Professional Documents

Culture Documents

T, Chip Thickness 0.6 MM, RPM 590, D 100 MM, F

T, Chip Thickness 0.6 MM, RPM 590, D 100 MM, F

Uploaded by

Zó LáOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T, Chip Thickness 0.6 MM, RPM 590, D 100 MM, F

T, Chip Thickness 0.6 MM, RPM 590, D 100 MM, F

Uploaded by

Zó LáCopyright:

Available Formats

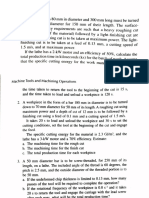

1.

Drive an expression of frictional force (Ff), shear force (Fs), normal force (N)

and normal force on shear face (F n) in terms of thrust force (F t), cutting force

(Fc), shear angle (ɸ) and rack angle (α).

2. For the measured value of parameters after machining operation of mild steel

are depth of cut

t o=0.2 mm , width=2.6 mm , α =15° , chip thickness=0.6 mm , RPM=590 , D=100 mm , F C =900 N ,

Determine the following:

a. Cutting ratio

b. Shear angle

c. Shear force

d. Normal force to the shear surface

e. Frictional force

f. Normal force to the friction surface

g. Co-efficient of friction

h. Friction angle

i. Power consumption

j. Shear stress and normal stress

3. A turning operation has to be performed on an aluminum rod of diameter 50

mm and length of 300 mm. the spindle speed of lathe is given to be 500 RPM.

The feed and depth of cut are 0.15 mm/rev and 0.3 mm. draw the neat sketch

of the turning described and determine cutting speed in mm/s and volumetric

material removal rate (MRR)

4. An Aluminum block of length 50 mm and width 70 mm is being milled using a

slab milling cutter with 50 mm diameter. The feed of table is 15 mm/min. The

milling cutter rotates at 60 RPM in clockwise direction and width of cut is

equal to the width of the workpiece. Draw a neat sketch of thickness of

workpiece is 20 mm and determine the cutting speed and volumetric material

removal rate (MRR) if depth of cut is 2 mm.

5. Following the milling operations, a through hole is to be drilled on the same

workpiece. Determine the cutting speed and volumetric material removal rate

if the drill diameter 10 mm is being rotated at 60 RPM with feed rate of 0.5

mm/rev.

You might also like

- Sheets - Sep 2013Document13 pagesSheets - Sep 2013Mohamed OsamaNo ratings yet

- Theory of Metal Cutting Numericals PDFDocument2 pagesTheory of Metal Cutting Numericals PDFsanjayNo ratings yet

- Theory of Metal Cutting - NumericalsDocument2 pagesTheory of Metal Cutting - Numericalspmagrawal100% (1)

- TUTORIALS 1 (1) - MergedDocument23 pagesTUTORIALS 1 (1) - MergedRUGERO KeslyneNo ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- 09 Problem Sheet 02Document2 pages09 Problem Sheet 02Shweta raiNo ratings yet

- Assignment No1Document2 pagesAssignment No1Thakur Kali DassNo ratings yet

- Tutorial Sheet: 1 Manufacturing Science and Technology-IIDocument2 pagesTutorial Sheet: 1 Manufacturing Science and Technology-IIDeepam ShyamNo ratings yet

- Assignment 1 2Document2 pagesAssignment 1 2Jeevan GNo ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- Tutorial - Metal Removal ProcessDocument2 pagesTutorial - Metal Removal ProcessbananaNo ratings yet

- Problems Sheet Machine Tools 2015 16Document9 pagesProblems Sheet Machine Tools 2015 16Shafiq AhmadNo ratings yet

- Man ProDocument2 pagesMan ProlividiveNo ratings yet

- Assign 1 2012Document2 pagesAssign 1 2012chiru1431No ratings yet

- AssignmentDocument2 pagesAssignmentgirma workuNo ratings yet

- AssignmentDocument2 pagesAssignmentgirma workuNo ratings yet

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDocument7 pagesAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilNo ratings yet

- SHEETSDocument13 pagesSHEETSXHaMzAXNo ratings yet

- Problem Sheet Metal Machining and Cutting Conditions 2016Document3 pagesProblem Sheet Metal Machining and Cutting Conditions 2016Muhammad imranNo ratings yet

- Tutorial 4 Sheet Metal WorkingDocument2 pagesTutorial 4 Sheet Metal WorkingSawai PariharNo ratings yet

- Lect 8Document13 pagesLect 8shashankmay18No ratings yet

- 414 TutorialsDocument2 pages414 TutorialsAMOS SIFUNANo ratings yet

- 2 Problems Sheet Machine ToolsDocument9 pages2 Problems Sheet Machine ToolsALOKSRK0% (1)

- Tutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMDocument2 pagesTutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMrandyooiNo ratings yet

- Ch-2 Force & Power in Metal CuttingDocument43 pagesCh-2 Force & Power in Metal CuttingNimish JoshiNo ratings yet

- Question Bank For Machining and MetrologyDocument7 pagesQuestion Bank For Machining and MetrologyAbhisheak DineshNo ratings yet

- Deber 1Document15 pagesDeber 1jmgavilanes0% (1)

- Metrology M2Document91 pagesMetrology M2jibinNo ratings yet

- 1) The Following Data Related To An Orthogonal Cutting ProcessDocument1 page1) The Following Data Related To An Orthogonal Cutting Processgirma workuNo ratings yet

- Sheet Metal Working& Powder MetallurgyDocument13 pagesSheet Metal Working& Powder Metallurgyanant709skNo ratings yet

- Numerical Sheet - Orthogonal CuttingDocument1 pageNumerical Sheet - Orthogonal CuttingManan GuptaNo ratings yet

- Homework Solution p3Document10 pagesHomework Solution p3Petro ManNo ratings yet

- Cos Tan Here Is The Chip T 1 Si Hickness Ratio. N: R R R WDocument1 pageCos Tan Here Is The Chip T 1 Si Hickness Ratio. N: R R R WpmagrawalNo ratings yet

- Tutorial Sheet 3Document2 pagesTutorial Sheet 3Ajay yadavNo ratings yet

- UTA026 Manufacturing Processes Work SheetDocument3 pagesUTA026 Manufacturing Processes Work SheetGUNJAN KHULLARNo ratings yet

- Question Bank: Subject:Tool Engineering/Tool Design Q.No QuestionDocument3 pagesQuestion Bank: Subject:Tool Engineering/Tool Design Q.No QuestionhemendraNo ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- ME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)Document23 pagesME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)WILYNo ratings yet

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Practice Sheet 2Document2 pagesPractice Sheet 2GUNJAN KHULLARNo ratings yet

- Ch-4 LatheDocument99 pagesCh-4 LatheMahendra TantuwayNo ratings yet

- Mechanical Engineering DepartmentDocument2 pagesMechanical Engineering DepartmentArjit Goswami100% (1)

- Practice Sheet 2Document2 pagesPractice Sheet 2Arshpreet SinghNo ratings yet

- Chapter Two PDFDocument70 pagesChapter Two PDFberhaneNo ratings yet

- Solution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minDocument11 pagesSolution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minwoihoNo ratings yet

- Problem Set 2Document1 pageProblem Set 2shivam ojhaNo ratings yet

- 2 Numericals Bank MP II PDFDocument7 pages2 Numericals Bank MP II PDFThenarasumohanveluNo ratings yet

- ME 338 Manufacturing Processes II HW#1Document3 pagesME 338 Manufacturing Processes II HW#1jambu99No ratings yet

- Metrology M2Document85 pagesMetrology M2sidNo ratings yet

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Document4 pagesEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiNo ratings yet

- Problem Set 1Document5 pagesProblem Set 1riyaNo ratings yet

- Ch-4 LatheDocument98 pagesCh-4 LathePARESHNo ratings yet

- MP Unit-2Document113 pagesMP Unit-2Parth MaldhureNo ratings yet

- Mid-Term Test: Material and Metal ProcessingDocument8 pagesMid-Term Test: Material and Metal ProcessingekanandaardiansyahNo ratings yet

- Chap3 (D) MillDocument22 pagesChap3 (D) MilljojoNo ratings yet

- Assignment-1 (MEN-301) Mechanics of Metal CuttingDocument1 pageAssignment-1 (MEN-301) Mechanics of Metal Cuttingbt19107101 Sidharth MahajanNo ratings yet

- Assignment 1Document4 pagesAssignment 1antonushany52No ratings yet

- Tutorial - Mechanics - 4 Example in The LectureDocument1 pageTutorial - Mechanics - 4 Example in The LectureChen WANYINGNo ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Vibration Assignment On Chapter-Three: 0.1 M, X 5 M/secDocument2 pagesVibration Assignment On Chapter-Three: 0.1 M, X 5 M/secZó LáNo ratings yet

- Explain Each Briefly and ClearlyDocument5 pagesExplain Each Briefly and ClearlyZó LáNo ratings yet

- Wachemo University Department of Mechanical Engineering Wachemo UniversityDocument14 pagesWachemo University Department of Mechanical Engineering Wachemo UniversityZó LáNo ratings yet

- Wachemo University College of Engineering and Technology Department of MechanicalDocument2 pagesWachemo University College of Engineering and Technology Department of MechanicalZó LáNo ratings yet

- 1rst Yr RV Assignment ZELALEM SHETAHUNDocument2 pages1rst Yr RV Assignment ZELALEM SHETAHUNZó Lá100% (2)