Professional Documents

Culture Documents

MP 23 PDF

MP 23 PDF

Uploaded by

Ashraf TomizehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MP 23 PDF

MP 23 PDF

Uploaded by

Ashraf TomizehCopyright:

Available Formats

Standard Specification for

Reclaimed Asphalt Shingles

for Use in Asphalt Mixtures

AASHTO Designation: MP 23-151

American Association of State Highway and Transportation Officials

444 North Capitol Street N.W., Suite 249

Washington, D.C. 20001

© 2015 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

Standard Specification for

Reclaimed Asphalt Shingles

for Use in Asphalt Mixtures

AASHTO Designation: MP 23-151

1. SCOPE

1.1. This specification covers reclaimed asphalt shingle material used in asphalt mixtures. The use of

reclaimed asphalt shingles in other recycling applications such as hot-in-place pavements, and

cold recycled pavements is not included in this specification.

Note 1—Refer to PP 78, “Design Considerations When Using Reclaimed Asphalt Shingles

(RAS) in Asphalt Mixtures” for information on design considerations, determining shingle

aggregate gradation, and the grade of the binder.

2. REFERENCED DOCUMENTS

2.1. AASHTO Standards:

PP 78, Design Considerations When Using Reclaimed Asphalt Shingles (RAS) in Asphalt

Mixtures

T 2, Sampling of Aggregates

T 27, Sieve Analysis of Fine and Coarse Aggregates

3. TERMINOLOGY

3.1. Definitions:

3.1.1. aggregate—coarse and fine aggregate introduced into asphalt mixtures that is exclusive of the

shingle aggregate.

3.1.2. coarse and fine aggregate—see T 27 for definitions.

3.1.3. manufactured shingle waste—rejected asphalt shingles or shingle tabs that are discarded in the

manufacturing process of new asphalt shingles.

3.1.4. postconsumer asphalt shingles—asphalt shingles that are removed from the roofs of residential

dwellings or commercial buildings. Postconsumer asphalt shingles are often called “tear-off”

shingles.

3.1.5. reclaimed asphalt shingles (RAS)—manufactured shingle waste or postconsumer asphalt shingles

that have been processed into a product that meets the requirements of this standard.

3.1.6. RAS asphalt binder—asphalt binder that is present in the reclaimed asphalt shingles.

3.1.7. RAS aggregate—mineral granules, sand, or other mineral matter present in the reclaimed asphalt

shingles, excluding the shingle fiber content.

TS-2d MP 23-1 AASHTO

© 2015 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

3.1.8. RAS fiber—glass felt, paper felt, foil, and fabrics or films used as the structural basis of asphalt

shingles.

4. SOURCES AND SAMPLING

4.1. Reclaimed asphalt shingles may be derived from either manufactured shingle waste or from

postconsumer asphalt shingles (Note 2).

Note 2—Various state and local regulations may be applicable to the use of asphalt shingle

material. The user of this specification is advised to contact state and local transportation

departments and environmental agencies to determine what additional requirements may be

necessary.

4.2. Postconsumer asphalt shingles shall be processed prior to use to meet the requirements of this

specification and shall consist of asphalt roll roofing, cap sheets, and shingles, including

underlayment, only. Roofing debris, including coal tar epoxy, rubber materials, or other

undesirable components, shall not be included or used in RAS from postconsumer asphalt

shingles. Postconsumer asphalt shingles shall be certified as conforming to local requirements

concerning asbestos.

4.3. Manufactured shingle waste and postconsumer asphalt shingles shall not be blended together for

the production of asphalt mixtures.

4.4. Reclaimed asphalt shingle samples collected and analyzed for the purpose of identifying the

properties of reclaimed asphalt shingles as defined in this specification shall be representative of

the reclaimed asphalt shingle material that will be used in the full production of asphalt mixtures.

5. GRADATION OF RECLAIMED ASPHALT SHINGLES

5.1. Reclaimed asphalt shingles shall be processed so that 100 percent passes the 9.5 mm (3/8 in.) sieve.

Gradation requirements apply to processed and dry shingle material prior to the extraction of the

asphalt binder.

Note 3—The asphalt mixture supplier may choose to uniformly blend fine aggregate, powdered

zeolites, or reclaimed asphalt pavement (RAP) with the reclaimed asphalt shingles as a method of

preventing the agglomeration of reclaimed asphalt shingle particles. Any amount of fine

aggregate, RAP, or other material added must be considered in the final gradation of the asphalt

mixture.

6. DELETERIOUS REQUIREMENTS

6.1. Reclaimed asphalt shingles shall not contain extraneous waste materials and shall be essentially

nail-free. Extraneous materials such as metals, glass, rubber, soil, brick, paper, wood, and plastic

shall not exceed 1.5 percent of the total mass measured on material retained on and above the

4.75-mm (No. 4) sieve. Nonmetallic extraneous material shall not exceed 0.5 percent of the total

mass measured on material retained on and above the 4.75-mm (No. 4) sieve.

6.2. Reclaimed asphalt shingles shall contain less than the maximum percentage of asbestos fibers

based on testing procedures and frequencies established in conjunction with the specifying

jurisdiction and state or federal environmental regulatory agencies.

TS-2d MP 23-2 AASHTO

© 2015 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

7. METHODS OF SAMPLING AND TESTING

7.1. Sample and test the reclaimed asphalt shingles using the following AASHTO standards, except as

otherwise provided in this specification:

7.1.1. Sampling according to T 2.

8. KEYWORDS

8.1. Aggregate; gradation; manufactured shingle waste; postconsumer asphalt shingles; RAS

aggregate; RAS fiber.

1

This provisional standard was first published in 2014.

TS-2d MP 23-3 AASHTO

© 2015 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

You might also like

- Asphalt Mix Design 71-06-101Document14 pagesAsphalt Mix Design 71-06-101colbmNo ratings yet

- Technical Note On Class 6A Selected Well-Graded Granular Material (2010)Document4 pagesTechnical Note On Class 6A Selected Well-Graded Granular Material (2010)sandycastleNo ratings yet

- AustStab Model Specification For Insitu Stabilisation For Main RoadsDocument20 pagesAustStab Model Specification For Insitu Stabilisation For Main RoadsprmraoNo ratings yet

- Superpave Volumetric Mix Design: Standard Specification ForDocument17 pagesSuperpave Volumetric Mix Design: Standard Specification ForLaura VelozNo ratings yet

- Asphalt and Asphalt Paving Materials ReviewerDocument7 pagesAsphalt and Asphalt Paving Materials ReviewerWillard ApengNo ratings yet

- BS-1377 PART-4 (R) SOIL Compaction Related TestsDocument52 pagesBS-1377 PART-4 (R) SOIL Compaction Related TestsAshraf Tomizeh100% (2)

- Curriculum Map in Tle 7 Subject: Tle Grade Level: Grade 7 TEACHER: Mr. Israel M. MarquezDocument31 pagesCurriculum Map in Tle 7 Subject: Tle Grade Level: Grade 7 TEACHER: Mr. Israel M. MarquezIsrael Marquez0% (1)

- Bsi-7263-1 Concrete Pre-Cast Unreinforced Concrete Paving F PDFDocument42 pagesBsi-7263-1 Concrete Pre-Cast Unreinforced Concrete Paving F PDFAshraf TomizehNo ratings yet

- BS594 1-2003Document28 pagesBS594 1-2003Marcelo Rodriguez FujimotoNo ratings yet

- Reclaimed Asphalt Pavement (RAP) Management PlanDocument13 pagesReclaimed Asphalt Pavement (RAP) Management Planali ghNo ratings yet

- Astm C131-06 PDFDocument4 pagesAstm C131-06 PDFAshraf Tomizeh100% (1)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- BS 594-1 2005 Hot Rolled Asphalt For Roads and Othe Rpaved AreasDocument32 pagesBS 594-1 2005 Hot Rolled Asphalt For Roads and Othe Rpaved Areassallymazeera100% (2)

- Asphalt Additives and Modifiers: Standard Practice ForDocument7 pagesAsphalt Additives and Modifiers: Standard Practice ForXarmdNo ratings yet

- Bsi - 6717 Concrete Unreinforced Concrete Paving Blocks RequDocument42 pagesBsi - 6717 Concrete Unreinforced Concrete Paving Blocks RequAshraf Tomizeh100% (2)

- Finalreport PDFDocument47 pagesFinalreport PDFNelCamHerNo ratings yet

- Bolter and Chainsword 5th Edition GuideDocument76 pagesBolter and Chainsword 5th Edition Guidetompson100% (7)

- Aashto M 6-13Document5 pagesAashto M 6-13Abu Alhassan A.No ratings yet

- en 196 7 1989 PDFDocument22 pagesen 196 7 1989 PDFAshraf TomizehNo ratings yet

- ASTM D3910 - Design, Testing, and Construction of Slurry Seal PDFDocument8 pagesASTM D3910 - Design, Testing, and Construction of Slurry Seal PDFLahcenLakdimNo ratings yet

- BS 1924 1990 PDFDocument20 pagesBS 1924 1990 PDFAshraf Tomizeh50% (2)

- R 5-03 Selection & Use of Emulsified Asphalts PDFDocument5 pagesR 5-03 Selection & Use of Emulsified Asphalts PDFWalticoZegarraHerreraNo ratings yet

- HMT RPA - A1079Document9 pagesHMT RPA - A1079Mohamed RiyasNo ratings yet

- Selection of Cutback Asphalts: Standard Practice ForDocument3 pagesSelection of Cutback Asphalts: Standard Practice ForD IZomer Oyola-GuzmánNo ratings yet

- Opss - Prov 1003 Apr13Document19 pagesOpss - Prov 1003 Apr13Brando BermejoNo ratings yet

- Opss - Prov 1151 - Apr 2021Document12 pagesOpss - Prov 1151 - Apr 2021Kyle MacWilliamNo ratings yet

- Materials For Roads and Pavements: Standard Terminology Relating ToDocument4 pagesMaterials For Roads and Pavements: Standard Terminology Relating ToOscar VillaNo ratings yet

- SABITA Manual-1 - 1998Document16 pagesSABITA Manual-1 - 1998Jacques Van HeerdenNo ratings yet

- EVACHMACriteriaFinal For2012Document10 pagesEVACHMACriteriaFinal For2012Assane LeyeNo ratings yet

- Slurry Seal Issa A105Document16 pagesSlurry Seal Issa A105Luis Miguel PachecoNo ratings yet

- Norma Slurry SealsDocument16 pagesNorma Slurry SealsFidelMtzNo ratings yet

- T 279-96 (2006) Accelerated Polishing of Aggregates Using THDocument7 pagesT 279-96 (2006) Accelerated Polishing of Aggregates Using THFranz Richard Sardinas MallcoNo ratings yet

- Recommended Construction Guidelines For Full Depth Reclamation (FDR) Using Bituminous StabilizationDocument13 pagesRecommended Construction Guidelines For Full Depth Reclamation (FDR) Using Bituminous StabilizationDao Phuc LamNo ratings yet

- Technical Specifications For Sand As Per BIS: August 29, 2016 10497Document16 pagesTechnical Specifications For Sand As Per BIS: August 29, 2016 10497Kanikaa B KaliyaNo ratings yet

- Mineral Filler For Asphalt MixturesDocument2 pagesMineral Filler For Asphalt MixturesAnonymous x7VY8VF7No ratings yet

- D 3628 - 97 Rdm2mjgtukveDocument5 pagesD 3628 - 97 Rdm2mjgtukveLuis LunaNo ratings yet

- Standard Practice For Materials Selection and Mixture Design of Permeable Friction Courses (PFCS)Document7 pagesStandard Practice For Materials Selection and Mixture Design of Permeable Friction Courses (PFCS)Martin MbaoNo ratings yet

- ASTM D6114 - 97 Standar Specification For Asphalt Rubber BinderDocument4 pagesASTM D6114 - 97 Standar Specification For Asphalt Rubber BinderVanessa Melgarejo Avila100% (1)

- Asphalt-Rubber Binder: Standard Specification ForDocument4 pagesAsphalt-Rubber Binder: Standard Specification FordsamotoNo ratings yet

- Chiu 2007Document7 pagesChiu 2007ibrahim tanko abeNo ratings yet

- Paving With SBR Latex ModifiedDocument28 pagesPaving With SBR Latex ModifiedPía TafurNo ratings yet

- Use of Waste Tyre in Road ConstructionDocument19 pagesUse of Waste Tyre in Road ConstructiondhanrajramotraNo ratings yet

- EVAHMADocument9 pagesEVAHMAbekimtolajNo ratings yet

- Bridge 06 ConcreteDocument17 pagesBridge 06 ConcretethakrarhitsNo ratings yet

- Astm D242 D242M 19Document1 pageAstm D242 D242M 19Mohamed SaadNo ratings yet

- Aashto Pp-14 (2018) Diseño OgfcDocument9 pagesAashto Pp-14 (2018) Diseño OgfcMario Esteban Solano RodriguezNo ratings yet

- Fhwa Ac Mix Design and Field ControlDocument10 pagesFhwa Ac Mix Design and Field Controlbiceli samet1No ratings yet

- Asphalt Emulsion Pavement Sealer (Mineral Colloid or Chemically Stabilized Type)Document2 pagesAsphalt Emulsion Pavement Sealer (Mineral Colloid or Chemically Stabilized Type)gt toniNo ratings yet

- Appendix P: ASTM - The Standards, Specifications and Guidelines For Coal Fly Ash and Bottom AshDocument6 pagesAppendix P: ASTM - The Standards, Specifications and Guidelines For Coal Fly Ash and Bottom AshErwin Scott KennedyNo ratings yet

- Department of Public Works and Highways: - "V" .//-.U N Republic of The PhilippinesDocument4 pagesDepartment of Public Works and Highways: - "V" .//-.U N Republic of The PhilippinesFaustino AbadNo ratings yet

- Asphalt-Rubber Binder: Standard Specification ForDocument5 pagesAsphalt-Rubber Binder: Standard Specification ForMonica GuevaraNo ratings yet

- TRH 21Document49 pagesTRH 21AnantNo ratings yet

- Roads 08 Spray Sealing TDO 04oct2022Document31 pagesRoads 08 Spray Sealing TDO 04oct2022FehkalNo ratings yet

- LS-804 - Rev 34 - May 2020Document5 pagesLS-804 - Rev 34 - May 2020ming_zhu10No ratings yet

- Rubber Compounding Materials-Recycled Vulcanizate Rubber: Standard Classification ForDocument4 pagesRubber Compounding Materials-Recycled Vulcanizate Rubber: Standard Classification ForMonica Guevara100% (1)

- ContinueDocument2 pagesContinueHarshit DubeyNo ratings yet

- AASHTO M 323-13 Superpave Volumetric Mix DesignDocument13 pagesAASHTO M 323-13 Superpave Volumetric Mix DesignMir Shahnewaz ArefinNo ratings yet

- Aashto T 182-84 (2002)Document2 pagesAashto T 182-84 (2002)latifjandawoodzai888No ratings yet

- JETIR1901809Document5 pagesJETIR1901809Nirman rodNo ratings yet

- Asphalt-Rubber An Anchor To Crumb Rubber MarketsDocument30 pagesAsphalt-Rubber An Anchor To Crumb Rubber MarketsFlorence DanNo ratings yet

- Highway Deptt BookDocument13 pagesHighway Deptt BookM iqbalNo ratings yet

- Use of Asphalt Arisings As A Type 4 Sub-BaseDocument50 pagesUse of Asphalt Arisings As A Type 4 Sub-BaseWasimuddin SheikhNo ratings yet

- AASHTO M6-08 Fine Aggregate For Cement ConcreteDocument8 pagesAASHTO M6-08 Fine Aggregate For Cement ConcreteDucnguyenNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Next Generation Golf Course: Synthetic Turf Study: Lakeside Hills Golf Course, Olathe, KansasFrom EverandNext Generation Golf Course: Synthetic Turf Study: Lakeside Hills Golf Course, Olathe, KansasNo ratings yet

- Sustainable Winter Road OperationsFrom EverandSustainable Winter Road OperationsXianming ShiNo ratings yet

- BS en 10052 94 PDFDocument35 pagesBS en 10052 94 PDFAshraf TomizehNo ratings yet

- BS 812 Part 102 89 PDFDocument16 pagesBS 812 Part 102 89 PDFAshraf TomizehNo ratings yet

- BS-1377 PART-5 SOIL Soil Comressability Permibility andDocument37 pagesBS-1377 PART-5 SOIL Soil Comressability Permibility andAshraf Tomizeh100% (1)

- BS 812 Part 101 84 PDFDocument8 pagesBS 812 Part 101 84 PDFAshraf TomizehNo ratings yet

- BS-1377 Part-6 Standrard Test For Con Solidation PermeabilitDocument65 pagesBS-1377 Part-6 Standrard Test For Con Solidation PermeabilitAshraf Tomizeh100% (1)

- BS-1377 P (ART8 (R) SOIL Soil Shear TestDocument32 pagesBS-1377 P (ART8 (R) SOIL Soil Shear TestAshraf TomizehNo ratings yet

- BS-7263-1 Part - 1 Concrete Spesification of Pre-Cast ConcrDocument24 pagesBS-7263-1 Part - 1 Concrete Spesification of Pre-Cast ConcrAshraf TomizehNo ratings yet

- BS-1881-118 Concrete Flexural Strength PDFDocument12 pagesBS-1881-118 Concrete Flexural Strength PDFAshraf TomizehNo ratings yet

- Thesis Statement For Breast Cancer Paper PDFDocument6 pagesThesis Statement For Breast Cancer Paper PDFgcq5c1pv100% (1)

- SF DumpDocument18 pagesSF DumpIsamar UrvinaNo ratings yet

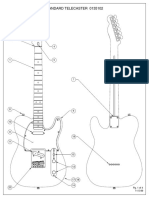

- Standard Telecaster 0135102Document4 pagesStandard Telecaster 0135102Gonzalo Torres BarreraNo ratings yet

- Explorations Introduction To Astronomy 8th Edition Arny Test Bank 1Document36 pagesExplorations Introduction To Astronomy 8th Edition Arny Test Bank 1brandonpoolecjptayorfn100% (24)

- Y 240 (3.47) P K Y F PaDocument3 pagesY 240 (3.47) P K Y F PaANER MOHAMED100% (1)

- Dual 5V Regulator With Reset: DescriptionDocument10 pagesDual 5V Regulator With Reset: DescriptionSandroCezardeAraujoNo ratings yet

- Dry Chemical PowderDocument4 pagesDry Chemical Powdervisio20040% (1)

- IoT Based Car Parking SystemDocument3 pagesIoT Based Car Parking SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Technical Data Sheet: DescriptionDocument3 pagesTechnical Data Sheet: DescriptionFrancesco VignaliNo ratings yet

- PDF 20221128 184203 0000Document20 pagesPDF 20221128 184203 0000Ana StolpovencoNo ratings yet

- Rent To Own FlyerDocument2 pagesRent To Own FlyerKobe BinamiraNo ratings yet

- PriyankaDocument22 pagesPriyankapriyankaNo ratings yet

- Masjid Option2 PDFDocument2 pagesMasjid Option2 PDFUmerNo ratings yet

- English 104 t1 Abstraction 5 Conceptual Versus Associative Meaning 1 2Document26 pagesEnglish 104 t1 Abstraction 5 Conceptual Versus Associative Meaning 1 2KENNETH JOSEPH MONROIDNo ratings yet

- UT Dallas Syllabus For Phys3411.001.11f Taught by Paul Mac Alevey (Paulmac)Document14 pagesUT Dallas Syllabus For Phys3411.001.11f Taught by Paul Mac Alevey (Paulmac)UT Dallas Provost's Technology GroupNo ratings yet

- Relieving Symptoms of Meralgia Paresthetica Using Kinesio Taping - A Pilot StudyDocument3 pagesRelieving Symptoms of Meralgia Paresthetica Using Kinesio Taping - A Pilot StudyAdam MorrellNo ratings yet

- Accessories and Consumables 2011 en SDocument32 pagesAccessories and Consumables 2011 en SRobert Abath Rojas CarreñoNo ratings yet

- Hemorrhoids InformationDocument29 pagesHemorrhoids InformationsheilapedzNo ratings yet

- Mp3 Gilda Carrasco Wall J Alejandro Gomez Marvin Goldstein Himnos Predilectos de Los Profetas Vol 2Document3 pagesMp3 Gilda Carrasco Wall J Alejandro Gomez Marvin Goldstein Himnos Predilectos de Los Profetas Vol 2salgadoquiroz0% (1)

- Cotech 9264341418014Document48 pagesCotech 9264341418014paktenNo ratings yet

- QA Monthly Report 2022-10 OctoberDocument30 pagesQA Monthly Report 2022-10 OctoberMark Mirosevic-SorgoNo ratings yet

- Easa Part-Camo Came Checklist: 1. ScopeDocument32 pagesEasa Part-Camo Came Checklist: 1. Scopehalil ibrahim kizilayNo ratings yet

- PDF Official Sat Study Guide Sample Math Questions Student Produced ResponseDocument12 pagesPDF Official Sat Study Guide Sample Math Questions Student Produced ResponseAmaan SurtiNo ratings yet

- 1 Mtap ReviewerDocument2 pages1 Mtap ReviewerKristel Andrea VillanuevaNo ratings yet

- Device Level Ring Within A Converged Plantwide Ethernet ArchitectureDocument8 pagesDevice Level Ring Within A Converged Plantwide Ethernet Architecturemaesh foneNo ratings yet

- ST FleetDocument9 pagesST FleetMouyaser KodabNo ratings yet

- URINALYSIS Power Point PresentationDocument20 pagesURINALYSIS Power Point PresentationOlugbenga A AdetunjiNo ratings yet