Professional Documents

Culture Documents

2019-08-30+-+SEQ Water Supply Drawings PDF

Uploaded by

Tim VoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2019-08-30+-+SEQ Water Supply Drawings PDF

Uploaded by

Tim VoCopyright:

Available Formats

WATER SUPPLY DRAWINGS

DRAWING INDEX - SHEET 1 OF 2

DRAWING No. DRAWING TITLE REV No.

SEQ-WAT-INDEX WATER SUPPLY DRAWING INDEX SHEET 1 OF 2 D

SEQ-WAT-INDEX WATER SUPPLY DRAWING INDEX SHEET 2 OF 2 D

SEQ-WAT-1100-1 WATER RETICULATION TYPICAL LOCALITY PLAN SHEET 1 B

SEQ-WAT-1100-2 WATER RETICULATION TYPICAL LOCALITY PLAN AND DETAILS SHEET 1 B

SEQ-WAT-1101-2 WATER RETICULATION TYPICAL DESIGN PLAN AND DETAILS SHEET 2 C

SEQ-WAT-1101-3 WATER RETICULATION TYPICAL DESIGN PLAN NOTES SHEET 3 A

SEQ-WAT-1102-1 TYPICAL MAINS CONSTRUCTION RETICULATION MAIN ARRANGEMENTS B

SEQ-WAT-1103-1 TYPICAL MAINS CONSTRUCTION DISTRIBUTION AND TRANSFER MAIN ARRANGEMENTS A

SEQ-WAT-1104-1 TYPICAL DN63 PE CUL-DE-SAC ARRANGEMENT B

SEQ-WAT-1104-2 TYPICAL FLUSHING DETAILS FOR DN63 PE MAINS B

SEQ-WAT-1105-1 TYPICAL PE WATER MAIN DETAILS C

SEQ-WAT-1105-2 TYPICAL CONNECTION TO EXISTING MAINS D

SEQ-WAT-1105-3 TYPICAL CONNECTION TO EXISTING STEEL MAINS A

SEQ-WAT-1106-1 TYPICAL PROPERTY SERVICE CONNECTION MAIN TO METER D

SEQ-WAT-1106-2 TYPICAL PROPERTY SERVICE CONNECTION MAIN TO METER C

SEQ-WAT-1107-1 TYPICAL PE PROPERTY SERVICES PE MAIN TO METER AND CONDUIT DETAILS C

SEQ-WAT-1107-2 TYPICAL COPPER PROPERTY SERVICES MAIN TO METER AND CONDUIT DETAILS C

SEQ-WAT-1107-3 TYPICAL PROPERTY SERVICES GENERAL ARRANGEMENT 20mm OR 25mm METERS B

SEQ-WAT-1108-1 PROPERTY SERVICES POTABLE SERVICE CONNECTION CONDUIT DETAILS B

SEQ-WAT-1108-2 PROPERTY SERVICES POTABLE SERVICE CONNECTION TYPICAL MAIN TO METER D

SEQ-WAT-1108-3 PROPERTY SERVICES POTABLE SERVICE CONNECTION 20mm DOMESTIC SERVICE METER BOX DETAILS D

SEQ-WAT-1109-1 WATER CONNECTIONS SINGLE, DOUBLE AND GHOST ABOVE GROUND METER A

SEQ-WAT-1109-2 WATER CONNECTIONS SUBDIVISIONAL A

SEQ-WAT-1110-1 PROPERTY SERVICES GENERAL ARRANGEMENT AND CONDUIT DETAILS A

SEQ-WAT-1110-2 PROPERTY SERVICES WATER METER AND INSTALLATION ASSEMBLY DETAILS A

SEQ-WAT-1200-1 TYPICAL SOIL CLASSIFICATION GUIDELINES AND ALLOWABLE BEARING PRESSURES FOR ANCHORS & THRUST BLOCKS A

SEQ-WAT-1200-2 EMBEDMENT & TRENCHFILL TYPICAL ARRANGEMENT C

SEQ-WAT-1201-1 STANDARD EMBEDMENT TYPICAL FLEXIBLE & RIGID PIPES A

SEQ-WAT-1202-1 TYPICAL SPECIAL EMBEDMENT INADEQUATE FOUNDATIONS REQUIRING OVER EXCAVATION & REPLACEMENT A

SEQ-WAT-1203-1 TYPICAL SPECIAL EMBEDMENT CONCRETE & STABILISED EMBEDMENT AND FLEXIBLE JOINT DETAILS B

SEQ-WAT-1204-1 TYPICAL TRENCH AND BEDDING DETAILS WITHIN EXISTING ROADS TYPE K TO N B

SEQ-WAT-1205-1 TYPICAL THRUST BLOCK DETAILS MASS CONCRETE B

SEQ-WAT-1206-1 TYPICAL THRUST AND ANCHOR BLOCKS FOR VALVES C

SEQ-WAT-1207-1 TYPICAL THRUST AND ANCHOR BLOCKS FOR VERTICAL BENDS A

SEQ-WAT-1208-1 TYPICAL RESTRAINED JOINT SYSTEM DN 100 TO DN 375 DI MAINS B

SEQ-WAT-1209-1 TYPICAL TRENCH DRAINAGE BULKHEADS AND TRENCHSTOP A

SEQ-WAT-1210-1 TYPICAL TRENCH DRAINAGE TRENCH SYSTEMS A

SEQ-WAT-1211-1 TYPICAL BURIED CROSSINGS UNDER OBSTRUCTIONS C

SEQ-WAT-1212-1 TYPICAL BURIED CROSSINGS MAJOR ROADWAYS C

SEQ-WAT-1213-1 TYPICAL BURIED CROSSINGS RAILWAYS C

SEQ-WAT-1214-1 TYPICAL BURIED CROSSINGS BORED AND JACKED ENCASING PIPE DETAILS C

SEQ-WAT-1300-1 TYPICAL VALVE AND HYDRANT IDENTIFICATION MARKERS D

SEQ-WAT-1300-2 TYPICAL VALVE AND HYDRANT IDENTIFICATION MARKER POSTS C

SEQ-WAT-1301-1 TYPICAL VALVE AND HYDRANT INSTALLATION VALVE ARRANGEMENT D

SEQ-WAT-1302-1 TYPICAL HYDRANT INSTALLATION D

SEQ-WAT-1303-1 TYPICAL VALVE AND HYDRANT INSTALLATION FUTURE EXTENSION INSTALLATION B

SEQ-WAT-1303-2 TYPICAL VALVE AND HYDRANT INSTALLATION FUTURE EXTENSION INSTALLATION B

SEQ-WAT-1304-1 TYPICAL AIR VALVE INSTALLATION FOR TRUNK MAIN B

SEQ-WAT-1305-1 TYPICAL SURFACE FITTING INSTALLATION VALVE AND HYDRANT SURFACE BOXES TRAFFICABLE AND NON-TRAFFICABLE B

SEQ-WAT-1306-1 TYPICAL SURFACE FITTING INSTALLATION VALVE AND HYDRANT SURFACE BOXES SUPPORT AND SURROUND DETAILS C

SEQ-WAT-1307-2 PE WATER MAINS TYPICAL DETAILS SCOURS C

SEQ-WAT-1307-3 TYPICAL APPURTENANCE INSTALLATION SCOUR ARRANGEMENTS B

SEQ-WAT-1308-1 TYPICAL APPURTENANCE INSTALLATION LARGE VALVE CHAMBERS B

SEQ-WAT-1308-2 TYPICAL APPURTENANCE INSTALLATION LARGE VALVE - BURIED INSTALLATION A

SEQ-WAT-1309-1 TYPICAL APPURTENANCE INSTALLATION PASSIVE PRESSURE REDUCING VALVES (PRV) A

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER WATER SUPPLY

DRAWING No. VERSION

D 30/0819 VERSION NUMBERS UPDATED

SERVICE PROVIDERS DRAWING INDEX SEQ-WAT-INDEX D

C 20/12/18 VERSION NUMBERS UPDATED

SHEET 1 OF 2

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 31/03/15 VERSION NUMBER UPDATED OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

WATER SUPPLY DRAWINGS

DRAWING INDEX - SHEET 2 OF 2

DRAWING No. DRAWING TITLE REV No.

SEQ-WAT-1309-2 TYPICAL APPURTENANCE INSTALLATION ACTIVE PRESSURE REDUCING VALVES (PRV) DN100 TO DN300 A

SEQ-WAT-1309-3 TYPICAL APPURTENANCE INSTALLATION ACTIVE PRESSURE REDUCING VALVES (PRV) DN100 AND DN150 A

SEQ-WAT-1309-4 TYPICAL APPURTENANCE INSTALLATION ACTIVE PRESSURE REDUCING VALVES (PRV) DN200 TO DN300 A

SEQ-WAT-1310-1 TYPICAL APPURTENANCE INSTALLATION ACTIVE PRESSURE REDUCING VALVES (PRV) ABOVE GROUND B

SEQ-WAT-1310-2 TYPICAL APPURTENANCE INSTALLATION ACTIVE PRESSURE REDUCING VALVES (PRV) ABOVE GROUND B

SEQ-WAT-1310-3 TYPICAL APPURTENANCE INSTALLATION ACTIVE PRESSURE REDUCING VALVES (PRV) ABOVE GROUND CABINET DETAILS B

SEQ-WAT-1310-4 TYPICAL APPURTENANCE INSTALLATION FLOWMETER DETAILS BELOW GROUND INSTALLATION A

SEQ-WAT-1311-1 AERIAL CROSSINGS TYPICAL AQUEDUCT A

SEQ-WAT-1311-2 TYPICAL AERIAL CROSSINGS AQUEDUCT PROTECTION GRILLE A

SEQ-WAT-1312-1 AERIAL CROSSINGS TYPICAL BRIDGE CROSSING CONCEPTS B

SEQ-WAT-1313-1 FLANGED JOINTS TYPICAL BOLTING DETAILS A

SEQ-WAT-1314-1 TYPICAL SMALL WATER SUPPLY PUMP STATION OR RESERVOIR DRAWING 1 OF 4 B

SEQ-WAT-1315-1 TYPICAL SMALL WATER SUPPLY PUMP STATION OR RESERVOIR DRAWING 2 OF 4 B

SEQ-WAT-1316-1 TYPICAL SMALL WATER SUPPLY PUMP STATION OR RESERVOIR DRAWING 3 OF 4 B

SEQ-WAT-1317-1 TYPICAL SMALL WATER SUPPLY PUMP STATION OR RESERVOIR DRAWING 4 OF 4 B

SEQ-WAT-1318-1 TYPICAL ARRANGEMENT MAIN SWABBING CHAMBER A

SEQ-WAT-1319-1 FALL PREVENTION COVERS AND GRATES AT WATER PUMPING STATIONS DRAWING INDEX, NOTES AND LEGEND A

GENERAL ARRANGEMENT AND OPENING/CLOSING

SEQ-WAT-1319-2 FALL PREVENTION COVERS AND GRATES AT WATER PUMPING STATIONS A

SEQUENCE

SEQ-WAT-1319-3 FALL PREVENTION COVERS AND GRATES AT WATER PUMPING STATIONS CROSS SECTIONS AND DETAILS SHEET 1 OF 2 A

SEQ-WAT-1319-4 FALL PREVENTION COVERS AND GRATES AT WATER PUMPING STATIONS CROSS SECTIONS AND DETAILS SHEET 2 OF 2 A

SEQ-WAT-1400-1 TYPICAL STEEL PIPE JOINTING BUTT WELDING OF JOINTS B

SEQ-WAT-1401-1 TYPICAL STEEL PIPE JOINTING RUBBER RING JOINT SPIGOT BAND SPECIALS B

SEQ-WAT-1402-1 TYPICAL STEEL PIPE JOINTING WELDED PIPE COLLARS B

SEQ-WAT-1403-1 TYPICAL STEEL PIPE JOINTING BENDS A

SEQ-WAT-1404-1 TYPICAL STEEL FABRICATION ACCESS OPENING FOR PIPES ≥ DN 750 A

SEQ-WAT-1405-1 TYPICAL STEEL FABRICATION DISMANTLING AND FLEXIBLE JOINTS A

SEQ-WAT-1406-1 TYPICAL STEEL FABRICATION VALVE CONNECTION AND BYPASS A

SEQ-WAT-1407-1 DI INSTALLATION VALVE BYPASS ARRANGEMENT TYPICAL DI PIPE FITTINGS A

SEQ-WAT-1408-1 TYPICAL JOINT CORROSION PROTECTION CEMENT MORTAR LINED STEEL PIPE > DN750 TO DN1200 A

SEQ-WAT-1409-1 HYDRANT INSTALLATION FITTINGS TYPICAL PE ASSEMBLIES NOMENCLATURE A

SEQ-WAT-1410-1 TYPICAL CHLORINATION TEST POINT DETAILS A

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER WATER SUPPLY

DRAWING No. VERSION

D 30/08/19 VERSION NUMBERS UPDATED

SERVICE PROVIDERS DRAWING INDEX SEQ-WAT-INDEX D

C 20/12/18 VERSION NUMBERS UPDATED

SHEET 2 OF 2

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 31/03/15 NEW DRAWINGS ADDED, VERSION NUMBER UPDATED OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

W

ANG

X

X

W US

ST

X

IVY

W

X

X

X

E

W

AD

W

X

RW

PA

ST

SITE OF WORKS PASSING W

W

W WX W WX W W

W

W

LOGA

W

N RIVE W

R

PA

C W

FELI

MIN

W

W

X CR

E

X

IF

X

W

DV

IC PALM PL T

T

M

W

O

TO

RW

W

ST

PASSING PDE

GALWAY ST

BAR AY EM

K

M AC

ST

W

IN CAD

W

R T

HA

NE I ST X

R W

BUS

W

CI W

H

X

W

RC

X

W X

X

LE

W

XW ST

DRIVE BEENLEIGH W CA

ST

DASH

W

W

W

OR

W

W

PL LD

W

W ST

FIE

W

W

AY

DVE

W

EN

LW

GA W

REGIONAL PLAN LOCALITY PLAN

NTS SCALE 1 : 2500

UBD MAP REFERENCE NO

NOTE:

FOR EACH DRAWING, A CROSS ON A SERVICE

DEVELOPMENT STAGE/AREA

PROVIDER'S NAME IN THE TITLE BLOCK

BELOW MEANS THAT THE DRAWING IS NOT

APPLICABLE TO THAT SERVICE PROVIDER

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL WATER RETICULATION

DRAWING No. VERSION

SERVICE PROVIDERS LOCALITY PLAN SEQ-WAT-1100-1 B

SHEET 1

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 01/09/15 ADDED NOTE REGARDING CROSSES ON SP OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

DARRA DEPOT ASSET REGISTER

X W

AN WATER RETICULATION

IV

OVER 8 Km RADIUS X

W GU

SS AS CONSTRUCTED RECEIVED

Y

X

T ESTATE/STAGE UPSON DOWNS

X

W

X

WX

ST

W

E SITE ADDRESS PASSING PDE, DURACK BY

AWD

X

R

PA FILE/APPLICATION 253/30/5-4321/97

PASSING UTILITY/DELEGATE

W

W

W X W W W W W

W

QUU DELEGATES APP. DATE 12.3.96

W DATE / /

CLIENT

ON MAINTENANCE DETAILS

W

W

DRAWING/PLAN No.

MIN

W W FELI MAINS DIAMETER MATERIAL LENGTH START / / FINISH / /

X CR

X

W

X

W

T T DESIGN CONST DESIGN CONST

DV

PALM PL

DN63 PE100 100.000

UTILITY/DELEGATE'S COMMENTS

W

DN100 MPVC 304.000

DICL 5.000

EM

W

MA DN150 MPVC 230.000

ST

1.000

ST

CR DN180 PE100

X T X

30.000

DN200 DICL

W

BUS (REFER TO SEQ ACCEPTED PRODUCTS &

FUNDING

W

H MATERIAL LENGTH

X

SERVICES DIAMETER

W

W MATERIALS FOR SEQ-SPS ACCEPTED MATERIALS).

X

X

W X DESIGN CONST DESIGN CONST

W

X

PRIVATE BOOSTER REQUIRED? YES/NO

W

DASH

X 81.000

W

X

X ST 20 CU

CA

HA

65.000

W

S 25 CU FUNDED BY UTILITY ( ) COUNCIL ( )

TO

W

X

X

W

R 32 CU 72.000

W

DVE

ST

W W

PL D

X METERS DIAMETER NUMBER FED GOV'T ( ) STATE ( )

W

W

FIE

20 44 DEVELOPER ( ) OTHER ( )

AY

W

EN

25 1

LW

W

32 OFFICER

GA

DATE RELEASED / /

EXAMPLE LOCALITY PLAN AS CONSTRUCTED DETAILS PLAN CUSTODIAN

SCALE 1 : 2500 SERVICE DETAILS

I CERTIFY THAT THE "AS CONSTRUCTED" DETAILS OFFICER/REC'D / /

UBD MAP REFERENCE NO SHOWN ON THIS PLAN ARE A TRUE AND ACCURATE

NO SIZE LOT NUMBERS

DATE RELEASED / /

RECORD OF THE WORKS. 1 32 mm LOT 31

12 25 mm LOTS 1-4,15-18,23-25,30.

LIVE CONNECTION(S)/PASSED(W)

ALL WATER AND SEWER CONSTRUCTION WORK SIGNED_____________ DATE_______ REFERENCE

32 20 mm LOTS 5-14,20-22,26-29,32-44,46,47.

UNDERTAKEN BY THE CONTRACTOR SHALL COMPLY NAME OF SIGNATORY (PRINT)___________

OTHER LOT 45 SERVICE SIZE AND POSITION TO DATE / /

WITH ALL APPLICABLE WORKPLACE HEALTH AND RPEQ NO._________ BE DETERMINED ON APPLICATION BY GIS CAPTURE

SAFETY LEGISLATION COMPANY NAME________________ INDIVIDUAL OWNER

JOB NUMBER

METER TO LOT 19 TO BE SUPPLIED ON

APPLICATION (AT APPLICANTS EXPENSE) OFFICER

IRRIGATION SERVICE WITH 25 mm METER DATE / /

32 mm

IN PARK NEAR LOT 44

GIS COMMENTS

NOTE : SERVICES & METERS TO LOTS 6-14

CONNECTIONS & SUBSTITUTION WILL CONNECT TO EXISTING WATER MAIN

AND SHALL BE INSTALLED BY QUU.

STREET HAWK DRIVE STREET PASSING PARADE

AT PASSING PARADE AT MINT STREET SERVICE DETAILS - FELIX COURT

LENGTH TYPE OF MAIN 150 MPVC SUBSTITUTE 200 DICL

TYPE/DIA. OF SERVICE 100 DOM.

DATE DATE FOR 225 AC PIPE TYPE 100 DICL

COMMENCED COMPLETED EACH DRAWING OF

LENGTH 30.000 TYPE OF MAIN 225 DICL THE DESIGN SHALL LENGTH OF SERVICE 2.300 m

CONTAIN THE

SIGNATURE DATE DATE CONSULTING ENGINEERS DATE COMMENCED

COMMENCED COMPLETED TITLE BLOCK,

SIGNATURE AND DATE COMPLETED

STREET HAWK DRIVE RPEQ NUMBER.

SIGNATURE SIGNATURE:

AT BUSH STREET REFER SHEET 3 SER. APPL. NO. T45689

FOR NOTES AND

LENGTH 5.000 TYPE OF MAIN 150 MPVC STREET MINT STREET ENVIRONMENTAL CHARGE:

CONDITIONS.

DATE DATE NEAR BUSH STREET

LEVELS - MIN COVER 600 mm BELOW

COMMENCED COMPLETED TEXT SHOWN IN

LENGTH 5.000 TYPE OF MAIN 100 MPVC ITALICS IS FOR

SIGNATURE DATE DATE INFORMATION ONLY.

REMARKS FOR "WSI" RECORD

COMMENCED COMPLETED

METER INSTALLATION BY CONTRACTOR

SUPPLY BY QUU.

SIGNATURE

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL WATER RETICULATION

DRAWING No. VERSION

SERVICE PROVIDERS LOCALITY PLAN AND DETAILS SEQ-WAT-1100-2 B

SHEET 1

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 14/07/15 OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

PASSING PARADE E SEQ-SPS CONNECTION

200 DICL W

225 AC L 225 X 150 F & F SKEW (15.8KN)

DIC

W W W W W W W W W W W W W W W W W W W W E

W E E E E E E E E E E E E E E E E E E E E E

00 2-225 F & S CONNECTORS

1.5

W W

E

2

E

E E E

150 F & S VALVE

00

E WE

225 APPROVED CONNECTOR

W W

1.500

E F AS CONST. REF

SWD

W

W

SERVICE PROVIDER E

.R

DE

118/81

W

W

CONNECTION & SUBSTITUTION E ST 54

RA N

CO 43

/

7 10 11 12 13

8 9

W

W

200 X 100 F & F SKEW (7.1KN) S 2

PA

14

S

E A

225 X 200 DF REDUCER

6

E

W

0

225 F & S CONNECTOR E S 1.50

W

1.

225 APPROVED CONNECTOR 150 X 22 1/2° BEND (8.6KN)

50

150 X 11 1/4° BEND (4.4KN)

100 F & S VALVE E

PROPOSED GROUP TITLE 47

0

W

CL TEST POINT

S

225 X 200 DS REDUCER 100 X 22 1/2° BEND (3.9KN)

DI

0.

E

E

E

W

100 X 11 1/4° BEND (2.0KN) TEST POINT

25

W

19 15

T

0 W

20 E 2-150 X 22 1/2° BENDS

0

100 END OF LINE (10.0KN)

G FH (8.6KN EA)

IN

E

W

5

E W

00

T

S 1.5 31

W

E 3-100 X 45° BENDS S

18

S

S 17

EET

(7.8KN EA) 46

PA AC E

25 W 2.0

0 0 W

E W

S

2 FH S

STR

100x100 P&F TEE

W

E

E

32 0.800 COVER

S

T

E

E 100 DF VALVE

IV

W SW SW

S

16

S

S

1.830 x 100 DF

W

1.500

FELIX

DR

W S

E 30 DICL PIPE

W

W

COURT

T

OPTIONAL

VC

E

100 DEADPLATE

S

T

S

S 150 X 11 1/4° BEND

E

100 S

4

W oP

63 SCOUR ASSEMBLY (METER TO BE ON

E

W W oPVC

W

(4.4KN)

E

0

E E

TEST POINT W W

0

APPLICATION) 50 FH

E

15

S

W

100 X 11 1/4° BEND W

· LEGEND REFER SEQ-GEN-1100-1

E

S

1.

S

E

W

E

E

(2.0KN) 100 X 22 1/2° BEND (3.9KN)

33

E

· ALL SCOURS SHOWN ARE TYPICALLY TO

E

E W

2-100 X 11 1/4° BENDS W

SW

5.000

E SW

29 0.400 COVER

W

(2.0KN EA)

T FH THE REQUIREMENTS OF QUU.

S

W

20 1.500

E

27

E

100 X 22 1/2° BEND

E

E 45

W

E E E

3 E (3.9KN) · FOR SPECIFIC SEQ-SP CUL-DE-SAC END

SW

E

21 100 DS VALVE W SW

A

W

S

W

T

SW

E

150 X 100 TEE FORMATS FOR SCOURING OR FLUSHING

SW

E

0.850 COVER

W

0.900 COVER (10.0KN)

SW

PALM PLACE

E

W

REFER SEQ-WAT-1104-1 AND

E

FH 1.500

W

100 X 100 TEE (10.0KN) W 63 28 SEQ-WAT-1104-2.

W

W 63 SCOUR ASSEMBLY

PE

SW

6.0

S

10 00 TEST POINT

E

E

22

W

2 0 · FOR SPECIFIC SEQ-SP MAIN LINE FORMATS

A

W E

1.

100 oPVC

W

E W

W 50 26

100 PVC W

FOR SCOURING REFER SEQ-WAT-1307-2

S

100 X 11 1/4° BEND (2.0KN) 0

1.50

25 24

2-100x11 1/4° BEND 0

23 0.750 COVER AND SEQ-WAT-1307-3

E W

(2.0 KN)

T

E

W

S

34 2.500 x 100 FL/SP DICL PIPE · FOR SPECIFIC SEQ-SP WATER SERVICE AND

E

1.000 COVER

FH 100 PUDDLE FLANGE

W

CONDUIT FORMATS REFER SEQ-WAT-1106,

S

100 DEAD PLATE B&T 2" BSP

T

W

E

T

EM

E

W

1.50 63 x 2" BSP MALE ADAPTOR

1 0 0

E

50 MA

E

1107, 1108 AND 1109 SET.

K

36 1. PARK

W

W

S

63

W

0

E

E PE1 100 DS VALVE

5.00

35 00

CO

W

100 DS VALVE

HA

W

E

FH

E

TEST POINT 37 W

100 UR OPTIONAL

E

DRAWINGS ARE INDICATIVE ONLY.

W

T

E

E

W oPV

ET

2.500 x 100 FL/SP DICL PIPE C 32CU IRRIGATION SERVICE

W

ALL ALIGNMENTS SHALL BE AS PER COUNCIL/ROAD

E

E

T

E

100 PUDDLE FLANGE WITH 25 METER

W

E

100 DEAD PLATE B&T 2" BSP E S

MINT

W

S

AUTHORITY REQUIREMENTS.

W

SW

63 x 2" BSP MALE ADAPTOR FH

SW

E W

SERVICE CONDUITS AND PROPERTY SERVICES FOR UW,

E

E W

38

S

2-100 X 11 1/4° BEND E

W

W

1.500 (2.0KN EA)

39 CoGC, LCC AND RCC AREAS TO BE PROVIDED IN

BUS SERVICE PROVIDER CONNECTION 2-100 X 45° BENDS E

W

SW

H

S

(7.8KN EA) 1.500 ACCORDANCE WITH APPLICABLE STANDARD DRAWINGS.

E

REMOVE EXISTING DEAD END

W 150 X 100 TEE

SW

C

E

W

STR 40 (10.0KN)

100 A

W INSTALL 100 APPROVED CONNECTOR

EET 0.850 COVER

W

S

W

44

E

00

W 41 DRAWING NOT PRODUCED TO SCALE, HOWEVER

W E1

150

W

W AC

P

W S SCALES SHOWN ARE INDICATIVE OF THOSE REQUIRED.

E

0

0

18

1.50

W 0.900 COVER

S

REFER SEQ-WAT-1101-3 FOR NOTES AND CONDITIONS.

S

W

AS CONST. REF

E W

207/92 43

1.

50 TEXT SHOWN IN ITALICS IS FOR INFORMATION ONLY.

SW

EW

0

S

FH 150 DS VALVE

NOTE:

W

TO BE NOTED TO BE NOTED

E

SW

42 UNITYWATER REQUIRES ALIGNMENTS OF WATER MAINS IN

ROAD RESERVES TO BE 1.5 m BOUNDARY OFFSET FOR

E

W

1.

500 TO BE NOTED

50 WATERMAINS EQUAL TO OR <DN375.

E

W

W 0

0

00

FOR W.M. >DN375, BOUNDARY OFFSET TO BE ADVISED BY

35

35

150 AC

0

W W

DN180 PE DN180 PE

5.

0

W

(OR 150 PVC) (OR 150 PVC) UNITYWATER.

AS CONST. REF SERVICE PROVIDER

CONNECTION

207/92 MARKERS FOR PROPERTY SERVICES SHALL BE IN

REMOVE DEAD END

ROCKER PIPE

1.200 X 150 MSCL MAIN INSTALL 150 APPROVED CONNECTOR ACCORDANCE WITH SEQ-WAT-1106 TO 1108.

Ø525 RCP 4-150 X 45° MSBW BENDS

EACH END MARKERS FOR WATER MAIN ROAD CROSSINGS, HYDRANTS

150 MSCL 2-150 MS LOOSE FLANGES (A.S.2129 TYPE C)

2-150 F & S CONNECTORS SITE PLAN AND VALVES SHALL BE IN ACCORDANCE WITH

150 DICL FL-FL PIPE

OPTIONAL

MILD STEEL PIPE TO BE SINTAKOTED. SCALE 1:500 SEQ-WAT-1300-1.

ALL FLANGED AND WELDED JOINTS TO BE

PROTECTED WITH DENSO WRAPPING TAPE.

EXAMPLE SECTION A (REFER TO SEQ ACCEPTED PRODUCTS & MAIN TO BE DISUSED DESIGN DRAWINGS TO CLEARLY SHOW CLEARANCES

SCALE 1:25 - MATERIALS FOR SEQ-SPS ACCEPTED MATERIALS).

STREET DIA TYPE LENGTH FOLIO/YEAR F.H. BETWEEN PROPOSED & EXISTING SERVICES. STRUCTURES

(NOT APPLICABLE TO UNITYWATER)

PASSING PARADE 225 AC 30.000 193/1954 AND OBSTRUCTIONS.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL WATER RETICULATION

DRAWING No. VERSION

SERVICE PROVIDERS DESIGN PLAN AND DETAILS SEQ-WAT-1101-2 C

C 21/09/18 ADDED NOTE TO EXAMPLE SECTION FOR UW AND MINOR CHANGES

SHEET 2

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 09/11/15 CORRECTED MINOR DRAFTING ISSUES IN SECTION A OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

TYPICAL NOTES TO BE INCLUDED WITH DRAWING SET

ENVIRONMENTAL CONDITIONS GENERAL NOTES

PLACE ON YOUR DRAWING NOTES AS RECEIVED IN YOUR APPROVAL LETTER 1. ALL WORK AND MATERIALS SHALL BE IN ACCORDANCE WITH CURRENT

FROM THE ENVIRONMENTAL REGULATOR OR MANAGER. IF NOTES RELEVANT SOUTH EAST QUEENSLAND WATER SUPPLY CODE SPECIFICATIONS AND

TO THIS ESTATE ARE NOT SPECIFIED IN YOUR APPROVAL LETTER, TYPICAL STANDARDS.

NOTES AS FOLLOWS SHALL BE PLACED ON ALL DRAWINGS. 2. UNLESS SPECIFIED OTHERWISE ALL MATERIALS AND WORK SHALL COMPLY

WITH THE RELEVANT AUSTRALIAN STANDARDS.

VEGETATION PROTECTION 3. ADOPT LIP OF KERB OR SHOULDER OF ROAD AS PERMANENT LEVEL.

4. COVER ON MAINS FROM PERMANENT LEVEL TO BE AS SHOWN IN

A. TREES LOCATED ALONG THE FOOTPATH SHALL BE, TRANSPLANTED PRIOR SEQ-WAT-1200-2.

TO CONSTRUCTION, OR REPLACED IF DESTROYED. 5. CONDUITS TO BE INSTALLED IN ACCORDANCE WITH THE STANDARD

B. WHEN WORKING WITHIN 4m OF TREES, RUBBER OR HARDWOOD GIRDLES DRAWINGS.

SHALL BE CONSTRUCTED WITH 1.8 m BATTENS CLOSELY SPACED AND 6. A WATER METER SUPPLIED AT THE DEVELOPER'S COST, IS TO BE INSTALLED

ARRANGED VERTICALLY FROM GROUND LEVEL. GIRDLES SHALL BE AT THE SERVICE POINT OF EACH LOT IN ACCORDANCE WITH THE STANDARD

STRAPPED TO TREES PRIOR TO CONSTRUCTION AND REMAIN UNTIL DRAWING FOR THE SEQ-SP.

COMPLETION. 7. ALL MATERIALS USED IN THE WORKS SHALL COMPLY WITH THE SEQ-SP's

C. TREE ROOTS SHALL BE TUNNELLED UNDER, RATHER THAN SEVERED. ACCEPTED PRODUCTS AND MATERIALS LIST OR BE APPROPRIATELY SHOWN,

IF ROOTS ARE SEVERED THE DAMAGED AREA SHALL BE TREATED WITH A LISTED AND DEFINED IN THE ENGINEERING SUBMISSION SO THAT THE

SUITABLE FUNGICIDE. CONTACT RELEVANT COUNCIL ARBORIST FOR ALTERNATIVE PRODUCT OR MATERIAL CAN BE ASSESSED AND IF

FURTHER ADVICE. APPROPRIATE, APPROVED BY THE SEQ-SP.

D. ANY TREE LOPPING REQUIRED SHOULD BE UNDERTAKEN BY AN APPROVED 8. ALL CONCRETE FOOTPATHS TO BE CLEAR OF WATER MAINS.

ARBORIST. 9. TEST/CHLORINATION POINTS TO BE INSTALLED IN ACCORDANCE WITH

STANDARD DRAWING NO.SEQ-WAT-1410-1.

SOIL 10. THE CONSTRUCTION OF THE WATER RETICULATION WORK SHOWN ON THIS

DRAWING MUST BE SUPERVISED BY AN ENGINEER WHO HAS RPEQ

A. TOPSOIL AND SUBSOIL SHALL BE STOCKPILED SEPARATELY. REGISTRATION. WORKS NOT COMPLYING WITH THIS REQUIREMENT WILL

B. CARE SHALL BE TAKEN TO PREVENT SEDIMENT FROM ENTERING THE NOT BE PERMITTED TO CONNECT TO THE RETICULATION SYSTEM.

STORMWATER SYSTEM. THIS MAY INVOLVE PLACING APPROPRIATE

SEDIMENT CONTROLS AROUND STOCKPILES.

C. ACID SULPHATE SOILS EXIST IN THE WORKS AREA. THE OUTPUTS FROM THE

RISK ASSESSMENT BASED ON THE QUEENSLAND ACID SULPHATE SOIL

TECHNICAL MANUAL REQUIRES THAT ACID SULPHATE SOILS BE

MANAGED AS FOLLOWS:

CREEK CROSSINGS

ALL ENVIRONMENT PROTECTION MEASURES SHALL BE

A. SILTATION CONTROL MEASURES SHALL BE PLACED DOWNSTREAM OF

IMPLEMENTED PRIOR TO ANY CONSTRUCTION WORK,

ANY EXCAVATION WORK.

INCLUDING CLEARING,COMMENCING.

B. APPROPRIATE SEDIMENT CONTROLS SHALL BE USED TO PREVENT

SEDIMENT FROM ENTERING THE CREEK.

C. NO SOIL SHALL BE STOCKPILED WITHIN 5 m OF THE CREEK.

REHABILITATION

A. PREDISTURBANCE SOIL PROFILES AND COMPACTION LEVELS

SHALL BE REINSTATED.

B. PREDISTURBANCE VEGETATION PATTERNS SHALL BE RESTORED.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL WATER RETICULATION

DRAWING No. VERSION

SERVICE PROVIDERS DESIGN PLAN NOTES SEQ-WAT-1101-3 A

SHEET 3

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

BOUNDARY

PROPERTY

ALIGN WITH PROPERTY

TRUNCATION POINT (UNLESS

NOTES

SPECIFIED OTHERWISE) DI PRETAPPED CONNECTORS

1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN OTHERWISE.

FOR SERVICE CONNECTIONS

2. INSTALL PIPEWORK PARALLEL TO PROPERTY BOUNDARIES.

AS REQUIRED (SEE NOTE 8)

3. MAIN, SERVICE AND METER SHALL BE INSTALLED BY THE DEVELOPER.

PROPERTY 4. WRAP FLANGES AND BOLTS, WITH A PETROLATUM TAPE SYSTEM IN

BOU ACCORDANCE WITH SEQ-WAT-1313.

NDA

FL-SOC CONNECTOR RY

5. DEFLECTION DETAILS I.E. PIPE LENGTH AND OFFSET SHALL BE

THRUST BLOCK DETAILED ON DESIGN DRAWING.

SOC-SOC BEND

DI & PVC PIPE

TAPPING BAND SEE

NOTES 8 TO 16 6. DUCTILE IRON FITTINGS MAY BE USED WITH DI & PVC PIPE.

FITTINGS SHALL BE FBE COATED AND LINED. CEMENT LINED WITH

SOC-SOC CONCENTRIC

A BITUMINOUS EXTERNAL COATING MAY BE USED WITH APPROVAL.

TAPER IF REQUIRED.

DO NOT USE PVC FITTINGS.

PERMANENT 7. PE SLEEVING, COLOURED FOR THE PRODUCT IS REQUIRED ON ALL

SLUICE VALVE WITH END BLOCK DI PIPE AND FITTINGS APPLIED IN ACCORDANCE WITH AS 3681.

THRUST RESTRAINT REFER DETAIL TWO THICKNESS REQUIRED BETWEEN FITTINGS AND THRUST

SOC-SOC TEE FOR

TO SEQ-WAT-1303-1 THRUST BLOCK SEQ-WAT-1303-1 BLOCK. REINSTATE ANY DAMAGED SLEEVING AS PER

HYDRANT

MANUFACTURER'S SPECIFICATIONS.

DICL SOC-SOC-FL TEE

FL-SOC HYDRANT FLUSHING / 8. USE PRE-TAPPED CONNECTORS ON DN100 TO DN300 NEW MAIN

WASHOUT BEND FOR DEAD END INSTALLATIONS.

MAIN ONLY SEE SEQ-WAT-1302-1 FOR QUU INSTALL 9. USE TAPPING BANDS FOR CONNECTIONS TO EXISTING MAINS.

SCOUR AFTER

TYPICAL INSTALLATION OF PVC & DI PIPES & FITTINGS HYDRANT REFER

SEQ-WAT-1303-2 PVC PIPE

BOUNDARY

PROPERTY

10. USE PRE-TAPPED CONNECTORS, REFER NOTE 8.

11. PVC PIPE SHALL NOT BE IN CONTACT WITH THRUST BLOCK

ALIGN WITH PROPERTY CONCRETE.

TRUNCATION POINT (UNLESS 12. MAXIMUM SIZE OF DRILLED HOLES FOR SERVICE CONNECTIONS IN

ELECTROFUSION

SPECIFIED OTHERWISE) PVC PIPE TO BE 30% OF DN OR 50 (LOWER VALUE TO BE USED).

COUPLING

PROPERTY 13. DI SPIGOTS SHALL NOT BE FITTED INTO PVC SOCKETS.

OR BUTT FUSION

ELECTROFUSION COUPLING BOU 14. PVC PIPE SHALL NOT BE BENT OR CURVED.

JOINT NDA

RY

OR BUTT FUSION JOINT

ELECTROFUSION, BUTT FUSION,

DI PIPE

HYDRANT TEE OR SADDLE PE100 PN16 PIPE 15. DIRECT TAPPING OF DICL PIPE IS PROHIBITED.

850 MIN TO SUIT (SEE NOTE 17) 16. ELECTRICALLY ISOLATE COPPER SERVICES FROM DI PIPE.

SURFACE FITTINGS ELECTROFUSION, BUTT

FUSION, HYDRANT TEE PE PIPE

PE TEE OR SADDLE

FOR QUU INSTALL

17. PE PIPE MAY BE COLD BENT TO MAXIMUM RADIUS AS PER POP 202,

HYDRANT ADJACENT TO

STAKES OR OTHER SOURCES OF POINT LOADS SHALL NOT BE USED

SLUICE VALVE FLANGE SCOUR TEE REFER

TO ASSIST IN BENDING THE PIPE.

OR GRIPPER OR E-F ELECTROFUSION SADDLE OR SEQ-WAT-1303-2

MECHANICAL TAPPING BAND 18. MAKE ALLOWANCE DURING CONSTRUCTION FOR EXPANSION AND

END CONNECTIONS CONTRACTION OF PE PIPE DUE TO TEMPERATURE CHANGES.

FOR SERVICE CONNECTION

PE FULL FACE FLANGE WITH 19. ELECTROFUSION AND BUTT WELDING TO BE IN ACCORDANCE

SS316 BACKING RING ELECTRO-FUSION, BUTT WITH WSA-01 (POLYETHYLENE CODE), BUTT WELDING IN TRENCHES

FUSION OR GRIPPER TEE IS NOT PERMITTED.

PE100 PN16 PIPE 20. ALL MECHANICAL COUPLINGS TO BE SELF-RESTRAINING.

ELECTROFUSION SADDLE OR MECHANICAL SCOUR VALVE SCOUR TEE

(SEE NOTE 17) 21. REFER SEQ-WAT-1409-1 FOR TYPICAL PE ARRANGEMENTS.

TAPPING BAND FOR SERVICE CONNECTION FLANGE OR E-F

END CONNECTIONS

TYPICAL INSTALLATION OF PE PIPES & FITTINGS

(FOR CUT-IN DETAILS SEE SEQ-WAT-1105-1)

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL MAINS CONSTRUCTION

DRAWING No. VERSION

SERVICE PROVIDERS RETICULATION MAIN ARRANGEMENTS SEQ-WAT-1102-1 B

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 16/09/15 OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

BYPASS SEE SEQ-WAT-1308-1

VALVE CHAMBER FOR >DN

SEQ-WAT-1406-1 AND 1407-1

750 & ALL GEARED VALVES

SOCKETED DI TEE FOR

HYDRANT OR AIR VALVE

THRUST BLOCK

THRUST BLOCK

TYPICAL PIPE SOCKET

DI PIPE

SOC-SOC-SOC TEE

FLANGED VALVE THRUST

RESTRAINT REQUIRED

DI PIPE SEE SEQ-WAT-1206-1 SOCKETED DI TEE FOR

HYDRANT OR AIR VALVE

TYPICAL INSTALLATION OF DI MAINS

BYPASS SEE SEQ-WAT-1308-1

VALVE CHAMBER FOR >DN SEQ-WAT-1406-1 AND 1407-1

750 & ALL GEARED VALVES

TEE FOR HYDRANT WELDING COLLARS OR

OR AIR VALVE BUTT WELDED JOINTS

WELDING COLLARS OR

TYPICAL PIPE JOINT

BUTT WELDED - SEE SEQ-WAT-1400-1

BUTT WELDED JOINTS TEE

RUBBER RING - TO MANUFACTURER'S REQUIREMENTS

WELDED COLLARS - SEE SEQ-WAT-1402-1

SCL PIPE

FLANGED VALVE

FABRICATED TEE FABRICATED BEND

SP-SP-SP OR FL-FL-FL SEE SEQ-WAT-1403-1

STEEL PIPE

NOTES

TYPICAL INSTALLATION OF STEEL MAINS 1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN OTHERWISE.

2. PROVIDE CORROSION PROTECTION FOR ALL MAINS AND FITTINGS IN

(THRUST BLOCKS REQUIRED WHERE NON-RESTRAINING RUBBER RING JOINTS USED)

ACCORDANCE WITH CODE.

3. SERVICE CONNECTIONS NOT PERMITTED ON DN375 AND LARGER MAINS.

(REFER SEQ-SP CONNECTIONS POLICY).

4. CONTACT SEQ-SP FOR PREFERRED TRUNK MAIN AND VALVE LAYOUT AND

DESIGN

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL MAINS CONSTRUCTION

DRAWING No. VERSION

SERVICE PROVIDERS DISTRIBUTION AND TRANSFER MAIN SEQ-WAT-1103-1 A

ARRANGEMENTS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

HYDRANT RECYCLED PLASTIC BOX

FLUSHING POINT BOX TO BE ACO CABLEMATE TYPE ALL WATER SYSTEM LIDS SHALL

WITH D.I. LID.

45 POLYCRETE PIT WITH ACO TYPE 45 GALVANISED BE COLOURED AND MARKED IN

STEEL COVER OR EVERHARD 450x450x450 PE PIT ACCORDANCE WITH THE TABLE

ON D.I. OR POLYPROP BASE WITH GALVANISED STEEL COVER OR EQUALS. ALL SHOWN ON SEQ-WAT-1300-1

HYDRANT RISER SP-FL DICL PIPE (1000 PITS ARE TO HAVE THE BASE CORED NOT CUT OFF

SOC-SOC-FL LONG)

HYDRANT TEE PE ELECTROFUSION COUPLER 150x150 CAST IN-SITU

SEE TABLE CONCRETE SURROUND

OR REDUCING COUPLER

WHEN NOT LOCATED IN

VERGE FOOTPATH

DN100 PIPE PE PIPE

EF TRANSITION COUPLING

FACTORY FITTED PUDDLE MALE BRASS BSP

FLANGE PLACED CENTRALLY PE ELECTROFUSION FULL FACE

FLANGE ADAPTOR WITH SS 316

POLY PIPE

METAL BACKING RING OR

THRUST BLOCK DETAIL

RESTRAINT FLANGE GRIPPER

REFER SEQ-WAT- 1206-1

ADAPTOR

DETAIL B

DETAIL A

FLUSHING POINT AT END OF LINE

IN-LINE CONNECTION

AND HEAD OF CUL-DE-SAC

(FOR QUU END OF LINE SEE SEQ-WAT-1104-2)

LOT F LOT G

MAXIMUM NUMBER OF

W W

PROPERTY SERVICE

W

W

LOT H CONNECTIONS TO FLUSHING POINT FITTINGS TABLE

W

W DN63 MAINS - 10 ET

LOT E

VALVE F-F COUPLING-M DUST CAP

W

1 1/2" BRASS GATE VALVE 38 mm BRASS

W

W

40 METERS FROM HYDRANT

POTABLE WITH BRASS HAND WHEEL STORZ X 1 1/2" BSP YES

PROPERTY LOT I

TO FURTHEST PROPERTY

BOUNDARY (SEE NOTE 13) (SEE NOTE 13)

W

1000

SEE DETAIL B ABOVE

W

LOT D FOR QUU END OF LINE

SEE SEQ-WAT-1104-2 NOTES

W

W

1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN OTHERWISE.

2. PIPE MATERIAL TO BE IN ACCORDANCE WITH ACCEPTED PRODUCTS AND MATERIALS LIST.

W

LOT C 3. PE ELECTROFUSION (EF) FITTINGS TO BE CLASS PN16.

DN63 PE MAIN

LOT J 4. WHERE POSSIBLE USE A SINGLE LENGTH OF PE PIPE.

W

5. DO NOT CURVE PE PIPES TO A RADIUS OF LESS THAN 25 TIMES PIPE OD.

6. BACKING FLANGES, NUTS, BOLTS AND WASHERS TO BE MANUFACTURED FROM

W

GRADE 316 STAINLESS STEEL.

LOT B PROPERTY BOUNDARY 7. THRUST BLOCKS TO BE IN ACCORDANCE WITH SEQ-WAT-1205-1.

W

8. PVC PIPE MAY BE USED AS SHROUD PIPE, CUT AS REQUIRED TO CLEAR HYDRANT FLANGE.

9. FOR HYDRANT COVERS AND SURROUNDS DETAILS SEE SEQ-WAT-1302.

W

SEE DETAIL A LOT K 10. FIT THE FLUSHING POINT VALVE IN SUCH A WAY AS TO PREVENT MOVEMENT OR

LOT A ROTATION OF THE VALVE BODY. PROVIDE A SUITABLE DUST CAP TO KEEP OUT DIRT AND

W

GRAVEL. DRILL DUST CAP WITH 4 DIA DRILL.

PROPERTY BOUNDARY PROPERTY BOUNDARY 11. FOR CONNECTION TO EXISTING MAINS SEE ALSO SEQ-WAT-1105-1.

W

ISOLATION VALVE WATER MAIN 12. TYPICAL HYDRANT PIPEWORK ASSEMBLIES ARE DETAILED IN SEQ-WAT-1302-1.

W W W W W W W W W W W W

KERB LINE 13. UNITYWATER REQUIRES STAINLESS STEEL BALL VALVE AND STAINLESS STEEL STORZ

KERB LINE

FITTING

TERMINAL END OF CUL-DE-SAC

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL

DRAWING No. VERSION

SERVICE PROVIDERS DN63 PE CUL-DE-SAC ARRANGEMENT SEQ-WAT-1104-1 B

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 25/06/18 NOTE ADDED FOR UNITYWATER CUL-DE-SAC UPDATED OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

CONCRETE TO BE PLACED BETWEEN BEND NOTES

AND UNDISTURBED WALL OF EXCAVATION

1. ALL WORK AND MATERIALS SHALL BE IN ACCORDANCE WITH CURRENT SOUTH EAST

OPTION 2

QUEENSLAND WATER SUPPLY CODE SPECIFICATIONS AND STANDARDS.

2. UNLESS SPECIFIED OTHERWISE ALL MATERIALS AND WORK SHALL COMPLY WITH THE

RELEVANT AUSTRALIAN STANDARDS.

3. DN63 POLYETHYLENE PIPES SHALL BE CLASS PN16 PE100 AND COMPLY WITH A.S.

A A LIP OF CHANNEL 4130. FITTINGS SHALL COMPLY WITH A.S. 4129.

- - 4. ALL DIMENSIONS ARE IN MILLIMETRES.

5. FLUSHING PIPE SHALL ONLY DISCHARGE INTO OPEN GRATED TYPE GULLY PITS.

6. FLUSHING PIPE SHALL BE NOMINALLY < 6.0 METRES LONG.

7. PROVIDE CHAMBER OVER 50NB GATE VALVE IN ACCORDANCE WITH STANDARD

330

NOMINAL FACE OF KERB DRAWING SEQ-WAT-1301-1.

8. CONCRETE SHALL BE CLASS N20.

9. PROVIDE A 10 kg BAG OF CONCRETE FOR PIPE SUPPORT AS SHOWN.

BACK OF KERB

10. FLUSHING PIPE SHALL BE GROUTED IN TO GULLY PIT WALL AND FINISH FLUSH WITH

90° ELBOW 63 mm THE INSIDE FACE OF THE GULLY PIT.

DN63 PE 11. THE END OF THE FLUSHING PIPE THAT DISCHARGES INTO THE GULLY PIT SHALL

COMP. x 2" B.S.P. MI FLUSHING PIPE OPTION 1 (PREFERRED) PAINTED BLUE WITH A SUITABLE HEAVY DUTY PAINT TO ASSIST IN VISUALLY

IDENTIFYING THAT THIS PIPE RELATES TO WATER RETICULATION INFRASTRUCTURE,

50NB GATE VALVE 50NB GATE VALVE RATHER THAN STORMWATER DRAINAGE INFRASTRUCTURE.

SEE NOTE 9

SEE NOTE 9 12. FOR GREENFIELD INSTALLATIONS, END OF LINES SHALL BE DESIGNED TO ENABLE

DN63 PE PIPE MAIN TO DISCHARGE INTO EXISTING OR PROPOSED GULLY PIT, WHERE PRACTICABLE.

13. FOR BROWNFIELD INSTALLATIONS, END OF LINES SHALL BE DESIGNED TO

DN63 PE PIPE 90° ELBOW 63 mm DISCHARGE INTO EXISTING GULLY PITS WHERE PRACTICABLE.

COMP. x 2" B.S.P. MI 14. DISCHARGE TO KERB OR CHANNEL MAY NOT BE ALLOWED BY SOME ROAD OWNERS.

15. WHERE IT IS NOT POSSIBLE FOR THE FLUSHING PIPE TO DISCHARGE INTO A GULLY

MALE ADAPTOR MALE ADAPTOR PIT, A DESIGN THAT IS ACCEPTABLE TO THE ROAD OWNER AND THE SEQ-SP SHALL BE

63 mm COMP. x 2" 63 mm COMP. x 2" PROVIDED.

B.S.P. MI B.S.P. MI 16. IN SITUATIONS WHERE THERE IS NO KERB AND CHANNEL, THE FLUSHING PIPE MAY

DISCHARGE ON TO A 500 (L) X 250 (W) X 250 (D) CONCRETE APRON CONSTRUCTED

IN A GRASSED AREA, OR OTHERWISE DISCHARGE INTO A WATER COURSE, PROVIDED

PLAN THAT THE ARRANGEMENT IS APPROPRIATELY DESIGNED TO ENSURE EROSION OF THE

SURROUNDING ENVIRONMENT DOES NOT OCCUR AND THE PROPOSED ARRANGEMENT

FLUSHING PIPE INTO GULLY PIT IS ACCEPTABLE TO THE RELEVANT ROAD OWNER AND IMPACTED LAND OWNERS.

17. ALL POLY TO METAL CONNECTIONS SHALL BE EITHER MALE TO FEMALE

CONFIGURATION. ie. METAL FEMALE FITTINGS AND POLY MALE FITTINGS, OR E.F.

TRANSITION COUPLERS.

18. GATE VALVES SHALL BE FITTED WITH BRASS HAND WHEELS.

OPTION 1 (PREFERRED)

DN63 PE FLUSHING PIPE

TOP OF KERB TOP OF KERB

INVERT OF CHANNEL INVERT OF CHANNEL

REFER NOTES 10 & 11

OPTION 2

TYPE 'A' VALVE BOX ABOVE SHROUD

DN63 PE FLUSHING PIPE

DN150 PVC CUT TO SUIT REFER NOTE 7

DN63 PE PIPE

MIN

300

50NB GATE VALVE

ELEVATION

SECTION A GATE VALVE ARRANGEMENT

-

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL

DRAWING No. VERSION

SERVICE PROVIDERS FLUSHING DETAILS FOR SEQ-WAT-1104-2 B

DN63 PE MAINS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 17/12/18 AMENDED DETAILS AND DRAWING NO LONGER APPLIES TO RCC OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

2 x STAINLESS STEEL

STRAPS SEE DETAIL

LONG TYPE

LONG TYPE SEQ-WAT-1207-1

GIBAULT DI SOC-FL TEE

EXISTING DI, CI, EXISTING DI, CI, EXISTING DI, CI, GIBAULT

DI SOC-FL TEE

AC, GRP, PVC-O, THRUST BLOCK AC, GRP, PVC-O, AC, GRP, PVC-O,

THRUST BLOCK

PVC-U AND DI/PVC PIPE PVC-U AND PVC-U AND DI/PVC PIPE

PVC-M MAIN 600 MIN. LENGTH PVC-M MAIN PVC-M MAIN 600 MIN. LENGTH

FL/GRIPPER EXISTING DI, CI,

DI/PVC PIPE DI/PVC PIPE LONG

ADAPTOR AC, GRP, PVC-O,

600 MIN. LENGTH LONG TYPE 600 MIN. LENGTH TYPE GIBAULT

PVC-U AND

GIBAULT PVC-M MAIN

FLANGE VALVE WITH THRUST PE FULL FACE FLANGE FL/GRIPPER

RESTRAINT REFER DI SHORT WITH S.S. BACKING RING OR

SEQ-WAT-1206-1 ADAPTOR

THRUST BLOCK REFER

PE FULL FACE FLANGE OR OR SEQ-WAT-1206-1

PE MAIN

PE MAIN

DI/PVC MAIN

S.S. BACKING RING

PE MAIN

PE MAIN

PE MAIN

VALVE FLANGE/GRIPPER

WITH PE MAIN

VIEW CUT-IN TO EXISTING MAIN

SLIP

POLY, SP-SP-SP TEE

CUT-IN WITH VALVE INTO EXISTING MAIN MECHANICAL GRIPPER MECHANICAL GRIPPER

OR EF COUPLING OR EF COUPLING

(CoGC PREFERRED METHOD SEE NOTE 5)

EXISTING PE MAIN EXISTING PE MAIN

POLY, SP-SP-FL TEE

MECHANICAL GRIPPER MECHANICAL GRIPPER

OR EF COUPLING OR EF COUPLING

PE TAIL

EXISTING PE MAIN EXISTING PE MAIN VALVE WITH PE

VALVE WITH

PIPE TAILS

E-F COUPLING OR GRIPPER

TO BE RESTRAINED

END CONNECTION

FLANGE VALVE TO

OR

BE RESTRAINED

PE MAIN

PE MAIN

PE FULL FACE FLANGE

S.S. BACKING RING FL/GRIPPER ADAPTOR

OR

CUT-IN TO EXISTING PE MAIN WITH VALVE

PE MAIN

PE MAIN

WITH PE TAIL, E-F OR GRIPPER CONNECTION

CUT-IN TO EXISTING PE MAIN WITH FLANGE VALVE 3. EF FITTINGS SHALL ONLY BE USED IF EXISTING PE MAIN IS COMPLETELY DRY.

4. PE MAIN SHALL HAVE APPROPRIATE THRUST RESTRAINTS / LINE ANCHORS

NOTES WHERE PIPE MATERIAL CHANGES.

1. REFER TO DRAWINGS SEQ-WAT-1102-1 AND SEQ-WAT-1105-2 FOR NOTES. 5. CoGC PREFERS SOC-SOC TEE CUT-IN WITH TWO SHORT PIPES FOR CUTTING

2. HYDRANT CONNECTIONS AND DI TO PE FLANGE CONNECTIONS SHALL INTO EXISTING DI/PVC PIPES. USE OF SP-SP TEE WITHOUT SHORT PIPES

COMPRISE PE FULL FACE FLANGE WITH 316 S.S BACKING RING. NEEDS CoGC'S APPROVAL.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL

DRAWING No. VERSION

SERVICE PROVIDERS CONNECTION TO EXISTING MAINS SEQ-WAT-1105-1 C

C 23/05/19 ADDED SPLIT VIEW, NOTE 5. DRAFTING IMPROVEMENT. MINOR CHANGES.

SHEET 1 OF 2

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 3/12/18 UPDATED NOTES AND DETAILS OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

EXISTING DI, CI, AC, GRP, EXISTING DI, CI, AC, PE, PVC-U

PVC-O, PVC-U AND PVC-M MAIN AND PVC-M MAIN (HOST MAIN)

SP-SP-FL TEE FLANGED

THRUST BLOCK HYDRANT TEE WITH HYDRANT OFF-TAKE CLAMP

FOR DI OR PVC PIPE (WHERE REQUIRED) PE FULL FACE FLANGE

(SEE SEQ-WAT-1205-1) WITH BACKING RING

PE FULL FACE FLANGE THRUST BLOCK

WITH BACKING RING (REFER NOTE 5)

REFER NOTE 10

(REFER NOTE 5)

PE PIPE PE PIPE

SPLIT SPLIT

VIEW VIEW

DI OR PVC PIPE DI OR PVC PIPE

PROVIDE 0.4MM PE HYDRANT TEE WITH HYDRANT

FL-SOC DI CONNECTOR SLEEVE BETWEEN (WHERE REQUIRED)

CONCRETE AND CLAMP FL-FL SLUICE VALVE

FL-FL SLUICE VALVE

REFER NOTE 8 (REFER NOTE 8)

MECHANICAL COUPLING

CUT-IN CONNECTION METHOD UNDER PRESSURE CONNECTION METHOD

(SEE NOTE 5 OF SEQ-WAT-1105-1) (REFER WSA03 APPENDIX 'C' UPCIC)

(USING FULL WRAP FLANGED OFFTAKE)

CONNECTION METHODS FOR OFFTAKE ≥ DN 100 DI, PVC AND PE PIPE

NOTES

DN 100-DN 50 1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN OTHERWISE.

FL-FL TAPER 2. S.S. OFF-TAKE CLAMP TO BE GRADE 316 S.S. AND OF FULL WRAP CONFIGURATION.

3. ALL DICL PIPE AND FITTINGS TO BE SLEEVED OR RE-SLEEVED WITH POLYETHYLENE

DN 63 PE EF COUPLING SLEEVING OR PETROLATUM TAPE SYSTEM.

(SEE NOTE 4) 4. PE ELECTROFUSION (EF) FITTINGS TO BE CLASS PN 16 ALTERNATIVE PE

CONNECTIONS SHOWN IN SEQ-WAT-1313-1.

5. BACKING RINGS FOR PE FLANGES TO BE MANUFACTURED FROM 316 S.S. ALL BOLTS,

NUTS & WASHERS TO BE 316 GRADE S.S.

6. USE GASKETS IN ACCORDANCE WITH CODE FOR ALL FLANGED CONNECTIONS.

DN 63 PE FULL FACE FLANGE

7. DO NOT USE 'UNDER PRESSURE CONNECTIONS' ON GRP PIPE.

WITH SS BACKING RING

8. ALL VALVES SHALL BE THRUST RESTRAINED BY EITHER FORMAT SHOWN IN

SEQ-WAT-1206-1.

FL-FL HYDRANT TEE DN100

9. WHERE A CUT-IN CONNECTION IS REQUIRED INTO AN EXISTING AC MAIN, THE AC

FL-FL SLUICE VALVE

FOR CONNECTION MAIN SHALL BE REPLACED FROM COLLAR TO COLLAR WITH AN APPROVED PIPE

DN100 (REFER NOTE 8) MATERIAL.

DETAILS SEE ABOVE

10. FOR UNDER PRESSURE CONNECTIONS, THRUST BLOCKS ARE NOT REQUIRED FOR

CONNECTION METHOD FOR DN 63 PE PIPE EXISTING HOST MAINS SMALLER THAN DN300. THRUST BLOCKS ARE REQUIRED FOR

DN300 AND LARGER BRANCHES, IN WHICH CASE THE THRUST BLOCK MAY BE

(WHERE VALVE & HYDRANT REQUIRED) REDUCED IN SIZE BY 50%. REFER MRWA-W-106 FOR ADDITIONAL DETAILS.

11. REFER TO DRAWINGS SEQ-WAT-1102-1 AND SE-WAT-1105-1 FOR NOTES.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL

DRAWING No. VERSION

D 23/05/19 NOTE 11, DRAWING REFERENCES AND DRAWING TITLE AMENDED.

SERVICE PROVIDERS CONNECTION TO EXISTING MAINS SEQ-WAT-1105-2 D

C 21/09/18 UPDATED CONNECTION METHOD DETAILS AND NOTES

SHEET 2 OF 2

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 22/07/15 AMENDED UNDER PRESSURE CONNECTION METHOD. ADDED NOTE 9. OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

MILD STEEL WELD COLLAR IN

ACCORDANCE WITH EXISTING MSCL MAIN

SEQ-WAT-1402-1 NOTE : CEMENT MORTAR LINING TO BE REPAIRED IN APPROVED

MANNER AFTER CUTTING. HEAT SHRINK SLEEVE COATING TO BE

SPOOL FL-PL MSCL C/W PE APPLIED OVER WELD COLLAR TO MANUFACTURERS REQUIREMENTS

COATING (600 MIN. LENGTH)

FL-FL-FL TEE

PE FULL FACE FLANGE WITH

BACKING RING (REFER NOTE 5)

PE PIPE

SPLIT

VIEW

SPOOL FL-SP OR

COUPLING END DI OR PVC PIPE

HYDRANT TEE WITH HYDRANT

(WHERE REQUIRED)

MECHANICAL COUPLING FL-FL SLUICE VALVE

(REFER NOTE 6)

EXISTING MSCL MAIN

SPOOL PL - COUPLING END

MSCL C/W PE COATING

MILD STEEL WELD COLLAR

IN ACCORDANCE WITH

SEQ-WAT-1402-1

ALTERNATIVE MECHANICAL COUPLING CUT-IN CONNECTION METHOD

STEEL MAIN CONNECTION (USING FLANGED FITTING)

(ACCEPTED BY UW ONLY)

NOTES

1. ALL DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN OTHERWISE.

2. ALL DICL PIPE AND FITTINGS TO BE SLEEVED OR RE-SLEEVED WITH

POLYETHYLENE SLEEVING OR PETROLATUM TAPE SYSTEM.

3. PE ELECTROFUSION (EF) FITTINGS TO BE CLASS PN 16; ALTERNATIVE

PE CONNECTIONS (FLANGED) SHOWN IN SEQ-WAT-1313-1.

4. BACKING RINGS FOR PE FLANGES TO BE MANUFACTURED FROM 316

S.S. ALL BOLTS, NUTS & WASHERS TO BE 316 GRADE S.S.

5. USE GASKETS IN ACCORDANCE WITH CODE FOR ALL FLANGED

CONNECTIONS.

6. ALL VALVES SHALL BE THRUST RESTRAINED BY EITHER FORMAT SHOWN

IN SEQ-WAT-1206-1.

7. PE MAIN SHALL HAVE APPROPRIATE THRUST RESTRAINTS / LINE

ANCHORS WHERE PIPE MATERIAL CHANGES.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL

DRAWING No. VERSION

SERVICE PROVIDERS CONNECTION TO EXISTING SEQ-WAT-1105-3 A

STEEL MAINS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 4/12/18

9 DI PRETAPPED PROPERTY

LOCATE MARKER DISCS DIRECTLY SERVICE FITTING.

WATER METER BOX CL ROAD

OVER SERVICE CONDUITS REFER NOTE 5

REFER NOTE 7 & 8

PAVEMENT REFER NOTE 4 10

LAYERS VARY

MAINTAP BALL VALVE ELECTRICAL

LOCATION OF MARKERS REFER NOTE 6 PILLAR

K & C

K & C

(SEE SEQ-WAT-1300-1 FOR 11

MARKER LOCATION DETAIL) SUBGRADE

LEVEL ELECTRICAL PILLAR

COMPACTED PAVEMENT MATERIAL, SEE ABOVE 12

REFER SEQ-WAT-1200-2 PROPERTY SERVICE MARKER SETOUT

200

UTILITY SERVICE CONDUIT 150 MIN PIPE. REFER NOTE 2

COMBINATIONS AS REQUIRED 200

13

APPROVED TRENCH BACKFILL VARIES (DUPLEX LOT)

MATERIAL, REFER CODE

SPECIFICATION SERVICE CONDUIT MARKER

SEE NOTE 11

PROPERTY

TYPICAL SECTION C-C - SERVICE CONDUIT SERVICE PIPE

15 SERVICE ONLY MARKERS 14

(DUPLEX LOT)

AT E AT E

A A PLAN

W

B B

W

R

R

40 NOM. 40 NOM.

W

R

W

R

AT E AT E

6

DRINKING WATER SERVICE CONDUIT DRINKING WATER NOTES

25

SERVICE PIPE (BRASS) SERVICE PIPE REFER 1. PROPERTY SERVICE PIPE SHALL BE POLYETHYLENE PIPE TO AS/NZS4130

(STAINLESS STEEL) (STAINLESS STEEL) NOTE 4 SERIES1 PN16 SDR11 PE100 COLOURED BLACK WITH BLUE STRIPES.

2. SINGLE PROPERTY SERVICE PIPE TO 20 m IN LENGTH IS DN25.

WATER SERVICE PIPE AND CONDUIT MARKERS SECT A-A SECT B-B SINGLE PROPERTY SERVICE PIPE OVER 20 m IN LENGTH IS DN32.

(SERVICE PIPE MARKER ONLY ON KERB OF VERGE WITH METERS) (BRASS) (STAINLESS STEEL) TWIN PROPERTY SERVICE PIPE TO 20 m IN LENGTH SHALL BE DN32.

3. METER BOX INSTALLATION REFER TO SEQ-WAT-1106-2. METER

RP BOUNDARY

INSTALLATION APPLICATION TO BE PROVIDED TO COUNCIL BY THE

CONTRACTOR AFTER THE CONTRACTOR INSTALLS METER BOX.

PVC SERIES 1 PN12 SOLVENT CEMENT 4. PROPERTY SERVICE PIPE STAMPED IDENTIFICATION TAG (35 MIN DIA)

JOINTING CONDUIT DN100 FOR RESIDENTIAL SHALL BE STAINLESS STEEL RETAINED BY A STAINLESS STEEL PIN.

DN150 FOR INDUSTRIAL/COMMERCIAL 5. PROPERTY SERVICE PIPE, BALL VALVES, DUCTILE IRON PRE-TAPPED

SERVICE ALLOCATION

PROPERTY SERVICE FITTING AND ASSOCIATED FITTINGS SHALL BE

RP BOUNDARY

SEE ROAD OWNER

50 CLEARANCE BETWEEN CONDUIT JOINTED IN ACCORDANCE WITH THE MANUFACTURER'S

C AND ROAD DRAINAGE RECOMMENDATIONS.

1500 L 6. THE MAIN TAP BALL VALVE SHALL BE LEFT IN THE FULLY OPEN

WATERMAIN

TYPICAL POSITION.

7. THE WATER METER BALL VALVES WITHIN BOX SHALL BE LEFT IN THE

600 MIN

C CL

FULLY CLOSED POSITION.

200 REFER 100 8. THE PROPERTY SERVICE PIPE SHALL BE PERPENDICULAR TO THE FRONT

NOTE 6 SWALE RP BOUNDARY FOR THE LAST 300 OF THE PIPE.

DRAIN 9. PROVIDE PROPERTY SERVICE MARKER TAPE FOR BURIED PIPE.

200 TYPICAL 10. DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN OTHERWISE.

200 11. REFER METERING TECHNICAL SPECIFICATIONS FOR DETAILED

TYPICAL 75 FALL REFER NOTES LOCATIONS OF METER BOX SERVICING DUPLEX LOT.

300

300 3&7

C

SUB-SURFACE ROAD DRAINAGE

TYPICAL SECTION AS DIRECTED BY COUNCIL

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL PROPERTY SERVICE

DRAWING No. VERSION

D 30/04/19 CLARIFIED CONDUIT JOINTS

SERVICE PROVIDERS CONNECTION SEQ-WAT-1106-1 D

C 30/11/18 AMENDED METER BOX & NOTES 1&2. ADDED NOTE 11. MINOR CHANGES

MAIN TO METER

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 31/03/15 ALTERED MARKER DISC LOCATION OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

20 mm METER BOX

200

RP BOUNDARY CL REFER NOTE 6 ON

WATER MAIN SEQ-WAT-1106-1

ALTERNATIVE TAPPING

200

TO BE PLUGGED WHEN

PROPERTY WATER NOT USED.

*

SERVICE SUPPLY

PIPE 1000 LONG REFER NOTE 3

75

PRETAPPED CONNECTOR (DI)

75

SAND BEDDING (FOR DN100 - DN150 PVC & DI PIPES)

PROPERTY SERVICE MATERIAL

TYPICAL 20 mm WATER METER

* GRADE DOWN TO MAIN

STRAIGHT PIPE LOT 1 LOT 2

LOT 1 LOT 2 SEE NOTE 7

RP BOUNDARY RP BOUNDARY

PRETAPPED TWIN CONNECTOR (DI)

(FOR DN 200+ PIPES SINGLE PORT)

METER

NOTES

1. FOR SINGLE PROPERTY SERVICE AND GENERAL

PROPERTY SERVICE INSTALLATION DETAILS REFER TO

SEQ-WAT-1106-1.

2. FOR DUAL RETICULATION WATER SERVICE TYPICAL

INSTALLATION DETAILS REFER TO SEQ-NDW-23##

DN20 PROPERTY SERVICE

MINIMUM RADUIS DRAWING SET.

WATER METER BALL

FOR DN25 PIPE IS POTABLE DN25 PIPE. 3. FOR PROPERTY SERVICE PIPE DETAILS REFER TO

VALVE, CLOSED

375. REFER TO NOTE 3 NOTE 2 & 5 AND THE GENERAL DETAILS ON

DN25 PIPE. SEQ-WAT-1106-1.

REFER NOTE 3 4. FOR POTABLE WATER SERVICE PRESSURE PIPE

ALL PROPERTY STRAIGHT PIPE COLOURS AND MARKING DETAILS REFER TO

SERVICE PIPEWORK SEE NOTE 7 SEQ-WAT-1106-1.

SHALL BE SAND

BEDDED. 5. DIMENSIONS ARE IN MILLIMETRES UNLESS SHOWN

BRASS/PE OTHERWISE.

DN25 TEE 6. REFER METERING TECHNICAL SPECIFICATIONS FOR

DN32 PIPE DETAILS OF METER BOX AND COMPONENTS

REMOVE SHARP EDGES REFER TO ARRANGEMENT.

FROM CONDUIT ROAD NOTE 3 7. A LENGTH OF MINIMUM 100MM SERVICE PIPES

CROSSING POTABLE IMMEDIATELY OUTSIDE METER BOXES AS WELL AS

NEXT TO MAINTAP BALL VALVES SHALL BE INSTALLED

STRAIGHT FOR EITHER SIDE OF A BOX.

LONG SERVICES - COMBINED OR SEPARATE SHORT SERVICES - SEPARATE PREFERRED

(COMBINED LONG SERVICES SHOWN)

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER TYPICAL PROPERTY SERVICE

DRAWING No. VERSION

SERVICE PROVIDERS CONNECTION SEQ-WAT-1106-2 C

C 30/11/18 ADDED NOTES 6 & 7, CHANGED METER BOX. OTHER MINOR CHANGES

MAIN TO METER

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 14/07/15 REMOVED LCC FROM DRAWING OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

WATER MAIN

TYPICAL CONDUIT MARKER 40

BOUNDARY

BOUNDARY

SEE NOTE 5 75 37 MAX LENGTH OF A PROPERTY SERVICE IS

21 40 m

40 DIA

6

DETAIL A

BACK OF KERB

5

PROPERTY

25

22

PROPERTY

DIA3 DIA3

75 FALL

SEE NOTE 3

10 10

0 12 TYPICAL ROAD CROSSING SECTION

10

NOMINAL ROAD INDIVIDUAL HYDRANT TO BE OFFSET HYDRANT TO BE IN-LINE WITH SIDE

BACK OF KERB

SERVICE METER

SERVICE CROSSING SERVICE WHEN BEHIND LIGHT POLE BOUNDARY WHERE POSSIBLE

CONDUIT MARKER CONFIGURATION SIZE

SIZE PIPE SIZE PIPE SIZE

SEE NOTE 5 Single service,

DN25 PE

50

no road crossing, DN20 Not applicable DN20 300 300

(DN20 Cu) PROPERTY E E E E

non-hatchet block

Single service,

DN32 PE BOUNDARY W W W W

Not applicable DN20

no road crossing, DN25 (DN25 Cu) 300 MIN

hatchet block DN25 PE

DN25 PE PE100 WATERMAIN

CONDUIT MARKER DETAILS Single service,

DN32 PE DN32 PE

across road, DN25 (DN25 Cu) (DN25 Cu)

DN20 DN40 PE

all block shapes DN40 PE

Dual service, KERB LINE E-F SADDLES

CONDUIT MARKER DN40 PE DN32 PE

across road, DN25 DN20 POSSIBLE

(DN32 Cu) (DN25 Cu) POSSIBLE

all block shapes E-F SADDLES

KERB AND CHANNEL DN100 MPVC SINGLE STREET LIGHT STREET LIGHT

PAVEMENT CONDUIT (SOLVENT

TYPICAL ROAD

WELD JOINTS)

300 600 MIN COVER MIN RADIUS FOR

TO TOE OF KERB DN32 PE IS 480 BRASS/PE TEE KERB LINE

CONSTRUCTION

100

DN40 PE

TYPICAL ROAD

DN40 PE

DN32 PE DN32 PE DN32 PE DN32 PE

PROPERTY W W W W

BOUNDARY

VOID FILLER E E E E

DN40 PE100 PIPE (TYPICAL)

100 mm MIN SAND SURROUND LEGEND

TYPICAL MAIN CONNECTIONS

OR CRUSHER DUST

FILTER MATERIAL E - ELECTRICITY CONNECTION POINT

DN100 MPVC SINGLE CONDUIT

SEEPAGE DRAIN W - WATER CONNECTION & METER POINT

(SOLVENT WELD JOINTS)

DETAIL A POLY MALE ADAPTOR OR

NOTES 6. E-F TAPPING SADDLES SHALL BE USED FOR ALL NEW PE MAINS. E-F TRANSITION COUPLER

1. ALL WORK SHALL BE IN ACCORDANCE WITH QUEENSLAND FOR EXISTING PE PIPE, E-F FITTINGS SHALL BE USED UNLESS THIS

CODES, SPECIFICATIONS AND STANDARDS. IS IMPRACTICABLE, IN WHICH CASE MECHANICAL TAPPING PE100 WATER SERVICES TO METER

2. UNLESS SPECIFIED OTHERWISE ALL MATERIALS AND WORK SADDLES/BANDS MAY BE USED.

SHALL COMPLY WITH THE RELEVANT AUSTRALIAN STANDARD. 7. PE SERVICES SHALL HAVE APPROVED DETECTABLE MARKER TAPE

3. THE MAIN TAP BALL VALVE SHALL BE LEFT IN THE FULLY OPEN LAID ON TOP OF THE BEDDING, EXTENDING FROM THE WATER

MAIN TO THE METER. WHERE CONDUITS ARE USED THE MARKER BALL VALVE WITH THREAD

POSITION. THE WATER METER BALL VALVE WITHIN METER BOX

SHALL BE LEFT IN THE FULLY CLOSED POSITION. TAPE SHALL BE ATTACHED TO THE WATER SERVICES AND PASS

4. WATER CONNECTION AND CONDUIT LAYOUT TO BE DESIGNED SO THROUGH THE CONDUIT. E-F TRANSITION COUPLER OR

THAT WATER METERS ARE NOT ADJACENT TO ELECTRICITY 8. BACKFILLING IN ROADWAYS SHALL COMPLY WITH RELEVANT ROAD MECHANICAL COMPRESSION ADAPTOR

CONNECTION POINTS. AUTHORITY REQUIREMENTS.

9. SERVICE CONDUITS SHALL EXTEND 300mm BEYOND ALL EXISTING E-F TAPPING SADDLE TO SUIT SIZE

5. CONDUIT MARKERS SHALL BE INSTALLED AS DETAILED WITH "W"

OR PLANNED CONCRETE FOOTPATHS, BIKEWAYS AND OTHER HARD OF PE MAIN

MARKING FOR WATER SERVICES AND "I" MARKING FOR

IRRIGATION SYSTEMS. KERB MARKERS TO BE INSTALLED ON TOP STANDING AREAS.

OF KERB WHERE POSSIBLE. 10. ALL DIMENSIONS ARE IN MILLIMETRES.

11. ALSO SEE NOTES ON SEQ-WAT-1107-3. E-F SADDLE DETAILS (SEE NOTE 6)

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL PE PROPERTY SERVICES

DRAWING No. VERSION

SERVICE PROVIDERS PE MAIN TO METER AND SEQ-WAT-1107-1 C

C 19/06/18 ADDED TABLE AND AMENDED NOTES, MAIN CONNECTIONS DETAIL & COVER

CONDUIT DETAILS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 05/08/15 CHANGED UPVC TO MPVC OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

40 NOTES

STRAIGHT UNION CONNECTOR 37

21 1. E-F TAPPING SADDLES SHALL BE USED FOR ALL NEW PE MAINS. FOR EXISTING PE PIPE, E-F

TYPE A ANNEALED COPPER TUBE FITTINGS SHALL BE USED UNLESS THIS IS IMPRACTICABLE, IN WHICH CASE MECHANICAL

TAPPING BANDS/SADDLES (ONLY BANDS IN LCC) MAY BE USED.

2. CONDUIT MARKERS SHALL BE INSTALLED AS DETAILED WITH "W" MARKING FOR WATER

5

W

SERVICES AND "I" MARKING FOR IRRIGATION SYSTEMS.

BALL VALVE WITH THREAD

22

3. SERVICE CONDUITS SHALL EXTEND 300mm BEYOND ALL EXISTING FOOTPATHS, BIKEWAYS

AND OTHER HARD STANDING AREAS.

E-F TRANSITION COUPLER OR

4. FOR QUU METER ARRANGEMENTS REFER SEQ-WAT-1107-3 AND FOR RCC METER

MECHANICAL COMPRESSION ADAPTOR

ARRANGEMENTS REFER SEQ-WAT-1109-1 AND SEQ-WAT-1109-2.

E-F TAPPING SADDLE TO 12 5. ALSO REFER NOTES ON SEQ-WAT-1107-3 FOR QUU AND SEQ-WAT-1109-1 AND

TYPICAL CONDUIT

SUIT SIZE OF PE MAIN SEQ-WAT-1109-2 FOR RCC.

MARKER SEE NOTE 2 75

6. THE MAIN TAP BALL VALVE SHALL BE LEFT IN THE FULLY OPEN POSITION. THE WATER METER

40 DIA BALL VALVE WITHIN METER BOX SHALL BE LEFT IN THE FULLY CLOSED POSITION.

E-F TAPPING SADDLE - PE MAINS

6

7. QUU REQUIRES PROPERTY SERVICES TO BE SIZED IN ACCORDANCE WITH SEQ-WAT-1107-1

BACK OF KERB

(SEE NOTE 1)

BOUNDARY

WATER MAIN

PROPERTY

SERVICE CONDUIT AND

MARKER DETAILS AS SHOWN

25

TAPPING POINTS

ROAD

PRE-TAPPED WITH 1, 2 OR 4 PORTS DEPENDING DIA3 DIA3 DETAILS AS SHOWN

300

ON APPLICATION

10 10

0

BALL VALVE 10 SIDE

ER

SIDE DN25 COPP BOUNDARY

L)

BACK OF KERB

STRAIGHT UNION CONNECTOR (TYP IC A

FOOTPATH

BOUNDARY

CONDUIT MARKER

SEE NOTE 2 METER BOXES

POSSIBLE

300

STREET SEE NOTE 4

TYPE A ANNEALED COPPER TUBE

LIGHT

SINGLE DIRECT SERVICE KERB AND

15° DN20 COPPER (TYPICAL) CHANNEL

CONDUIT MARKER DETAILS

COPPER SERVICES

RCC USE ABOVE GROUND METER SIDE

PRE-TAPPED ARRANGEMENT - DICL OR PVC MAINS ARRANGEMENT SEE NOTE 4 BOUNDARY

CONDUIT MARKER 300 300

300. SEE NOTE 3

KERB AND CHANNEL PROPERTY

PAVEMENT BOUNDARY

BALL VALVE TYPE A ANNEALED COPPER TUBE

50 MAX

50 MAX

600 MIN

1200 mm

COVER TO

CONSTRUCTION

100

UNION BEND FOR DN20 AND DN25

TYPICAL ROAD

ELBOW FOR ≥ DN32 TOE OF KERB

DN20 COPPER

20 mm METERS

AND BOXES

VOID FILLER ALTERNATIVE ARRANGEMENT

DN25 COPPER (TYPICAL)

DN20 COPPER

TO METER BOXES

GUNMETAL TAPPING BAND

100 mm MIN SAND SURROUND

TO SUIT SIZE OF MAIN 20 x 20 x 25 CAPILLARY TEE

OR CRUSHER DUST

FILTER MATERIAL DN25 COPPER

TAPPING BAND ARRANGEMENT DN100 mPVC SINGLE (OR 25 x 25 x 25 CAPILLARY

SEEPAGE DRAIN CONDUIT (SOLVENT WELD TEE WITH REDUCER)

JOINTS) WITH 75 FALL.

CONDUITS DETAILS MULTIPLE SERVICE DETAILS AT PROPERTY BOUNDARY

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL COPPER PROPERTY SERVICES

DRAWING No. VERSION

SERVICE PROVIDERS MAIN TO METER AND SEQ-WAT-1107-2 C

C 4/06/18 AMENDED NOTE 1, NOTE 3, MARKER DETAIL HEADINGS AND ADDED NOTE 7.

CONDUIT DETAILS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 14/07/15 REMOVED LCC FROM DRAWING. CHANGED UPVC TO MPVC. OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

PROPERTY PROPERTY NOTES

BOUNDARY BOUNDARY

GENERAL

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 1. ALL WORK AND MATERIALS SHALL BE IN

BOUNDARY

BOUNDARY

PROPERTY

PROPERTY

ACCORDANCE WITH CURRENT QUEENSLAND CODES,

SPECIFICATIONS AND STANDARDS.

300

300

2. UNLESS SPECIFIED OTHERWISE ALL MATERIALS AND

WORK SHALL COMPLY WITH THE RELEVANT

AUSTRALIAN STANDARDS.

FLOW FLOW

3. ALL DIMENSIONS ARE IN MILLIMETERS.

4. 20 mm METERS SHALL BE INSTALLED ON ALL DN25

PE AND DN32 PE SERVICES UNLESS OTHERWISE

SPECIFIED.

DN20 OR DN25 DN25 OR DN32 5. 25 mm METERS SHALL ONLY BE INSTALLED WHERE

COPPER SERVICES PE SERVICES REQUIRED BY THE OWNER AND AGREED BY SEQ-SPS.

6. SERVICES LARGER THAN DN32 PE ARE SUBJECT TO

APPROVAL BY SEQ-SPS.

50 MAX 7. SERVICES SHALL BE LAID ACROSS FOOTPATHS

COPPER SERVICES PLAN 50 MAX PE SERVICES PLAN

PERPENDICULAR TO THE FRONT PROPERTY

BOUNDARY OF THE PROPERTY BEING SERVED.

FITTINGS REQUIRED FOR DN20 COPPER SERVICES FITTINGS REQUIRED FOR DN25 PE SERVICES 8. MULTIPLE SERVICES MAY ONLY BE USED WHERE THE

SERVICE CROSSES A ROADWAY AND THE SERVICE

ITEM No DESCRIPTION ITEM No DESCRIPTION

SHALL BE ONE SIZE UP WHERE CROSSES A

1 PE METER BOX WITH LID (APPROVED HDPE TYPE) 1 PE METER BOX WITH LID (APPROVED HDPE TYPE)

2 PE ADAPTOR - DN25 COMPRESSION TO 3/4" BSP, M ROADWAY.

2 STRAIGHT CONNECTOR - 20mm CAPILLARY TO 3/4" BSP, F

3 NOT USED 3 DN20 BALL VALVE - 3/4" BSP, F-F 9. BACKFILLING IN ROADWAYS SHALL COMPLY WITH

4 DN20 BALL VALVE 3/4" BSP, M-F 4 DN20 WATER METER COUPLING - 3/4" BSP, M TO 3/4" METER THREAD x 14 TPI, F RELEVANT ROAD AUTHORITIES REQUIREMENTS.

5 DN20 WATER METER COUPLING 3/4" BSP, M TO 3/4" METER THREAD x 14 TPI, F 5 20mm INLINE WATER METER (APPROVED)

DN20 WATER METER COUPLING - 3/4" METER THREAD x 14 TPI, F TO 3/4" BSP, M

TAPPING

6 20mm INLINE WATER METER (APPROVED) 6

DN20 WATER METER COUPLING - 3/4" METER THREAD x 14 TPI, F TO 3/4" BSP, M 7 PLASTIC CAP 10. INDIVIDUAL TAPPING POINTS SHALL BE USED FOR

7

8 PLASTIC CAP SERVICES WHERE THE MAIN IS ON THE SAME SIDE

FITTINGS REQUIRED FOR DN32 PE SERVICES OF THE ROADWAY AS THE PROPERTIES BEING

FITTINGS REQUIRED FOR DN25 COPPER SERVICES ITEM No DESCRIPTION SERVED.

1 PE METER BOX WITH LID (APPROVED HDPE TYPE) 11. APPROVED PRE-TAPPED DI FITTINGS SHALL BE USED

ITEM No DESCRIPTION 2

1

PE ADAPTOR - DN32 COMPRESSION TO 3/4" BSP, M TO ON ALL NEW DICL OR PVC MAINS PROVIDED THEY

PE METER BOX WITH LID (APPROVED HDPE TYPE) 3 DN20 BALL VALVE - 3/4" BSP, F-F

2 STRAIGHT CONNECTOR - 25mm CAPILLARY TO 1" BSP, F 4

COMPLY WITH THE REQUIREMENTS ON THIS WATER

DN20 WATER METER COUPLING - 3/4" BSP, M TO 3/4" METER THREAD x 14 TPI, F

3 ADAPTOR - 1" BSP, M TO 3/4" BSP, F 5 20mm INLINE WATER METER (APPROVED) CODE AND AS/NZ 2280.

4 DN20 BALL VALVE - 3/4" BSP, M-F 6 DN20 WATER METER COUPLING - 3/4" METER THREAD x 14 TPI, F TO 3/4" BSP, M 12. WHERE REQUIRED APPROVED TAPPING BANDS WITH

5 DN20 WATER METER COUPLING - 3/4" BSP, M TO 3/4" METER THREAD x 14 TPI, F 7 PLASTIC CAP

6 20mm INLINE WATER METER (APPROVED) POSITIVE STOPS SHALL BE USED ON ALL PVC AND PE

7 DN20 WATER METER COUPLING - 3/4" METER THREAD x 14 TPI, F TO 3/4" BSP, M 19. ALL POLY TO METAL CONNECTIONS SHALL BE EITHER MALE TO FEMALE PIPES.

8 PLASTIC CAP CONFIGURATION ie. METAL FEMALE FITTINGS WITH POLY MALE 13. WHERE TAPPING BANDS ARE INSTALLED ON DICL

FITTINGS, OR E-F TRANSITION COUPLERS. PIPE, THE SECTION OF THE MAIN AT THE PROPOSED

20. DN25 AND DN32 PE SERVICES ARE EQUIVALENT TO DN20 AND DN25 TAPPING POINT, SHALL BE FIRST CLEANED AND

COPPER SERVICES. WRAPPED WITH A MINIMUM OF TWO LAYERS OF

PE METER BOX WITH ISOLATING VALVE 21. PE PIPE SHALL BE LAID WITH 100 mm MINIMUM SURROUND OF SAND. SELF-ADHESIVE POLYVINYCHLORIDE WRAPPING.

WIRE ATTACHED LID (LID 22. ALL CAPILLARY JOINTED FITTINGS SHALL BE LONG ENGAGEMENT POLYETHYLENE SLEEVING SHALL BE REPLACED

SIZE APPROX 492x271) 50 MAX

SOCKET TYPE. AROUND PIPE AND TAPPING BAND.

PROPERTY 23. ALL CAPILLARY JOINTS SHALL BE SOLDERED WITH 15% SILVER SOLDER MATERIAL

BOUNDARY TO AS 1515.3. 14. COPPER SERVICES SHALL BE ANNEALED TYPE "A"

24. BRASS SEATED BARRELL UNIONS SHALL BE USED IN ALL INSTANCES AND CONFORM WITH AS 1432. POLYETHYLENE

225 mm TO EXCEPT FOR UNION CONNECTORS AT 25 mm METERS, WHICH SHALL BE SERVICES SHALL BE CLASS PN16 PE100 AND

316 mm

APPROX

70

300 mm FLAT SEATED WITH A 3 mm x 25 mm RUBBER GASKET. CONFORM WITH AS 4130.

MAX 25. COMPRESSION FITTINGS SHALL NOT BE USED WITH COPPER SERVICES. 15. POLYETHYLENE SERVICES SHALL BE CONTINUOUS

MARKER TAPE WITHOUT JOINTS.

26. PE SERVICES SHALL HAVE APPROVED DETECTABLE MARKER TAPE LAID 16. ALL COPPER ALLOY FITTINGS SHALL BE

INLINE METER ON TOP OF THE BEDDING, EXTENDING FROM THE WATER MAIN TO THE DEZINCIFICATION RESISTANT AND COMPLY WITH AS

GEOTEXTILE FABRIC METER. WHERE CONDUITS ARE USED THE MARKER TAPE SHALL PASS 3688.

TAPED EACH SIDE THROUGH THE CONDUIT WITH THE WATER SERVICE. 17. ALL BALL VALVES INCLUDING HANDLES SHALL BE

AND AROUND PIPE METER BOX EITHER STAINLESS STEEL OR DEZINCIFICATION

27. METER BOX LIDS SHALL HAVE A NON SLIP PATTERN. RESISTANT COPPER ALLOY.

SECTION VIEW 28. LETTERING INDICATING "WATER METER" SHALL BE CAST INTO LIDS OF 18. ALL FITTINGS FOR POLYETHYLENE PIPE SHALL

METER BOXES. COMPLY WITH AS 4129.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL PROPERTY SERVICES

DRAWING No. VERSION

SERVICE PROVIDERS GENERAL ARRANGEMENT SEQ-WAT-1107-3 C

C 4/06/18 AMENDED FITTING TABLES.

20mm OR 25mm METERS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 14/07/15 AMENDED NOTE 12. FIXED TYPOS IN NOTE 17. REMOVED LCC FROM DRAWING. OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

TYPICAL CONDUIT 1500

MARKER 75 40 NOM

WATER MAIN

37

BOUNDARY

40 DIA

BOUNDARY

21

BACK OF KERB

DETAIL A

25

5

DIA3 DIA3

22

PROPERTY

PROPERTY

10 10

0 75 FALL

10

12

BACK OF KERB

CONDUIT MARKER TYPICAL ROAD CROSSING SECTION

MINIMUM 800 MM CLEAR

SPACE TO ELECTRICAL PRE-TAPPED CONNECTOR

HYDRANT IN LINE WITH

BOUNDARY

TO BE OFFSET

PROPERTY

BRASS SERVICE CONDUIT MARKER SIDE BOUNDARIES PILLAR

WHEN IN CONFLICT WITH

BRASS CONDUIT MARKER HYDRANT

150 mm BOTH ENDS) W W W W

E E E E

PROPERTY

KERB AND CHANNEL

1500

BOUNDARY

NOM

PAVEMENT

300

DN100 OR DN150 WATERMAIN

KERB LINE

600 MIN URBAN AND

CONSTRUCTION

UNCLASSIFIED ROADS 100

TYPICAL ROAD

850 MIN STATE ROADS

OR AS NOMINATED BY SINGLE CONDUIT TYPICAL ROAD

RELEVANT ROAD (SOLVENT WELD JOINTS)

AUTHORITY

KERB

STREET LIGHT

VOID FILLER TO MARKER

UNITYWATER REQUIREMENTS

KERB LINE

2 x DN25 PE100 PIPE

TO METER BOXES

MIN. 50 CLEARANCE BETWEEN PROPERTY

100 mm MIN SAND SURROUND

SUBSOIL DRAIN AND CONDUIT OR CRUSHER DUST BOUNDARY

E E W W E E W W

FILTER MATERIAL 100 DIA uPVC PN9 SERIES 1 CONDUIT

BOUNDARY

PROPERTY

SEEPAGE DRAIN (SOLVENT WELD JOINTS) FOR RESIDENTIAL.

150 DIA uPVC PN 9 SERIES 1 (SOLVENT WELD

NOTES DETAIL A JOINTS) FOR INDUSTRIAL/COMMERCIAL

1. ALL WORK SHALL BE IN ACCORDANCE WITH QUEENSLAND CODES, SPECIFICATIONS AND STANDARDS. TYPICAL MAIN CONNECTIONS

2. UNLESS SPECIFIED OTHERWISE ALL MATERIALS AND WORK SHALL COMPLY WITH THE RELEVANT

AUSTRALIAN STANDARD.

3. BACKFILLING IN ROADWAYS SHALL COMPLY WITH RELEVANT ROAD AUTHORITY REQUIREMENTS. LEGEND

4. WATER CONNECTION AND CONDUIT LAYOUT TO BE DESIGNED SO THAT WATER METERS ARE NOT

ADJACENT TO ELECTRICITY CONNECTION POINT. E - ELECTRICITY CONNECTION POINT

5. ALL DIMENSIONS ARE IN MILLIMETRES. W - WATER CONNECTION & METER POINT

6. SERVICE CONDUITS TO BE ANGLED ACROSS ROADWAY WITH KERB MARKERS PERPENDICULAR TO

COMMON PROPERTY BOUNDARY.

7. HYDRANTS MUST BE 10 M CLEAR OF PAD MOUNT TRANSFORMERS AND RMU'S.

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER PROPERTY SERVICES

DRAWING No. VERSION

SERVICE PROVIDERS POTABLE SERVICE CONNECTION SEQ-WAT-1108-1 B

CONDUIT DETAILS

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 25/08/15 TYPICAL MAIN CONNECTIONS DETAIL AMENDED . NOTE 7 ADDED. OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

DN100 / DN150

RETICULATION

BRASS CONDUIT MARKER SET INTO KERB

BOUNDARY

BOUNDARY

PROPERTY

PROPERTY

TURF

150 BOTH ENDS) TURF

SURROUND

MAIN

SURROUND

GROUND

GROUND

LEVEL

LEVEL

DICL/CI PRE-TAPPED WATER METER IN PE

CONNECTOR CONDUIT (REFER STD DRG BOX (REFER STD DRG

BOUNDARY

SEQ-WAT-1108-3)

PROPERTY

SEQ-WAT-1108-1)

WATER METER IN PE

BOX (REFER STD DRG TYPICAL ROAD ELEVATION

BOUNDARY

SEQ-WAT-1108-3)

PROPERTY

4

500 5 5

4

4 4

2 2

3 3 4

300

300

500

PROPERTY PROPERTY

BOUNDARY BOUNDARY

500 500

300

300

2 x OD25 PE100

1

PN16 PIPE

REFER

SAME SIDE OPPOSITE SIDE

NOTES

SEQ-WAT-1108-3

SERVICE SERVICE 1. MINIMUM BENDING RADIUS FOR DN25 PE PIPE = 400 mm, DN32 PE PIPE = 500mm. ENSURE

FOR DETAILS OF PLAN PIPE DOES NOT KINK DURING BENDING.

PIPE EXTENSION

2. ANY PIPEWORK SHOWING SIGNS OF KINKING OR STRAIN FROM OVER BENDING WILL BE

POLY MALE ADAPTOR OR REJECTED.

E-F TRANSITION COUPLER 3. SERVICE PIPEWORK SHALL BE PN16 PE100 BLACK POLYETHYLENE PIPE WITH BLUE STRIPE

PE100 WATER SERVICES TO METER 50X32 BUSH IN ACCORDANCE WITH AS/NZS 4130.

32X32X32 4. ALL CONNECTIONS TO POLYETHYLENE PIPE TO BE APPROVED BRASS OR PLASTIC

WITH 32X32

BALL VALVE WITH THREAD TEE WITH MECHANICAL FITTINGS.

HEX. NIPPLE

2/32X25 25X25X25 5. PE PIPE SHALL BE LAID WITH 100 mm MINIMUM SURROUND OF SAND OR APPROVED

E-F TRANSITION COUPLER OR GRANULAR MATERIAL.

HEX. NIPPLE TEE EACH

MECHANICAL COMPRESSION ADAPTOR 6. PE PIPE SHALL BE CONTINUOUS WITHOUT JOINTS. INSTALLATION OF BENDS OR JOINTS

END

E-F TAPPING SADDLE TO SUIT REQUIRE SP APPROVAL.

SIZE OF PE MAIN 7. PRE-TAPPED WATER SERVICE FITTING SHALL BE DICL MIN PN16 POLYMERIC COATED AND

E-F SADDLE DETAILS (SEE NOTE 11) CONFORM WITH A.S. 2280.

FITTING SCHEDULE 8. PE SERVICES SHALL HAVE APPROVED DETECTABLE MARKER TAPE LAID ON TOP OF THE

BEDDING, EXTENDING FROM THE WATER MAIN TO THE METER. WHERE CONDUITS ARE USED

ITEM DESCRIPTION

DN20 BALL VALVE THE MARKER TAPE SHALL BE ATTACHED TO THE WATER SERVICES AND PASS THROUGH THE

1 DN100 or DN150 DICL/CI PRE-TAPPED CONNECTOR CONDUIT.

EACH END

2 20 mm BRASS BALL VALVE M/F 9. BALL VALVES AT THE MAIN ARE TO BE LEFT IN THE OPEN POSITION AFTER CONSTRUCTION.

3 0D25 PE TO DN20 BSP MALE BRASS OR PLASTIC 10. VALVES AT THE METER ARE TO BE LEFT IN THE CLOSED POSITION AFTER CONSTRUCTION.

MECHANICAL CONNECTORS. PRETAPPED TWIN CONNECTOR (DI) 11.E-F TAPPING SADDLES SHALL BE USED FOR ALL NEW PE MAINS. MECHANICAL

4 DN25 PE100 PN16 PIPE WITH BLUE STRIPE FOR FOR DN200+ PIPES SINGLE PORT TAPPINGS MAY BE USED FOR EXISTING/RENEWAL INSTALLATIONS,WHERE APPROVED BY SP.

SERVICE < 20 m LONG 12. DIMENSIONS ARE IN MILLIMETERS UNLESS SHOWN OTHERWISE.

5 DN32 PE100 PN16 PIPE WITH BLUE STRIPE FOR

SERVICE > 20 m LONG

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER PROPERTY SERVICES

DRAWING No. VERSION

D 10/06/19 NOTE 1 AND 6 UPDATED

SERVICE PROVIDERS POTABLE SERVICE CONNECTION SEQ-WAT-1108-2 D

C 25/06/18 NOTE 11 UPDATED

TYPICAL MAIN TO METER

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 24/05/15 OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

FOOTPATH PROPERTY

NOTES

1. METERS SHALL BE APPROVED BY UNITYWATER AND MEET THE REQUIREMENTS

AND PERFORMANCE REQUIREMENTS OF AS 3565.1 METERS FOR WATER

SUPPLY PART 1: COLD WATER METERS.

2. METERS SHALL BE FACTORY FITTED WITH 2 INDEPENDENTLY ACTING

SEQ-WAT-1108-2 FOR

6 4

NON-RETURN VALVES IN SERIES AT THE DOWNSTREAM END OF THE

1 2 3 3 5 1 METER IN COMPLIANCE WITH AS 3565.3 METERS FOR WATER SUPPLY PART 3:

REFER STD.DWG.

WATER METERS WITH INTEGRAL DUAL CHECK VALVES.

CONTINUATION

3. METERS CONSTRUCTED FROM COPPER ALLOYS SHALL BE DEZINCIFICATION

RESISTANT AND COMPLY WITH AS 2345.

POLY. PIPE TO EXTEND 600 mm MIN. OUTSIDE 4. ALL MATERIALS IN CONTACT WITH POTABLE WATER SHALL COMPLY WITH

METER BOX AND SEALED WITH DUCT TAPE AS/NZS 4020.

FLOW 5. SERVICE PIPEWORK SHALL BE DN25 PE100 PN16 BLACK POLYETHYLENE PIPE

WITH BLUE STRIPE IN ACCORDANCE WITH AS/NZS 4130.

6. ALL CONNECTIONS TO POLYETHYLENE PIPE SHALL BE APPROVED BRASS OR

PLASTIC MECHANICAL FITTINGS.

7. ALL WATER INSTALLATIONS SHALL BE CARRIED OUT BY A LICENSED PLUMBER

300

AND SHALL BE IN ACCORDANCE WITH RELEVANT BY-LAWS OF PLUMBING AND

DRAINAGE ACT.

8. ALL GUNMETAL OR BRASS - DEZINCIFIED RESISTANT "DR" AND APPROVED TO

500 AS 3855.

9. ALL BRASS FITTINGS SHALL HAVE MAKERS NAME OR MARK AND WATERMARK

IMPRINTED ON SURFACE OF FITTING TO PROVE COMPLIANCE WITH AS 3855.

WATER METER DETAIL PLAN VIEW 10. VALVES AT THE METER SHALL BE LEFT IN THE CLOSED POSITION AFTER

SIDE PROPERTY

CONSTRUCTION.

BOUNDARY

11. WATER SERVICES SHALL BE INSPECTED BY UNITYWATER INSPECTOR PRIOR

TO BACKFILL.

12. BALL VALVE, WATER METER AND METER BOX SHALL BE APPROVED.

13. METER BOX LID SHALL HAVE NON SLIP PATTERN, LETTERING CAST INTO LID

INDICATING "WATER METER" AND BE BLACK OR GREEN IN COLOUR.

BOUNDARY

PROPERTY 14. METER BOX LID SHALL BE LEFT SO THAT IT SITS FLUSH WITH TURF

SURROUND.

15. FOR NEW INSTALLATIONS, TURF SURROUND SHALL EXTEND A MINIMUM OF

LID SHALL BE ATTACHED 600 mm AROUND SIDES OF METER BOX.

TO BOX WITH CHAIN OR TURF SURROUND

REFER NOTE 15 16. GEOTEXTILE FABRIC SHALL BE LAID UNDERNEATH METER BOX TAPED EACH

STAINLESS STEEL WIRE SIDE AND AROUND PIPE TO PREVENT INGRESS OF SAND AND SOIL.

GROUND

LEVEL

FITTINGS SCHEDULE

PE METER BOX (NOM SIZE 400 x 275)

ITEM No OFF

265

WITH NO BASE (TO ALLOW DRAINAGE) DESCRIPTION

1 DN25 PE100 PN16 PIPE WITH BLUE STRIPE AS REQ.

GEOTEXTILE FABRIC 2 20 mm x 25 mm FEMALE/PE BRASS LOCKABLE BALL VALVE WITH

SEAL WITH 1

REFER NOTE 13 HANDLE (REFER NOTE 9)

DUCT TAPE

3 CONNECTION KIT (COMPRISES OF 2xDN20 BSP M/F BRASS UNIONS) 1

4 DN20 METER WITH DUAL CHECK VALVES (REFER NOTE 1) 1

5 OD25 PE TO DN20 MALE BRASS OR PLASTIC MECHANICAL 1

CONNECTOR

POLY PIPE TO EXTEND

20 mm METER 6 PE METER BOX WITH LID (REFER NOTE 9)

WATER METER DETAIL SECTIONAL VIEW

REV. No. DATE DESCRIPTION AUTH.

WATER SUPPLY STANDARD DRAWING CoGC LCC RCC QUU UW

SEQ WATER PROPERTY SERVICES

DRAWING No. VERSION

D 06/06/19 NOTES 8, 13, & 15 AMENDED

SERVICE PROVIDERS POTABLE SERVICE CONNECTION SEQ-WAT-1108-3 D

C 25/06/18 REPLACED 'TO BE' WITH 'SHALL' IN NOTES

20mm DOMESTIC SERVICE

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

B 21/07/15 ITEM 5 IN FITTINGS SCHEDULE AND NOTE 3 AMENDED OCCUPATIONAL HEALTH & SAFETY LEGISLATION METER BOX DETAILS NOT TO SCALE 1/1/2013

MARK DESCRIPTION

NO

9 1. 20 mm WATER METER. DIMENSIONS TO AS 3565 FIG 1.1

9A 6 12 14 10 NOM 750 2B. METER TAIL PIECE WITH 20 mm BSP SUPPLLIED WITH WATER METER

3 (PRE DRILLED TO SUITE WIRE SEAL)

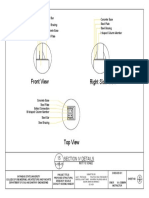

GHOST

CONNECTION 3. 20 mm MALE MI TO 20 mm OD CAPILLARY ADAPTOR

3A. RT. ANGLED 20 mm LOCKABLE F & F BALL VALVE