Professional Documents

Culture Documents

Carpeting: Carpet Fiber Materials

Carpeting: Carpet Fiber Materials

Uploaded by

Zepol RotcivOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carpeting: Carpet Fiber Materials

Carpeting: Carpet Fiber Materials

Uploaded by

Zepol RotcivCopyright:

Available Formats

Carpeting

Carpet Fiber Materials

Most wall-to-wall carpeting is produced by looping Manufacturers prefer to specify the trade names of

yarns through a coarse-fiber backing, binding the their yarns rather than chemical type, because they

backs of the loops with latex, then applying a second all claim to have variations with superior qualities.

backing for strength and dimensional stability. Finally, However, the general characteristics are as shown

the loops may be left uncut for a tough, nubby surface below.

or cut for a soft, plush surface. The quality of carpet-

ing is determined mostly by its face weight, defined as Carpet Materials

ounces of yarn (pile) per square yard. Fiber Advantages Disadvantages

Acrylic Resembles wool Not very tough

Installation Attracts oily dirt

There are two basic carpet installation methods: Nylon Very tough None

Padded and Stretched carpeting is stretched (most popular) Resists dirt

Resembles wool

over a separate pad and mechanically fastened at joints Low static buildup

and the perimeter. Soft foam pads are inexpensive Polyester Soft, luxurious Less resilient

and give the carpet a soft, luxurious feel. The more deep pile Attracts oily dirt

expensive jute and felt pads give better support and Polypropylene Waterproof Crushes easily

dimensional stability and make the carpet last longer. indoor/outdoor Resists fading

Resists stains

Glued-Down carpets are usually used in areas Easily cleaned

such as offices and stores, where carpets are subjected Wool Most durable Most expensive

to heavily loaded wheel traffic. They are usually Easy to clean

Feels good

glued down with carpet adhesive with a pad. This

Easily dyed

minimizes destructive flexing of the backing and

prevents rippling.

Carpet Pile Types

UNCUT LEVEL LOOP UNCUT UNEVEN LOOP CUT YARN, MINIMUM TWIST

Good for offices and high-wear areas Good for offices and high-wear areas Good for living rooms and bedrooms

CUT YARN, TIGHT TWIST CUT YARN AND UNCUT LOOP CUT YARN (SHAG)

Good for living rooms and bedrooms Good for family and children's rooms Entries, family and children's rooms

402 FLOORS, WALLS, AND CEILINGS

Resilient Flooring

Resilient Flooring Ordinary sanded plywood grades such as A-C or

No-wax cushion vinyl is the most popular type of B-C Exterior and C-D Plugged Exposure 1 plywood

resilient flooring, mainly because of its economical are not adequate substitutes for underlayment grade,

price, ease of installation, and variety of patterns because they do not insure equivalent resistance to

and styles. However, linoleum flooring is making indentation or puncture.

a comeback because it offers similar advantages The thickness of plywood underlayment required

without any of the adverse environmental impact of over uneven floors depends on floor roughness and

vinyl products. Vinyl is made with petroleum prod- expected loads. Usually a minimum thickness of

ucts and can produce toxic fumes when it burns. 11⁄32 inch, although 1⁄4 inch is acceptable for under-

Linoleum is made from natural materials. layment over smooth subfloors, especially in remod-

Available as 12-foot-wide rolls and as 9-by-9- eling work. Thicker plywood underlayment, which

inch and 12-by-12-inch tiles, cushion vinyl consists is stiffer and more dimensionally stable, is recom-

of a shiny (no-wax) clear vinyl coating, colored vinyl mended for large floor areas where sidelighting

substrate, high-density vinyl foam, and a felt back. across long expanses of flooring tends to highlight

The roll material may be loose-laid, with double- any floor surface irregularities.

sided tape or joint adhesive only at seams, or it may Plywood underlayment also provides a smooth

be fully glued down. Tiles are meant to be glued surface for installation of adhered carpet flooring.

down. Some are self-sticking; others are applied over Concentrated loads from wheel traffic may

vinyl adhesive. cause deterioration of the plywood underlayment

The primary measure of quality and longevity is face beneath resilient floor covering. For such appli-

the thickness of the clear no-wax wear layer. When cations, smooth, tempered hardboard underlayment

the wear layer is worn through, the flooring has to may be more appropriate.

be replaced or periodically treated with a vinyl dress-

ing or wax. Bases for Resilient Flooring

All resilient flooring must be applied over a solid, Existing Floor Cover or Repairs

smooth base. If the base is not smooth, the vinyl will Plywood subfloor, not Hardboard or plywood

appear wavy. If the base is not solid (plywood with a rated as underlayment underlayment

missing knot, for example), women's heels or other Plywood rated as None needed

heavily loaded objects may punch through. underlayment

The table at right describes adequate bases for OSB rated as None needed

underlayment

resilient flooring. However, plywood is recom-

Single-layer Plywood underlayment,

mended as the best underlayment by most resilient- board subfloor 5 ⁄ 8" minimum

flooring manufacturers. Subfloor plus finish Replace damaged strips;

floor of strips less renail loose spots;

Plywood Underlayment than 3" wide sand smooth

Underlayment grades of plywood have a solid, sanded Subfloor plus finish Hardboard or plywood

floor of strips more underlayment

surface and solid inner plies for resistance to indenta- than 3" wide

tion and punctures from concentrated loads. APA Concrete None needed, but clean

underlayment-rated plywood is also dimensionally thoroughly by degreasing

stable and eliminates swelling, buckling, and humps and wire brushing

around nails. Where floors may be subject to mois-

ture, use panels with an Exterior exposure rating.

Resilient Flooring 403

Ceramic Tile

Tile Varieties Floor Tile Ratings

The word tile generally means any hard-wearing Floor tiles, unlike wall tiles, are subject to wear and

material used to cover floors, walls, and roofs. In freezing, and must not be slippery underfoot. The

building we are most interested in six categories of most important ratings to consider are as follows:

tile intended to cover floors and walls Coefficient of Friction (ASTM C 1028)

Glazed Wall Tile is intended for decorative tells how slippery the tile is when dry and when wet.

interior applications. The most popular size is 41⁄2 by It is thus vital when trying to avoid slip and fall inju-

41⁄2 inches, but many other rectangular, hexagonal, ries. The American Disabilities Act (ADA) requires

octagonal sizes are available. ratings of ≥0.6 for level floors and ≥0.8 for ramps.

Mosaic Tile is premounted and spaced on a Water Absorption (ASTM C 373) tells the

fabric backing. All mosaics come with 1⁄16-inch joints. maximum amount of water the tile can absorb as a

Paver Tile is formed by compressing clay percentage by weight. It is important if exposed to

dust. Most pavers are rectangular, but hexagons and freeze–thaw cycles. Non-vitreous absorbs >7 percent

Spanish patterns are also available. water, semi-vitreous absorbs 3 to 7 percent water,

Floor Tile (Porcelain) is made of highly vitreous absorbs .5 to 3 percent water, and impervious

refined clay and fired at extreme temperatures, result- absorbs <0.5 percent water.

ing in a floor surface which wears well and is water- Abrasive Hardness (ASTM C 501)

and frost-resistant. Measures the resistance to abrasion of the tile surface.

Quarry Tile is an extremely hard, wear-re The higher the number, the harder the tile surface:

sistant, unglazed, moderately-priced tile which is 1. walls only.

ideal for floors.

2. low-traffic residential.

Natural Stone, usually cut to standard sizes, is

also used as a flooring tile. Granite, marble, and slate 3. residential and medium interior commercial.

are the most popular, with the granite and marble 4. heavy interior commercial.

usually polished to a mirror finish. 5. extra-heavy interior or exterior commercial.

Modular Ceramic Tile Sizes

Type Thickness Shape Dimensions, inches

Glazed Wall 5⁄16 rectangular 3x6, 41⁄4x41⁄4, 6×41⁄4, 6x6, 6x8, 8x10

Mosaic 1⁄4 rectangular 1x1, 1x2, 2x2

1⁄4 hexagonal 1x1, 2x2

Paver 3⁄8 rectangular 4x4, 4x8, 6x6

1⁄2 rectangular 4x4, 4x8, 6x6

Floor 3⁄8 rectangular 6x6, 6x12, 12x12, 13x13, 16x16

Quarry 1⁄2 rectangular 3x3, 3x6, 4x4, 4x8, 6x6, 8x8

3⁄4 rectangular 4x8, 6x6

404 FLOORS, WALLS, AND CEILINGS

Tile Setting Materials

Cement Backerboard tiles up to 6 by 6 inches which are not subject to

Other than concrete, the best base for setting tiles is loads. They are convenient in that they are sup-

cement backerboard, a fiberglass-reinforced cement plied premixed in a can.

panel which is rigid and water-resistant. It comes in Thin-set mortars consist of premixed sand and

panel sizes of 3×5 feet, 4×4 feet, and 4×8 feet and portland cement. A latex additive improves bonding,

thicknesses of 1⁄4 and 1⁄2 inches. water resistance, and flexibility. The latex version is

Fasten the backerboard in place using 11⁄4-inch recommended over all wood substrates.

(11⁄2-inch for 1⁄2-inch board) No. 8 galvanized, wafer-

head, self-countersinking screws, available where Grout

backerboard is sold. Grout (for filling the joints between tiles) may be

identical to the tile-setting material, except that

Mortars and Adhesives organic mastic may be used only for setting tile. More

A wide variety of materials is available for setting tiles. commonly the grout is of finer consistency and con-

The choice depends on the application (wet or dry, tains dye to match or complement the color(s) of the

freezing or not) and the skill level of the tile setter. tile. Latex grout, like latex-additive mortar, improves

Organic mastics are used exclusively for wall bonding, water resistance, and flexibility.

Tile-Setting Materials

Material Form Bed, in Advantages Disadvantages

Organic adhesive

Ready-set mastic 1⁄16 Easy application Interior only

Low cost Immersion resistance

Flexible bond

Epoxy mortar 2 or 3 parts 1⁄16–1⁄8 Excellent resistance to Limited working time

mixed on site water and chemicals Difficult application

Very strong bond

Thin-set mortar Dry mix of 1⁄4 Immersion resistance Requirement of being

portland cement, Freeze resistance kept moist for 3 days

sand, and latex before grouting

Portland cement Portland cement, 3⁄4 walls Allowance for slight Presoaking of tiles

mortar sand, and water 11⁄4 floors leveling of uneven required; metal lath

mixed on site surfaces reinforcement

recommended

Tile Setting Materials 405

Standard Tile Sizes

Wall Tile

FIELD TILE (thickness ⁄")

8"

6"

3" 6"

41/4" 6"

10"

8"

6" 6"

41/4" 41/4"

3" X 6" 41/4" X 41/4" 6" X 41/4" 6" X 6" 6" X 8" 8" X 10"

field field field field field field

TRIM SECTIONS (thickness ⁄")

6"

6"

5"

33/4" 41/4" 41/4"

3/4"

2" 2"

6" X 2" 6" X 33/4" 6" X 41/4" 41/4" X 6" 6" X 2" 41/4" X 41/4" 41/4" X 6" 6" X 5" 6" X 3/4"

bullnose bullnose bullnose 6" X 6" surface 41/4" X 6" surface curb bead

bullnose bullnose surface bullnose

bullnose

55/8" 55/8"

55/8" 55/8"

37/8" 37/8" 37/8" 37/8"

33/8"

41/4" X 37/8" 6" X 33/8" 6" X 37/8" 41/4" X 55/8" 6" X 37/8" 6" X 37/8" 6" X 55/8" 6" X 55/8" 6" X 55/8"

cove cove cove 6" X 55/8" base base base base base

cove

406 FLOORS, WALLS, AND CEILINGS

Mosaic Tile

FIELD TILE (thickness ¼")

1" 2"

1"

2" 2"

1"

1" X 1" 1" X 2" 2" X 2"

field field field

2"

1"

1" octagon 2" octagon

field field

TRIM SECTIONS (thickness ¼")

1" 1"

1" 1"

1" 1"

1" 1"

1" X 1" 2" X 1" 1" X 1" 2" X 1"

bead bead cove cove

2" 2"

1" 1"

1" X 1" 1" X 2" 1" X 2" 2" X 2"

surface surface surface surface

bullnose bullnose bullnose bullnose

Standard Tile Sizes 407

Paver Tile

PAVER FIELD TILE

(both ½" and ⁄" thick)

4" 6" 4"

4"

6"

8"

PAVER TILE TRIM

(½" thick unless noted)

3/8" 3/8"

8"

6" 6"

41/4" 4" 41/4"

6" X 6" 41/4" X 41/4" 4" X 8" surface 6" X 6" surface 8" X 4" surface 41/4" X 41/4"

bullnose bullnose bullnose bullnose bullnose surface

bullnose

6" 51/2" 51/2"

4" 6"

6" X 6" double 8" X 4" double 6" X 51/2" 6" X 51/2" 6" X 6" window sill

bullnose bullnose cove cove base or step nosing

408 FLOORS, WALLS, AND CEILINGS

Quarry Tile

FIELD TILES (thickness ½") FIELD TILES (thickness ½" & ¾")

8" 4"

3" 6"

4"

3" 8" 8"

6" 6"

3" 4"

3" X 3" 3" X 6" 4" X 4" 8" X 8" 4" X 8" 6" X 6"

field field field field field field

QUARRY TILE TRIM

8"

6" 6" 6"

4" 4" 4"

4" X 4" X 1/2" 8" X 4" X 1/2" 6" X 6" X 1/2" 4" X 8" X 1/2" 6" X 6" X 3/4" 6" X 4" X 1/2" 6" X 6" X 1/2"

6" X 4" X 1/2" bullnose bullnose bullnose bullnose double double

bullnose bullnose bullnose

2" 6"

6"X 2" X 1/2" 6" X 6" X 3/4"

5" 5" cove window sill or step nosing

5"

5"

2" 6"

6" X 6" X 3/4"

6" X 5" X 1/2" 6" X 5" X 3/4" 6" X 5" X 1/2" 6" X 5" X 3/4" 6" X 2" X 3/4" window sill or step nosing

cove base cove base cove cove cove

Standard Tile Sizes 409

Tile Patterns

Tile Patterns

Dark rectangle 50% Dark rectangle 50% Dark rectangle 50%

Light rectangle 50% Light rectangle 50% Light rectangle 50%

Dark rectangle 50% Dark rectangle 67% Dark rectangle 50%

Light rectangle 50% Light rectangle 33% Light rectangle 50%

Dark rectangle 50% Dark square 20% Dark square 50%

Light rectangle 50% Light rectangle 80% Light square 50%

Dark rectangle 50% Dark rectangle 89% Dark rectangle 58% Dark square 25%

Light rectangle 50% Light square 11% Light rectangle 17%

410 FLOORS, WALLS, AND CEILINGS

Tile Patterns—Continued

Dark square 56% Dark square 75% Dark square 67%

Light square 44% Light square 25% Light square 33%

Dark square 25% Dark rectangle 50% Dark square 80% Dark square 31%

Light square 25% Light square 20% Light square 69%

Dark square 50% Light rectangle 25% Dark rectangle 40% Dark square 20% Small light square 4% Dark rectangle 32%

Light square 25% Light rectangle 40% Large light square 64%

Small light square 33% Light rectangle 33% Dark square 50% Dark square 20%

Large dark square 33% Light square 50% Light rectangle 80%

Tile Patterns 411

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- (1904) Old English FurnitureDocument272 pages(1904) Old English FurnitureHerbert Booker100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Complete: HandbookDocument776 pagesComplete: HandbookLuis Torres GalmesNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Bedroom Furniture by Drexel HeritageDocument7 pagesBedroom Furniture by Drexel Heritagemap00007No ratings yet

- Truss 3 Detail Section Plan: 6Mm X 5Mm X 50Mm Angle Bar Top and Bottom Chords 2-6Mmx38Mmx38Mm Angle Bar Member ChordsDocument1 pageTruss 3 Detail Section Plan: 6Mm X 5Mm X 50Mm Angle Bar Top and Bottom Chords 2-6Mmx38Mmx38Mm Angle Bar Member Chordsalezandro del rossiNo ratings yet

- Handbook of Construction Tolerances (Tolerancias)Document385 pagesHandbook of Construction Tolerances (Tolerancias)FaRS100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 13a - SOR - BuildersDocument74 pages13a - SOR - BuilderskokueiNo ratings yet

- Topic 2 Design Concept and ConstructionDocument54 pagesTopic 2 Design Concept and ConstructionAbdullah Ramzi100% (1)

- Visit Report of Construction SiteDocument9 pagesVisit Report of Construction Siteउमेश गावंडे75% (4)

- Window Installation BTDocument18 pagesWindow Installation BTArnelyn Angel AbarquezNo ratings yet

- List of Drawings - Structural DetailsDocument687 pagesList of Drawings - Structural DetailsCreation Group100% (1)

- Bill of Materials v2Document14 pagesBill of Materials v2Henry Tugano80% (5)

- Long Span in ConcreteDocument57 pagesLong Span in ConcretePrakharVirendraNo ratings yet

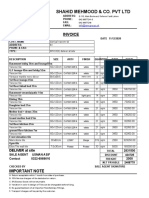

- Shahid Mehmood & Co. PVT LTD: InvoiceDocument2 pagesShahid Mehmood & Co. PVT LTD: InvoiceMuhammadUsman Asif2017No ratings yet

- Chapter-I Definitions: Commercial & Residential Bye-Laws Dha IslamabadDocument3 pagesChapter-I Definitions: Commercial & Residential Bye-Laws Dha IslamabadsajawalhashmatNo ratings yet

- Bill of MaterialsDocument68 pagesBill of MaterialsWilson EnriquezNo ratings yet

- Architectural Character Aegean and GreekDocument5 pagesArchitectural Character Aegean and GreekClaire BarriosNo ratings yet

- Boq 6-14-2022Document5 pagesBoq 6-14-2022kiran NeedleweaveNo ratings yet

- Amps Location Draw Circuit Box Breaker#Document3 pagesAmps Location Draw Circuit Box Breaker#JJNo ratings yet

- 2 OF 7 - Sep3,2020 - P8 - Balaji at Vandhavasi West Elevation WD PDFDocument1 page2 OF 7 - Sep3,2020 - P8 - Balaji at Vandhavasi West Elevation WD PDFepe civil1No ratings yet

- SL - No Particulars Unit BOQ Qty Items QtyDocument2 pagesSL - No Particulars Unit BOQ Qty Items QtyJacob PriyadharshanNo ratings yet

- Unit 1Document60 pagesUnit 1Alston DsouzaNo ratings yet

- Toobe: Ferruccio Laviani 2007Document1 pageToobe: Ferruccio Laviani 2007AnaDanilovNo ratings yet

- Inglés I. Guía Segundo Parcial.Document2 pagesInglés I. Guía Segundo Parcial.Anonymous 85m1XB4No ratings yet

- Control Schedule: 2723, Manila Golden Bay Casino, Philippine 菲律宾马尼拉金海湾赌场Document7 pagesControl Schedule: 2723, Manila Golden Bay Casino, Philippine 菲律宾马尼拉金海湾赌场Victor PaderNo ratings yet

- Byzantine Arch'reDocument86 pagesByzantine Arch'reJanine Abuyan Obligado0% (1)

- WA203 - Decor Floor Plan Rev.BDocument1 pageWA203 - Decor Floor Plan Rev.BSTS-SPARK GAMINGNo ratings yet

- Trevi TowersDocument16 pagesTrevi TowerselvinperiaNo ratings yet

- Aluplus Catalog Final PDFDocument19 pagesAluplus Catalog Final PDFMiguel Prabowo Dos SantosNo ratings yet

- Islamic Architecture: TH THDocument5 pagesIslamic Architecture: TH THQwin San AndresNo ratings yet

- Maple Homes BrochureDocument6 pagesMaple Homes BrochurerajuwithualwaysNo ratings yet