Professional Documents

Culture Documents

1990 Aug Krasilnikov Linyuchev SovietDesign LargeTurbines PDF

1990 Aug Krasilnikov Linyuchev SovietDesign LargeTurbines PDF

Uploaded by

ShahbazKhan0 ratings0% found this document useful (0 votes)

9 views4 pagesOriginal Title

348768542-1990-Aug-Krasilnikov-Linyuchev-SovietDesign-LargeTurbines.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pages1990 Aug Krasilnikov Linyuchev SovietDesign LargeTurbines PDF

1990 Aug Krasilnikov Linyuchev SovietDesign LargeTurbines PDF

Uploaded by

ShahbazKhanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Soviet design of large

turbines for wide head

ranges

By MF. Krasilnikov and V.A. Linyuchev

the USSR (whereby turbines are commissioned well

ahead of completion of the civil works, and operate

Initially at ow heads) can make a substantial contribution

{o the return on the schemes’ capital Investment, because of

the large amount of extra electricity which can be

Produced. This poses new challenges for the design of

lectromechanical equipment, which is required to operate

cover a wide head range. This article discusses the current

Soviet approach to this problem, and experience which has

been gained at some of the world’s largest plants, for

‘example, Nurek and Sayano-Shushensk.

T he construction in stages of large scale projects in

‘The operation of hydropower plants with large head

variations may be necessary in three cases:

@ at an over-year storage scheme;

© when a project is constructed in two stages, and the dam

hheight isto be raised during the second stage; or,

© where there is a need 10 begin power generation at an

incomplete dam, before the reservoi is fully impounded,

170 nto, Vltlastn She 3 1812 Meow 48 USSR

While the frst case requires an extensive economic

analysis to select the turbine type for the recurring

‘operating conditions in the low head range, the other two

cases need only the replacement or refurbishment of the

‘main equipment components when the head increases.

In the USSR, a great deal of experience has been gained

in manufacturing hydro equipment for operation over &

wide range of heads. Three types of equipment are used in

such cases, selected on the basis of a technical and econ-

comical feasibility study for the specific conditions of the

project site

© A turbine with a wide range of allowable operating heads

‘may be selected. This may be a Kaplan, Francis or Deriaz

turbine. According to Soviet standards, these turbines are

suitable for a head variation Of Hyin/Ha = 0.5 oF less.

Such equipment is used for heads'of less than 150 m at

hydro plants where deep drawdown of the reservoir is

necessary.

(© Temporary runners with an increased specific speed may

‘be installed for the period of operation at low heads. This

done at high dam projects, where the civil works and prep

aration of the reservoir for filling take a particularly long,

time. In this case, asa rule, a single generator with a perm=

nent speed is used.

rs

@ two-speed generators may be

Insalled "Thi option has been

ted at wo Soviet hydro plants,

which were bull in two sage,

Wiha substantial increase in head

ihe second tage sonstetion |

anda fong interval between the |

Stages (ore than 10 yar)

Ail tree of these options ae,

of course, only economically |

feasible in the case of large scale |

dam project, where te conse

thle anova of era power gent.

fated as a rol of the average

Increase in eine in the lw

head range covers the. cost of

Imanufactring the special ex

iment, and “aso. theacties

involed in dmantng the gen

‘ing set end italing new Com

ponent

examples ofthe application in

tne USS of all thee of the

Optons described wil be sven

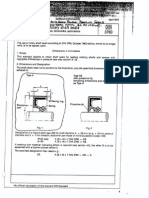

next. ig, 2. Section through the Rogun underground powerhouse, where: 1 = wurbines 2 =

yr generator: and, 3 = $50 overhead travelling crane.

Diagonal flow turbines for

operation under a wide range

‘of heads have been installed atthe Zeya and Kolyma hydro-

power plants. The world’s largest diagonal flow turbines

with 6 m-diameter runners, rated at 220 MW with a speed

(of 136.4 rev/min, are installed at Zeya. The rated head of|

the turbines is 78.5 m with maximum and minimum values

fof 97.3 mand 74.5 m respectively. Initially the turbine was

PUL on stream at a head of 40_m, that i, 41 percent of the

‘maximum head. The temporary runners were not necessary

{as would have been the case in the Francis turbine applica:

tion), which covered the cost of the more expensive Deriaz

turbine. The efficiency gain of the Deriaz turbine in the

range of “starting” heads in comparison with the Francis

cone (with a temporary runner) was 3-4 per cent, which

permitted about 3 TWh of electric energy to be generated

Additionally for three years during initial operation,

‘Temporary runners in Francis turbines have been used

for a number of very large high head hydro schemes in the

USSR: for example, in the Nurek 310 MW turbines which

operate at a rated head of 223 m, and the Sayano-

‘Shushensk 650 MW turbines which operate at rated head of |

194m.

‘Tabies I and II give parameters of the turbines at Nurek

and Sayano-Shushensk with permanent and temporary

‘A design has been developed for 6 m runner diameter 600,

MW machines for a maximum head of 320 m, for the

Rogun dam. These units are now under construction. A

cross section of the machine hall cavern for the

‘underground powerplant is shown in Fig. 2.

"The payback of capital costs as a result of running the

turbines at lower heads is particularly important inthe case

Of this project because of the large scale ofthe civil works

G25 m-high rockfill dam with a fill volume of 71 x

TOs’), I was therefore decided to design the six turbines

to be able to operate at an initial head of 70 to 80 m,

Operation under a head range of 70 to 320 m is to be

‘ment for the associated hydraulic system.

‘© Phase 2: When the available head reaches 120-185 m, the

temporary runners will be replaced by the permanent ones

atthe first two units, without interrupting operation, and

fetaining the temporary generators and temporary water

ake

(© Phase 3: When the head exceeds 185 m, the curbines with

permanent runners and generators, connected to the perm-

nent water intake structure, will be put into operation

‘The original starting turbines, Nos. 5 and 6, will main in

operation, however, for some time during the second

phase, for operation when the reservoir is drawn down

to below el. 185 m during releases for irigation.

Implementation of the proposed starting scheme means

that the Rogun hydropower plant can be put into operation

using virtually only the 6.5.x 10 m? cofferdam, rather

than the main rockfll dam. Thus more than 7 TWh of

electricity will be able to be generated ahead of completion

(Continued on page 38.)

[Table 1 — Characteristics of the turbines at Nurek

‘Runner | Head (m

diameter | Speed. | Capaciy

o™ ev/min)| MW)

Temporary | 4 [17s 90 90 | 20 | 20

Permanent | 475 | 278 17s. — | 200° | 300330)

[Fable It — Characteristics ofthe Sayano-Stushensk units

TRunner| Head (m)

iameer| Start| Speed | Capacity

Operation under head range of 70 to 320 m isto be | I pamaers [tah [mat in in| r/min)

turbines for these phases ae given in Fig 3): eames eoosd|iabtonn lan eas

© Phase 1: When the head has reached 80120 m, two | | MONE

{orbines wil stat operating (numbers $ and 6) with emp- | | Petmaneat | 6277 J 20 17s 0) eas | 640

rary runners, temporary generators and special arange

ater Fomor & Dam Conmtcon. Regu 150 8

|

|

Fig. 4 Vertical shaft Kaplan tarbine »

©f 210 MW capacity, where: 1 = 28

{ividevanes; and, =” seven Dladed

(Continued from page 38.)

‘of the main dam because ofthis earlier startup of the nits

Specification of the speed for the starting turbines was &

separate problem associated with the design of the equip

ment. From the view point of selection of the temporary

runners to be developed (on the bass of existing models),

136.4 rev/min was found to be the mos suitable speed. But

this meant that new temporary generators would have had

to have been developed, because only the thrust bearing,

bracket, rotor spider and other non-clectromagnetic

components of the standard set could be used. Then,

tunrecoverable costs would have been as high as 60 per cent

of the total cost of the generator. The best compromise

therefore was to adopt a speed of 125 rev/min. The new

temporary runner, 4,835 m in diameter, was designed for

this speed. It features high power and cavitation-resistance

characteristics, with runaway speed not exceeding the

Standard speed, and achieves optimum operation within the

130-120 m head range. During replacement of the temporary

‘generator (with a speed of 125 rev/min) for the permanent

fone (with a speed of 166.7 rev/min), the unrecoverable

‘costs will be reduced by 20-25 per cent.

“The custom-made designs of both the turbines and gen-

erators for the Rogun dam project was necessitated by the

need to reduce as far as possible the overall dimensions of

the underground machine hall. For instance, the standard

design of the 600 MW turbine with a 6 m runner diameter

‘would have required the provision of the spherical shutoff

valves directly in front of the spiral case, calling for the

Water Power & Dam Construction, August 1090

double entry spiral cases and the installation of two 4.2

‘mdiameter shutoff valves for each turbine. This would

hhave required a substantial capital investment for the civil

works, equipment and additional space to accommodate

the spherical shutoff valves, and this turned out to be

‘unacceptable from the viewpoint of the stress state in the

rock mass around the underground caverns. Therefore

turbine with a follower ring valve, provided between the

stayvanes and the guidevanes was developed.

“The follower ring valve has a riumber of advantages: iis

cheaper than shutoff valves, does not cause extra hydraulic

losses, and achieves teliable closure of the hydrauli

passage almost without increasing the overall dimensions of

i hall, beeause ofits location within the turbine

tors for the Rogun project (Fig. 1) have water-

cooling (de-ionized water) for the rotor windings, stator

land core. The adoption of complete water cooling for the

generator allowed for the overall dimensions ofthe ventil-

tion enclosure to be reduced by 2.5 m (in comparison with

the generator with the water cooling system for the stator

winding only) and a corresponding reduction in the size of

‘the machine hall cavern was thus achieved.

‘The installation of double speed generators allows forthe

same runner to be used for two head ranges. It reduces the

cost of the turbine, and costs relating to the complete

replacement of the turbine, although the generator is

slightly higher (approximately $-10 per cent),

‘This arrangement was adopted for the Shulba hydro:

powerplant, where the frst unit was commissioned in 1988.

‘The range of heads was 16-30 m for the first phase, and

30-48 m for the second phase. The rated power of the

turbine inthe first phase was 120 MW with arated head of

| 23.5'm, and at the second phase, 230 MW, with a rated

| head of 40m,

This turbine is the largest adjustable-blade Kaplan

turbine in the world, Unfortunately, its normal operation

was not verified at the second phase. The cross section of

the turbine is given in Fig. 4.

Conclusion

‘The tendency for staged construction of the large scale

hydropower projects with gradual increase inthe head, 10

reduce the initial capital investment for the projec,

Dresents new requirements for electromechanical equip-

iment. As has been shown, efficient operation of the

equipment under a wide range of heads can be achieved by

the application of Francis and Deriaz turbines, temporary

Francis runners or two speed generators. a

A new approach to

turbine speed

By J.L. Gordon, Vice President*

mination of turbine speed is to develop empirical

Tormulae for each type of turbine, relating specific

speed to the net head. Turbine runaer speed thus becomes &

function of head, diameter, and runner throat velocity. In

‘wo previous articls!2 the author demonstrated that the

‘number of runner blades has an influence on the turbine

Setting. Such is also the case for runner speed. By including

‘the number of runner blades and the type of draft tube, itis

possible to develop a more accurate equation for speed,

‘with one equation covering all types of reaction (pit, bulb,

‘Kaplan, propeller and Francis) turbines, as will be shown in

this article The new equation is based om an analysis of 155

turbine units.

‘The most recent data on specifi speed have been developed

by Schweiger and Gregori? with three equations relating

specific speed n, to head h as follows:

Francis turbines

304 0084

Kaplan turbines

791 hae -@)

ap i PO en Merl i

| Bub srins

ny = 1089 A-ves -@)

ed from the specific speed

‘Turbine flow @ is a function of turbine throat diameter d

and throat velocity, since

= 0785 av =)

(Continued on pe $1)

= actual runner sped (t¥/min)

‘alculated runner speed (e/a)

= turbine specific speed, based on ow

= turbine rated flow (m/s)

¥ = groseasial velocity through turbine runner throat, with 0,

deduction for area occupied by runner hub or blades (m8)

|

°

4.

*

‘Water Power & Dam Construction August 1980 ®

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aise Standard No.7 (Ladle Hooks)Document7 pagesAise Standard No.7 (Ladle Hooks)Marcus Alvarez100% (1)

- Determining Weld SizeDocument19 pagesDetermining Weld SizeMarcus AlvarezNo ratings yet

- 2001 Intake Gates-Up or Downstream SkinPlatesDocument3 pages2001 Intake Gates-Up or Downstream SkinPlatesMarcus AlvarezNo ratings yet

- 1977 Jun Singhota&Goyal DesignPenstockWyes BasiHydroStatDocument5 pages1977 Jun Singhota&Goyal DesignPenstockWyes BasiHydroStatMarcus AlvarezNo ratings yet

- 1982 - Aug - Falvey, H.T. Predicting Cavitation in Tunnel SpillwaysDocument3 pages1982 - Aug - Falvey, H.T. Predicting Cavitation in Tunnel SpillwaysMarcus AlvarezNo ratings yet

- 1990 - Feb J.L.gordon Hydro Turbine SizingDocument4 pages1990 - Feb J.L.gordon Hydro Turbine SizingMarcus Alvarez100% (1)

- 1978 - Nov - J.L.gordon-Est - Hydro Powerhouse Cran CapacityDocument2 pages1978 - Nov - J.L.gordon-Est - Hydro Powerhouse Cran CapacityMarcus AlvarezNo ratings yet

- ANSI A14.3-2002 Standards For LaddersDocument38 pagesANSI A14.3-2002 Standards For LaddersMarcus AlvarezNo ratings yet

- Din3760 Shaft SealsDocument8 pagesDin3760 Shaft SealsMarcus AlvarezNo ratings yet

- Rope TorqueDocument4 pagesRope TorqueMarcus AlvarezNo ratings yet

- Cmaa 74Document9 pagesCmaa 74Marcus AlvarezNo ratings yet