Professional Documents

Culture Documents

ASTM A105 Matl Property PDF

ASTM A105 Matl Property PDF

Uploaded by

Athiphap SrisupareerathCopyright:

Available Formats

You might also like

- GBT3077-2015 enDocument29 pagesGBT3077-2015 enSinan Chen100% (1)

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- Asme Sa 213 Grade t92 TubesDocument1 pageAsme Sa 213 Grade t92 TubesFerroPipENo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatNo ratings yet

- Toriconical Head 87 PsiDocument2 pagesToriconical Head 87 PsiFabio Augusto Hincapie HenaoNo ratings yet

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNo ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- PIPE SpecificationDocument5 pagesPIPE SpecificationNilesh GohelNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- Cupola Malleable Iron: Standard Specification ForDocument4 pagesCupola Malleable Iron: Standard Specification Forali ahmedNo ratings yet

- Astm A234-A234m-06Document8 pagesAstm A234-A234m-06NadhiraNo ratings yet

- Technical Data Handbook of Carbon Steel FittingsDocument244 pagesTechnical Data Handbook of Carbon Steel FittingsKrishna KumarNo ratings yet

- ASME B16.47 Serie A & BDocument1 pageASME B16.47 Serie A & BVivi OktaviantiNo ratings yet

- Certificado Copla SW 2Document1 pageCertificado Copla SW 2juan aguilarNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Sa 36Document4 pagesSa 36edisson_barreraNo ratings yet

- BS Bolt MaterialDocument1 pageBS Bolt MaterialKamlesh LuharNo ratings yet

- Asme Sa 333 Grade 6 PipesDocument1 pageAsme Sa 333 Grade 6 PipesFerroPipENo ratings yet

- 1018 Mechanical PropertiesDocument2 pages1018 Mechanical PropertiesjangaswathiNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

- ASTM A572 Grade 50 Plate: AnalysisDocument2 pagesASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoNo ratings yet

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet

- Fr20-016.007-1-Bridas de 10-SlipDocument1 pageFr20-016.007-1-Bridas de 10-SlipEduardo Dudlei Jimenez CarbajalNo ratings yet

- DIN 3015 ClampsDocument17 pagesDIN 3015 ClampsBalderas Rosas WilibaldoNo ratings yet

- Astm A53Document2 pagesAstm A53DeepakNo ratings yet

- ASTM A536 Ductile Iron Castings Tensile Requirements PDFDocument1 pageASTM A536 Ductile Iron Castings Tensile Requirements PDFTheOne Yasir100% (1)

- Astm C547Document7 pagesAstm C547DilaFirizqinaNo ratings yet

- Douglas Chero Catalogue Valve 6-2003Document89 pagesDouglas Chero Catalogue Valve 6-2003Yurizki LhzNo ratings yet

- Surface Vehicle Standard: 400 Commonwealth Drive, Warrendale, PA 15096-0001Document5 pagesSurface Vehicle Standard: 400 Commonwealth Drive, Warrendale, PA 15096-0001Angel HernándezNo ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowLuna LukaNo ratings yet

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Document16 pagesVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNo ratings yet

- Astm Materials-Piping SpecDocument3 pagesAstm Materials-Piping Speckaushalacharya100% (1)

- LE B-255 H4R: ClassificationDocument2 pagesLE B-255 H4R: ClassificationVivien EmeraldoNo ratings yet

- B4A3Document6 pagesB4A3ashokclineNo ratings yet

- Certificado de Calidad Brida WN SCH-80 2.5Document1 pageCertificado de Calidad Brida WN SCH-80 2.5Jackelin MayraNo ratings yet

- PV Elite (Construccion de Recipiente) MDMTDocument8 pagesPV Elite (Construccion de Recipiente) MDMTAlejandro CanoNo ratings yet

- Din 2448Document3 pagesDin 2448Cristian Adrian ANo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- 1 Pipes Weights and Dimensions ASME ANSI B36.10-19Document1 page1 Pipes Weights and Dimensions ASME ANSI B36.10-19Leonardo Cusó ContrerasNo ratings yet

- Stainless Steel Tube SpecificationsDocument7 pagesStainless Steel Tube Specificationsgkamesh84No ratings yet

- L80 - Continental AlloysDocument2 pagesL80 - Continental Alloystoxa0707No ratings yet

- ASTM Comparison PDFDocument1 pageASTM Comparison PDFRaja HoneNo ratings yet

- DIN 17100 TablasDocument2 pagesDIN 17100 Tablasanonimarium100% (3)

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizNo ratings yet

- AWH Catalogue DIN 11864-11853 1.1Document70 pagesAWH Catalogue DIN 11864-11853 1.1dingobk1No ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105lavius_mNo ratings yet

- 1 4571a316ti69Document2 pages1 4571a316ti69Admir TalicNo ratings yet

- 1330 Crni Mo 831Document2 pages1330 Crni Mo 831sajay_suryaNo ratings yet

- 1 4305a30365Document2 pages1 4305a30365skidanjeNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 1.4125 440c PDFDocument2 pages1.4125 440c PDFsuntansueNo ratings yet

- En10083-2 - 1996 - C35eDocument3 pagesEn10083-2 - 1996 - C35ealextentwentyNo ratings yet

- 1.0577 S355J2Document1 page1.0577 S355J2sergonNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105Venkat NarasimmanNo ratings yet

- C45EDocument3 pagesC45ETrương Định100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- A 504 - 93 R99 QtuwnaDocument9 pagesA 504 - 93 R99 QtuwnaCHRISTIAN ZAVALANo ratings yet

- Revamping Ammonia ConverterDocument5 pagesRevamping Ammonia ConverterHsein WangNo ratings yet

- Engineering Materials and Metallurgy (ME 2253)Document23 pagesEngineering Materials and Metallurgy (ME 2253)Praven KumarNo ratings yet

- Sae j429 Vs Astm A354 BD PDFDocument2 pagesSae j429 Vs Astm A354 BD PDFAdam GordonNo ratings yet

- Steel StandardsDocument29 pagesSteel Standardssuvra100% (2)

- Mechanical Relaxation of Residual StressDocument120 pagesMechanical Relaxation of Residual Stressrginunes9044100% (1)

- Steel Hardenability Measurement by Jominy Test: Santiago Aguirre OspinaDocument3 pagesSteel Hardenability Measurement by Jominy Test: Santiago Aguirre OspinaSantiago Aguirre OspinaNo ratings yet

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Document3 pagesASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNo ratings yet

- 6.1 - Heat Treatment of SteelDocument69 pages6.1 - Heat Treatment of Steelsuhas110No ratings yet

- BG42 Data SheetDocument0 pagesBG42 Data SheetTroy AshcraftNo ratings yet

- Tribology International: Miroslav Babic, Slobodan Mitrovic, Branislav JeremicDocument6 pagesTribology International: Miroslav Babic, Slobodan Mitrovic, Branislav JeremicmohammedNo ratings yet

- Part 66 MaterialsDocument42 pagesPart 66 MaterialsmikeNo ratings yet

- TC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)Document2 pagesTC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)SAMANONo ratings yet

- Training Report RACDocument33 pagesTraining Report RACTarun RaghavNo ratings yet

- CQI-9 Heat Treat System Assessment - Forms and Process Tables V3 2016Document83 pagesCQI-9 Heat Treat System Assessment - Forms and Process Tables V3 2016aperezpi26606No ratings yet

- Is 276 2000Document12 pagesIs 276 2000gotosudNo ratings yet

- HeattreatmentDocument21 pagesHeattreatmentroyalmechnoNo ratings yet

- Heat Treatment Lab ReportDocument12 pagesHeat Treatment Lab ReportCarl Behlmer100% (5)

- High Strength Steel FatigueDocument214 pagesHigh Strength Steel Fatigueskkong100% (1)

- Macsteel VRN - Wear Abrasion Steels - VRN 400Document4 pagesMacsteel VRN - Wear Abrasion Steels - VRN 400Pond KampeeraNo ratings yet

- Heat Treatment of SteelDocument3 pagesHeat Treatment of SteelpramodNo ratings yet

- Presentacion TTA PDFDocument48 pagesPresentacion TTA PDFdavid peralesNo ratings yet

- AISI 5160 Steel, Oil Quenched From 830°C (1525°F), 540°C (1000°F) Temper, 13 MM (0.5 In.) RoundDocument1 pageAISI 5160 Steel, Oil Quenched From 830°C (1525°F), 540°C (1000°F) Temper, 13 MM (0.5 In.) RoundLizbeth HuertaNo ratings yet

- En36c ChemDocument9 pagesEn36c Chempghoshco2023No ratings yet

- Ugima 4116N: Technical Data SheetDocument6 pagesUgima 4116N: Technical Data SheetSamirNo ratings yet

- Mpif 35-2007 粉末冶金结构零件材料标准简介Document80 pagesMpif 35-2007 粉末冶金结构零件材料标准简介Jou0411No ratings yet

- Quenching Oils: Product DescriptionDocument1 pageQuenching Oils: Product DescriptionalmasNo ratings yet

- 4140HW Alloy Steel Technical DataDocument8 pages4140HW Alloy Steel Technical DatawinasharNo ratings yet

ASTM A105 Matl Property PDF

ASTM A105 Matl Property PDF

Uploaded by

Athiphap SrisupareerathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM A105 Matl Property PDF

ASTM A105 Matl Property PDF

Uploaded by

Athiphap SrisupareerathCopyright:

Available Formats

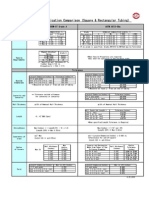

Quality ASTM A 105 Technical card

According to standards ASTM A 105M - 05 Lucefin Group

Number

Chemical composition

C% Si% Mn% P% S% Cu% Ni% Cr% Mo% V% Nb%

max max max max max max max max max

0,35 0,10-0,35 0,60-1,05 0,035 0,040 0,40 0,40 0,30 0,12 0,08 0,02

The sum of copper (Cu), chromium (Cr), nickel (Ni) and molybdenum (Mo) should not exceed 1,00%

The sum of chromium (Cr) and molybdenum (Mo) should not exceed 0,32%

For each reduction of 0,01% under max carbon value (0,35), it is admitted a 0,06% increase of manganese over its max value (1,05%)

up to 1,35%

On request, this steel grade may be supplied Calcium (Ca) treated

Min Al content 0,020% (to be certified)

Carbon Equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/ 15 max 0,47

Temperature °C

Hot-forming Normalizing . Quenching Tempering Stress-relieving

1150-850 843-927 880-930 593 50° under the temperature of

air cooling oil / polymer water air cooling tempering

Soft Normalizing Isothermal Pre-heating welding Stress-relieving

annealing and Tempering annealing after welding (PWHT)

700 843-927 air 860 furnace 250 590 furnace cooling

air cooling 593 air cooling to AC1 AC3 MS Mf

660, then air

Mechanical properties

Forged values as reference Heat treatments must guarantee the reported values ASTM A 105M - 05

all dimension Testing at room temperature (longitudinal)

mm R Rp 0.2% A% L A% T C% L C% T Kv HB

N/mm2 min N/mm2 min. min. min. min. min. J min. max

T 485 250 22 30 187

Forged over 4540 Kg may be ordered according to ASTM A 266/A 266M – 03a

all dimension R Rp 0.2% A% A% T C% L C% T Kv HB

mm N/mm2 N/mm2 min. min. min. min. min. J min.

T 415-585 205 23 20 38 30 121-170

T= max heat-treated thickness. Test specimen should correspond to the ¼ T

Minimum values at high temperatures

Rp 0.2 N/mm2 248 228 219 212 202 190 184 178

°C 38 93 149 204 260 316 343 371

Mechanical properties ( longitudinal testing) LUCEFIN experience

Heat treatment Ø product test at R Rp 0.2 A C-Z Kv 0 °C Kv -18 °C Kv -46 °C product

mm °C N/mm2 N/mm2 % % J J J

Normalizing 920 °C 90 +20 603 485 30 69.5 56-64-57 Hot-rolled

Normalizing 920 °C 90 +400 312 217 Hot-rolled

Normalizing 900 °C 240 +20 578 417 32.4 63.8 111-136-133 Hot-rolled

Normalizing 900 °C 240 +400 506 248 Hot-rolled

Normalizing 900 °C 400 +20 470 309 39.2 69.0 181-222-220 Forged

Normalizing 900 °C 400 +400 424 206 Forged

Quenched end tempered 95 +20 579 403 35.6 68.6 210-203-207 Hot-rolled

Quenched and tempered 95 +400 520 325 Hot-rolled

Natural 90 +20 580 400 28.0 63.0 20-18-18 14-12-12 10-8-8 Hot-rolled

EUROPE EN ITALY UNI CHINA GB GERMANY DIN FRANCE AFNOR U.K. B.S. RUSSIA GOST USA AISI/SAE

C21 20G A 105

You might also like

- GBT3077-2015 enDocument29 pagesGBT3077-2015 enSinan Chen100% (1)

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- Asme Sa 213 Grade t92 TubesDocument1 pageAsme Sa 213 Grade t92 TubesFerroPipENo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatNo ratings yet

- Toriconical Head 87 PsiDocument2 pagesToriconical Head 87 PsiFabio Augusto Hincapie HenaoNo ratings yet

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNo ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- PIPE SpecificationDocument5 pagesPIPE SpecificationNilesh GohelNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- Cupola Malleable Iron: Standard Specification ForDocument4 pagesCupola Malleable Iron: Standard Specification Forali ahmedNo ratings yet

- Astm A234-A234m-06Document8 pagesAstm A234-A234m-06NadhiraNo ratings yet

- Technical Data Handbook of Carbon Steel FittingsDocument244 pagesTechnical Data Handbook of Carbon Steel FittingsKrishna KumarNo ratings yet

- ASME B16.47 Serie A & BDocument1 pageASME B16.47 Serie A & BVivi OktaviantiNo ratings yet

- Certificado Copla SW 2Document1 pageCertificado Copla SW 2juan aguilarNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Sa 36Document4 pagesSa 36edisson_barreraNo ratings yet

- BS Bolt MaterialDocument1 pageBS Bolt MaterialKamlesh LuharNo ratings yet

- Asme Sa 333 Grade 6 PipesDocument1 pageAsme Sa 333 Grade 6 PipesFerroPipENo ratings yet

- 1018 Mechanical PropertiesDocument2 pages1018 Mechanical PropertiesjangaswathiNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

- ASTM A572 Grade 50 Plate: AnalysisDocument2 pagesASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoNo ratings yet

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet

- Fr20-016.007-1-Bridas de 10-SlipDocument1 pageFr20-016.007-1-Bridas de 10-SlipEduardo Dudlei Jimenez CarbajalNo ratings yet

- DIN 3015 ClampsDocument17 pagesDIN 3015 ClampsBalderas Rosas WilibaldoNo ratings yet

- Astm A53Document2 pagesAstm A53DeepakNo ratings yet

- ASTM A536 Ductile Iron Castings Tensile Requirements PDFDocument1 pageASTM A536 Ductile Iron Castings Tensile Requirements PDFTheOne Yasir100% (1)

- Astm C547Document7 pagesAstm C547DilaFirizqinaNo ratings yet

- Douglas Chero Catalogue Valve 6-2003Document89 pagesDouglas Chero Catalogue Valve 6-2003Yurizki LhzNo ratings yet

- Surface Vehicle Standard: 400 Commonwealth Drive, Warrendale, PA 15096-0001Document5 pagesSurface Vehicle Standard: 400 Commonwealth Drive, Warrendale, PA 15096-0001Angel HernándezNo ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowLuna LukaNo ratings yet

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Document16 pagesVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNo ratings yet

- Astm Materials-Piping SpecDocument3 pagesAstm Materials-Piping Speckaushalacharya100% (1)

- LE B-255 H4R: ClassificationDocument2 pagesLE B-255 H4R: ClassificationVivien EmeraldoNo ratings yet

- B4A3Document6 pagesB4A3ashokclineNo ratings yet

- Certificado de Calidad Brida WN SCH-80 2.5Document1 pageCertificado de Calidad Brida WN SCH-80 2.5Jackelin MayraNo ratings yet

- PV Elite (Construccion de Recipiente) MDMTDocument8 pagesPV Elite (Construccion de Recipiente) MDMTAlejandro CanoNo ratings yet

- Din 2448Document3 pagesDin 2448Cristian Adrian ANo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- 1 Pipes Weights and Dimensions ASME ANSI B36.10-19Document1 page1 Pipes Weights and Dimensions ASME ANSI B36.10-19Leonardo Cusó ContrerasNo ratings yet

- Stainless Steel Tube SpecificationsDocument7 pagesStainless Steel Tube Specificationsgkamesh84No ratings yet

- L80 - Continental AlloysDocument2 pagesL80 - Continental Alloystoxa0707No ratings yet

- ASTM Comparison PDFDocument1 pageASTM Comparison PDFRaja HoneNo ratings yet

- DIN 17100 TablasDocument2 pagesDIN 17100 Tablasanonimarium100% (3)

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizNo ratings yet

- AWH Catalogue DIN 11864-11853 1.1Document70 pagesAWH Catalogue DIN 11864-11853 1.1dingobk1No ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105lavius_mNo ratings yet

- 1 4571a316ti69Document2 pages1 4571a316ti69Admir TalicNo ratings yet

- 1330 Crni Mo 831Document2 pages1330 Crni Mo 831sajay_suryaNo ratings yet

- 1 4305a30365Document2 pages1 4305a30365skidanjeNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 1.4125 440c PDFDocument2 pages1.4125 440c PDFsuntansueNo ratings yet

- En10083-2 - 1996 - C35eDocument3 pagesEn10083-2 - 1996 - C35ealextentwentyNo ratings yet

- 1.0577 S355J2Document1 page1.0577 S355J2sergonNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- Quality: Astm A 105Document1 pageQuality: Astm A 105Venkat NarasimmanNo ratings yet

- C45EDocument3 pagesC45ETrương Định100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- A 504 - 93 R99 QtuwnaDocument9 pagesA 504 - 93 R99 QtuwnaCHRISTIAN ZAVALANo ratings yet

- Revamping Ammonia ConverterDocument5 pagesRevamping Ammonia ConverterHsein WangNo ratings yet

- Engineering Materials and Metallurgy (ME 2253)Document23 pagesEngineering Materials and Metallurgy (ME 2253)Praven KumarNo ratings yet

- Sae j429 Vs Astm A354 BD PDFDocument2 pagesSae j429 Vs Astm A354 BD PDFAdam GordonNo ratings yet

- Steel StandardsDocument29 pagesSteel Standardssuvra100% (2)

- Mechanical Relaxation of Residual StressDocument120 pagesMechanical Relaxation of Residual Stressrginunes9044100% (1)

- Steel Hardenability Measurement by Jominy Test: Santiago Aguirre OspinaDocument3 pagesSteel Hardenability Measurement by Jominy Test: Santiago Aguirre OspinaSantiago Aguirre OspinaNo ratings yet

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Document3 pagesASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNo ratings yet

- 6.1 - Heat Treatment of SteelDocument69 pages6.1 - Heat Treatment of Steelsuhas110No ratings yet

- BG42 Data SheetDocument0 pagesBG42 Data SheetTroy AshcraftNo ratings yet

- Tribology International: Miroslav Babic, Slobodan Mitrovic, Branislav JeremicDocument6 pagesTribology International: Miroslav Babic, Slobodan Mitrovic, Branislav JeremicmohammedNo ratings yet

- Part 66 MaterialsDocument42 pagesPart 66 MaterialsmikeNo ratings yet

- TC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)Document2 pagesTC 302010-3 602 BW SCH 80-11121B1,10440B1,19M3792B2 (440 To 476) (JC 6303)SAMANONo ratings yet

- Training Report RACDocument33 pagesTraining Report RACTarun RaghavNo ratings yet

- CQI-9 Heat Treat System Assessment - Forms and Process Tables V3 2016Document83 pagesCQI-9 Heat Treat System Assessment - Forms and Process Tables V3 2016aperezpi26606No ratings yet

- Is 276 2000Document12 pagesIs 276 2000gotosudNo ratings yet

- HeattreatmentDocument21 pagesHeattreatmentroyalmechnoNo ratings yet

- Heat Treatment Lab ReportDocument12 pagesHeat Treatment Lab ReportCarl Behlmer100% (5)

- High Strength Steel FatigueDocument214 pagesHigh Strength Steel Fatigueskkong100% (1)

- Macsteel VRN - Wear Abrasion Steels - VRN 400Document4 pagesMacsteel VRN - Wear Abrasion Steels - VRN 400Pond KampeeraNo ratings yet

- Heat Treatment of SteelDocument3 pagesHeat Treatment of SteelpramodNo ratings yet

- Presentacion TTA PDFDocument48 pagesPresentacion TTA PDFdavid peralesNo ratings yet

- AISI 5160 Steel, Oil Quenched From 830°C (1525°F), 540°C (1000°F) Temper, 13 MM (0.5 In.) RoundDocument1 pageAISI 5160 Steel, Oil Quenched From 830°C (1525°F), 540°C (1000°F) Temper, 13 MM (0.5 In.) RoundLizbeth HuertaNo ratings yet

- En36c ChemDocument9 pagesEn36c Chempghoshco2023No ratings yet

- Ugima 4116N: Technical Data SheetDocument6 pagesUgima 4116N: Technical Data SheetSamirNo ratings yet

- Mpif 35-2007 粉末冶金结构零件材料标准简介Document80 pagesMpif 35-2007 粉末冶金结构零件材料标准简介Jou0411No ratings yet

- Quenching Oils: Product DescriptionDocument1 pageQuenching Oils: Product DescriptionalmasNo ratings yet

- 4140HW Alloy Steel Technical DataDocument8 pages4140HW Alloy Steel Technical DatawinasharNo ratings yet