Professional Documents

Culture Documents

Sample Formalin 10 Per Cent Chemical Agents Risk Assessment

Uploaded by

madmossyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Formalin 10 Per Cent Chemical Agents Risk Assessment

Uploaded by

madmossyCopyright:

Available Formats

National Health and Safety Function, Workplace Health and Wellbeing Unit, National HR Division

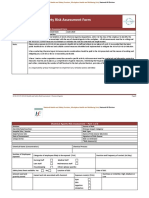

Chemical Agents Risk Assessment – Part 1 of 3

Division: Acute Hospital Source of Risk: Risk assessment

HG/CHO/NAS/Function: RCSI Hospital Group Primary Impact Category: Harm to a Person/Compliance

Hospital Site / Service: ABC Hospital Risk Type: Operational

Dept/Service Site : Histology Laboratory Name of Risk Owner (BLOCKS):Joe Black

Date of Assessment: 17/9/2018 Signature of Risk Owner: Joe Black

Unique ID No: 1234 Risk Co-Ordinator: N/A

Risk Assessor(s) Joe Black/Joe Bloggs

Chemical Name (Concentration): Chemical Process:

Used to fix and process samples in Histology

Formalin 10% neutral buffered

Number of

Categories of employees likely to be exposed: (Tick) Duration and frequency of contact (Hr/day):

Employees Exposed:

Nursing Staff Medical Staff

7 employees in Daily exposure for up to one hour at a time

contact with product Care Staff Maintenance Staff maximum.

at any one time. Housekeeping

Others (please specify): Laboratory Technicians

Safety Data Sheet available: Yes X No Location of SDS :Attached in Date of SDS:28/3/2017

departmental chemcial inventory list on “X

drive”.

Amount used and Dustiness or Volatility: High, Medium

Hazard and risk associated with chemical: Exposure route(s) (Tick):

quantity stored or Low

1 x 5 litres drums in Eyes X No dust generated from this product

H315 Causes skin irritation

17 11 10 CF 003_02 Health and Safety Risk Assessment - Chemical Agents Page 1

National Health and Safety Function, Workplace Health and Wellbeing Unit, National HR Division

lab used weekly. Skin X Volatility- no data available

H317-May cause an allergic skin reaction

Ingestion

2x5 litres stored in H318- Causes serious eye damage.

lab store at any one H350- May cause cancer Inhalation)

time. Inhalation

H402- Harmful to aquatic life.

Chemical Agents Risk Assessment – Part 2 of 3

Classification, Labelling and Packaging (CLP) Hazard Symbols

CLP SYMBOLS

Acute Serious Health Corrosion Environment Flammability Oxidising Explosion Stored as

toxicity long term hazard Hazard al hazard hazard Hazard Hazard gas under

hazard health pressure

hazard

Tick appropriate pictogram. Refer

to section 2 of SDS

Insert appropriate signal word i.e.

danger or warning.

Danger

Occupational Exposure Limit Value (OELV) if applicable insert airborne OELV. Refer to Code of Practice to Chemical Agents Regulations

2018.

OELV :0.2ppm OEL (8 hour reference period) & 0.4 ppm OEL (15 min reference period)

17 11 10 CF 003_02 Health and Safety Risk Assessment - Chemical Agents Page 2

National Health and Safety Function, Workplace Health and Wellbeing Unit, National HR Division

HAZARD & RISK ADDITIONAL ACTION DUE DATE

EXISTING CONTROL MEASURES

DESCRIPTION CONTROLS REQUIRED OWNER

Storage: Stored away from sources of ignition and direct sunlight. Continuous 17/12/2018

Risk of ill health Joe Black/all

Drums are stored in a chemical storage cabinet currently separate to monitoring & review

due to potential Employees

incompatible products such as strong bases, strong acids, & strong of all existing controls.

exposure to

oxidizers as per SDS. Implementation and

formalin to the

supervision of all

Laboratory

Use: Use in accordance with manufacturer’s instructions. standard operating

Technicians staff.

Staff must adhere to the safety precautions as set out in the standard procedures by all staff.

The potential

operating procedures for the fixation & processing of samples (SOP

exposure route is

001). Use chemicals in designated areas only and by trained staff.

via skin/ eye/

Students are supervised at all times in histology lab.

inhalation while

processing

Engineering controls:

histology samples

All specimen cut up tables have a down draft system, which is serviced

daily.

annually and records maintained in the Lab Managers office.

All heating, ventilation & air conditioning (HVAC) systems are on a

preventative maintenance /validation schedule & records are

maintained in lab Managers office.

Occupational Hygiene: a comprehensive Occ Hygiene programme is in

place within the lab. Results are reviewed carefully to ensure there are

no OEL exceedances. Last monitored in September 2018, report results

have been communicated to staff in the H&S meeting of October 2018,

minutes available. Any recommendations implemented. Future

monitoring planned for September 2019 unless work practices change.

17 11 10 CF 003_02 Health and Safety Risk Assessment - Chemical Agents Page 3

National Health and Safety Function, Workplace Health and Wellbeing Unit, National HR Division

PPE: Based on Occ hygiene results the following PPE is mandated for

use. Gloves, chemical goggles or safety glasses, chemical resistant

apron (pouring formalin) provided to staff.

Waste: All waste containers/materials labelled and placed in the store

room for collection by licensed chemical disposal company in

accordance with the transportation of Dangerous Goods requirements.

Spill Procedure:

In the event of a spillage safety glasses, protective clothing, gloves, a

combined gas/dust mask with filter type A/P3 to be worn.

Ventilate the area, spillage kit to be used. Spillage procedure to be

implemented. Spill kit located in lab reception. Employees trained in

its use. All spillages recorded on incident reporting form by lab

Manager. Investigation completed by lab manager and staff.

In the event of a fire follow local procedures and training.

First Aid:

Skin Contact: Wash with plenty of liquid soap &water. If skin irritation

or rash occurs get medical advice/ attention.

Eye Contact: Rinse cautiously with water for several minutes. Remove

contact lenses, if present and easy to do. Continue rinsing refer to ED

department for review.

Ingestion: Rinse mouth. Do not induce vomiting. Refer to ED

department for review.

Inhalation: If safe remove the staff member from the area and allow the

staff member to breathe fresh air and to rest.

Following an incident/accident all staff to be sent to Emergency

department with a copy of Formalin SDS for medical review.

Hygiene measures: to reduce potential exposure wash hands with

17 11 10 CF 003_02 Health and Safety Risk Assessment - Chemical Agents Page 4

National Health and Safety Function, Workplace Health and Wellbeing Unit, National HR Division

liquid soap & water before eating, drinking and when leaving work.

Health surveillance: The Occupational Health team/ safety

professionals have reviewed the Occ hygiene results and the risk

assessment and have determined that Health Surveillance is not

required at this time. Should a staff member suffer any symptoms,

which is suspected to be the result of exposure to Formalin then a

referral to the local Occ health Department will be made by the Lab

Manager.

Training: All staff have completed chemical safety module on HSEland.

Records maintained by Lab manager. Tailored training on the specific

chemicals used in the lab has been provided, records maintained by Lab

Manager.

INITIAL RISK Risk Status

Likelihood Impact Initial Risk Rating Open Monitor Closed

Unlikely (2) Minor(2) L4

17 11 10 CF 003_02 Health and Safety Risk Assessment - Chemical Agents Page 5

National Health and Safety Function, Workplace Health and Wellbeing Unit, National HR Division

17 11 10 CF 003_02 Health and Safety Risk Assessment - Chemical Agents Page 6

You might also like

- Guidance On Completing A Biological Risk AssessmentDocument2 pagesGuidance On Completing A Biological Risk AssessmentmadmossyNo ratings yet

- A Parent S Guide To Close Contacts in School PDFDocument3 pagesA Parent S Guide To Close Contacts in School PDFmadmossyNo ratings yet

- Stay-Safe-at-Work-A2 Covid 19Document1 pageStay-Safe-at-Work-A2 Covid 19madmossyNo ratings yet

- National Health and Safety Risk AssessmentDocument4 pagesNational Health and Safety Risk AssessmentCarmen M AvinazarNo ratings yet

- Sample Bleach Chemical Agents Risk AssessmentDocument4 pagesSample Bleach Chemical Agents Risk AssessmentmadmossyNo ratings yet

- Guidance on Completing Cytotoxic Drug Risk AssessmentsDocument4 pagesGuidance on Completing Cytotoxic Drug Risk AssessmentsmadmossyNo ratings yet

- Guidance To Support The Review and Updating of Laboratory Biological AgentsDocument14 pagesGuidance To Support The Review and Updating of Laboratory Biological AgentsmadmossyNo ratings yet

- Getting Ready To Go To The Test Centre. Explainer Guide For ChildrenDocument17 pagesGetting Ready To Go To The Test Centre. Explainer Guide For ChildrenmadmossyNo ratings yet

- Covid 19 Information Booklet PDFDocument16 pagesCovid 19 Information Booklet PDFajithathreyasNo ratings yet

- Form EU1 Application Guide for Family MembersDocument3 pagesForm EU1 Application Guide for Family MembersmadmossyNo ratings yet

- National Framework - COVID-19Document1 pageNational Framework - COVID-19UndisclosedNo ratings yet

- Full Licence Application Guidance NotesDocument4 pagesFull Licence Application Guidance NotesmadmossyNo ratings yet

- Form EU2 Explanatory LeafletDocument3 pagesForm EU2 Explanatory LeafletmadmossyNo ratings yet

- 71477Document5 pages71477madmossyNo ratings yet

- The Socio-Economic Impact of Forestry in Co. LeitrimDocument149 pagesThe Socio-Economic Impact of Forestry in Co. Leitrimmadmossy100% (1)

- Action Plan 2018: A Strategy For Ireland'S International Financial Services Sector 2015-2020Document51 pagesAction Plan 2018: A Strategy For Ireland'S International Financial Services Sector 2015-2020Ali PaquiraNo ratings yet

- Irish Government Spending Review 2018 Sports Capital ProgrammeDocument30 pagesIrish Government Spending Review 2018 Sports Capital ProgrammemadmossyNo ratings yet

- Movementplantsplantproductsinto EUfrom Third Countries 290115Document3 pagesMovementplantsplantproductsinto EUfrom Third Countries 290115madmossyNo ratings yet

- Ireland's Public Finances Slowly Recovering After CrisisDocument4 pagesIreland's Public Finances Slowly Recovering After CrisismadmossyNo ratings yet

- Culturally Curious PDFDocument18 pagesCulturally Curious PDFmadmossyNo ratings yet

- SláinteCare Ireland 2019Document58 pagesSláinteCare Ireland 2019madmossyNo ratings yet

- Wild Atlantic Way IrelandDocument22 pagesWild Atlantic Way IrelandmadmossyNo ratings yet

- EC Plant Passport GuideDocument8 pagesEC Plant Passport GuidemadmossyNo ratings yet

- SamphireIslandDocument1 pageSamphireIslandmadmossyNo ratings yet

- Guide to Irish education systemDocument39 pagesGuide to Irish education systemmadmossyNo ratings yet

- Gastronomy of IrlelandDocument13 pagesGastronomy of IrlelandDreamsAvenue.comNo ratings yet

- 2018 Dublin One City One Book Programme FinalDocument2 pages2018 Dublin One City One Book Programme FinalmadmossyNo ratings yet

- Rebuilding Ireland - Action PlanDocument115 pagesRebuilding Ireland - Action PlanmadmossyNo ratings yet

- The Tipperary: WWW - Discoverireland.ie/thetipperary10Document24 pagesThe Tipperary: WWW - Discoverireland.ie/thetipperary10madmossyNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Urine Indican Excretion in Malabsorptive DisordersDocument8 pagesUrine Indican Excretion in Malabsorptive DisordersBiancake Sta. AnaNo ratings yet

- TABLE 160-9: Treatment of DermatophytesDocument11 pagesTABLE 160-9: Treatment of DermatophytesIrsa SevenfoldismNo ratings yet

- Assessment Diagnosis Planning Intervention Rationale Evaluation Short Term GoalDocument3 pagesAssessment Diagnosis Planning Intervention Rationale Evaluation Short Term GoalJanelle Cabida SupnadNo ratings yet

- Vaginal DischargeDocument1 pageVaginal DischargeRAHMANo ratings yet

- Aat Dementia PDFDocument3 pagesAat Dementia PDFMinodora MilenaNo ratings yet

- Megan Haky: M.M.Haky@eagle - Clarion.eduDocument2 pagesMegan Haky: M.M.Haky@eagle - Clarion.eduapi-285540869No ratings yet

- Patients Discharged From Medium Secure Forensic Psychiatry Services: Reconvictions and Risk FactorsDocument9 pagesPatients Discharged From Medium Secure Forensic Psychiatry Services: Reconvictions and Risk FactorsIrisha AnandNo ratings yet

- Significance of Fermented Food in Nutrition and Food ScienceDocument14 pagesSignificance of Fermented Food in Nutrition and Food Scienceoryzae sativaNo ratings yet

- 9 Reasons Why An Apple A Day Keeps The Doctor Away PDFDocument4 pages9 Reasons Why An Apple A Day Keeps The Doctor Away PDFrahul singhNo ratings yet

- Nursing Care Plan for Child with Otitis MediaDocument4 pagesNursing Care Plan for Child with Otitis MediaAde HerlambangNo ratings yet

- PodStick ManualDocument40 pagesPodStick ManualMusafir QolbuNo ratings yet

- Cummings Otolaryngology Chapter 201Document14 pagesCummings Otolaryngology Chapter 201Zllison Mae Teodoro MangabatNo ratings yet

- Black Book Project 3Document69 pagesBlack Book Project 3Pragya SinghNo ratings yet

- People's Vision for Mumbai's DevelopmentDocument86 pagesPeople's Vision for Mumbai's DevelopmentAravind UnniNo ratings yet

- Nutrition SurveilanceDocument15 pagesNutrition SurveilanceBereket G.D.No ratings yet

- NST 11 Spring 2017 Assignment 1Document2 pagesNST 11 Spring 2017 Assignment 1HelenNo ratings yet

- Capillary Blood Glucose Performance Checklist: Numerical Rating Adjectival Description DescriptionDocument2 pagesCapillary Blood Glucose Performance Checklist: Numerical Rating Adjectival Description DescriptionAngeline NavarroNo ratings yet

- Fast Food Addiction: A Major Public Health ConcernDocument12 pagesFast Food Addiction: A Major Public Health ConcernA. K. Mohiuddin100% (1)

- Interview QDocument2 pagesInterview Qziadhammouda60No ratings yet

- 2020-Indian Journal of Public Health Research and Development (Scopus Q-4)Document5 pages2020-Indian Journal of Public Health Research and Development (Scopus Q-4)NoniAndayaniNo ratings yet

- Prevalence of Eating Disorders Among College Students in India: A Systematic ReviewDocument10 pagesPrevalence of Eating Disorders Among College Students in India: A Systematic ReviewIJAR JOURNALNo ratings yet

- Vox Populix On Coronavirus PandemicDocument17 pagesVox Populix On Coronavirus PandemicayuNo ratings yet

- Sleep Deprivation Impacts SHS StudentsDocument64 pagesSleep Deprivation Impacts SHS StudentsAirey Alasan EconarNo ratings yet

- 2018 01 Early Pregnancy Loss LightDocument41 pages2018 01 Early Pregnancy Loss LightMishal FatimaNo ratings yet

- Ngoa, Jose Troy - Sas3Document7 pagesNgoa, Jose Troy - Sas3Ella AroNo ratings yet

- POST ACTIVITY REPORT-MH Caravan-PalananDocument5 pagesPOST ACTIVITY REPORT-MH Caravan-PalananKeith Clarence BunaganNo ratings yet

- COVID-19 Test Report for Mr. AUDARYA MANEDocument1 pageCOVID-19 Test Report for Mr. AUDARYA MANENeutral GodNo ratings yet

- Mono - African Wild Mango Irvingia Gabonensis - EnglishDocument5 pagesMono - African Wild Mango Irvingia Gabonensis - EnglishTom DelongeNo ratings yet

- Type 1 Diabetes Mellitus in Pediatric Patients and Its Impact On Relationships in The Family Enviroment - 2020Document8 pagesType 1 Diabetes Mellitus in Pediatric Patients and Its Impact On Relationships in The Family Enviroment - 2020Nisa FjrNo ratings yet

- Multiple Disability Original HandoutDocument42 pagesMultiple Disability Original HandoutHabtamu DebasuNo ratings yet