Professional Documents

Culture Documents

SUS302 Vs SUS304

Uploaded by

enrico susanto0 ratings0% found this document useful (0 votes)

431 views3 pagesOriginal Title

SUS302 vs SUS304

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

431 views3 pagesSUS302 Vs SUS304

Uploaded by

enrico susantoCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Parameter Material

Composition SUS302 SUS 304

Cr 17.0-19.0% 18.0-20.0%

Ni 8.0-10% 8.0-12 %

Mn 0.0-2.0% 0.0-2.0%

Si 0.00-0.75% 0.00-0.75%

P 0.00-0.04% 0.00-0.04%

C 0.00-0.15% 0.00-0.08%

S 0.00-0.03% 0.00-0.03%

Brinell Hardness 170-440 170-360

Elastic modulus GPa 200 200

Elongation at Break, % 4.5-46 8.0-43

Fatigue Strength, MPa 210-520 210-440

Poisson's Ratio 0.28 0.28

Shear Modulus, GPa 77 77

Shear Strength, MPa 400-830 400-690

Tensile Strength: Ultimate (UTS), MPa 580-1430 580-1180

Tensile Strength: Yield (Proof), MPa 230-1100 230-860

Latent Heat of Fusion, J/g 280 290

Maximum Temperature: Corrosion, °C 410 420

Maximum Temperature: Mechanical, °C 710 710

Melting Completion (Liquidus), °C 1420 1450

Specific Heat Capacity, J/kg-K 480 180

Thermal Conductivity, W/m-K 16 16

Thermal Expansion, µm/m-K 17 17

PREN (Pitting Resistance) 19 20

Material SUS302 SUS 304

Keterangan Grade 302 is a slightly higher Grade 304 is a standard "18/8" stainless.

carbon version than grade 304. It is the most versatile and most widely used

It is widely found in strip and wire stainless steel available, even though a wide

forms. It is a standard range of alternatives are available; and has

specification for chromium and excellent forming and welding characteristics.

chromium-nickel stainless steel The balanced austenitic structure of Grade

sheet, plate, and strip used for 304 enables it to be severely deep drawn

pressure vessels and for general without intermediate annealing.

applications. This means that this grade steel is dominant

Grade 302 stainless steel is in the manufacture of drawn stainless parts

widely used in the stamping, such as sinks, hollow-ware and saucepans.

spinning and wire forming For these applications, it is common to use

industry. This alloy is also used to special "304DDQ" (Deep Drawing Quality)

form springs, washers, screens variants.

and cables. Grade 304 can be readily braked or roll-

formed into a variety of components for

applications in the industrial, architectural,

and transportation fields.

It also has outstanding welding

characteristics. Post-weld annealing is not

required when welding thin sections.

Grade 304L, the low carbon version of 304,

does not require post-weld annealing and is

therefore extensively used in heavy gauge

components (over about 6mm).

Grade 304H with its higher carbon content is

used in applications at elevated

temperatures. The austenitic structure also

gives these grades excellent toughness,

even down to cryogenic temperatures.

Grade 304 stainless steel is excellent in a

wide range of atmospheric environments and

many corrosive media.

It is subject to pitting and crevice corrosion in

warm chloride environments, and to stress

corrosion cracking above 60 °C

(approximate).

Grade 304 is considered to be resistant to

potable water up to approximately 200 mg/L

chlorides at ambient temperatures, reducing

to approximately150 mg/L at 60 °C.

Grade 304 has good oxidation resistance in

intermittent service to 870 °C, and in

continuous service to 925 °C.

Continuous use of 304 in the 425-860 °C

range is not recommended if subsequent

aqueous corrosion resistance is important.

Grade 304L is more resistant to carbide

precipitation and can be heated into this

temperature range.

Grade 304H has higher strength at elevated

temperatures so is often used for structural

and pressure-containing applications at

temperatures above 500 °C up to about 800

Material SUS302 SUS 304

°C (approximate).

304H will become sensitized in the

temperature range of 425-860 °C. Whilst this

is not a problem for high-temperature

applications, it will result in reduced aqueous

corrosion resistance.

During Solution Treatment (Annealing) Grade

304 can be heated to 1010-1120 °C and is

then cooled rapidly. These grades cannot be

hardened by thermal treatment.

Aplication

Food processing equipment, particularly

in beer brewing, milk processing &

winemaking

Kitchen benches, sinks, troughs,

equipment and appliances

Architectural paneling, railings & trim

Chemical containers, including for

transport

Heat Exchangers

Woven or welded screens for mining,

quarrying & water filtration

Threaded fasteners

Springs

A general purposed steel, 302 stainless steel is designed to offer a greater resistance to corrosion than 301

stainless steel. Constructed with a lower percentage of carbon, 304 stainless steel is designed to limit carbide

precipitation. This type of stainless steel is often used in high-temperature applications.

Sumber :

https://www.makeitfrom.com/compare/AISI-302-S30200-Stainless-Steel/AISI-304-S30400-Stainless-

Steel

https://www.azom.com/article.aspx?ArticleID=8197

https://www.azom.com/article.aspx?ArticleID=965

You might also like

- JSG 0116-1996Document158 pagesJSG 0116-1996Loknath MathnikarNo ratings yet

- Rubber Research Institute Testing FeeDocument15 pagesRubber Research Institute Testing FeemoumonaNo ratings yet

- 3455 1971 Reff2020Document17 pages3455 1971 Reff2020Ashish DubeyNo ratings yet

- Gauging Practice For Plain SurfacesDocument20 pagesGauging Practice For Plain SurfacesAVINASHNo ratings yet

- Determination of Copper in Anode and Blister Copper: Standard Test Method ForDocument3 pagesDetermination of Copper in Anode and Blister Copper: Standard Test Method ForEric GozzerNo ratings yet

- 4711Document10 pages4711Gaurav AgarwalNo ratings yet

- Lab Asst AdmitDocument2 pagesLab Asst AdmitTathagata DasNo ratings yet

- Is 2708 1993Document10 pagesIs 2708 1993ghosh_ranjoyNo ratings yet

- Test Certificate: Fosroc Chemicals (India) PVT LTDDocument1 pageTest Certificate: Fosroc Chemicals (India) PVT LTDVimal Tiwari100% (1)

- Astm e 1251-2011Document10 pagesAstm e 1251-2011ERDA TPI REPORTNo ratings yet

- C 561Document2 pagesC 561Asep TheaNo ratings yet

- Surface Treatments Rust Preventer Phosphatic Coating On Ferrous Materials Norm 2801Document4 pagesSurface Treatments Rust Preventer Phosphatic Coating On Ferrous Materials Norm 2801anhthoNo ratings yet

- Is 736 1986Document21 pagesIs 736 1986atulNo ratings yet

- TolerancesDocument2 pagesTolerancesAdithya ShourieNo ratings yet

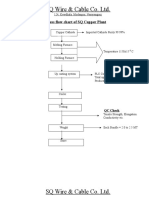

- Process Flow Chart of SQ CABLES FinalDocument9 pagesProcess Flow Chart of SQ CABLES Finaljamil100% (1)

- In-House Calibration SheetDocument4 pagesIn-House Calibration SheetKannan MurugesanNo ratings yet

- Is 209 - 1992 Zinc Ingot - SpecificationDocument5 pagesIs 209 - 1992 Zinc Ingot - SpecificationRam NiwasNo ratings yet

- Iso 6508 3 2015 en PDFDocument8 pagesIso 6508 3 2015 en PDFMohan.v100% (1)

- Jed 021M1Document2 pagesJed 021M1Reginaldo Santos100% (1)

- As 1544.4-2003 Methods For Impact Tests On Metals Calibration of The Testing MachineDocument8 pagesAs 1544.4-2003 Methods For Impact Tests On Metals Calibration of The Testing MachineSAI Global - APACNo ratings yet

- Project - 1: - PROJECT TITLE:-To Reduce Bolt Loosening Problem inDocument38 pagesProject - 1: - PROJECT TITLE:-To Reduce Bolt Loosening Problem inmanpreetNo ratings yet

- Preece TestDocument18 pagesPreece TestSyed Aftab AhmedNo ratings yet

- Henkel PDFDocument20 pagesHenkel PDFmangal deo pathakNo ratings yet

- Astm G85Document6 pagesAstm G85Abdul MunirNo ratings yet

- 6063 Aluminum Alloy PropertiesDocument1 page6063 Aluminum Alloy Propertiestrieu vy phamNo ratings yet

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 pagesControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNo ratings yet

- NABLStdProcedure PDFDocument4 pagesNABLStdProcedure PDFPower AgeNo ratings yet

- List of Etchant For MetallographyDocument3 pagesList of Etchant For Metallographyniraj_hwbNo ratings yet

- Fasteners Part-3 Is.1369.1.1993Document9 pagesFasteners Part-3 Is.1369.1.1993Manish ThakurNo ratings yet

- CM PF 307 Brand NameDocument1 pageCM PF 307 Brand NameJagannath Majhi100% (3)

- 2.9years Experience in Quality Department-Castings (Foundry) Sujith. DDocument3 pages2.9years Experience in Quality Department-Castings (Foundry) Sujith. Dsrsivaraman81No ratings yet

- Teclock - Hardness TesterDocument15 pagesTeclock - Hardness TesterAnton SuryaNo ratings yet

- Welding Wire Diameter CHART PDFDocument1 pageWelding Wire Diameter CHART PDFFerhat KahveciNo ratings yet

- Is 9879-1998 (Ra-2021)Document8 pagesIs 9879-1998 (Ra-2021)singaravelan narayanasamyNo ratings yet

- Corrosion Resistant TMT Bars and Which One To ChooseDocument15 pagesCorrosion Resistant TMT Bars and Which One To ChooseHiren DesaiNo ratings yet

- Is.4163.2004 Inclusion RatingDocument43 pagesIs.4163.2004 Inclusion Ratingmass3444100% (1)

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Document12 pagesCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNo ratings yet

- Is 9417 1989Document15 pagesIs 9417 1989Ganesh RajaNo ratings yet

- DIN - 17022-5-2000 Heat Treatment of Ferrous MaterialDocument13 pagesDIN - 17022-5-2000 Heat Treatment of Ferrous MaterialHitesh SuvarnaNo ratings yet

- Scheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFDocument6 pagesScheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFbipinagarwalNo ratings yet

- Mechanical Properties of Steel With A Widmanstatten StructureDocument3 pagesMechanical Properties of Steel With A Widmanstatten StructureblahsomNo ratings yet

- Riser Analysis Using Casting Simulation Techniques During SolidificationDocument2 pagesRiser Analysis Using Casting Simulation Techniques During SolidificationRizal SandiNo ratings yet

- Jis Z2243 1992Document9 pagesJis Z2243 1992feyoNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Automatic Portable Spot Welding MachineDocument24 pagesAutomatic Portable Spot Welding MachinekeerthanaNo ratings yet

- Automated Mechanism For Retrieval of Spectrocoin Sample From Copper DieDocument2 pagesAutomated Mechanism For Retrieval of Spectrocoin Sample From Copper DieBONFRINGNo ratings yet

- EM6 DatasheetDocument1 pageEM6 DatasheetFlorin Apopei0% (1)

- Shell Permeability PresentationDocument29 pagesShell Permeability Presentationbilalabbasi1990No ratings yet

- (Jaso) F102-09Document16 pages(Jaso) F102-09AJ100% (1)

- Welding StandardDocument22 pagesWelding Standardsonnu151No ratings yet

- J.K.Cement Works-Muddapur J K Super Cement: END of ReportDocument12 pagesJ.K.Cement Works-Muddapur J K Super Cement: END of ReportSiddhesh Kamat MhamaiNo ratings yet

- Is 1501 Part 1Document114 pagesIs 1501 Part 1Mohit DhimaanNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartSundar KumarNo ratings yet

- Dos A OilDocument5 pagesDos A OilimranNo ratings yet

- Is 733-1983Document17 pagesIs 733-1983lokesh38No ratings yet

- Astm A239Document4 pagesAstm A239Ngô Trung NghĩaNo ratings yet

- Stainless Steel Grade AISI 304 PDFDocument2 pagesStainless Steel Grade AISI 304 PDFSarita ForgingNo ratings yet

- 304 Technical Data PDFDocument3 pages304 Technical Data PDFNithin BasavaNo ratings yet

- Grade Data SheetDocument2 pagesGrade Data Sheetamitkharb111195No ratings yet

- Data Sheet For Ss 304 GradeDocument2 pagesData Sheet For Ss 304 Grades swamiNo ratings yet

- Douluo Dalu V28 Heaven Dou Palace RebellionDocument109 pagesDouluo Dalu V28 Heaven Dou Palace Rebellionenrico susantoNo ratings yet

- Douluo Dalu V34 Tang Sans Eight Spirit RingsDocument114 pagesDouluo Dalu V34 Tang Sans Eight Spirit Ringsenrico susantoNo ratings yet

- Douluo Dalu V32 Seagods TrialsDocument117 pagesDouluo Dalu V32 Seagods Trialsenrico susantoNo ratings yet

- Douluo Dalu V31 Ashore On Seagod IslandDocument117 pagesDouluo Dalu V31 Ashore On Seagod Islandenrico susantoNo ratings yet

- Douluo Dalu V27 Gengxin CityDocument121 pagesDouluo Dalu V27 Gengxin Cityenrico susantoNo ratings yet

- Douluo Dalu V33 Seven Devils AvatarsDocument116 pagesDouluo Dalu V33 Seven Devils Avatarsenrico susantoNo ratings yet

- Douluo Dalu V20 - Slaughter CityDocument102 pagesDouluo Dalu V20 - Slaughter Cityenrico susantoNo ratings yet

- Douluo Dalu V29 Sea God IslandDocument103 pagesDouluo Dalu V29 Sea God Islandenrico susantoNo ratings yet

- Douluo Dalu V25 - Single Category ClansDocument127 pagesDouluo Dalu V25 - Single Category Clansenrico susantoNo ratings yet

- Douluo Dalu V23 - Spirit Hunting OperationDocument86 pagesDouluo Dalu V23 - Spirit Hunting Operationenrico susantoNo ratings yet

- Douluo Dalu V24 - Otherworldly Tang SectDocument92 pagesDouluo Dalu V24 - Otherworldly Tang Sectenrico susantoNo ratings yet

- Douluo Dalu V11 - Vigorous GodDocument113 pagesDouluo Dalu V11 - Vigorous Godenrico susantoNo ratings yet

- Douluo Dalu V26 Xiao Wus ResurrectionDocument118 pagesDouluo Dalu V26 Xiao Wus Resurrectionenrico susantoNo ratings yet

- Douluo Dalu V22 - Clear Sky SchoolDocument109 pagesDouluo Dalu V22 - Clear Sky Schoolenrico susantoNo ratings yet

- Douluo Dalu V09 - Golden Iron TriangleDocument105 pagesDouluo Dalu V09 - Golden Iron Triangleenrico susantoNo ratings yet

- Douluo Dalu V19 - Purple God LightDocument108 pagesDouluo Dalu V19 - Purple God Lightenrico susantoNo ratings yet

- Douluo Dalu V21 - Tang San's Third Spirit BoneDocument108 pagesDouluo Dalu V21 - Tang San's Third Spirit Boneenrico susantoNo ratings yet

- Douluo Dalu V35 Challenge, Title DouluoDocument109 pagesDouluo Dalu V35 Challenge, Title Douluoenrico susantoNo ratings yet

- Douluo Dalu V16 - Consummate FusionDocument104 pagesDouluo Dalu V16 - Consummate Fusionenrico susantoNo ratings yet

- Douluo Dalu V17 - Arrival of The PhoenixDocument144 pagesDouluo Dalu V17 - Arrival of The Phoenixenrico susantoNo ratings yet

- Douluo Dalu V07 - Great Spirit BattleDocument106 pagesDouluo Dalu V07 - Great Spirit Battleenrico susantoNo ratings yet

- Douluo Dalu V15 - Illusion Breaking Demon EyeDocument141 pagesDouluo Dalu V15 - Illusion Breaking Demon Eyeenrico susantoNo ratings yet

- Douluo Dalu Volume 12 - A Hammer Called Clear SkyDocument133 pagesDouluo Dalu Volume 12 - A Hammer Called Clear SkyRay Joseph LealNo ratings yet

- Douluo Dalu V18 - Three Spirit BonesDocument144 pagesDouluo Dalu V18 - Three Spirit Bonesenrico susantoNo ratings yet

- Douluo Dalu V08 - Emperor TeamDocument107 pagesDouluo Dalu V08 - Emperor Teamenrico susantoNo ratings yet

- Douluo Dalu Volume 13 - The Fourth Spirit AbilityDocument127 pagesDouluo Dalu Volume 13 - The Fourth Spirit AbilityRay Joseph LealNo ratings yet

- Douluo Dalu Volume 14 - Elephant Armored SchoolDocument127 pagesDouluo Dalu Volume 14 - Elephant Armored SchoolRay Joseph LealNo ratings yet

- Douluo Dalu V01 - Douluo ContinentDocument115 pagesDouluo Dalu V01 - Douluo Continentenrico susantoNo ratings yet

- Douluo Dalu V04 - Shrek Seven DevilsDocument107 pagesDouluo Dalu V04 - Shrek Seven Devilsenrico susantoNo ratings yet

- Douluo Dalu V05 - Star Dou ForestDocument113 pagesDouluo Dalu V05 - Star Dou Forestenrico susantoNo ratings yet

- Ak-90le SuezDocument1 pageAk-90le Suezinversiones del peruNo ratings yet

- The Pulp and Paper IndustryDocument3 pagesThe Pulp and Paper IndustrysukanyagggNo ratings yet

- ShopNotes No. 136 FullDocument52 pagesShopNotes No. 136 FullKen Lock100% (3)

- ISO 2768 Machining Tolerance StandardDocument2 pagesISO 2768 Machining Tolerance Standardlohith.raviNo ratings yet

- Tabela - Lokring MachineDocument28 pagesTabela - Lokring MachineThalles AlmeidaNo ratings yet

- Technical Presentation On Engine ValvesDocument32 pagesTechnical Presentation On Engine ValvesRockey RahulNo ratings yet

- 7 - OligomerizationDocument16 pages7 - OligomerizationAn Lê TrườngNo ratings yet

- Universal Wps Stainless Steel Welding Lores enDocument1 pageUniversal Wps Stainless Steel Welding Lores en19MME-S1-323 Usman Ul Hassan PirzadaNo ratings yet

- Semi Solid RheocastingDocument21 pagesSemi Solid RheocastingGiacomo ZammattioNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- 913.1183.1 SmartWelding V5 ENDocument78 pages913.1183.1 SmartWelding V5 ENVudayabhaskarNo ratings yet

- 22565-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Document14 pages22565-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Shivraj KolambekarNo ratings yet

- Supply Range of AISI M42 Tool Steel High SpeedDocument4 pagesSupply Range of AISI M42 Tool Steel High SpeedSama UmateNo ratings yet

- New Low-Cost Manufacturing Methods To Produce SiliDocument9 pagesNew Low-Cost Manufacturing Methods To Produce Sililyxuannam lyNo ratings yet

- Mse 353 Lecture-1Document7 pagesMse 353 Lecture-1physical metallurgyNo ratings yet

- Centrifugal Shroud Tundish SteelmakingDocument12 pagesCentrifugal Shroud Tundish Steelmakingdebasish chatterjeeNo ratings yet

- Lathe Machine: Definition, Introduction, Parts, Types, Operations, and Specifications (With PDFDocument22 pagesLathe Machine: Definition, Introduction, Parts, Types, Operations, and Specifications (With PDFMrTurner HoodNo ratings yet

- Iso 1502 1996Document12 pagesIso 1502 1996Emaculata Monalisa0% (1)

- Belazo Elastomeric Roof PaintDocument2 pagesBelazo Elastomeric Roof PaintrumahsketchNo ratings yet

- UK MOD (Issue 3 Publication Date 20 September 2009) - Code of Practice For Protective FinishesDocument48 pagesUK MOD (Issue 3 Publication Date 20 September 2009) - Code of Practice For Protective FinishesLuis Gustavo PachecoNo ratings yet

- Steel Wind Dust Fence: Boegger CatalogueDocument7 pagesSteel Wind Dust Fence: Boegger CatalogueaanNo ratings yet

- Basic Bone Screw Set 2Document26 pagesBasic Bone Screw Set 2Bambang ApryantoNo ratings yet

- P-10915 2020 ForneyCatalogOnline 201130 v5-1 MS WeldingDocument60 pagesP-10915 2020 ForneyCatalogOnline 201130 v5-1 MS WeldingGreg EvansNo ratings yet

- CE3458 Parts ManualDocument84 pagesCE3458 Parts ManualMrbigg10No ratings yet

- TDS Teroson WT 112 DB en 29072019Document3 pagesTDS Teroson WT 112 DB en 29072019muraleejNo ratings yet

- Donner CompanyDocument1 pageDonner CompanyAsri Marwa UmniatiNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- Mitigation Intergranular Corrosion of SSDocument1 pageMitigation Intergranular Corrosion of SSsamy singaporeNo ratings yet

- 19PEE16Document50 pages19PEE16Amatari EbiNo ratings yet

- Muncaster 11 A3 Sheet 02Document1 pageMuncaster 11 A3 Sheet 02Juan PastorNo ratings yet