Professional Documents

Culture Documents

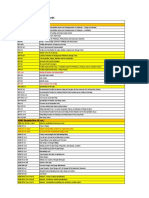

Welding of Pipelines and Related Facilities: 1 General

Uploaded by

Rohit KambleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding of Pipelines and Related Facilities: 1 General

Uploaded by

Rohit KambleCopyright:

Available Formats

Welding of Pipelines and Related Facilities

1 General ASNTI

RP SNT-TC-IA Personnel Qualification and Certification

1.1 SCOPE ill Nondestructive Testing

This standard covers the gas and arc welding of butt, fillet, ACCP ASNT Central Certification Program

and socket welds in carbon and low-alloy steel piping used in ASTM2

the compression, pumping, and transmission of cmde petro- E 164 Standard Practice for Ultrasonic Contact

leum, petroleum products, fuel gases, carbon dioxide, and Examination of Weldments

nitrogen and, where applicable, covers welding on distribution E 165 Standard Test for Liquid Penetrant

systems. It applies to both new constmction and in-service Examination

welding.The welding may be done by a shielded metal-arc E709 Standard Guide for Magnetic Particle

welding, submerged arc welding, gas tungsten-arc welding, Examination

gas metal-arc welding, flux-cored arc welding, plasma arc E747 Standard Practice for Design, Manu/ac-

welding, oxyacetylene welding, or flash butt welding process tue and Material Grouping Classification

or by a combination of these processes using a manual, semi- q/ Wire Image Quality Indicators (IQI)

automatic, or automatic welding technique or a combination of Usedfor Radiology

these techniques. The welds may be produced by position or E 1025 Standard Practice for Design, Manufac-

roll welding or by a combination of position and roll welding. ture, and Material Grouping Classification

This standard also covers the procedures for radiographic, of Hole-T.vpe Image Quality Indicators

magnetic particle, liquid penetrant, and ultrasonic testing as (IQI) UsedfiJr Radiology

well as the acceptance standards to be applied to production AWS3

welds tested to destmction or inspected by radiographic, A3.0 Welding, Terms and Definitions

magnetic particle, liquid penetrant, ultrasonic, and visual test- A5.I Covered Carbon Steel Arc Welding

ing methods. Electrodes

The values stated in either inch-pound units or SI units are A';.2 Iron and Steel Oryfuel Gas Welding Rods

to be regarded separately as standard. Each system is to be A5.5 Low Alloy Steel Covered Arc Welding

used independently of the other, without combining values in Electrodes

any way. AS. 17 Carbon Steel Electrodes and Flu.xes for

Processes other than those described above will be consid- Submerged Arc Welding

ered for inclusion in this standard. Persons who wish to have AS.I8 Carbon Steel Filler Metals for Gas

other processes included shall submit, as a minimum, the fol- Shielded Arc Welding

lowing infonnation for the committee's consideration: AS.20 Carbon Steel Electrodes for Flux Cored

Arc Welding

a. A description of the welding process. AS.28 Low Alloy Steel Filler Metals for Gas

b. A proposal on the essential variables. Shielded Arc Welding

c. A welding procedure specification. AS.29 Low Alloy Steel Electrodes for FilL><

d. Weld inspection methods. Cored Arc Welding

e. Types of weld imperfections and their proposed accep- BSI4

tance limits. BS 7448: Part 2 Fracture Mechanics Toughness Tests Part

f. Repair procedures. 2, Methodfor Determination of K/c Criti-

It is intended that all work perfonned in accordance with this cal CTOD and Critical J Values qfWelds

standard shall meet or exceed the requirements of this standard. in Metallic Materials

lAmerican Society for Nondestructive Testing, Inc., 1711 Arlingate

2 Referenced Publications Lane, P.O. Box 28518, Columbus, Ohio 43228-0518.

2American Society for Testing and Materials, 100 Barr Harbor

The following standards, codes, and specifications are

Drive, West Conshohocken, Pennsylvania 19428-2959.

cited in this standard: 3American Welding Society, 550 N.W. Lejeune Road, Miami,

Florida 33126.

API 4British Standards Institution. British Standards House. 389

Spec 5L Specification for Line Pipe Chiswick High Road, London, W4 4AL, United Kingdom.

You might also like

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- List of Welding CodeDocument16 pagesList of Welding CodeAmirul AsyrafNo ratings yet

- 8474l 000 Jss 6300 001 1 General Requirements For WeldingDocument69 pages8474l 000 Jss 6300 001 1 General Requirements For WeldinglebienthuyNo ratings yet

- MZLN-EL-XSPDS-00-290105_Upstream Line Pipe - API5LDocument38 pagesMZLN-EL-XSPDS-00-290105_Upstream Line Pipe - API5LPaul NieNo ratings yet

- Tubing and CasingDocument10 pagesTubing and CasingEnd LabNo ratings yet

- Clad and Lined Pipe Specification: Company SpecificationsDocument59 pagesClad and Lined Pipe Specification: Company SpecificationsrachedNo ratings yet

- Api1104 1-1Document17 pagesApi1104 1-1abidahad311No ratings yet

- Is - 9595Document55 pagesIs - 9595sanjeet_sengar100% (3)

- Indicators (IQI) Used For Radiology: 3 Terms, Definitions, Acronyms, and AbbreviationsDocument1 pageIndicators (IQI) Used For Radiology: 3 Terms, Definitions, Acronyms, and AbbreviationsRiaz AhmadNo ratings yet

- Normative and Informative References Drilling RigDocument2 pagesNormative and Informative References Drilling RigSatriaNo ratings yet

- 1.listado de Normas, Estandares y CódigosDocument16 pages1.listado de Normas, Estandares y CódigosjarajavierNo ratings yet

- List of Welding Codes PDFDocument3 pagesList of Welding Codes PDFAlienshow100% (2)

- Codes and Standards DocumentDocument4 pagesCodes and Standards DocumentOvaisNo ratings yet

- Standards & Codes: S.no Standard & CodeDocument6 pagesStandards & Codes: S.no Standard & CodeVishal SharmaNo ratings yet

- Codes & Standards For Natural GasDocument13 pagesCodes & Standards For Natural Gasharikrishnanpd3327No ratings yet

- Code and Standard in OGDocument8 pagesCode and Standard in OGTatit P. PrapancaNo ratings yet

- Normas Y Códigos Nacionales E Internacionales AsmeDocument6 pagesNormas Y Códigos Nacionales E Internacionales Asmeviviana gomezNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationMoustafa Bayoumi100% (1)

- Welding of Pipelines and Related Facilities: 1 ScopeDocument1 pageWelding of Pipelines and Related Facilities: 1 ScopeRiaz AhmadNo ratings yet

- Identificacion Y Clasificacion de Normas: Designacion TituloDocument5 pagesIdentificacion Y Clasificacion de Normas: Designacion TitulocarlosalbarNo ratings yet

- Sabp A 022Document40 pagesSabp A 022Muhammad Awais100% (3)

- Welding Inspector May 2021Document8 pagesWelding Inspector May 2021SUNIL BABURAO GAVADENo ratings yet

- ASME Standard & Code ListingDocument7 pagesASME Standard & Code ListingMyron CampbellNo ratings yet

- Alloy 52MDocument11 pagesAlloy 52Mharan2000No ratings yet

- British Standards For WeldingDocument8 pagesBritish Standards For Weldingsusanweb100% (2)

- StandardsDocument7 pagesStandardsMoch Rafi AnugrahNo ratings yet

- Offshore Skid Piping DesignDocument7 pagesOffshore Skid Piping DesignmihahudeaNo ratings yet

- Pipework SpecificationDocument111 pagesPipework Specificationwentroprem100% (2)

- Welding CodeDocument14 pagesWelding CodeKureiNo ratings yet

- Welding StandardsDocument14 pagesWelding Standardsnikidragon4u100% (1)

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Q1, Module 1, Lesson 2Document10 pagesQ1, Module 1, Lesson 2Jerome A. GomezNo ratings yet

- ACSR ConductorDocument13 pagesACSR ConductorHrshiya SharmaNo ratings yet

- SS Weld SpecificationDocument39 pagesSS Weld SpecificationmurugesanNo ratings yet

- Lesson X Specification No. DescriptionDocument1 pageLesson X Specification No. DescriptioncrysNo ratings yet

- List of International Standards: API Standards Block (25 Nos.)Document4 pagesList of International Standards: API Standards Block (25 Nos.)Siva baalan100% (1)

- Koc MP 019Document19 pagesKoc MP 019Ravi MahetoNo ratings yet

- AWS Standards Complete List 0503Document4 pagesAWS Standards Complete List 0503Ron GoolsbyNo ratings yet

- Code and StandardsDocument2 pagesCode and StandardsmarcoNo ratings yet

- Control Ferrite Content Stainless Steel WeldsDocument5 pagesControl Ferrite Content Stainless Steel Weldstedmer1No ratings yet

- AWS Standards List GuideDocument4 pagesAWS Standards List GuideShyam SinghNo ratings yet

- Mechanical Test Codes and Standards ListDocument6 pagesMechanical Test Codes and Standards ListIsmail TpNo ratings yet

- 01-SAMSS-048 2018 CRA Clad or Lined Steel PipeDocument22 pages01-SAMSS-048 2018 CRA Clad or Lined Steel PipeWHWENNo ratings yet

- 01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsDocument18 pages01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsWHWEN100% (1)

- Normas Mas Comunes Usadas en ProyectosDocument11 pagesNormas Mas Comunes Usadas en ProyectosAlvaro Gutiérrez TrocheNo ratings yet

- 1113 DWSDWSDDocument53 pages1113 DWSDWSDenjoygurujiNo ratings yet

- HFY PIP SP 00013 X Specification For Non Sour Service - A CommentedDocument9 pagesHFY PIP SP 00013 X Specification For Non Sour Service - A CommentedVignesh PanchabakesanNo ratings yet

- 01 Samss 048 PDFDocument21 pages01 Samss 048 PDFMohamed SolimanNo ratings yet

- List of AWSDocument5 pagesList of AWSkoneidinNo ratings yet

- Astm A403-A403m-04Document7 pagesAstm A403-A403m-04NadhiraNo ratings yet

- Code of Welding Process Qualification-CHINADocument71 pagesCode of Welding Process Qualification-CHINAParvee K Nakwal100% (1)

- Astm A1007Document3 pagesAstm A1007Damy ManesiNo ratings yet

- Astm f1548 1994Document6 pagesAstm f1548 1994dharlanuctcomNo ratings yet

- Steel Investment Castings General Requirements, For Pressure-Containing PartsDocument12 pagesSteel Investment Castings General Requirements, For Pressure-Containing PartsManivannanMudhaliarNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- 91symp11 1Document1 page91symp11 1Rohit KambleNo ratings yet

- To Populate The ANDE Community A Special Provision Was Made Within The ANDE Standard Called - Case I "Transitional Provisions"Document1 pageTo Populate The ANDE Community A Special Provision Was Made Within The ANDE Standard Called - Case I "Transitional Provisions"Rohit KambleNo ratings yet

- Effect of Chemical Elements in Steel PDFDocument2 pagesEffect of Chemical Elements in Steel PDFbill_lee_242No ratings yet

- Improved To Advance Public Safety and Quality Industry-Wide. SomeDocument1 pageImproved To Advance Public Safety and Quality Industry-Wide. SomeRohit KambleNo ratings yet

- ANDE Application RequirementsDocument1 pageANDE Application RequirementsRohit KambleNo ratings yet

- ANDE Certification: Certifications For All NDE Certificants Expire Every 5 YearsDocument1 pageANDE Certification: Certifications For All NDE Certificants Expire Every 5 YearsRohit KambleNo ratings yet

- 91symp11 2Document1 page91symp11 2Rohit KambleNo ratings yet

- 91symp11 3Document1 page91symp11 3Rohit KambleNo ratings yet

- 2Document1 page2Rohit KambleNo ratings yet

- Din en Iso 4014Document16 pagesDin en Iso 4014hasan_676489616100% (7)

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- Astm A6 PDFDocument59 pagesAstm A6 PDFAlexi SanjinésNo ratings yet

- PRINCE2 Foundation Sample PaperDocument24 pagesPRINCE2 Foundation Sample PaperAnil Basnet100% (1)

- Penguard Primer: Technical DataDocument4 pagesPenguard Primer: Technical DataRohit KambleNo ratings yet

- OffshoreDocument225 pagesOffshoreRohit KambleNo ratings yet

- HSC Rules July 2016Document362 pagesHSC Rules July 2016maaathanNo ratings yet

- Return Trip RedBus Ticket - TQ3K22800244Document3 pagesReturn Trip RedBus Ticket - TQ3K22800244Rohit KambleNo ratings yet

- Structural Welding Code - Steel: AWS D1.1/D1.1M:2010 An American National StandardDocument1 pageStructural Welding Code - Steel: AWS D1.1/D1.1M:2010 An American National StandardRohit KambleNo ratings yet

- Improved To Advance Public Safety and Quality Industry-Wide. SomeDocument1 pageImproved To Advance Public Safety and Quality Industry-Wide. SomeRohit KambleNo ratings yet

- View Indian Standards Under Compulsory Certification Free of CostDocument1 pageView Indian Standards Under Compulsory Certification Free of CostRohit KambleNo ratings yet

- Paint CalculatorDocument2 pagesPaint CalculatorHafiz Usama ShahzadNo ratings yet

- AWS D1.1 Structural Welding Code for SteelDocument1 pageAWS D1.1 Structural Welding Code for SteelRohit Kamble0% (1)

- Effect of Chemical Elements in Steel PDFDocument2 pagesEffect of Chemical Elements in Steel PDFbill_lee_242No ratings yet

- Taken From The ANDE StandardDocument1 pageTaken From The ANDE StandardRohit KambleNo ratings yet

- ASME Personnel Certification ANDE-1: Jon Labrador Madrid, Spain April 2018Document1 pageASME Personnel Certification ANDE-1: Jon Labrador Madrid, Spain April 2018Rohit KambleNo ratings yet

- This Standard Provides The Requirements For A "Central Qualification / Certification Program"Document1 pageThis Standard Provides The Requirements For A "Central Qualification / Certification Program"Rohit KambleNo ratings yet

- 4Document1 page4Rohit KambleNo ratings yet

- Aws DDocument1 pageAws DRohit KambleNo ratings yet

- View Indian Standards Under Compulsory Certification Free of CostDocument1 pageView Indian Standards Under Compulsory Certification Free of CostRohit KambleNo ratings yet

- 2Document1 page2Rohit KambleNo ratings yet