Professional Documents

Culture Documents

BAC Tab OpenCoolingTowers ENv06

Uploaded by

Abd Alkarim MohamedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BAC Tab OpenCoolingTowers ENv06

Uploaded by

Abd Alkarim MohamedCopyright:

Available Formats

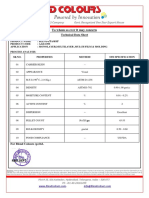

BAC participates in the CTI-ECC programme for cooling

G A Best towers. Check ongoing validity of certificate:

www.eurovent-certification.com

www.BaltimoreAircoil.eu S1500E S3000E PTE VT0 / VT1 VTL-E

CT N° 15.03.067 CT N° 15.03.068

Range SERIES V-VT0 Range SERIES V-VT1

CT N° 14.10.002 CT N° 15.03.066 CT N° 14.10.001 CT N° 15.03.069

Range S15E SERIES Range S3000E SERIES-S3E Range PTE SERIES Range SERIES V-VTL-E

Principle of

operation

Capacity 8 - 215 l/s 16 - 285 l/s 12- 170 l/s 7 - 455 l/s 3 - 130 l/s

Configuration crossflow crossflow counterflow counterflow counterflow

Air axial fan axial fan axial fan centrifugal fan centrifugal fan

entry induced draft induced draft induced draft forced draft forced draft

Water

gravity gravity pressurised pressurised pressurised

distribution

Maximum

55°C PVC fill 55°C PVC fill 55°C PVC fill 55°C PVC fill 55°C PVC fill

entering water 60°C alternative fill materials 60°C alternative fill materials 65°C alternative fill materials 65°C alternative fill materials 65°C alternative fill materials

temperature

Low sound C C F A A

Energy

A A A F F

efficiency

Easy

© 2018 Baltimore Aircoil International nv

maintenance A A D D D

Operational A A D E E

safety (hygiene)

Tab v06 EN

Open cooling towers

Open cooling towers

Open cooling towers

Principle of operation

Open cooling towers discharge heat from water-cooled systems into the atmosphere. The hot process water is distributed over a fill pack (heat

transfer media) to interface with air blown by a fan through the cooling tower. During this evaporative cooling, a small part of the water

evaporates while cooling the remaining process water.

Benefits

• optimal cooling, as proved by lab tests

• allowing low process temperatures

• open cooling towers have a small footprint

A unique benefit for all BAC cooling tower customers:

• the patented Baltibond hybrid coating

Configurations

Water down Water down

Counterflow configuration Crossflow configuration

Air across

Air up

Water distribution systems

Pressurized spray system Gravity spray system

• 0,15 through 0,5 bar of water • minimum pump head

pressure required at the water required

inlet • easy access for inspection

during operation

Fan systems

Centrifugal fan Forced draft

• can overcome external static • rotating air handling components are located on the air inlet

pressure, suitable for indoor face at the base of the tower

installations • easy access for maintenance

• inherently quiet • located in dry entering air stream

Induced draft

Axial fan • rotating air handling components are mounted in the top

• low energy usage deck of the unit

• minimal impact of fan noise

• maximum protection from fan icing

• located in the corrosive saturated discharge air stream

Tab_OCT_ENv06

You might also like

- SCM51432 TDSDocument2 pagesSCM51432 TDSAbd Alkarim MohamedNo ratings yet

- Universal Air Tool Oil SpecDocument1 pageUniversal Air Tool Oil SpecAbd Alkarim MohamedNo ratings yet

- United States Patent (10) Patent No.: Us 6,210,769 B1: Dipede Et Al. (45) Date of Patent: Apr. 3, 2001Document16 pagesUnited States Patent (10) Patent No.: Us 6,210,769 B1: Dipede Et Al. (45) Date of Patent: Apr. 3, 2001Abd Alkarim MohamedNo ratings yet

- 111 A Super PowerDocument1 page111 A Super PowerAbd Alkarim MohamedNo ratings yet

- An ISO 9001:2015 Company Govt. Recognised One Star Export HouseDocument1 pageAn ISO 9001:2015 Company Govt. Recognised One Star Export HouseAbd Alkarim MohamedNo ratings yet

- Sist en 15348 2015Document11 pagesSist en 15348 2015Abd Alkarim MohamedNo ratings yet

- Harp Lubricants - Technical Data Sheet Harp Mineral Oils: Harp MO32 Harp MO68 Harp MO100 Harp MOAB150Document1 pageHarp Lubricants - Technical Data Sheet Harp Mineral Oils: Harp MO32 Harp MO68 Harp MO100 Harp MOAB150Abd Alkarim MohamedNo ratings yet

- Manual For PEINER HV-Structural Bolt Sets" According To DIN EN 14399 DIN EN 1090-2 DIN EN 1993-1-8/NADocument14 pagesManual For PEINER HV-Structural Bolt Sets" According To DIN EN 14399 DIN EN 1090-2 DIN EN 1993-1-8/NAAbd Alkarim MohamedNo ratings yet

- How Many Layers Are Enough?: Properties of Multi-Layer Stretch Films ComparedDocument5 pagesHow Many Layers Are Enough?: Properties of Multi-Layer Stretch Films ComparedAbd Alkarim MohamedNo ratings yet

- DL085C enUS ASTMDocument1 pageDL085C enUS ASTMAbd Alkarim MohamedNo ratings yet

- SIAT-Datasheet-OneWrap ENG Rev1.3Document2 pagesSIAT-Datasheet-OneWrap ENG Rev1.3Abd Alkarim MohamedNo ratings yet

- Strapping, Nonmetallic (And Joining Methods) : Standard Specification ForDocument7 pagesStrapping, Nonmetallic (And Joining Methods) : Standard Specification ForAbd Alkarim MohamedNo ratings yet

- Discussion PaperDocument9 pagesDiscussion PaperAbd Alkarim MohamedNo ratings yet

- Stretch Film Technical Specification: 1 Product DescriptionDocument4 pagesStretch Film Technical Specification: 1 Product DescriptionAbd Alkarim MohamedNo ratings yet

- Polyethylene Perspectives December 2021Document1 pagePolyethylene Perspectives December 2021Abd Alkarim MohamedNo ratings yet

- Supplier Name: Alex International For Plastic Industry Product Date: 9/12/2020Document8 pagesSupplier Name: Alex International For Plastic Industry Product Date: 9/12/2020Abd Alkarim MohamedNo ratings yet

- Rotoplat 507 Aetna Robopac BrochureDocument4 pagesRotoplat 507 Aetna Robopac BrochureAbd Alkarim MohamedNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fluid MechanicsDocument85 pagesFluid MechanicsClaire De GuzmanNo ratings yet

- You'Ve Got A Problem: DV DT C M V V T Time S, G, CDocument3 pagesYou'Ve Got A Problem: DV DT C M V V T Time S, G, CagusNo ratings yet

- Electric Potential Energy & Electric PotentialDocument17 pagesElectric Potential Energy & Electric Potentialblismae genotivaNo ratings yet

- Chapter 9 - Motion Along A Straight LinesDocument5 pagesChapter 9 - Motion Along A Straight Linesahmadkamil9286% (7)

- Is 13779 1999 PDFDocument46 pagesIs 13779 1999 PDFchandranmuthuswamyNo ratings yet

- Steam Condensate Pot SizingDocument1 pageSteam Condensate Pot SizingSaeid Rahimi Mofrad100% (1)

- Quadratic EquationsDocument4 pagesQuadratic EquationsSaraf santhosh kumarNo ratings yet

- Ch1. Solutions Type 3. Multiple Choice Questions RememberingDocument9 pagesCh1. Solutions Type 3. Multiple Choice Questions RememberingAakriti JainNo ratings yet

- Ch2 Aircraft LoadsDocument24 pagesCh2 Aircraft LoadsDragon ZNNo ratings yet

- SVP2020 01 214 00199 PDFDocument7 pagesSVP2020 01 214 00199 PDFVikash KotteeswaranNo ratings yet

- Structural Design Analysis: Proposed Two (2) - Storey Residential BuildingDocument24 pagesStructural Design Analysis: Proposed Two (2) - Storey Residential BuildingJc JüsäyänNo ratings yet

- NEB Grade 11 Math Model Paper 2077-78Document3 pagesNEB Grade 11 Math Model Paper 2077-78Prem RajwanshiNo ratings yet

- Two-Way SlabsDocument178 pagesTwo-Way SlabsPaul Yvelt CésaireNo ratings yet

- Flender StandardCouplings FLE10 ENDocument376 pagesFlender StandardCouplings FLE10 ENRichard SilvaNo ratings yet

- Lapangan Gas ArunDocument8 pagesLapangan Gas ArunRnd JuliusNo ratings yet

- Calculations-In-Unit-1 SDocument9 pagesCalculations-In-Unit-1 SabdiNo ratings yet

- Rotation RollingDocument14 pagesRotation RollingMinh HuỳnhNo ratings yet

- Mechanical Product Handbook 15th EditionDocument606 pagesMechanical Product Handbook 15th EditionEsteban GNo ratings yet

- Terex Electrical DrawingsDocument33 pagesTerex Electrical DrawingsSandoval Ramos Eddy100% (1)

- Vdma 442 T. Klenk Et Al. Conductive SimmerringsDocument7 pagesVdma 442 T. Klenk Et Al. Conductive SimmerringsChandrasekar KrishnamurthyNo ratings yet

- 26 - Modern Francis TurbineDocument50 pages26 - Modern Francis TurbineSaharsha GadariNo ratings yet

- Buckling and Stability of ColumnsDocument49 pagesBuckling and Stability of ColumnsSalman ShabbirNo ratings yet

- GATE-2016 (Solution)Document30 pagesGATE-2016 (Solution)RahulNo ratings yet

- Differentiation 2Document87 pagesDifferentiation 2Ali SNo ratings yet

- DIAC and TRIAC - Working, Operation & ConstructionDocument14 pagesDIAC and TRIAC - Working, Operation & ConstructionSunil Kumbar100% (1)

- Hycox 20171116-A Yangzhou Hycox Industrial Co.,Ltd - BoliviaDocument3 pagesHycox 20171116-A Yangzhou Hycox Industrial Co.,Ltd - BoliviaCristian Sahonero MuñozNo ratings yet

- English Units SI UnitsDocument4 pagesEnglish Units SI UnitsChristian Jay GamboaNo ratings yet

- Handbook of Silicon Based MEMS Materials and Technologies (3rd Edition)Document16 pagesHandbook of Silicon Based MEMS Materials and Technologies (3rd Edition)adriana romeroNo ratings yet

- ME 2213 (Turning Moment Diagrams and Flywheel)Document26 pagesME 2213 (Turning Moment Diagrams and Flywheel)tanvir2013004No ratings yet

- Necessary and Sufficient Conditions For Riemann and Riemann-Stieltjes IntegrabilityDocument10 pagesNecessary and Sufficient Conditions For Riemann and Riemann-Stieltjes IntegrabilityAloyana Couto da SilvaNo ratings yet