Professional Documents

Culture Documents

Hiab ST Cranes: PB-STRG-EN-OS - 12sid - Indd 1 2014-09-09 11.03

Uploaded by

Hector MoragaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hiab ST Cranes: PB-STRG-EN-OS - 12sid - Indd 1 2014-09-09 11.03

Uploaded by

Hector MoragaCopyright:

Available Formats

HIAB ST crAneS

PB-STRG-EN-OS_12sid.indd 1 2014-09-09 11.03

2

PB-STRG-EN-OS_12sid.indd 2 2014-09-09 11.03

InTellIgenTly deSIgned

3

PB-STRG-EN-OS_12sid.indd 3 2014-09-09 11.03

HIAB ST crAneS

Powerful hoisting, long lifetime

The ST family has been designed to offer customers

powerful hoisting cranes with long lifetimes, easy to service

and maintain and with high-quality built-in features. We use

our renowned boom design, laser cutting, high-quality steel

and hexagonal boom profile with only one weld to guarantee

our customers a high payload. You can benefit from a boom

system that is tight, powerful and durable, has compact

dimensions and a low weight.

Load-holding valve T-boom system

The load-holding valve holds the load even in The T-boom system is a telescopic stiff boom

the event of hose leakage. system. Boom extensions are extended or

retracted using internally mounted cylinders.

Continuous worm gear slewing The crane is easy to park.

The worm gear enables continuous slewing,

which means it is not necessary to turn in the Protected hydraulics

opposite direction. The mechanism is Running hydraulic hoses inside the boom

extremely reliable, thus keeping maintenance structure greatly reduces the risk of damaging

costs at a minimum. The slewing house and them. This keeps maintenance costs down.

base of the crane take up very little space, The highly wear-resistant hoses have an

leaving more room for the load. impressively long service life and are very

easy to maintain.

PB-STRG-EN-OS_12sid.indd 4 2014-09-09 11.03

Hexagonal boom profile Side supports for stability Variable line pull

The hexagonal profile ensures the boom is Side supports, fitted on each boom Variable line pull means you get a very versatile

always in perfect balance, thanks to its shape extension, stabilize the boom laterally crane. Lighter loads can be lifted rapidly using

and large support surface. The profile also and minimize play. two-line pull, but you can quickly change to

minimizes boom deflection, which reduces using up to four-line pull to lift heavy loads.

maintenance costs and increases efficiency. Two pulleys at the boom tip and three on the

hook – four-line pull – is standard.

JIC couplings Large slide pads Hoisting system

JIC couplings are standard on most HIAB Wear is reduced, since using larger pads This smooth winding hoist mechanism

cranes. They ensure easy and secure means that the surface pressure of the pad provides fast and reliable load handling.

coupling, but are still very simple to is lower. This results in lower maintenance

disconnect for service. costs.

PB-STRG-EN-OS_12sid.indd 5 2014-09-09 11.03

FeATureS And BeneFITS

HIAB ST – hoisting at its best Controlling

What do you need? The most powerful stiff boom crane you ST cranes are manually controlled with levers positioned at

can have on a two-axle truck? Or a speedy light weight? the crane base: side controls. Furthermore, the user-friendly

A crane capable of running more functions simultaneously cross controls leave you free to choose which side of the

than other cranes on the market? Check out Hiab’s HIAB ST truck you want to work from. The lever sequence is the same

crane range. To get it all. on either side of the truck. This makes the crane both easy

to work with and versatile – an ideal partner for tough jobs.

Hoisting system

The hook is fitted with three pulleys. By increasing/decreasing Over-winding alarm

the number of pulleys used, the hoisting speed/capacity can Operators will be warned by the truck horn if the winding

be varied. In other words, speed versus capacity can be limit is reached and can then take quick action to prevent

optimized for each hoisting situation. You can spend less damage caused by over-winding. This is a reliable technique

time loading and unloading, since this hoisting system is to prevent over-winding.

strong and/or fast. This allows you to increase the amount

of work performed or the number of sites visited per day. Hexagonal boom profile

The low noise level improves working conditions. Being partly The hexagonal profile used on HIAB booms is a ground-

built-in also means that the hoisting system is protected from breaking design introduced by HIAB many years ago. It

being struck both by the load and other objects. The large is now standard throughout the market for loader cranes.

drum size makes it possible to use a long wire. The innovative Even the smallest HIAB crane benefits from this design.

design also makes servicing easy and quick.

The hoisting mechanism of HIAB ST cranes has been made

the centre of attention. We have focused on the need for a

strong and durable motor, a large hoist drum and mechanism

providing the speed and capacity you need for each and

every hoisting application.

The HIAB ST family has two models

in its ST 090 range:

• ST 093-040 with two extensions and

horizontal outreach just over 8 metres.

• ST 094-040 with three extensions and

horizontal outreach just over 10 metres.

Maximum load capacity for ST 094-040 is

9.6 tonne metres.

The HIAB ST family has two models

in its ST 170 range:

• ST 173-063 with horizontal outreach close

to 10 metres and maximum load capacity

17 tonne metres.

• ST 174-063, longer reach with three exten-

sions and an outreach close to 13 metres

horizontally and nearly 14 metres vertically.

Maximum load capacity of the ST 174-063

is 16.4 tonne metres.

PB-STRG-EN-OS_12sid.indd 6 2014-09-09 11.03

PB-STRG-EN-OS_12sid.indd 7 2014-09-09 11.04

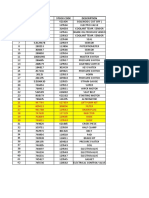

HIAB ST 090 And 170 BASIc dATA

Technical data 093-040 094-040 173-063 174-063

Max. lifting capacity (kNm) 94 94 167 161

Outreach, hydraulic extensions (m) 7.8 10 9.9 12.8

Max lifting capacity on hook load (kg) 4000 4000 6300 6300

0/3.4/1950 0/3.5/1860 0º/4.2/3260 0º/4.3/3030

Boom angle / outreach / lifting capacity, 1st boom (m/kg) 40/2.7/2980 40/2.8/2860 40º/3.1/5390 40º/3.2/5080

70/1.2/4000 70/1.3/4000 70º/1.3/6300 70º/1.3/6300

0/5.6/1100 0/5.6/1060 0º/7.0/1800 0º/7.1/1630

Boom angle / outreach / lifting capacity, 2st boom (m/kg) 40/4.3/1820 40/4.4/1740 40º/5.3/3090 40º/5.4/2880

70/1.9/2800 70/2.0/2800 70º/2.2/6000 70º/2.3/5200

0/7.8/780 0/7.8/720 0º/9.9/1250 0º/10.0/1110

Boom angle / outreach / lifting capacity, 3st boom (m/kg) 40/6.0/1300 40/6.1/1220 40º/7.5/2170 40º/7.6/2010

70/2.7/2000 70/2.7/2000 70º/3.2/4000 70º/3.3/3200

- 0/10/540 - 0º/12.8/820

Boom angle / outreach / lifting capacity, 4st boom (m/kg) - 40/7.7/960 - 40º/9.8/1520

- 70/3.5/1300 - 70º/4.2/2000

Max. lifting height above installation level (m) 9.2 11.4 11.5 13.9

Slewing angle ( ˚ ) ∞ ∞ ∞ ∞

Installation space needed (mm) 700 700 772 772

Weight, “standard” crane with stabilizer equipment (kg) 1461 1530 2200 2282

T-boom system

A telescopic T-boom system is excellent for

hoisting cranes. It is a long-life solution requiring

little maintenance. Due to the optimized

cross-sectional shape of the boom, it has

high durability and maintenance costs are

kept to a minimum. This is a cost-effective

solution providing fast load cycle speeds.

PB-STRG-EN-OS_12sid.indd 8 2014-09-09 11.04

HIAB ST 094-040

Min: 3690, Max: 10920

230 Min: 3460, Max: 10060 (Stroke: 2200x3)

m

14

2073

13

1792

12

11

10

606

9

304

8

7

6

230

374 323 5

4

3

MIN 1857, MAX 3597 FOR MEDIUM OUTRIGGER EXTENSION 2 1860 kg 1060 kg 720 kg 540 kg

MIN 2007, MAX 4700 FOR LONG OUTRIGGER EXTENSION 1

2047 FOR MEDIUM OUTRIGGER EXTENSION

2197 FOR LONG OUTRIGGER EXTENSION

0 1 2 3 4 5 6 7 8 9 10 11

HIAB ST 174-063

Min. 4250 Max. 12800

2320

2392

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 m

16

15 2000 kg

14

13

3200

12

11

2320

10

5200

9

8

7 6300

6

5 80º

4

3

0º

2

3030 1630 1110 820 kg

1

0

Disclaimer. HIAB cranes have been built to meet the highest standards of safety and service life and have been thoroughly tested. Strength calculations for

these models have been carried out in accordance with EN13001. HIAB’s certified Quality Assurance System complies with the ISO 9001.Some of the items

in our literature may be extra equipment. Certain applications may require an official permit. We reserve the right to change technical specifications without

prior notice.HIAB cranes produced for EU-countries are CE-marked and comply with the European Standard EN 12999.

PB-STRG-EN-OS_12sid.indd 9 2014-09-09 11.04

PB-STRG-EN-OS_12sid.indd 10 2014-09-09 11.04

THIS IS HIAB

The HIAB name has always been synonymous with innovation. No

other crane manufacturer invests more time, money and effort in

research, development and continuous improvement. And no other

manufacturer does more to add value to your crane. The ST cranes

are designed and equipped for high productivity and long life – an

investment that you will benefit from for many years to come.

Hiab is the global market-leading brand in on-road load handling

solutions. Customer-driven Hiab on-road load handling products

and solutions are utilised in moving goods and materials on the

road, for example in construction sites, forests, industry, waste

handling, recycling and by the defence forces.

11

PB-STRG-EN-OS_12sid.indd 11 2014-09-09 11.04

BuIlT TO PerFOrM

Hiab is the world’s leading provider of on-road load handling

equipment. Customer satisfaction is the first priority for us.

Hiab’s product range includes HIAB loader cranes,

JONSERED recycling and forestry cranes, LOGLIFT forestry

cranes, MOFFETT truck-mounted forklifts and MULTILIFT

demountables, as well as DEL, WALTCO and ZEPRO tail lifts.

www.hiab.com

Hiab is part of Cargotec. www.cargotec.com

PB-STRG-EN-OS_140909

hiab.com

PB-STRG-EN-OS_12sid.indd 12 2014-09-09 11.04

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Hiab ST 170-063 Capacity 16.4-17.0 TM: Product BrochureDocument8 pagesHiab ST 170-063 Capacity 16.4-17.0 TM: Product BrochureWin Min TunNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- HIAB 300: Capacity 30 TMDocument8 pagesHIAB 300: Capacity 30 TMNando nadandoNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Manual Grúa N65aDocument8 pagesManual Grúa N65aSaúlBorlandGalindoNo ratings yet

- ST chain hoists - Reliable hoists for demanding applicationsDocument5 pagesST chain hoists - Reliable hoists for demanding applicationsJESUSCALVILLONo ratings yet

- Compact Versatile 4 Ton HIAB 035 CraneDocument4 pagesCompact Versatile 4 Ton HIAB 035 CraneKlausNo ratings yet

- 330 ClreDocument16 pages330 ClreAnonymous xvETCQj0No ratings yet

- Hiab 800XSDocument12 pagesHiab 800XSSunny TanNo ratings yet

- XS077 Prel GBDocument2 pagesXS077 Prel GBtarnasNo ratings yet

- Eh1100 3Document7 pagesEh1100 3Alfonso BerRamNo ratings yet

- 330CL UhdDocument40 pages330CL UhdFgaier AhmedNo ratings yet

- Rolling Red Ring Stands enDocument12 pagesRolling Red Ring Stands enShubham Kumar Singh100% (2)

- Dump Truck: Nominal Payload With Standard Equipment: Maximum GMW: EngineDocument7 pagesDump Truck: Nominal Payload With Standard Equipment: Maximum GMW: Engineamir sadighiNo ratings yet

- Multipurpose Crane SystemDocument12 pagesMultipurpose Crane SystemPhu DoNo ratings yet

- PÖTTINGER TOP / TOP CDocument20 pagesPÖTTINGER TOP / TOP CdividoNo ratings yet

- Fdocuments - in Yts45e090210Document8 pagesFdocuments - in Yts45e090210William da Silva MarquesNo ratings yet

- AS 7 Wire Rope HoistDocument24 pagesAS 7 Wire Rope HoistDwiMaryantoNo ratings yet

- Spacemaster SX: Electric Wire Rope Hoists Electric Wire Rope HoistsDocument6 pagesSpacemaster SX: Electric Wire Rope Hoists Electric Wire Rope Hoistssarexcuca2010No ratings yet

- HMF CRANES FOR 70-95 TM LIFTING TASKSDocument12 pagesHMF CRANES FOR 70-95 TM LIFTING TASKSWilliam da Silva MarquesNo ratings yet

- EC700BDocument12 pagesEC700Badelmomoura100% (2)

- Material HandlingDocument15 pagesMaterial HandlingibrahimNo ratings yet

- Mini Excavator: 1035 KG 402J-05 IG84555R 5,9 KN 10 KNDocument8 pagesMini Excavator: 1035 KG 402J-05 IG84555R 5,9 KN 10 KNnqqcm6fw5nNo ratings yet

- Constant Effort SupportsDocument31 pagesConstant Effort SupportsKen SidhartaNo ratings yet

- Hiab XS 077 6-8 tm Product BrochureDocument4 pagesHiab XS 077 6-8 tm Product BrochureDavidNo ratings yet

- Polipasto YaleDocument8 pagesPolipasto YaleJose Luis Del AngelNo ratings yet

- 7562 Apfd5 1627815430tubeshor Groundworks RMD KwikformDocument12 pages7562 Apfd5 1627815430tubeshor Groundworks RMD KwikformGopu RNo ratings yet

- Hiab 035 2Document4 pagesHiab 035 2NunoNo ratings yet

- Anis Conveyor Belts Catalog en 3webDocument12 pagesAnis Conveyor Belts Catalog en 3webpios.helectorNo ratings yet

- Strike-Bar Crusher - Draft1Document5 pagesStrike-Bar Crusher - Draft1Luis CaballeroNo ratings yet

- EH5UDocument4 pagesEH5UTum BeginsNo ratings yet

- VTL SeriesDocument10 pagesVTL Seriesxojoga9602No ratings yet

- Hiab XS 477 Range 40-44 TM: Product BrochureDocument12 pagesHiab XS 477 Range 40-44 TM: Product Brochuremokhfi1976No ratings yet

- Rolling Section MillDocument12 pagesRolling Section MillRakesh SrivastavaNo ratings yet

- BSF42-5 Brochure 2021 inDocument6 pagesBSF42-5 Brochure 2021 inShubham SinghNo ratings yet

- hiab-knuckle-boom-cranes-spec-4af61bDocument8 pageshiab-knuckle-boom-cranes-spec-4af61bsistemas msgruasNo ratings yet

- PB-166CLX-EN-US L 111123 Original 76135Document8 pagesPB-166CLX-EN-US L 111123 Original 76135bharat singhNo ratings yet

- Pt. Magdatama - Wabo Modular JointDocument8 pagesPt. Magdatama - Wabo Modular JointMangisi Haryanto ParapatNo ratings yet

- Hiab Knuckle Boom Cranes Spec 7ef136Document8 pagesHiab Knuckle Boom Cranes Spec 7ef136Eduardo ServínNo ratings yet

- Case 440Document20 pagesCase 440Jairresistenciagt123No ratings yet

- ABUS GM Electric Wire Rope Hoists GuideDocument22 pagesABUS GM Electric Wire Rope Hoists GuideJose De Jesus MejiaNo ratings yet

- Dokumen - Tips Hiab Xs 166 CLX Capacity 17 TM 4 Hiab Xs 166 CLX Capacity 17 TM Front RunnersDocument8 pagesDokumen - Tips Hiab Xs 166 CLX Capacity 17 TM 4 Hiab Xs 166 CLX Capacity 17 TM Front Runnersbharat singhNo ratings yet

- Christensen 140: Surface Core Drilling RigDocument12 pagesChristensen 140: Surface Core Drilling RigAriel100% (2)

- EH5U - Spreader TélescopiqueDocument6 pagesEH5U - Spreader Télescopiquebaha100% (1)

- FD70-100NH CatalogueDocument4 pagesFD70-100NH CatalogueLui DavidNo ratings yet

- Demag slewing jibs and cranes for workplace improvementDocument22 pagesDemag slewing jibs and cranes for workplace improvementGogyNo ratings yet

- Sandvik HSI EN PDFDocument8 pagesSandvik HSI EN PDFkranthiNo ratings yet

- BestReach Telescopic Boom Conveyors Move Items Quickly and SafelyDocument2 pagesBestReach Telescopic Boom Conveyors Move Items Quickly and SafelyCristián Torres JaraNo ratings yet

- Aph Series: Aph Hydrostatic Vibratory PlatesDocument24 pagesAph Series: Aph Hydrostatic Vibratory PlatesАнтон ЛазаровNo ratings yet

- Compact and Powerful HIAB 360 E Crane Product BrochureDocument10 pagesCompact and Powerful HIAB 360 E Crane Product BrochureHagan Zhou0% (1)

- Euro Weigh-BridgeDocument12 pagesEuro Weigh-BridgeCalvinyeohNo ratings yet

- Wire Rope Hoist AustrDocument11 pagesWire Rope Hoist AustrJESUSCALVILLONo ratings yet

- Southworth CatalogDocument12 pagesSouthworth CatalogLizeth MontoyaNo ratings yet

- Paper On Modern Turnout For IPWE 2012-Ver2Document26 pagesPaper On Modern Turnout For IPWE 2012-Ver2Shipra Mishra100% (1)

- The ST Chain HoistDocument28 pagesThe ST Chain HoistVinoth SudalaiNo ratings yet

- Industrial Products BrochureDocument16 pagesIndustrial Products BrochureJames EllisNo ratings yet

- Komatsu WH613 Telescopic Handler SpecsDocument12 pagesKomatsu WH613 Telescopic Handler SpecsanzorNo ratings yet

- 2012 GrapesDocument3 pages2012 Grapesvorotyn_9479661530% (1)

- FN-03 EFN-06 Flow Controls, One Way Restrictor TypeDocument3 pagesFN-03 EFN-06 Flow Controls, One Way Restrictor TypeHector MoragaNo ratings yet

- Especificaciones Lowara C CE CK CEKDocument11 pagesEspecificaciones Lowara C CE CK CEKAlejandro MozoNo ratings yet

- Hereaus UT6 Heating and Drying OvensDocument18 pagesHereaus UT6 Heating and Drying OvensHector MoragaNo ratings yet

- Hereaus UT6 Heating and Drying Ovens - e - 12.02Document6 pagesHereaus UT6 Heating and Drying Ovens - e - 12.02Hector MoragaNo ratings yet

- Lifting PlatformsDocument12 pagesLifting PlatformsHector MoragaNo ratings yet

- Liebert Lntelecool®2 OPERATIONDocument1 pageLiebert Lntelecool®2 OPERATIONHector MoragaNo ratings yet

- Smart-UPS VT: Site Preparation and Installation ManualDocument60 pagesSmart-UPS VT: Site Preparation and Installation ManualМаксимNo ratings yet

- Line Choke - EMC FiltersDocument15 pagesLine Choke - EMC FiltersHector MoragaNo ratings yet

- Smartpower: AC Motors Users Manual Type - Side Motors (A & B Type)Document15 pagesSmartpower: AC Motors Users Manual Type - Side Motors (A & B Type)Hector MoragaNo ratings yet

- HS N55+hydraulic+schDocument1 pageHS N55+hydraulic+schHector MoragaNo ratings yet

- Rolling Door Operator ManualDocument8 pagesRolling Door Operator ManualHector MoragaNo ratings yet

- Rolling Door Operator ManualDocument8 pagesRolling Door Operator ManualHector MoragaNo ratings yet

- Type T Hydraulic Deadweight Tester: RessureDocument8 pagesType T Hydraulic Deadweight Tester: RessureHector MoragaNo ratings yet

- Om N55Document100 pagesOm N55Hector MoragaNo ratings yet

- Graco Xtreme 60 1 Airless Spray Pumps - Part Numbers and Schematics Guide - 260m540 PDFDocument24 pagesGraco Xtreme 60 1 Airless Spray Pumps - Part Numbers and Schematics Guide - 260m540 PDFomar leonNo ratings yet

- 1771 Universal IO ChassisDocument20 pages1771 Universal IO ChassisHector MoragaNo ratings yet

- Dry Running Screw CompressorsDocument16 pagesDry Running Screw CompressorsHector MoragaNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- HX2-100 2V AGM battery specsDocument2 pagesHX2-100 2V AGM battery specsdarwin gualotoNo ratings yet

- Natural Gas ProcessingDocument41 pagesNatural Gas Processingjomafeba100% (2)

- Industrial VisitDocument22 pagesIndustrial VisitInvincible GamerNo ratings yet

- In XXX Project in YYY Country VOLTE Call Failure Due To Insufficient Bearer ResourceDocument10 pagesIn XXX Project in YYY Country VOLTE Call Failure Due To Insufficient Bearer ResourceAchmad Amrulloh100% (1)

- EAO MC 61 Main-Catalogue En-469531Document104 pagesEAO MC 61 Main-Catalogue En-469531Saheer AmbadanNo ratings yet

- Axisym TutorialDocument13 pagesAxisym TutorialFredNo ratings yet

- Parallel Line Method PDFDocument80 pagesParallel Line Method PDFalbertNo ratings yet

- Man l32 44Document274 pagesMan l32 44Tran Duy NamNo ratings yet

- E060701020025 PDFDocument6 pagesE060701020025 PDFمنير أحمدNo ratings yet

- Life Cycle AssesmentDocument34 pagesLife Cycle AssesmentMayank Joshi100% (1)

- Frequency GeneratorDocument2 pagesFrequency GeneratormindchiNo ratings yet

- Oracle BOM Mass Changes - Oracle Functionality - ManojDocument29 pagesOracle BOM Mass Changes - Oracle Functionality - ManojVijay PawarNo ratings yet

- Complete Lesson 4 Assessment Task On The Maneuver of The ShipDocument2 pagesComplete Lesson 4 Assessment Task On The Maneuver of The ShipMixed VideosNo ratings yet

- Belt Conveyor BrochureDocument5 pagesBelt Conveyor BrochureMostafa Farahani100% (1)

- PMAS-Arid Agriculture University RawalpindiDocument3 pagesPMAS-Arid Agriculture University RawalpindiAli AzanNo ratings yet

- Operation Manual: Manufacturer and Designer of Marine Aids To Navigation EquipmentDocument27 pagesOperation Manual: Manufacturer and Designer of Marine Aids To Navigation EquipmentBhavin DoshiNo ratings yet

- C&I Engineering Field Cabinet SpecificationDocument6 pagesC&I Engineering Field Cabinet Specificationishu vohraNo ratings yet

- Assignment 3Document3 pagesAssignment 3Sarvani SekharNo ratings yet

- Compressor Tech May 2013Document89 pagesCompressor Tech May 2013H.a. UlicesNo ratings yet

- Cse3024 Web-Mining Eth 1.1 47 Cse3024 PDFDocument12 pagesCse3024 Web-Mining Eth 1.1 47 Cse3024 PDFAyush SoodNo ratings yet

- Structural CalculationDocument5 pagesStructural CalculationEze NonsoNo ratings yet

- Renovate Galvanized SteelDocument1 pageRenovate Galvanized SteelSam SamuelsonNo ratings yet

- Building DesignDocument68 pagesBuilding DesignRafael Lemos100% (1)

- Abraision ResistanceDocument28 pagesAbraision ResistancekattaaaaNo ratings yet

- Brochure Mush Comb PDFDocument23 pagesBrochure Mush Comb PDFDeepak SharmaNo ratings yet

- DL650K9Document187 pagesDL650K9Juan Abraham AjpopNo ratings yet

- Iowa Stormwater Management Manual Chapter 1 - Specifications Section 1E-2 - Infiltration TrenchesDocument5 pagesIowa Stormwater Management Manual Chapter 1 - Specifications Section 1E-2 - Infiltration TrenchesAnkit KodinariyaNo ratings yet

- Dual Output Ac Current - Voltage TransducerDocument7 pagesDual Output Ac Current - Voltage TransducerMagendran SurulivelNo ratings yet

- 318D L Series 2: Hydraulic ExcavatorDocument32 pages318D L Series 2: Hydraulic ExcavatorFelipe Pisklevits LaubeNo ratings yet