.03.20 - Wiring - Stylea - BrochureLeed ENNo ratings yet

- AC-DC Single Output Power ModuleDocument53 pagesAC-DC Single Output Power ModulePaulo Luís KlugeNo ratings yet

- Access RF ManualDocument24 pagesAccess RF Manualmusz730No ratings yet

- Denford Starmill PC Electrical DiagramsDocument11 pagesDenford Starmill PC Electrical Diagramsbillyb53No ratings yet

- Unit 2 High Frequency Transmission LinesDocument20 pagesUnit 2 High Frequency Transmission LinesrushitaaNo ratings yet