Professional Documents

Culture Documents

Types of Gaskets For Flanges (Soft, Spiral, Ring Joint) - Projectmaterials

Uploaded by

zhasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Types of Gaskets For Flanges (Soft, Spiral, Ring Joint) - Projectmaterials

Uploaded by

zhasCopyright:

Available Formats

Search the knowledge base...

Home » Gaskets & Bolts » Gaskets for Flanges » Types

of Gaskets for Flanges (Soft, Spiral, Ring Joint)

Types Of Gaskets

For Flanges (Soft,

Spiral, Ring Joint)

Author: Projectmaterials

Posted: September 20, 2017 7 Comments

! " # $ % ! "

Table of Contents #

Learn about the 5 key !ange gaskets

types (used in the oil and gas

industry): non-asbestos gaskets full

and raised face (used for low-

pressure, low-temperature and non-

critical applications), spiral wound

gaskets (for higher temperature and

pressure oil and gas applications),

Ring joint gaskets style R, RX, BX (for

RTJ !ange faces), Kammpro"le and

Jacketed gaskets. The article describes

the scope of each type of gasket, the

dimensions to ASME B16.20 and ASME

B16.21, the materials and give some

indications to select the right gasket

for piping applications.

Types of Gaskets for…

NON-ASBESTOS

GASKET

Non-asbestos gaskets are the

simplest type of gasket for flanges

and are produced by cutting graphite,

organic or inorganic non asbestos

sheets into shape (generally, with

water jet cutting machines). This type

of gaskets for !anges suits low

pressure, low temperature, and non-

critical piping and plumbing

applications.

The two main types of non-asbestos

gaskets are the “full face” (FF) for FF

flanges and the “flat ring” type for

raised face flanges (RF).

Non-asbestos gaskets have fully

replaced asbestos gaskets for

decades as studies demonstrated the

risks (for human health) associated

with the production, use, and

disposal of asbestos materials. The

ASME B16.21 speci"cation covers

non-asbestos sheet gaskets (types,

sheet materials, dimensions,

dimensional tolerances, and marking

requirements).

The terms, “!at-cut gaskets”, “die-cut

gaskets”, “compressed sheet gaskets”

and “asbestos-free gaskets” are

synonyms to de"ne this low-end

family of !ange gaskets.

To select the right material for non-

asbestos gaskets, multiple factors

shall be considered: !uid,

temperature, pressure, fugitive

emissions laws, and mechanical

issues.

NON-ASBESTOS

GASKET MATERIALS

The most common materials used to

manufacture compressed "ber

gaskets are aramid "bers (Kevlar),

glass "bers, elastomers, Te!on

(PTFE), graphite, neoprene mixed

with various binder materials (the

most common binder is NBR, i.e.

Buna-N):

Aramid NBR binder

carbon graphite reinforced

glass reinforced (steam service

gasket)

PTFE bi-axially oriented (silica

"ller)

SBR (styrene-butadiene)

CR-chloroprene (Neoprene)

EPDM gasket (ethylene

propylene)

!uorocarbon (Viton)

graphite

BUNA-n-rubber (nitrile, NBR

gasket)

chlorosulfonated polyethylene

(Hypalon gasket)

aramid + SBR binder (premium

type gasket)

graphite + ss316/316l insert

PTFE biaxially oriented (with

hollow glass microsphere) blue

PTFE biaxially oriented (pigment-

free)-gray

expanded PTFE gasket

PTFE joint sealant

PTFE envelope slit type

PTFE envelope milled type

PTFE envelope formed type

MICA sheet

ceramic "ber

Non-asbestos gaskets can also be

coated with graphite, for non-stick

and steam resistance, mixed with

PTFE for excellent chemical

resistance, or with EPDM for potable

water applications.

NON-ASBESTOS

GASKET DIMENSIONS

Soft Gaskets for ASME

B16.5 Flanges

Non-asbestos gaskets dimensions

(for ASME B16.5 !anges), in

millimeters

NPS d1 d2 (GASKET OUTSIDE DIAMETER)

(ID)

Class Class Class Class Class

150 300 400 600 900

1/2 21 48 54 54 54 64

3/4 27 57 67 67 67 70

1 33 67 73 73 73 79

1¼ 42 76 83 83 83 89

1½ 48 86 95 95 95 98

2 60 105 111 111 111 143

2½ 73 124 130 130 130.2 165

3 89 137 149 149 149 168

3½ 102 162 165 162 162 …

4 114 175 181 178 194 206

5 141 197 216 213 241 248

6 168 222 251 248 267 289

8 219 279 308 305 321 359

10 273 340 362 359 400 435

12 324 410 422 419 457 498

14 356 451 486 483 492 521

16 406 514 540 537 565 575

18 457 549 597 594 613 638

20 508 606 654 648 683 699

24 610 718 775 768 791 838

Комплект дисков с

доставкой

Гарантия качества. Безопасная

доставка до Ваших дверей.

All values in millimeters

Soft Gaskets for ASME

B16.47 – Series A Flanges

Non-asbestos gaskets dimensions

(for ASME B16.47 series A !anges), in

millimeters

NPS d1 d2 (GASKET OUTSIDE DIAMETER)

(ID)

Class Class Class Class

150 300 400 600

26 660 775 835 832 867

28 711 832 899 892 914

30 762 883 953 946 972

32 813 940 1006 1003 1022

34 864 991 1057 1054 1073

36 914 1048 1118 1118 1130

38 965 1111 1054 1073 1105

40 1016 1162 1114 1127 1156

42 1067 1219 1165 1178 1219

44 1118 1276 1219 1232 1270

46 1168 1327 1273 1289 1327

48 1219 1384 1324 1346 1391

50 1270 1435 1378 1403 1448

52 1321 1492 1429 1454 1499

54 1372 1549 1492 1518 1556

56 1422 1607 1543 1568 1613

58 1473 1664 1594 1619 1664

60 1524 1715 1645 1683 1721

All values in millimeters

Soft Gaskets for ASME

B16.47 – Series B Flanges

Non-asbestos gaskets dimensions

(for ASME B16.47 series B !anges), in

millimeters

NPS d1 d2 (GASKET OUTSIDE DIAMETER)

(ID)

Class Class Class Class

150 300 400 600

26 660 725 772 746 765

28 711 776 826 800 819

30 762 827 886 857 879

32 813 881 940 911 933

34 864 935 994 962 997

36 914 987 1048 1022 1048

38 965 1045 1099 … …

40 1016 1095 1149 … …

42 1067 1146 1200 … …

44 1118 1197 1251 … …

46 1168 1256 1318 … …

48 1219 1307 1368 … …

50 1270 1357 1419 … …

52 1321 1408 1470 … …

54 1372 1464 1530 … …

56 1422 1514 1594 … …

58 1473 1580 1656 … …

60 1524 1630 1705 … …

All values in millimeters. Dimensional tolerances:

For outside diameter NPS 12 and smaller: +0

/ -1.5 mm.; NPS 14 and larger: +0 / -3.0 mm.

For inside diameter NPS 12 and smaller: ±

1.5 mm; NPS 14 and larger: ± 3.0 mm

SPIRAL WOUND

GASKET

A Spiral wound gasket for !anges

feature a metal sealing element "lled

with graphite, PTFE, ceramic "bers

and, non-asbestos "bers ("llers). For

this reason, spiral wound gaskets are

classi"ed as “semi-metallic” gaskets.

The metal component of the spiral

wound gasket provides strength to

the seal, whereas the "llers enhance

the gasket’s conformability and

resilience. Inner and outer rings can

be added to the core sealing element

to facilitate the installation and

enhance the pressure rating. Spiral

wound gaskets with graphite "llers

are the most commonly sold type.

Flexitallic USA introduced spiral

wound gaskets in the petrochemical

industry back in 1912 to cope with an

increasing demand for leak-proof

seals in applications with higher and

higher (and !uctuating) temperatures

and pressures. Other reputable spiral

wound gasket manufacturers are

Garlock and Lamons.

Indeed, a spiral wound gasket is

designed to withstand, better than

other types of !ange gaskets, the

mechanical stress generated by high

temperature and pressure

applications. Spiral wound gasket

application range, therefore, from oil

and gas to power generation.

Предоставлено

Открыть

kaspi.kz

The diameter of a spiral wound

gasket may range between a few mm

up to 5.000 mm, and the spiral

wound gasket thicknesses range from

3.2, 4.5, 6.4, to 7.2 mm.

A Spiral wound gasket may be

ordered in di#erent shapes, such as

oblong, rectangular, oval, pear and

diamond.

ASME B16.20 is the spiral wound

gasket speci"cation.

The round type is, of course, the

standard shape for the raised face

(RF), male-and-female (M&F), and

tongue-and-groove !anges (T&G) for

petrochemical applications.

SPIRAL WOUND

GASKET TYPES

A few di#erent types of spiral wound

gaskets exist, depending on:

the number of rings (outer and

inner)

the materials of the inner and

the outer ring of the gasket

Type 00: Spiral Wound Gasket

without rings: they are used for

tongue and groove, male and

female !anges.

Type 01: Spiral Wound Gasket

with inner ring: they are used for

male and female or special

!ange types.

Type 10: Spiral Wound Gasket

with outer ring: they are used for

raised face !anges.

Type 101: Spiral Wound Gasket

with inner and outer rings: they

are used for raised face !anges.

Special Section: Spiral Wound

Gasket with special rings: they

are used for special !anges and

special usage.

Each manufacturer, of course, has

speci"c codes to designate the

di#erent spiral wound gasket types,

but the typical designs are recurring

regardless of the producer.

The image shows how the di#erent

spiral wound gasket types used for Privacy & Cookies Policy

You might also like

- Liquid Penetrant Inspection 50 Question QuizDocument10 pagesLiquid Penetrant Inspection 50 Question QuizAnonymous gFcnQ4go100% (6)

- CBLM Implementing Plant Nutrition ProgramDocument64 pagesCBLM Implementing Plant Nutrition Programmarlene a. dinlayanNo ratings yet

- Ductile Iron Fittings Weight ChartDocument3 pagesDuctile Iron Fittings Weight ChartNaveen Mat73% (52)

- Polycab Wires Latest Price ListDocument1 pagePolycab Wires Latest Price Listandcha.exe100% (1)

- Atoms Bonding GuideDocument729 pagesAtoms Bonding Guide1553No ratings yet

- ASTM D974 14 (For Acid and Base Number by Color-Indicator Titration)Document7 pagesASTM D974 14 (For Acid and Base Number by Color-Indicator Titration)Fabian Ricardo100% (1)

- EEC / Refractory Systems for Chemical and Hydrocarbon ProcessingDocument34 pagesEEC / Refractory Systems for Chemical and Hydrocarbon Processinggems_gce074325No ratings yet

- Spiral Wound Gaskets Data TableDocument42 pagesSpiral Wound Gaskets Data TableCharles OnyechereNo ratings yet

- Tricone Bit BrochureDocument8 pagesTricone Bit BrochureDony ArifNo ratings yet

- Projectmaterials Com Gaskets Gasket For Flange AsmeDocument46 pagesProjectmaterials Com Gaskets Gasket For Flange AsmeAbinNo ratings yet

- AEA-Pipe FitingDocument10 pagesAEA-Pipe Fitingdechi MartinezNo ratings yet

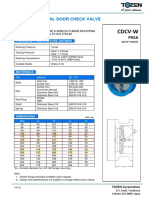

- CDCV-W (Group) (V1116)Document1 pageCDCV-W (Group) (V1116)ismi iqhwan ihsanNo ratings yet

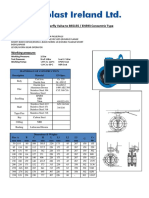

- Cast Iron Wafer Check ValveDocument1 pageCast Iron Wafer Check ValveNikhil RajanNo ratings yet

- Dimensions of Restriction Orifice Plates PDFDocument6 pagesDimensions of Restriction Orifice Plates PDFmahsaNo ratings yet

- Dimensions of Restriction Orifice Plates PDFDocument6 pagesDimensions of Restriction Orifice Plates PDFwalaNo ratings yet

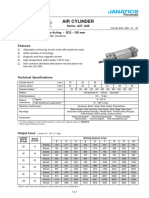

- Air Cylinder: Series A23, A24 Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument8 pagesAir Cylinder: Series A23, A24 Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- P1E ISO CylindersDocument31 pagesP1E ISO CylindersHenrique docinNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- Liku-Tech - Accessories - V2 PDFDocument5 pagesLiku-Tech - Accessories - V2 PDFAjay Krishna MNo ratings yet

- Gasket Dimensions for IBC Flanges up to DN 800Document1 pageGasket Dimensions for IBC Flanges up to DN 800Acrylic NFTsNo ratings yet

- Check Valve Keystone DualplateDocument2 pagesCheck Valve Keystone DualplateRobi KeiNo ratings yet

- Rupture DiscDocument2 pagesRupture Discbigs1303No ratings yet

- Garnitura SpirometalicaDocument3 pagesGarnitura SpirometalicaRadoo NephilaNo ratings yet

- Datasheet 102 103 202 203 302 303 Flange SealDocument5 pagesDatasheet 102 103 202 203 302 303 Flange SealD. Thanh NguyễnNo ratings yet

- AIR CYLINDER SPECSDocument8 pagesAIR CYLINDER SPECSN.Dinesh kumarNo ratings yet

- Spiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesDocument6 pagesSpiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesAntonio CardosoNo ratings yet

- Ai Cylinders - Heavyduty PDFDocument15 pagesAi Cylinders - Heavyduty PDFGM HerbalsNo ratings yet

- Dimensions of Spiral Wound Gaskets ASME B16.20 Used With Raised Face Flanges ASME B16.5Document4 pagesDimensions of Spiral Wound Gaskets ASME B16.20 Used With Raised Face Flanges ASME B16.5MANISH GUPTANo ratings yet

- JANATICS Cylinder CatalogueDocument8 pagesJANATICS Cylinder CatalogueUday Bagade100% (2)

- Norma AustralianaDocument26 pagesNorma AustralianaEdinson HerreraNo ratings yet

- En 10241 FittingsDocument6 pagesEn 10241 FittingsDhavalNo ratings yet

- STRONGFLEX CONVEYOR BELT GUIDEDocument13 pagesSTRONGFLEX CONVEYOR BELT GUIDEsjarguelleNo ratings yet

- A27 A28 CylinderDocument8 pagesA27 A28 CylinderBiswanath LenkaNo ratings yet

- A63 A64 Compact ISO High TempDocument2 pagesA63 A64 Compact ISO High TempNaveenraj SNo ratings yet

- IAC Valve SilencersDocument16 pagesIAC Valve SilencersvkumaranNo ratings yet

- Kingston Model 115: Kingston Safety & Relief ValvesDocument2 pagesKingston Model 115: Kingston Safety & Relief ValvesAntonio SerranoNo ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- Low Voltage Cable Price ListDocument7 pagesLow Voltage Cable Price ListSunny KumarNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- Standard Steel Bolt Torque SpecificationsDocument13 pagesStandard Steel Bolt Torque SpecificationsYvan Nuñez EscobedoNo ratings yet

- A63 A64 CylinderDocument5 pagesA63 A64 CylinderBiswanath LenkaNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- TITANIA 1717en-4Document4 pagesTITANIA 1717en-4bre brilianNo ratings yet

- Havells Cables Pricelist 01.05.2018 PDFDocument5 pagesHavells Cables Pricelist 01.05.2018 PDFjuga2013No ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Diaval ST Type Rubber Lined Flanged EndsDocument3 pagesDiaval ST Type Rubber Lined Flanged EndsMarketing RNSNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- R5T Capped Roof Panels Product DescriptionDocument4 pagesR5T Capped Roof Panels Product DescriptionAgonNo ratings yet

- Ribstrong BrochureDocument11 pagesRibstrong Brochuregeometric steelsNo ratings yet

- R4 Roof Panel: Product DescriptionDocument5 pagesR4 Roof Panel: Product DescriptionyodiumhchltNo ratings yet

- Capital Cables price list for LT power and control cablesDocument5 pagesCapital Cables price list for LT power and control cablessrinivasuNo ratings yet

- Sider Fra Brochure April 2019 4Document10 pagesSider Fra Brochure April 2019 4rahmat hidayatNo ratings yet

- Care Lifting CatalougeDocument28 pagesCare Lifting CatalougeHari KrishnaNo ratings yet

- Wafer Butterfly ValvesDocument8 pagesWafer Butterfly ValvesTerry SmithNo ratings yet

- SWG Data Sheet (TEFLEX)Document7 pagesSWG Data Sheet (TEFLEX)Brion Bara IndonesiaNo ratings yet

- Havells India Limited: LT Power Cables - Aluminium ConductorDocument5 pagesHavells India Limited: LT Power Cables - Aluminium Conductornaresh singlaNo ratings yet

- Datasheet Si-211 EN Butterfly Valve VSS LN (Low Noise Trim)Document16 pagesDatasheet Si-211 EN Butterfly Valve VSS LN (Low Noise Trim)Kawtar MoufadilNo ratings yet

- StrucSeal LoadTable-Ex 2Document4 pagesStrucSeal LoadTable-Ex 2عبد الباسط المغيربيNo ratings yet

- Check Valve - Wafer TypeDocument2 pagesCheck Valve - Wafer Typehuudung87No ratings yet

- Air Cylinder: Series A12, A13 AIR CYLINDERS Double Acting (Ø32 - 100) MMDocument7 pagesAir Cylinder: Series A12, A13 AIR CYLINDERS Double Acting (Ø32 - 100) MMgopi_krishnan_29No ratings yet

- Astm F879M 1991Document5 pagesAstm F879M 1991Jesse ChenNo ratings yet

- Engineering Stress-Strain and True Stress-Strain Analysis in Uniaxial Tension TestingDocument33 pagesEngineering Stress-Strain and True Stress-Strain Analysis in Uniaxial Tension TestingZANTHERNo ratings yet

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDocument4 pagesAnalysis of Flexible Pavements Using IIT Pave: Harish G RAyush KumarNo ratings yet

- Plasma-And Laser-Cutting ToolDocument17 pagesPlasma-And Laser-Cutting ToolRiyan EsapermanaNo ratings yet

- Unit 2 CapsuleDocument104 pagesUnit 2 Capsuleabdullah2020No ratings yet

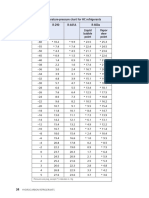

- Refri - Coca-Cola R290 P-T ChartDocument4 pagesRefri - Coca-Cola R290 P-T ChartmanonpomNo ratings yet

- Activity 3 - Mineral and The Nature of RockDocument2 pagesActivity 3 - Mineral and The Nature of RockSedsed QuematonNo ratings yet

- TYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsDocument6 pagesTYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsKapa KamalakarNo ratings yet

- Caldeira PEGASUS F2Document5 pagesCaldeira PEGASUS F2goncalo30No ratings yet

- 1596 - The Storage and Handling of LP GasDocument152 pages1596 - The Storage and Handling of LP GasVasko DrogriskiNo ratings yet

- Hydrostatic test results and stresses analysisDocument1 pageHydrostatic test results and stresses analysisToniNo ratings yet

- VinnapasDocument2 pagesVinnapasNguyễn Quốc TiếnNo ratings yet

- Nuclear ChemistryDocument42 pagesNuclear ChemistryneerajNo ratings yet

- EN4554/CV4554 Air Pollution Control Engineering: Tutorial 2Document2 pagesEN4554/CV4554 Air Pollution Control Engineering: Tutorial 2zzz_monsterNo ratings yet

- Carboxylic Acids and Their Derivatives.Document31 pagesCarboxylic Acids and Their Derivatives.AmanyNo ratings yet

- Preparation and Properties of Compounds-03 - Assignments (New)Document12 pagesPreparation and Properties of Compounds-03 - Assignments (New)Raju SinghNo ratings yet

- Astm G 145 - 96Document10 pagesAstm G 145 - 96AL DOMANo ratings yet

- IsomerismDocument61 pagesIsomerismSaket DubeyNo ratings yet

- Internship Report on Ghee Manufacturing ProcessDocument36 pagesInternship Report on Ghee Manufacturing ProcessNuman TariqNo ratings yet

- Nanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009Document9 pagesNanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009yerly ramirezNo ratings yet

- Materials and properties vocabularyDocument1 pageMaterials and properties vocabularycNo ratings yet

- Food BiochemistryDocument48 pagesFood BiochemistryFombang AtamNo ratings yet

- A Microstructure-Based Model For Creep of Gamma Prime Strengthened Nickel-Based SuperalloysDocument5 pagesA Microstructure-Based Model For Creep of Gamma Prime Strengthened Nickel-Based Superalloyshassan ghorbaniNo ratings yet

- Mock Test Gat - (28-3-22)Document8 pagesMock Test Gat - (28-3-22)Dhruva Chandra PandeyNo ratings yet

- Role of Chemical EngineerDocument5 pagesRole of Chemical EngineerRichard MamoneNo ratings yet