Professional Documents

Culture Documents

Arm To Bracket Weld PDF

Uploaded by

Homer Silva0 ratings0% found this document useful (0 votes)

36 views1 pageOriginal Title

Arm to Bracket Weld.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 pageArm To Bracket Weld PDF

Uploaded by

Homer SilvaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

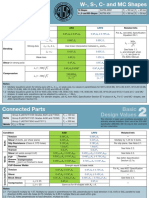

Section 5: DATE: 3/23/00

valmont v Arm-to-Bracket Weld 1% neg

NEWMARK APPROVED:

ARM— TO — BRACKET WELD

The weld connecting the arm to the arm bracket is a primary stress carrying weld. AS

such, it demands proper design, detailing and inspection practices. Valmont has

addressed these requirements by standardizing on a groove weld combined with a fillet

overlay sized to develop the full strength of the arm. Details of this weld are as follows

ARM =| GROOVE] FILLET | THROAT] ARM GROOVE] FILLET | THROAT

THICK THICK

=| 0.188" | 0,125" |:0.35” 0.34" 0.375" _| 0.313” 0,68"

0.219" | 0.156" | 0.40" 0.39" 0.406" __| 0.344" 0.73” |

—[o2s"_[ 0.188" T0.as*foas™ F038 | 0.373"

0.219" He 0.50" O51" 0.468"

ois [028" [055° [0367 [050"

oa" 0280.60" 10.0"

1. This detail develops the full strength of the arm while maintaining stress levels in the weld, and in

the thru-thickness directtion of the bracket, below ASCE allowables. Note that the allowable

stress level for partial penetration fillet weld design is nearly half that of a full penetration weld.

‘This detail can be fully inspected to AWS acceptance criteria

This detail eliminates problems associated with back-up strips in arm shafts (severe taper, oblique

angle of intersection with the bracket, and access to seal weld the back-up strip}.

UTILITY ENGINEERING DESIGN MANUAL

You might also like

- W Entre TDocument5 pagesW Entre THomer SilvaNo ratings yet

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaNo ratings yet

- Steel PoleDocument1 pageSteel PoleHomer SilvaNo ratings yet

- Basic Design Value AISCDocument4 pagesBasic Design Value AISCmrajansubramanian100% (2)

- Lum Hmled3 PDFDocument3 pagesLum Hmled3 PDFHomer SilvaNo ratings yet

- Sigma 500Document1 pageSigma 500Homer SilvaNo ratings yet

- Wind Response of Cable-Stayed Masts: July 2005Document9 pagesWind Response of Cable-Stayed Masts: July 2005Homer SilvaNo ratings yet

- Experimental Design Results/Acknowledgements: Local Buckling Behavior of Round Steel Tubes Subjected To Compressive LoadsDocument1 pageExperimental Design Results/Acknowledgements: Local Buckling Behavior of Round Steel Tubes Subjected To Compressive LoadsHomer SilvaNo ratings yet

- Fea SW PDFDocument480 pagesFea SW PDFHomer Silva100% (4)

- ASME Flange Bolt Torque ProcedureDocument13 pagesASME Flange Bolt Torque ProcedureHomer Silva100% (6)

- Troybilt TB200Document48 pagesTroybilt TB200Homer SilvaNo ratings yet

- Fea SW PDFDocument480 pagesFea SW PDFHomer Silva100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)