Professional Documents

Culture Documents

Deterioration of Mechanical Properties of High Strength Structural Steel S460N Under Steady State Fire Condition - PDF Free Download PDF

Deterioration of Mechanical Properties of High Strength Structural Steel S460N Under Steady State Fire Condition - PDF Free Download PDF

Uploaded by

Caline Nunes0 ratings0% found this document useful (0 votes)

6 views5 pagesOriginal Title

Deterioration of mechanical properties of high strength structural steel S460N under steady state fire condition - PDF Free Download.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views5 pagesDeterioration of Mechanical Properties of High Strength Structural Steel S460N Under Steady State Fire Condition - PDF Free Download PDF

Deterioration of Mechanical Properties of High Strength Structural Steel S460N Under Steady State Fire Condition - PDF Free Download PDF

Uploaded by

Caline NunesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

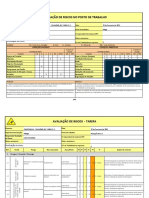

Morera and Design 96 (2012) 438-442

Contents lists available at SciVerse ScienceDirect

Materials and Design

journal homepage: www.elsevier.com/locate/matdes —

Deterioration of mechanical properties of high strength structural steel

S460N under steady state fire condition

Xuhong Qiang*, Frans S.K. Bijlaard, Henk Kolstein

Serucal an lng Engnerng. Deparment of Design ond Consacton, Fit of Ci Engineering an Geosciences, Deft University of Technolo,

2800 Gh Del, The Metherande

ARTICLE INFO ABSTRACT

‘tice sory

Received 1 Rovember 2011

Fires one ofthe most severe conditions to which steel structures may be subjected to. n order to analyze

the fire performance of stel structures, mechanical properties of steels at elevated temperatures are sig

nificant flor practical design, The recommendations of current European, American, Australian and British

‘Standards were mainly obtained from mild steels, whose validity should be checked when ured to con-

duct fre-resistance design of high strength steel structures. In order to reveal the deterioration of

Kerwod ‘mechanical properties othe commonly wed high strength ste! SAGON ude tay state re condition,

‘Feros mei ant lly tensile ests wer conducted a varius elevated temperatures fanged frm 20°C 0200 The reduction

factors of elastic modulus, yeld and ultimate strengths of S460N under steady state fire condition were

‘obtained and compared with current design standards and available literature. Is found the deteriora

‘don of mechanical properties of steels under steady state fire condition is dependent on steet grades.

Hence the recommendations in curent design standards are not applicable to high strength steels, and

‘unique reduction factrs should be proposed for various high strength steels. The elevated-temperature

properties reduction factors of S4GON presented herein can be used as input data to conduct safe fire~

1 Peformance indices

‘esistance design of steel structures with high strength steel S4G0N.

1. Introduction

The steel grade $355, which used to be considered as high

strength steel (HSS) 20 years ago, is now the main structural steel

in Europe. Currently the steels having a nominal yield stress not

less than 460 N/mm? are called high strength steel, based on the

implication of current European Design Standard Eurocode 3

(EC2) [1]. In recent years, high strength steel has been increasingly

applied in many structures all over the world because of its eco-

‘nomial benefits in comparison to mild steels, which are hot-rolled

carbon steels with normal strengths. Hence more and more atten-

tion has been paid to investigating high strength steel for various

applications Liu et al. stucied the effects of minute amounts of fer-

Fite and cooling process on mechanical properties of HSS [2.3].

Kong et al. investigated the influence of Mo content on microstruc-

ture and mechanical properties of high strength pipeline tee! [4].

In civil engineering, structural fie safety is one of the critical

considerations in the design of high-rise buildings where steel is

‘usually employed. As a basi of evaluating the performance of stee!

constructions in fire and even after fire, mechanical properties of

Covtsponding author. Adie: PO. box SOAS, 2600 GA Delt, The Netherlands

Tel: +30 15 2784752: 31 182783173.

‘Emaladieses: xalangotuclftal (X Qang) FSC Biaardonaceli al (ES,

yard MLXolesindcuelea (Kata)

(c261-2060)$- see rot mater © 2011 Hsevier Ln Al igs reserved.

so: 101016)matdes201111.069,

(© 2011 Elsovicr Lid. A ights reserved,

some structural steels at elevated temperatures have been re-

ported in literature. Outinen et al. conducted many tensile tests

fon various structural steels at elevated temperatures (5-7), and

developed fire design models for structural steels $355 and

420M [8.9]. Gunduz and Acarer studied the effect of heat treat-

‘ment on elevated-temperature mechanical properties of microal-

Toyed medium carbon steel [10]. Kodur et a. reviewed available

literature on elevated-temperature properties of steels and high-

lighted the variations between currently published experimental

results [11], However, the previous researches mainly focus on

‘mild steels For high strength structural steels, very limited infor-

‘mation has been reported by now. Lange and Schneider etal. con-

ducted experimental research on S460 at elevated temperatures

[12-15] and worked out some constitutive equations for calculat-

ing ereep strain; Chen et al. investigated the mechanical properties

of BISPLATE 80 under fire conditions [16] and reported the

elevated-temperature reduction factors of mechanical properties

for BISPLATE 80; Qiang etal. studied the residual mechanical prop-

erties of $460 and S690 after fire and presented some recommen-

dations for the practical evaluation and reuse of steel structures

alter cooling down from fire [17]. In EC3 part 1-2 [1] itis assumed

that the material properties of various structural steel grades un-

der fice conditions can be evaluated uniformly. And the specitica-

tions recommended by EC3 [1] are based on test results obtained

from mild steels. However, pervious research showed that the

2% lang aan an Design 36 (2012) 438-442

deterioration of HSS under fie conditions were different from that

of mild steels. Hence, using the recommendations from EC3 [1] 10

conduct fire-resistance design of structural members made of HSS

‘might run a risk, Not only European standard but also American,

British and Australian standards, no current design standard for

steel structures have specified recommendations for HSS under fre

condition. Therefore, accurate elevated-temperature material

properties of various HSS grades are urgently needed in practice,

to keep pace with the development of numerical modeling tech-

rhiques for predicting the fire performance of steel structures.

‘S460 is the most normally used high strength structural steel

for the time being. However, the researches on deterioration of

‘mechanical properties of HSS $460 under fie conditions re-

pported in English are very limited and focus on two types,

SAGON and S46OM. The difference between these two types is

delivery condition; S460N is normalized rolled while S460M is

thermo-mechanical rolled. Lange and Wohifeil [12] conducted

tensile tests on both S460N and S450M under transient state fire

condition: their stress-strain relationships at elevated tempera

tures up to 3% strain were reported. They pointed out the ele-

vated temperature performance of S460M was better than

SSABON. Schneider and Lange [13-15] extended the above exper-

imental investigation to 7 commercial HSS $460 with diferent

chemical compositions and delivery conditions, using, both stea~

dy state and transient state fie test methods. They pointed out

that EC3 overestimated the elevated-temperature yield strengths

if used for $460. Based on various heating rates, they developed.

aan empirical equation for ereep strain of S460 under fire condi

tions. Outinen et al [5,6] conducted test on S460M under tran-

sient state fire condition, and compared his experimental

results on elastic modulus and yield strength with that recom-

‘mended in EC3 [1]. However, a considerable discrepancy exists

between the data available in literature given by different

Fig 1 Test devce-leeble 3800 system,

PS aeaen

(a) Test coupons.

researchers, because of the variations in test methods, heating

conditions and data collection techniques. The discrepancy pre-

sents a challenge to a structural designer wishing to analyze

the response of steel structures under fire condition and might

result in safety-compromise.

For revealing more knowledge on the behavior of HSS S460N

under fire conditions and validate the available research results,

an experimental research was conducted, using steady state test

‘method at various temperatures ranged from 20 to 700°C. Based.

fon the tensile test results, the deteriorations of elastic modulus,

yield and ultimate strength of S460N at elevated temperatures un-

der steady state were presented and compared with current design

standards and available literature.

2. Experimental investigation

2uL Test device

The tensile tests were conducted using a Gleeble 3800 System,

which isa fully integrated digital closed loop control thermal and

mechanical testing system, as shown in Fig. 1, The direct heating

system of the Gleeble 3800 can heat specimens at rates of up to

10,000°Cjs, or can hold steady-state equilibrium temperatures,

Gleeble 3800 has a digital control system, which provides all

the signals necessary to control thermal and mechanical test vari=

ables simultaneously through the digital closed-loop thermal and

mechanical servo systems. The Gleeble 3800 mechanical system

is an integrated hydraulic servo system capable of exerting a5

much as 100 KN statie force in tension. In this study, 3 pairs of

thermocouples provided signals for accurate feedback control of

specimen temperatures, see Fig. 2b. The air temperature inside

the furnace was obtained by Gleeble 3800 System. A non-contact

laser extensometer was used to measure the strain of the speci-

mens. The experimental process was controlled by predefined

programming options using Quiksim Sofware. All data obtained

Irom the tests were recorded and could be monitored during

testing.

22. Test material and specimen

Al test specimens were cut from a SAG0NL steel sheet ordered

{or this study with a nominal thickness of 5 mm. S460NL is weld-

able normalized steel for steel constructions, with high yield

strength and high toughness, produced in compliance with EN

10025-3 [18]. S460 is the grade designation abbreviation of this

steel, where 5 means structural steel; 460 is its minimum yield

strength; N means normalized rolled delivery condition; and L

means low notch toughness testing temperature. The chemical

composition of the high strength steel S450N was presented in

Table 1. The geometry and dimension of the specimens were pre-

a 3] a

30 [10 J

(b) Dimensions

Fig. 2. Teale west coupon and dimensions

40 Xanga Matera and Design 26 (2012) 428-482

‘abet

Chemica composition of HSS 54508 mati (3)

€ a 5 ce @

017 aati 1500 op? 00S aga) 0025

pared in accordance with EN 10002-5 [19] and ASTM standard

£21-08 (20)

2.3. Test method and procedure

‘To obtain the mechanical properties of steels, the normally used

‘method is to conduct tensile tests under steady state or transient

state fire condition. Comparing to transient state test method,

the steady state test method is used more commonly 2s itis easier

to perform and provides the stress-strain curves directly. Thus

steady stale test method was conducted in this experimental

study,

In steady state test. the specimen was heated up to a specified

temperature then loaded until it filed while maintaining the ter-

perature constant. In this study, the heating rate was 50 °C/min,

‘and the preselected temperatures were 100°C, 200°C, 300°C,

350°C, 400°C, 450 °C, 500°C, 550°C, 600°C, 650°C and 700°C

‘After ‘reaching the preselected temperature, approximately

10 min was required for the temperature to stabilize, to ensure a

uniform temperature within the central part of specimen, And then

tensile load was applied to the specimen until failure. In the steady

state tests, strain-control was used. The strain rate used herein was

(0.005/min, which satisfied the requirement of ASTM Standard E

21-09 20}, In order to compare the deterioration of mechanical

properties of S460 at elevated temperatures, tensile tests were

conducted at ambient temperature as well,

3, Results and discussion

3.1. Elastic modulus

‘As an important factor influencing the stiffness of steel struc-

tures, the deterioration of elastic modulus with temperature

increasing affects load-bearing capacity of steel structures evi-

dently. Thus, itis significant to understand the deterioration of

‘elastic modulus under fie conditions quantitatively for evaluating

the fie performance of steel structures and correspondingly con-

‘ducting safe fre-resistance design

Under fire conditions the elastic modulus of ste! is determined,

from the stress-strain curve at the corresponding temperature,

based on the tangent modulus of the intial elastic linear curve.

table?

Baste modulus and reduction factors of SON ue steady state fire condition

Temperate CO) asic modulus (PS) Reduction ee

2 2a28i2 0

00 13s21 850

450 nas asi

600 sa019 ba9t

550 50300 o2ss

‘The deterioration of elastic modulus under fire conditions is repre-

sented by reduction factor at corresponding temperature. Reduc-

tion factor of elastic modulus is determined fiom the ratio of

elastic modulus at some elevated temperature to that at ambient

temperature. In current European, American and Australian stan-

dards, reduction factors are recommended for fire-resistance de-

sign and fire evaluation of steel structures because of their

simplicity. Herein the reduction factors of elastic modulus of

S460N under various steady state fire conditions were obtained

‘and presented in Table 2

“The reduction factors of elastic modulus under steady state fire

condition obtained from this experimental study were compared

with some current design standards (i.e, EC3 1], AISC [21] and

‘AS 4100 [22)) and the available researches on HSS 460, as shown

in Fig. 3. It confirmed the conclusion that the elastic modulus of

460M at elevated temperatures was higher than that of S460N.

For S4GQN the results from Lange and Wohifeil|12] agree well with

this experimental study. Moreover, AS 4100 |22| is generally non-

conservative for HSS $460, except the results trom Lange for

460M below 500°C [12]. EC3 [1] and AISC [21] are conservative

Tor S460M, but nonconservative for SAGON. [t means using the ree-

‘ommendations of EC3 [1] and AISC [21] for S460M is appropriate

but not safe for S460N. The recommendations of AS 4100 [22] on

clastic modulus under fire conditions are not applicable to HSS

5460, neither S4GOM nor SA6ON.

3.2. Veld strength

“The reduction factors of yield strength recommended by EC3 [1]

are based on the strain levels of 02% and 2.0%, and in BS 5950 [23],

different reduction factors are given according to three strain levels

(05%, 1.5% and 2.0%. In AISC [21], ASCE [24] or AS 4100 [22], no

specification on strain level accompanies the recommended reduc-

tion factors for yield strength. The yield strength under fire condli-

tions used herein was defined based on a total strain 2.0%, to agree

with the commonly used method at ambient temperature. The

reduction factors of yield strength under fire conditions were cal-

culated via the ratio of yield strength at elevated temperatures to

that at ambient temperature. The yield strengths and reduction

factors from steady s(ate fie test were shown in Table 3.

‘The reduction factors of yield strength were compared with

those given by Outinen et a. (5,6), Lange and Wohlfel [12], and

Schneider and Lange [13-15], as shown in Fig. 4, and the recom-

‘mendations of current design standards for steel structures were

also included. It was validated that the yield strength-reduction

.” ayaa 108

a ty 2 Santsuane

Eos 1 tatgesacon

5 ah + tee se

3 | sel

Pos a Sa istotn

é *

0 am wo alo am 100 1200

temperature (6)

ig. 3. Comparison of eduction factors of E-modulus tclevated temperatures.

2% lang aan an Design 36 (2012) 438-442 a

‘rate?

“Viel strength and seduction factors of SSN ander steady tat fe condition

Temperature CO) Yi strength (MPa) Reduction factor

20 “0 1.000

a0 am 0989

50 158 033

Steady sate 3260

to Scanider SAGON 1 (1

Semneer 45002]

Senne S4OON 3]

os Lange S408]

Lange sas0u (5)

Outi S450

oa]. [team

8s 5960 18)

AIST

02} | —-Asce 1a)

48 410017

Yield strength reducton factor

Eo

in eo a0 «000200

temperature (°C)

Fi. 4 Comparison of ye strength reduction factors with current standards and

salable research on $4650,

factors of S460M at elevated temperatures were higher than that of

SAGON, which was also confirmed by Lange and Wohlfel [12].

‘There were good agreements between this experimental study

‘with that given by Schneider and Lange on S4GON | 13]. The reduc

tion factors recommended in EC3 [1], BS 5950 [23] and AISC [21]

‘were similar to each other, but they were generally nonconserva-

{ive for SAGON in comparison to this experimental result and liter

ature. Fig. 4 showed that the predictions of ASCE [24] and AS41100,

[22] were not applicable to SA60N, either.

The reduction factors of yield strength for S460N obtained from

this study were also compared with that of several typical mild

steels given by Makelainen et al. (9| as shown in Fig. 5, the results

{or $460M given by Outinen et al [5-7] and the predictions of EC3

[1] were also involved as reference. This comparison showed that

there was a considerable discrepancy in the reduction factors for

different steel grades a elevated temperatures. It seemed that only

‘mild steels S235 and $355 could be predicted accurately by EC3 |

“This is because the recommendations of EC3 [1] were mainly ob-

tained according to mild steels. Hence, ECS [1] is confirmed not

applicable o all structural steel grades. Similar to EC3 [1] none cur

rent design standard has any specifications on the difference of

‘mechanical properties lor different steel grades, which might raise

risks to conduct fre-resistance design of steel structures with high

strength steels

2.3, Ultimate strength

‘The ultimate strength reduction factors were calculated based

fon the ratio of ultimate strength at a specified elevated tempera-

im

1

- > Satya si

prbeeerg | t cambctate

i TTA | Feeney

2 > heen sed

5 2 tien east

Bos 7

Bot

Las

° ao oo aon om wo ta

temperature (°C)

ig. 5. Comparson of yield suength reduc factors with avalable research on

‘ile ele

Unate strength seduction tars of SA60N under

steady sate re anda

Temperature CO Reduction ctr

100) oses

‘ure to that at ambient temperature. The ultimate strengths reduc-

tion factors oblained under steady state fire condition were given

in Table 4. They were compared with the recommendations of

‘American design standard AISC 21}, a8 presented in Fig. 6. The

redluction factors of ultimate strength for S460N were generally be-

low the recommendations of AISC |21].In AISC [21] the recommen-

42

temperature (*C)

ig. 6. Comparison of ulmate strength reduction facts with Ameen design

nacd a.

ae Xanga Matera and Design 26 (2012) 428-482

ig. 7. flue modes of S460 specimens 2 various elevated temperatures

dations for ultimate strength reduction factors obtained mainly

from mild steels are uniform for all stel grades, which are proved

‘ot safe for evaluating HSS S460N under fire condition. Therefore

some unique recommendations are necessary for S460N as well

‘as other high strength steel grades, to accurately predict the dete

Floration of their ultimate strengths under fire conditions.

3.4 Typical failure modes

‘Typical failure modes of high strength steel S46ON tensile spec-

mens under various fire conditions obtained from steady state

tests were shown in Fig. 7. It can be seen that for all specimens

necking appeared before failure. No brittle failure was observed

under all tested fie conditions from 20°C up to 700°C.

4. Conclusions

‘This paper has presented a detailed experimental study on the

deterioration of mechanical properties of high strength steel

SS4GON under steady state fire condition. The elevated-temperature

‘elastic modulus, yield and ultimate strengths and typical failure

modes of S460N were obtained from steady state tensile tests.

‘he reduction factors of mechanical properties of HSS S46ON ob-

tained from this study were compared with current European,

‘American, Australian and British design standards. tis found that

‘no current design standard can be safely used to conduct fire-resis-

tance design or evaluation of stee! structures with high strength

steel SAGON. The experimentally obtained reduction factors of

‘mechanical properties of HSS S460N presented herein can be used

as input data for numerical modeling to evaluate the performance

‘of steel structures with HSS S460N under fire conditions, and they

Offer proof for structural engineers to conduct sae fire-resistance

‘design as well. Further, the comparison of HSS S460N with HSS

460M and mild steels showed the deterioration of mechanical

properties of sieels under fire conditions is dependent on steel

‘grades. Thus, more unique reduction factors of mechanical proper~

ties for various specified high strength structural steel grades (ie,

‘9690, $890, $960 and so on) at elevated temperatures should be

proposed in future research for safe practical design and analysis.

References

|i) CEN. Eucode 3. Design of ste structures ~ Part 1-2: General ules —

Structural ve aesign rusts! CEN; 2005

[2] uc, Wy Lis YC Mechanical properties of high strength quenched eo

‘th minute amounts offre, Mater Des 198 1249-82.

[B) Ue & Lu Wf CT, Zhu Ob Zhang JK. cooling process and mechanical

Properties desig o high carbo he rl high seg (HRS) secs Mater

Dew 9819-1757

Fa] Kong J, Zen 1, CoB, Li FH Wang AN, Xie. Inlene of Mo content on

Imirosructure ind’ mechanical properties of high stengtn pipeline scl

[5] Detinen at 0, MsklinenP Migh temperature esting of structural tec

hd madcing of ucts fie temperatures. ill Hand: Heh

University offechoology Laboratory of Ste Structures; 200

{6} Dutinen | Mechanical properties of ctl tse 3 high temperatures and

after colin down, PRD thes. Helsing, Finland Helin University of

Technolgy: 2007

(7) utinenMakesine P Mechanical properties of stitute at covated

[s} urinen J Rest J Maklanen Fre design rode for strctral te 8355,

based" upon erasien ste tense est resus] Const. Stel Res

fo} Matctainen P, Oucinen Kat Fe design made! for structural tet SAz0M

Based upon” tansent state tense test results. J Constr” Stel Res

Ino) Gundur S Acer M, The effect of heat ueatment on high temperature

mechankal properties of mcraloyed medium carn steel. Mater Des

[11] Koeiur ¥, Owaikat M, Fike High-temperature properties of steel for fre

Fesistance meting of structure) Mat Cv ag 2010 22:25 98

112] Lange 1. WohifeN txamination of the mechanical properties of the

ricrosloyed grain refine steel S460 at elevated emperatures.Bauteehak

11) Schneider Lange |. Constantive equations of structural sel $860 at bigh

[14] Schneider R Lange J. Constitutive equations and empirical creep law of

Suctual tcl S150 a igh wemperatares ns Kocur V, Parson edt.

703.10 °

115] Schneider, Lange J Material and creep Behaviour of S450 incase of fre-

experimental investigation and anayal modcling. In) Wald F Howova K

estore Ian Cote spaon of sce

[16] Chen Youn 6, Ly 8. Behavior of igh strength stractrl scl at levated

emperatures Suc ng-Asce 2000132 198-54,

1171 Gana Xe Bifaid PSK Reason HL Post-hte mechanical properties of igh

Strength srr sels $400 and So. Eng Secs m pest. ds LOL

Jengsiuct2011,1.005,

[ny CEN He ole podscts of strctual ste — Part 3: Teco decry

Conditions for armalzenormalzed alle welds fe pa srt

Stes EN 1002541 Bree 7008

Ing) CEN Meealte matenal-tensie testing art : Method of esting at levated

temperature EN 100025. russel 102.

[20] ASIA Standard fest mods for slvatd emperaare tension tests of

reac mates E 21-08 West Consoacken, United States, 208,

[21] ASC speieaton fer stracaral tee uengs Chisgo:Amenan ston

of Scel constiuction: 2008.

[22] AS Australlon Standards cel structures AS 4100. yey, Australis; 1908,

1231. Stroctural use of stetwork inti. Part 8: Cade 9 rate for fire

ressane design 59508 London: 1288

(ea) ASCE Stuctuta fre protection New York 1982.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1 Guia Carreira FCDDocument30 pages1 Guia Carreira FCDCaline NunesNo ratings yet

- Guia Carreira FADDocument21 pagesGuia Carreira FADCaline NunesNo ratings yet

- Guia Carreira FEBDocument14 pagesGuia Carreira FEBCaline NunesNo ratings yet

- Guia Carreira FEDDocument19 pagesGuia Carreira FEDCaline NunesNo ratings yet

- Guia-Carreira FrpaDocument14 pagesGuia-Carreira FrpaCaline NunesNo ratings yet

- Guia-Carreira FeiDocument19 pagesGuia-Carreira FeiCaline NunesNo ratings yet

- 1 DireitoDocument3 pages1 DireitoCaline NunesNo ratings yet

- Guia Carreira FEMLDocument17 pagesGuia Carreira FEMLCaline NunesNo ratings yet

- 1-Business Intelligence X Ciencia de DadosDocument8 pages1-Business Intelligence X Ciencia de DadosCaline NunesNo ratings yet

- Catalogo Tec 2018Document47 pagesCatalogo Tec 2018Caline NunesNo ratings yet

- 1 TurismoDocument4 pages1 TurismoCaline NunesNo ratings yet

- Trabalho Especialista 2Document35 pagesTrabalho Especialista 2Caline NunesNo ratings yet

- 2-O Cientista de DadosDocument2 pages2-O Cientista de DadosCaline NunesNo ratings yet

- Elevated Temperature Material Behaviour of High Strength SteelDocument22 pagesElevated Temperature Material Behaviour of High Strength SteelCaline NunesNo ratings yet

- Fillet Welded Joints - A Review of The Practicalities - TWIDocument9 pagesFillet Welded Joints - A Review of The Practicalities - TWICaline NunesNo ratings yet

- The in Uence of Temperature On Mechanical Properties of The Base Material (BM) and Welded Joint (WJ) Made of Steel S690QLDocument5 pagesThe in Uence of Temperature On Mechanical Properties of The Base Material (BM) and Welded Joint (WJ) Made of Steel S690QLCaline NunesNo ratings yet

- Relatório de Estágio LUSOSIDER - FinalDocument178 pagesRelatório de Estágio LUSOSIDER - FinalCaline NunesNo ratings yet

- Comparison of Welding Processes in Welding of Fillet Joints: June 2013Document9 pagesComparison of Welding Processes in Welding of Fillet Joints: June 2013Caline NunesNo ratings yet

- Deterioration of Mechanical Properties of Novel Constructional Steel Material at Elevated TemperaturesDocument7 pagesDeterioration of Mechanical Properties of Novel Constructional Steel Material at Elevated TemperaturesCaline NunesNo ratings yet

- Mechanical Properties of S355 Under Extreme Coupled Effect of High Temperatures and High Strain RatesDocument8 pagesMechanical Properties of S355 Under Extreme Coupled Effect of High Temperatures and High Strain RatesCaline NunesNo ratings yet