Professional Documents

Culture Documents

2 Blinex PTFE Fluoropolymer Fluorocarbon Coating For Fasteners Studs Bolts Nuts2

2 Blinex PTFE Fluoropolymer Fluorocarbon Coating For Fasteners Studs Bolts Nuts2

Uploaded by

ANANDAN N0 ratings0% found this document useful (0 votes)

6 views4 pagesOriginal Title

2 Blinex PTFE Fluoropolymer Fluorocarbon Coating for Fasteners Studs Bolts Nuts2

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views4 pages2 Blinex PTFE Fluoropolymer Fluorocarbon Coating For Fasteners Studs Bolts Nuts2

2 Blinex PTFE Fluoropolymer Fluorocarbon Coating For Fasteners Studs Bolts Nuts2

Uploaded by

ANANDAN NCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Nae gene GNI e Al ea

CORROSION PROTECTION +FiLtration An ISO 9001:2008 CERTIFIED ORGANIZATION

ole) 0t 3024 ue fe aod Vt)

Se Te Uae aa

FLUOROCARBON / PTFE / FLUOROPOLYMER

TEFCOT™ - HIGH PERFORMANCE

PO Nac SBE Laat

STUDS, BOLTS, NUTS & SCREWS

ge ia a See

SPECIALIZED IN

HUTTON AT Bar LT

US UCAS N aay

MU ae Sal

GST ALPS LT

UN DUETS

fefeyn clos

Ley

BE. (Prod.), DIPI (Lon.), M.BA., P&C| (NACE)

Director (Technical & Exports)

era

cae a

LTD"

Cr een Om eta Mt eC ee ot ee eA alee

An ISO 900.

ED ORGANIZATION

MANUFACTURER AND EXPORTER

FLUOROPOLYMER / PTFE - TEFCOT™

HIGH PERFORMANCE FLUOROCARBON COATED

FASTENERS + STUDS, BOLTS, NUTS & SCREWS

For Offshore and Oil Gas Industries

Since 1972, with the introduction of Fluoropolymer

coating in America, TEFCOT™ coated studs bolts and

nuts are widely used for enhanced corrosion resistance,

permanent: thread lubrication and consistently low

applied torque to induced tension (clamping load).

Since then, almost all international petrochemical, oil

drilling rigs and chemical process industries have

specified these studs for both offshore and land based

applications. Apart from these TEFCOT™ coated B7

stud, bolts are installed under sea splash zones and

chemical environments with great success.

The use of TEFCOT™ coated bolts is increasing in

industrial applications, offshore, petrochemicals and

marine industries due to their property of withstanding

extreme corrosive environments and providing

permanent lubrication over a very wide temperature

range.

ts wont eee The introduction of PT.RE, (Fluoropolymer) as a

Resists: \ surface coating material provided TEFCOT™ with a

‘galling & sezing ee nae: product, which would, after development, defeat both

\ ) problems simultaneously.

Over a phosphate pretreatment, a TEFCOT™ system

ohh far exceeds in performance when compared with

Withstands high Reduce torque wena a galvanised, cadmium plated, aluminised or moly-

‘temperatures: ‘embrittlement coated studs and other premium types of studs. A

TEFCOT™ coating prevents galling and reduces both

‘make-up’ and ‘break-out’ torques.

TECHNICAL SPECIFICATIONS OF PTFE

1. Thickness of Coating : 25 microns TO 40 microns

2, Temperature Resistance :- 100° C to + 260°C

3. Operating Pressure : Up to 1,00,00 PSI

4. Salt Spray Life up to 3,000 Hrs as per ASTM B117

il 4H - 6H (ASTM D3363-92A)

9. Elongation : 35%-50%

10. Co-efficient of Friction : As low as 0.02

Website : www.blinexindia.com + Email: kirtan@blinexindia.com, blinex@vsnl.com

Bline

VUE RY TF ly haste ett PN

ANUFACTURER ANO EXPORTER.

least scatter of clamp load to applie

The chart shows that make-up torque is considerably less with a TEFCOT™ coating and that the TEFCOT™ stud shows the

sd torque, therefore the greatest uniformity, of all the materials tested

‘MAKE-UP TORQUE

‘ee No TRE ——~wouy — BARE

TEFCOT™ TEFLON SULFDE ETAL

“The mau qe ecored ee ws este at

Aabening at pists oto soe bain

‘Te us then ated eo uns and em

ere regured wos eased Least ru was eared ot

‘he teh TEFCOT" cog

"7 STUDS

Relationship of BREAKOUTTORQUE —_ ama. Toe

Loadto Torque << | Tiere

cvomr

au cox

oumnse

Torque increase, | suevew

S a a

Blinex recommends the use of direct tension indicators (OT) to | BREAKOUT TORQUE (FOOT POUNDS)

determine proper make-up torque for ach size ot tof fastnecs. | Toru for reskut was messed by

Used ona given appicatin. fee (10 fot pounds). Aer 720i

fore meet breakeach conection w=

The TEFCOT" coated mts cugertemed al ters

di

Website : www. blinexin

Capabilities

BLINEX FILTER COAT PVT LTD has 5,000 square feet-of production space

dedicated to the coating of fasteners. A variety of fastener types and sizes are

coated at our facility

‘Supplying PTFE Coated Fasteners in High Tensile & Stainless Steel

1. Studs/Bolts : Grades ASTM A193 : GRB7, B7M, B 16, L7, B8,

BBM, SS 306, S316

:Grades ASTM A 194: GR2H, 2HM, GR, GR8,

GREM, IS 1367, GR8.8, 10.9, 12.9, SS306

2. Nuts

Fluoropolymer Coating Process for the 21st Century

BLINEX FILTER COAT PVT LTD has perfected the Fluoropolymer fastener

coating process. Surface preparation of the fastener prior to coating is 3 very

Important step. We use the latest industry accepted methods to thoroughly

clean all contaminants from the fasteners. Manufacturing oils, rust and scale are

removed to ensure the highest quality coating,

Superior corrosion resistance is created by the application of a series of

Coatings. A metallic base coat is applied first, followed by an adhesion coat. The

adhesion coat creates a chemical bond between the base coat and the top coat.

‘The top coat, a heat cured fiuoropolymer coating containing PTFE, is used to

seal the two Under coatings and give easy on/easy off characteristics.

|LINEX FILTER COAT PVT LTD Coating process fully protects fasteners

by guaranteeing 100% coverage of the surfaces, even inside the nuts.

Coating Com

Black, cadmium plated, and hot dipped galvanized bolts will freeze when

subjected to the corrosive environments found in manufacturing plants,

offshore oil rigs etc. Most often removing the nuts requires a cutting torch. With

TEFCOT” these same nuts andbolts exhibit easy on and easy of characteristics

Increasing worker safety.

Cadmium plated and hot dipped galvanized bolts provide similar corrosion

resistance. These coatings have undergone the standard salt fog test (ASTM

B117) and have been rated at 96 hours of corrosion resistance. With a Blinex

coated bolt that rating jumpsto as much as 1000 hours,

Galvanizing produces a coating that is uneven, rough and thick. The rough

surfaces make assembly difficult and a tight even tension on each bolt

impossible.

ADVANTAGES OF PTFE / FLUOROPOLYMER COATED FASTENERS

» Non Stick , Excellent Corrosion Resistance in Nature.

High Durability and Good Abrasion Resistance .

PTFE Coated mild Steel Fasteners are low on cost as compared to

Stainless Steel Fasteners.

Suitable for High and Low Temperature Ranges -

Torch Cutting can be avoided for offshore or marine applications

as it enhances lubrication and non-stick properties and maintains

a low co-efficient of friction in both makeup and breakout

operations .

PTFE Coated Fasteners can be re-used .

‘tan@b!

a.com * Email: jexindia.com, blinex@vsnl.com

Bline An ISO 9001:2008 CERTIFIED ORGANIZATION

MANUFACTURER AND EXPORTER

oe ACID TEST - stud bolts subjected to 720 hours in 15% HCL.

‘at ambient temperature

(6) PTFECoated Bott: ()Cadmium Plated Bolt: (c)Black 8.7 Bolt:

smal easing damage. Teal coating faze, stensvecorosin

Nuts tum easly. Bo stl Extensive coven and Nuts not zen.

able ral atlack Nuts not zen

(© Alumiized Bot: (e) Galvanized Bot: (0 Moty Coated Bot:

“ell coating fare, “etl coating ze, Extensive coating fale,

irs cavoson and Extensive covoson and___Exreme corosion and metal

real aac Nuts fozen, real alack Nuts not azn, ack. One nut zen,

oe o on

BROMINE TEST - stud bolts exposed to bromine 1/10 ppm

solution for 720 hours at ambient temperature

(@)PTFECoated Bok: (Cadmium Plated Bok: (Black B7 Bol

Madera coating damage, Tol coating fale. ‘Consieate oto,

aerate oxiaton Severely coro. Severe blistering

damage. Nus rot fozen Nu not zen

(@Aluminized Bot: (¢) Galvanized Bot (9 Moty Coates Bot:

‘Serius coaing ale, Moderalpcoag damage, Toll coating flue,

Hein xian, Heavy extn Exons oxo damage

One ut ozen ls ot zen, One nit oz,

ae oO

CAUSTIC TEST - stud bolts subjected to 12.5 pH caustic at

ambient temperature for 720 hours

(a) PTFE Coated Bot: (b)Cadmium Plated Bott: ()Black 87 Bot

Mrialcoairg damage. Mineral coaing darage, Moderate cxaton.

Nuts ur easiy. Boletus nal fen, Nas tum easy

sable

(0) Aluminized Bot (c) Gavvanized Bot (0 Maly Coated Bot

jercoating damage, Minar enaing damage, Wino coaing damage

Nats fozen. Sightondason Mus Sipitondaton. Nuts

lum easy tum fea,

or o @ @ © 0

SALT FOG TEST - stud bolts subjected to 720 hours

ina 5% brine spray at 110°F. (As per ASTM B117)

(@)PTFECoated Bolt: 2) Cadmium Plated Bolt: (Black -7 Bot

otra coaing damage. Tl casing fue Bot uty destroyed

orale oxdaten Severo coToded. Woua fn sence,

nage. Nu nt fozan

(6) Alumiized Bot:

(©) Gatvanized Bot (0 Moly Coated Bol

‘Whe ponder allouer Haar oto, “etal coaig fa.

orate corasie Nuts faze, ‘rene oxdton damage,

lets Nts tozen

1 BLINEX FLTER-COAT PVT LTD Fluoropolymer Coated Stud Assembly (a)

ieseeet==4 BLINEX FILTER - COAT PVT. LTD

.

MANUFACTURER & EXPORTER A? & A3, Nand Bhuvan Industrial Estate, Mahakali Caves Road, Andheri (E), Mumbai - 400 093 INDIA

COMPLETED 40 YEARS Tolefax : 91-22-2832 6007 | 4005 6674 » Email : blinex@vsnl.com + Website : www-blinexindia.com

Contact Person : Kirtan R. Dhami (Director) » Mobile : 09892060194 » Email: kirtan@blinexindia.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Petronas Technical Standards: Radiographic TestingDocument22 pagesPetronas Technical Standards: Radiographic Testingradzi100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument8 pagesHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNo ratings yet

- PTS 12.32.07 PAT Valve - FinalDocument55 pagesPTS 12.32.07 PAT Valve - Finalradzi100% (2)

- Common Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeDocument13 pagesCommon Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeradziNo ratings yet

- Astm d4065 PDFDocument7 pagesAstm d4065 PDFradziNo ratings yet

- Astm B633 98Document5 pagesAstm B633 98radziNo ratings yet

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocument9 pagesCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsradziNo ratings yet

- CQAcert RequirementsDocument1 pageCQAcert RequirementsradziNo ratings yet

- Cqa Changes 2012Document2 pagesCqa Changes 2012radziNo ratings yet

- Certified Quality Auditor Body of Knowledge 2012: Case Studies For The CQA ExamDocument9 pagesCertified Quality Auditor Body of Knowledge 2012: Case Studies For The CQA ExamradziNo ratings yet

- Petronas Technical Standards: Human Factors Engineering - Valve AnalysisDocument24 pagesPetronas Technical Standards: Human Factors Engineering - Valve Analysisradzi100% (1)

- PMRC$MAR$VA$107 Ball ValvesDocument13 pagesPMRC$MAR$VA$107 Ball ValvesradziNo ratings yet

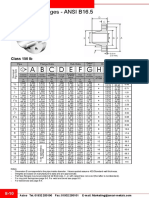

- ASME B16.5-Flanges Class 150Document1 pageASME B16.5-Flanges Class 150radziNo ratings yet

- Marco Material Datasheet Z1028Document3 pagesMarco Material Datasheet Z1028radziNo ratings yet