Professional Documents

Culture Documents

Air Spring Types: 1B Single Convolute - Bellows

Uploaded by

Maximus Maxis0 ratings0% found this document useful (0 votes)

26 views5 pagesOriginal Title

02 Air Spring Types

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views5 pagesAir Spring Types: 1B Single Convolute - Bellows

Uploaded by

Maximus MaxisCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

AIR SPRING TYPES

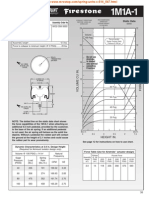

1B SINGLE CONVOLUTE – BELLOWS

* SLEEVE TYPE

* CRIMPED

2B DOUBLE CONVOLUTE – BELLOWS

* SLEEVE TYPE

* CRIMPED

3B TRIPLE CONVOLUTE – BELLOWS

* CRIMPED

1S SLEEVE TYPE ROLLING LOBE

* SLEEVE TYPE

1R CONVENTIONAL ROLLING LOBE

* CRIMPED

PRODUCT IDENTIFICATION SYSTEM

Elements of the part identification system are shown in the following example for

ordering an assembly with the part number 2B12-300.

2 B 12-300 The three digits that represent a unique

identifier for this particular air spring

The nominal outside working

diameter of the air spring

assembly, in inches

Refers to the type of air spring:

B – Bellows

R – Rolling lobe (bead type conventional)

S – Sleeve (beadless rolling lobe type)

Number of convolutions in the assembly:

1 – Single convolute

2 – Double convolute

3 – Triple convolute

PRODUCT DESCRIPTION

Rolling Lobe Air Spring

Rolling lobe air springs incorporate a

piston which allows the flexible member

to roll along the piston’s surface.

Sleeve Type Rolling Lobe

Sleeve type rolling lobe air springs

employ a flexible member without an

internally molded bead. The flexible

member is attached to the end retainers

by pinching the material between the end

retainers and exterior crimp rings which

are then swaged to the proper diameter.

Bellows Type Air Spring

Bellows air springs have one, two

or three convolutions in the flexible

member. There are two styles of bellows;

crimped design and sleeve type.

With the crimped design, the end

retainers are permanently attached by

mechanically crimping the retainer

around the built-in bead wire of the

flexible member.

Sleeve Type Bellows

Sleeve type bellows offer similar

characteristics to the crimped design

bellows, but, as with the sleeve type

rolling lobe the flexible member is

constructed without internally molded

bead wires. The end retainers are

permanently attached by pinching

the flexible member between the end

retainers and external crimp rings which

are then swaged to the proper diameter.

Sleeve type bellows offer the lowest

force to compress of any type of air

spring.

SUPER-CUSHION® AIR SPRING

COMPONENTS

FLEX MEMBERS Upper and lower retainers are made with blind taps, or

protruding bolts to facilitate attachment. The upper retainer has

Super-Cushion® air spring flex members are built of two plies

a tap to accommodate a 1/4”, 1/2” or 3/4” air fitting or valve.

of either nylon or polyester fabric, coated with rubber. They

Although it is called the upper retainer for reference, it need not

are designed to withstand inflation pressure, frequent flexing

be in the up position to function properly; the attitude of the air

and misalignment. The rubber cover protects against abrasion,

spring does not affect its function.

aging and the external environment. A rubber liner protects

against the interior environment and loss of air. The elastomer

used in Super-Cushion air springs can be a natural rubber BUMPERS

compound or Wingprene®. A rubber bumper inside the air spring assembly helps protect

The majority of vehicular Super-Cushion air springs are made the flexible member and the end retainers in those applications

of natural rubber for durability and low temperature capability. where external compression stops are not practical. Internal

Wingprene springs are available for special applications bumpers are recommended when:

where excessive exposure to oil may exist. Contact Veyance 1. The assembly will frequently reach the “compressed height

Technologies, Inc. for details. without a bumper.”*

2. The assembly will occasionally reach the “compressed height

RETAINERS without a bumper,”* but with a significant load and impact.

The purpose of the upper and lower retainers is to attach to 3. A vehicle may have to operate on a deflated air spring

the flexible member of the Super-Cushion air spring, thus assembly.

creating an air tight seal. All retainers and pistons are made of

an engineered thermoplastic or thermoset composite material; *See Glossary and/or Selection Charts

or corrosion resistant aluminum, zinc or steel.

END COMPONENT OPTIONS

1. CRIMPED ON RETAINERS 2. SWAGED ON RETAINERS 3. BOLTED BEAD RING

Available for springs: Available for springs: In certain applications, used in place of

-1B9 and larger Bellows -1B5 thru 1B8 Bellows crimped on retainers.

-2B9 and larger Bellows -2B6 thru 2B8 Bellows Available for springs:

-3Bl2 and larger Bellows -All 1S Sleeve Type Rolling Lobes

-1R8 and larger Rolling Lobes -lB9 and 2B9 Bellows

Upper and lower retainers are -1Bl 2, 2Bl 2 and 3Bl 2 Bellows

Upper and lower retainers are attached permanently attached by swaging a -2Bl9 and 2B22 Bellows

by mechanically crimping the retainer metal ring around the flexible member

around the bead wire built into the and end retainer. Upper and lower bead rings are

flexible member. attached by bolting each to the

customer’s own mounting plate. An air

tight seal is formed when all bolts are

securely fastened through the bead ring

into the mounting plate.

The GOODYEAR (and Winged Foot Design) trademark is used by STEMCO LP, under license from The Goodyear Tire & Rubber Company. Goodyear Air Springs are manufactured and sourced exclusively by STEMCO LP or its affiliates.

goodyearrep.com

Aftermarket Parts - Automotive and Commercial Truck, Air Springs,

Conveyor Belt - Heavyweight and Lightweight, Home and Garden,

Hydraulics, Industrial Hose, Military, Power Transmission Products,

Powersports, Rubber Track, Seawing Offshore Oil Hose

You might also like

- 171-Tubular-AcoustaFoil 4Document1 page171-Tubular-AcoustaFoil 4drewtwitchNo ratings yet

- Approved Catalog - PUBL-7610 - August 2017 - 2017 - 09 - 21Document20 pagesApproved Catalog - PUBL-7610 - August 2017 - 2017 - 09 - 21sandeepbheemanNo ratings yet

- Stemco Air Spring CatalogDocument162 pagesStemco Air Spring CatalogJhon Henry Pinzon AlmonacidNo ratings yet

- Counter Sniper Manual - The Official US Army ManualFrom EverandCounter Sniper Manual - The Official US Army ManualNo ratings yet

- Model: Butterfly DamperDocument3 pagesModel: Butterfly DamperdrNo ratings yet

- Shotgun Chronicles Volume II - Semi-auto & Pump Shotguns: Essays on all things shotgunFrom EverandShotgun Chronicles Volume II - Semi-auto & Pump Shotguns: Essays on all things shotgunRating: 5 out of 5 stars5/5 (1)

- Firestone Air Spring W02-358-3000Document29 pagesFirestone Air Spring W02-358-3000MROstop.comNo ratings yet

- BEARINGS: - Bearing Is A Machine Member, Which Supports Moving Parts &Document24 pagesBEARINGS: - Bearing Is A Machine Member, Which Supports Moving Parts &sachinNo ratings yet

- Landing Gear SystemDocument16 pagesLanding Gear SystemLeanne SisonNo ratings yet

- Tork-Mate Pneumatic ActuatorDocument8 pagesTork-Mate Pneumatic ActuatorYing Kei ChanNo ratings yet

- Av010agr SPC 13Document2 pagesAv010agr SPC 13floresguevara987No ratings yet

- Horizontal Split Case LN TypeDocument38 pagesHorizontal Split Case LN TypeprojashNo ratings yet

- Plunger Tips - Amp: PurposeDocument2 pagesPlunger Tips - Amp: PurposeAlson LeeNo ratings yet

- FE 700 Sealing of Fan HousingsDocument8 pagesFE 700 Sealing of Fan HousingsAvery OppegardNo ratings yet

- Convair Traveler Vol - Xix 1967Document44 pagesConvair Traveler Vol - Xix 1967TateNo ratings yet

- Description Assembly Order No. Static DataDocument29 pagesDescription Assembly Order No. Static DataMROstop.comNo ratings yet

- Automatic Air Release Valve For Low PressureDocument2 pagesAutomatic Air Release Valve For Low PressuresijilNo ratings yet

- Firestone Air Spring W02-358-3004Document29 pagesFirestone Air Spring W02-358-3004MROstop.com100% (1)

- Double Seat Valves Complete Sudmo Brochure v2113 enDocument16 pagesDouble Seat Valves Complete Sudmo Brochure v2113 enJOSE MANUEL PEREZ PRIETONo ratings yet

- Firestone Air Spring W02 358 3003Document29 pagesFirestone Air Spring W02 358 3003Billy ChrisNo ratings yet

- Gardner Denver PZ-11revF3Document66 pagesGardner Denver PZ-11revF3Luciano GarridoNo ratings yet

- RevA AirbratorDocument4 pagesRevA AirbratorJuan Jose FloresNo ratings yet

- Why Air Bearing? 3. Why Air Bearing? 5. Working PrincipleDocument18 pagesWhy Air Bearing? 3. Why Air Bearing? 5. Working PrinciplesachinNo ratings yet

- Mueller Fire HydrantDocument6 pagesMueller Fire Hydrantfarshan296015No ratings yet

- Jacketed Molten Sulfur Pumps: Pumps Mixers Strainers Engineered Systems and ControlsDocument6 pagesJacketed Molten Sulfur Pumps: Pumps Mixers Strainers Engineered Systems and ControlsPavel GonzalezNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Goulds 3196 i-FRAME: ANSI Process Pump With i-ALERT Patented Intelligent MonitoringDocument24 pagesGoulds 3196 i-FRAME: ANSI Process Pump With i-ALERT Patented Intelligent MonitoringJefferson David VilladaNo ratings yet

- Tsurumi Air BlowersDocument7 pagesTsurumi Air BlowersKhiara Claudine EspinosaNo ratings yet

- Press Brake Capacities BrochureDocument20 pagesPress Brake Capacities Brochurealexayala5151No ratings yet

- W02 358 4001Document30 pagesW02 358 4001MROstop.comNo ratings yet

- NDD130 PC 31 Air Aspirating Foam NozzleDocument4 pagesNDD130 PC 31 Air Aspirating Foam NozzleAnonymous S9qBDVkyNo ratings yet

- CTS Plunger Tips ABP 1Document2 pagesCTS Plunger Tips ABP 1Alson LeeNo ratings yet

- Air BearingDocument10 pagesAir BearingPrathyusha RamadurgamNo ratings yet

- Savitribai Phule University of PuneDocument21 pagesSavitribai Phule University of PunesachinNo ratings yet

- Sealing High-Speed Shafts in TurbomachineryDocument4 pagesSealing High-Speed Shafts in TurbomachineryimtiazNo ratings yet

- Louvre DamperTandem DamperengfinDocument16 pagesLouvre DamperTandem DamperengfinDan PascaruNo ratings yet

- W01 358 7742Document29 pagesW01 358 7742MROstop.comNo ratings yet

- W01 358 9048Document29 pagesW01 358 9048MROstop.comNo ratings yet

- Static Data Description Assembly Order No.: Do Not Use Airstroke in Shaded Area Without Consulting FirestoneDocument29 pagesStatic Data Description Assembly Order No.: Do Not Use Airstroke in Shaded Area Without Consulting FirestoneMROstop.comNo ratings yet

- The Original Dome Valve: Heavy Duty Pneumatic Bulk Solids Cut-Off ValveDocument6 pagesThe Original Dome Valve: Heavy Duty Pneumatic Bulk Solids Cut-Off ValveFelipe Ribeiro da CostaNo ratings yet

- CR UiDocument20 pagesCR UiLEKH021No ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6911Document29 pagesW01 358 6911MROstop.comNo ratings yet

- W01 358 9099Document29 pagesW01 358 9099MROstop.comNo ratings yet

- Centrifugal & Axial Compressor - ConstructionDocument16 pagesCentrifugal & Axial Compressor - ConstructionNikesh100% (3)

- Working Pressure ChartsDocument6 pagesWorking Pressure ChartsBinodNo ratings yet

- Ngineering ATA: Sealing of Fan HousingsDocument7 pagesNgineering ATA: Sealing of Fan HousingsMohamed TahounNo ratings yet

- Bombas Centífugas KSBDocument12 pagesBombas Centífugas KSBkarmencitaconk4035No ratings yet

- 4.2 Ambient Conditions: AssemblyDocument2 pages4.2 Ambient Conditions: Assemblyalang_businessNo ratings yet

- Powerex SLAE Operational ManualDocument12 pagesPowerex SLAE Operational ManualJulio Molina MuñozNo ratings yet

- Lit C316 Usa - 2013 PDFDocument20 pagesLit C316 Usa - 2013 PDFLuis Eduardo Albarracin RugelesNo ratings yet

- W01 358 7039Document29 pagesW01 358 7039MROstop.comNo ratings yet

- Parkin 2007Document138 pagesParkin 2007Raja Sekaran SajjaNo ratings yet

- ATRO Field Manual 061214Document68 pagesATRO Field Manual 061214Raja Sekaran Sajja100% (1)

- MET2016 Snyder AlexDocument31 pagesMET2016 Snyder AlexRaja Sekaran SajjaNo ratings yet

- Spring Tech 101Document8 pagesSpring Tech 101Raja Sekaran SajjaNo ratings yet

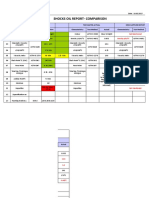

- Shocks Oil - Comparison ReportDocument2 pagesShocks Oil - Comparison ReportRaja Sekaran SajjaNo ratings yet

- Road SignsDocument24 pagesRoad SignsRaja Sekaran SajjaNo ratings yet

- 3D Asphalt Contruction of Special ProfilesDocument30 pages3D Asphalt Contruction of Special ProfilesRaja Sekaran SajjaNo ratings yet

- IPHONE - How To Free Up SpaceDocument34 pagesIPHONE - How To Free Up SpaceRaja Sekaran SajjaNo ratings yet

- Pedestrian SignalsDocument2 pagesPedestrian SignalsRaja Sekaran SajjaNo ratings yet

- Gabriel Annual Report 2015-16Document151 pagesGabriel Annual Report 2015-16Raja Sekaran SajjaNo ratings yet

- Paving Streets-Part 1Document15 pagesPaving Streets-Part 1Raja Sekaran SajjaNo ratings yet

- Pavement MarkingsDocument4 pagesPavement MarkingsRaja Sekaran SajjaNo ratings yet

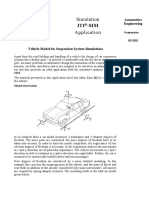

- ITI - Sim: Simulation ApplicationDocument2 pagesITI - Sim: Simulation ApplicationRaja Sekaran SajjaNo ratings yet

- ViewNX 2 - NikonDocument3 pagesViewNX 2 - NikonRaja Sekaran SajjaNo ratings yet

- LENOVO K3 NOTE K50-T3S Specifications, Price Compare, Features, ReviewDocument11 pagesLENOVO K3 NOTE K50-T3S Specifications, Price Compare, Features, ReviewRaja Sekaran SajjaNo ratings yet

- US4095682 - Position Sensitive DampingDocument8 pagesUS4095682 - Position Sensitive DampingRaja Sekaran SajjaNo ratings yet

- How To Photograph The Milky Way - A Detailed Guide For BeginnersDocument44 pagesHow To Photograph The Milky Way - A Detailed Guide For BeginnersRaja Sekaran SajjaNo ratings yet

- Everything You Need To Know About Macro Lenses - Food Photography AcademyDocument30 pagesEverything You Need To Know About Macro Lenses - Food Photography AcademyRaja Sekaran SajjaNo ratings yet

- Landscape PhotographyDocument9 pagesLandscape PhotographyRaja Sekaran SajjaNo ratings yet

- 13 Effective Natural Remedies To Keep Bees AwayDocument14 pages13 Effective Natural Remedies To Keep Bees AwayRaja Sekaran SajjaNo ratings yet

- Dynamic Behaviour of An Air Spring ElementDocument4 pagesDynamic Behaviour of An Air Spring ElementRaja Sekaran SajjaNo ratings yet

- Real Time Vibration Control of Active Suspension System With Active Force Control Using Iterative Learning AlgorithmDocument6 pagesReal Time Vibration Control of Active Suspension System With Active Force Control Using Iterative Learning AlgorithmRaja Sekaran SajjaNo ratings yet

- Experimental Investigation On Road Vehicle Active SuspensionDocument6 pagesExperimental Investigation On Road Vehicle Active SuspensionRaja Sekaran SajjaNo ratings yet

- Part Ix: Reactive Silencers: Industrial Noise SeriesDocument8 pagesPart Ix: Reactive Silencers: Industrial Noise SeriesRaja Sekaran SajjaNo ratings yet

- Stabilizer Bars: Part 2. Calculations - Example: Adam-Markus WITTEK, Hans-Christian RICHTER Bogusław ŁAZARZDocument9 pagesStabilizer Bars: Part 2. Calculations - Example: Adam-Markus WITTEK, Hans-Christian RICHTER Bogusław ŁAZARZRaja Sekaran SajjaNo ratings yet

- ITI - Sim: Simulation ApplicationDocument4 pagesITI - Sim: Simulation ApplicationRaja Sekaran SajjaNo ratings yet

- ITI - Sim: Simulation ApplicationDocument2 pagesITI - Sim: Simulation ApplicationRaja Sekaran SajjaNo ratings yet

- Acoustical Silencers (Mufflers)Document5 pagesAcoustical Silencers (Mufflers)Raja Sekaran SajjaNo ratings yet

- RP Maint GuideDocument10 pagesRP Maint GuideRaja Sekaran SajjaNo ratings yet

- Your Partner in Drive Simulation, Vehicle Dynamics, and Virtual TestingDocument2 pagesYour Partner in Drive Simulation, Vehicle Dynamics, and Virtual TestingRaja Sekaran SajjaNo ratings yet

- Industrial Power Transmission: South Pacific CatalogueDocument188 pagesIndustrial Power Transmission: South Pacific CatalogueVolodymуr VorobetsNo ratings yet

- Truck & Bus BrochureDocument8 pagesTruck & Bus BrochureAkhilesh RaiNo ratings yet

- Lamborghini Revuelto AI59L8 23.07.31Document16 pagesLamborghini Revuelto AI59L8 23.07.31Taticul lor PazMallNo ratings yet

- Eh4500 2Document5 pagesEh4500 2Arifin Wicaksono AdhananditoNo ratings yet

- SRF Corporate Brochure PDFDocument25 pagesSRF Corporate Brochure PDFAmritesh MishraNo ratings yet

- WorkSafeBC - Forklift Inspection ChecklistDocument0 pagesWorkSafeBC - Forklift Inspection ChecklistjohnzepolNo ratings yet

- Guidelines Safe Operation of Forklift TrucksDocument35 pagesGuidelines Safe Operation of Forklift TrucksJustin ChongNo ratings yet

- Man TGSDocument2 pagesMan TGSPaul CiobanuNo ratings yet

- MFS (Michelin Fleet Solutions)Document3 pagesMFS (Michelin Fleet Solutions)Dew dropsNo ratings yet

- Sakai SV540Document108 pagesSakai SV540George PlishkoNo ratings yet

- Goodyear Tyre ReadingDocument4 pagesGoodyear Tyre ReadingAttique TahirNo ratings yet

- Harley Davidson Touring Models 2007 Manual de Intretinere WWW - Manualedereparatie.infoDocument92 pagesHarley Davidson Touring Models 2007 Manual de Intretinere WWW - Manualedereparatie.infoVincent Roy100% (1)

- 04 Vue - Lower Control ArmDocument4 pages04 Vue - Lower Control ArmBrian PurdyNo ratings yet

- Manual WA - 430-6 PIEZAS PARTESDocument315 pagesManual WA - 430-6 PIEZAS PARTESBrahian Mijael Garrado Gonzales75% (4)

- Wheels and Tyres Guide PDFDocument256 pagesWheels and Tyres Guide PDFGustavo Barria Daniel'sNo ratings yet

- HD 465 605-7 KomatsuDocument8 pagesHD 465 605-7 KomatsuHarry Wart WartNo ratings yet

- LEON Conduccion 11 22 ENDocument30 pagesLEON Conduccion 11 22 ENttrtNo ratings yet

- Bajaj Platina 100 EsDocument42 pagesBajaj Platina 100 Eslakshankrishantha524No ratings yet

- Operation & Maintenance of Ordnance in Cold Weather - FM 9-207Document113 pagesOperation & Maintenance of Ordnance in Cold Weather - FM 9-207Jared A. Lang100% (2)

- Continental Catalogue 2009 enDocument62 pagesContinental Catalogue 2009 enGoodBikesNo ratings yet

- Rider'S Guide: To Operation, Safety and LicensingDocument66 pagesRider'S Guide: To Operation, Safety and Licensingsome119886909No ratings yet

- MRL - Paint Crayon-2Document1 pageMRL - Paint Crayon-2Febriono AdiNo ratings yet

- Hitachi ZX170W-3 ZX190W-3 - Workshop ManualDocument604 pagesHitachi ZX170W-3 ZX190W-3 - Workshop ManualIliyan Vasilev100% (2)

- Es10 10es - Es12 12esDocument7 pagesEs10 10es - Es12 12esLacatusu MirceaNo ratings yet

- Sidewall Brochure E Oct 14Document4 pagesSidewall Brochure E Oct 14canito73No ratings yet

- All-Wheel Drive Four-Wheel Drive Systems and Strategies PDFDocument7 pagesAll-Wheel Drive Four-Wheel Drive Systems and Strategies PDFjohn ayengahNo ratings yet

- Manual de Operacion LTM 1400NX PDFDocument1,639 pagesManual de Operacion LTM 1400NX PDFfrancescomateus100% (7)

- MPB F200 102Document1 pageMPB F200 102marranNo ratings yet

- 962C-SOP-002-R3 - Dump Stockpile ManagementDocument7 pages962C-SOP-002-R3 - Dump Stockpile ManagementAmsal SinagaNo ratings yet

- How To Handle Hot SpotDocument6 pagesHow To Handle Hot SpotMustafa Ramadan100% (4)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsFrom EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo ratings yet

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsFrom EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsNo ratings yet

- Bulletproof Seduction: How to Be the Man That Women Really WantFrom EverandBulletproof Seduction: How to Be the Man That Women Really WantRating: 4.5 out of 5 stars4.5/5 (170)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesFrom Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedFrom EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedRating: 5 out of 5 stars5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersFrom EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersRating: 3.5 out of 5 stars3.5/5 (3)

- Metric Pattern Cutting for Women's WearFrom EverandMetric Pattern Cutting for Women's WearRating: 4.5 out of 5 stars4.5/5 (3)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldFrom EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldRating: 4.5 out of 5 stars4.5/5 (30)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeFrom EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeRating: 5 out of 5 stars5/5 (1)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Edward's Menagerie: Dogs: 50 canine crochet patternsFrom EverandEdward's Menagerie: Dogs: 50 canine crochet patternsRating: 3 out of 5 stars3/5 (5)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreFrom EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreRating: 4 out of 5 stars4/5 (6)

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsFrom EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsRating: 5 out of 5 stars5/5 (3)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookFrom EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookRating: 4.5 out of 5 stars4.5/5 (2)

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearFrom EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearRating: 5 out of 5 stars5/5 (1)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsFrom EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo ratings yet

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.From EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Rating: 2 out of 5 stars2/5 (1)

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesFrom EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesRating: 5 out of 5 stars5/5 (3)

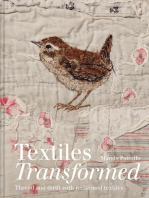

- Textiles Transformed: Thread and thrift with reclaimed textilesFrom EverandTextiles Transformed: Thread and thrift with reclaimed textilesNo ratings yet