Professional Documents

Culture Documents

MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70

MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70

Uploaded by

jmz mtzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70

MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70

Uploaded by

jmz mtzCopyright:

Available Formats

Bond | Protect | Beautify

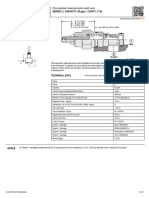

Robotic Bell Spray

Technical Data

Weight NANOBELL 2

Both versions NANOBELL 2, without hoses (kg) 5 kg

Fluid supply NANOBELL 2

Fluid pressure maxi. (bar) 10 (150 psi)

Paint flow (cc/min) according type of paint 30 to 750(1)

Viscosity range - FORD n°4 (seconds) 20 to 50

(1): depending on viscosity

Pneumatic power NANOBELL 2

Operating air pressure (bar) 6 (90 psi) to 10 (150 psi)

Magnetic bearing air pressure (bar) 6 (90 psi) to 10 (150 psi) 85 Nl/min.

Air shroud pressure (bar) 6 (90 psi) constant

Micro air pressure (bar) 1.9 to 3 bar constant

Operating consumption (Nl/min.) 10

Bearing air consumption (Nl/min.) 125

Air shroud consumption (Nl/min.) 0 to 600 (depending skirt)

Turbine air consumption (Nl/min.) 190 to 700

Performances Turbine

Rotation speed 5000 to 40 000 rpm (upon diameter of bell cup used)

High Voltage UHT 158 EEX e UHT 287 EEX e

Voltage maxi. 70 kV 70kV

Current maxi. 100 µA 500 µA

ATEX marking:

NANOBELL 2 UHT 158 EEx e: NANOBELL 2 UHT 287 EEx e: GNM200(2):

solvent-based product water-based paint

70kV/100µA with ≈ kΩ.cm 70kV/500µA

with R ≥ 6 MΩ.cm:

II (2) G

0080 II 2 G III 3 G X T 60°C [EEx > 350 mJ]

SEVERAL VERSIONS DEPENDING

II 2 G II 2 GD

ISSeP05ATEX032X

EEx > 350mJ EEx e II W>2J EEx e II ISSeP06ATEX032X

ISSeP05ATEX032X ISSeP01ATEX002U ISSeP01ATEX002U

(2): This control module allows piloting the UHT. It is an associated equipment that is part ON YOUR NEEDS:

of the configuration of the certified equipment and that contributes to its good working. It

has to be installed into a non explosive area.

Product

HI-TE TECHNOLOGY VERSION Compatible with Resistivity

NANOBELL 2 SB

The external shroud is composed of solvent based

High voltage unit (UHT 158) ≥ 6 MΩ.cm

product

couples of combined air holes. integrated into the atomizer

This external shroud allows many NANOBELL 2 WB water-based paint

applications; the pattern can fastly Remote high voltage unit (3)nonflammable or ≈ 0 MΩ.cm

vary from a narrow and (UHT 287) from atomizer hardly flammable

penetrating spray to a wide

(3): the product distribution system must be isolated from the ground potential.

and wrapping spray for an

optimal transfer efficiency.

MAIN BENEFITS:

• More paint savings

• Better finishing quality and RECOMMENDATIONS

color match High voltage (kV) Solvent paint Resistivity

• Easy operation thanks to

single air adjustment 30 kV 0.5 to 1 MΩ.cm

50 kV 1 to 6 MΩ.cm

70 kV > of 6 MΩ.cm

70 www.sames-kremlin.com

You might also like

- Sizing and Rating BLOWDOWN - ExerciseDocument19 pagesSizing and Rating BLOWDOWN - Exercisepolaris44No ratings yet

- Huawei 4 Band AntennaDocument2 pagesHuawei 4 Band AntennaMoussa TouréNo ratings yet

- JumboDocument4 pagesJumboWilliam Valeriano100% (1)

- IGV Commissioning For AddFem POCO+ LogicDocument17 pagesIGV Commissioning For AddFem POCO+ LogicHankar Aravins100% (4)

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 84Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 84jmz mtzNo ratings yet

- DNG CompressorDocument4 pagesDNG CompressorsirtmxNo ratings yet

- TE Raychem HVBT Tape - Product DescriptionDocument2 pagesTE Raychem HVBT Tape - Product Descriptionnathan.schmittouNo ratings yet

- 3010E620 Spec Sheet Nov2016-EDocument2 pages3010E620 Spec Sheet Nov2016-Em44No ratings yet

- Eba200-200s enDocument4 pagesEba200-200s enOsama Ben DawNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- CCCALBN en Us LetterDocument1 pageCCCALBN en Us Letterisaiahsamsonm_948069No ratings yet

- Datasheet GinoLED HO Module E V1.2 - EN - DraftDocument8 pagesDatasheet GinoLED HO Module E V1.2 - EN - DraftadityhotNo ratings yet

- dd321 Specification Sheet EnglishDocument4 pagesdd321 Specification Sheet Englishgkqztsy9skNo ratings yet

- Brochure EBA 200 ENDocument4 pagesBrochure EBA 200 ENSerhii HolovizninNo ratings yet

- XL 2600Document2 pagesXL 2600javier perezNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- Ginoled Ho Module G1: DatasheetDocument8 pagesGinoled Ho Module G1: DatasheetDevin Yhojan Viafara MancillaNo ratings yet

- Casb 500 2T 15 - Ie3 - EngDocument3 pagesCasb 500 2T 15 - Ie3 - EngGonzalo GasparNo ratings yet

- Sandvik Dd321 Development Drill: Technical SpecificationDocument4 pagesSandvik Dd321 Development Drill: Technical SpecificationFERNANDO INOCENTE TRINIDAD GUERRANo ratings yet

- SpecificationsDocument4 pagesSpecificationsSebastian VasquezNo ratings yet

- EBA 200 - 200 S: Small CentrifugesDocument4 pagesEBA 200 - 200 S: Small CentrifugesAbdulrahman AssaidNo ratings yet

- Ds311-Ficha Tecnica PDFDocument4 pagesDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyNo ratings yet

- HF 690 Series: in Line Medium Pressure FiltersDocument4 pagesHF 690 Series: in Line Medium Pressure FilterssitnikovsNo ratings yet

- Alkitronic Ehpc enDocument2 pagesAlkitronic Ehpc enLuis Alberto Silva NavarroNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- Sandvik Dd311 Development Drill: Technical SpecificationDocument4 pagesSandvik Dd311 Development Drill: Technical SpecificationJuan David Rondinel BulejeNo ratings yet

- HydropompeDocument4 pagesHydropompeReggie TopsNo ratings yet

- Chave de N¡vel Vibratoria - Nivoswith - R400-500Document2 pagesChave de N¡vel Vibratoria - Nivoswith - R400-500raphaelpessNo ratings yet

- EV58-34 Vented Directional ElementDocument2 pagesEV58-34 Vented Directional ElementcaiNo ratings yet

- Bomba Weda D60Document1 pageBomba Weda D60CARLOS DAVILANo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- RDBALAN Full en Metric A4Document2 pagesRDBALAN Full en Metric A4David AltarribaNo ratings yet

- CJW EngDocument7 pagesCJW EngVictor MacrinoNo ratings yet

- Datasheet GinoLED HO Module V2.2 - 201701012 - EN - ReleaseDocument8 pagesDatasheet GinoLED HO Module V2.2 - 201701012 - EN - ReleaseTauviq Al Zein TriiadtmajaNo ratings yet

- ds2710 Specificaiton Sheet EnglishDocument4 pagesds2710 Specificaiton Sheet EnglishHumberto Esquivel PuentesNo ratings yet

- 2 - Premium Line (PDT) - SB-MB-HB 2006Document14 pages2 - Premium Line (PDT) - SB-MB-HB 2006Cristian LuqueNo ratings yet

- Rev1 - 154-AC-YTKI-V-22-DH - PT. YTK INDONESIA - Rev.1Document2 pagesRev1 - 154-AC-YTKI-V-22-DH - PT. YTK INDONESIA - Rev.1sales-admin.bdgNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- ADU450900 V 06Document2 pagesADU450900 V 06RobertNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 44Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 44jmz mtzNo ratings yet

- Grease PumpDocument4 pagesGrease Pumparshad shahNo ratings yet

- Aqu4518r4 PDFDocument2 pagesAqu4518r4 PDFTourchian100% (1)

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogJuan Francisco Sanchez MassadiNo ratings yet

- Motion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - ZDocument2 pagesMotion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - Zvictor bastardoNo ratings yet

- 3mn0405 00 MN 18737 Deluxe Series by Acrrev 3Document2 pages3mn0405 00 MN 18737 Deluxe Series by Acrrev 3RiskiNo ratings yet

- Poz.3 BD - 1515 - T6 - 22kWDocument4 pagesPoz.3 BD - 1515 - T6 - 22kWAbc DefNo ratings yet

- EN7654 3 06 18 - FAM Economy PDFDocument8 pagesEN7654 3 06 18 - FAM Economy PDFPritesh KoratNo ratings yet

- CXL 70 1lw - en GBDocument2 pagesCXL 70 1lw - en GBOtero Gabriel (Carlinhos)No ratings yet

- 4-3/4" LBTB: - Mud Lubricated Bearing PackDocument3 pages4-3/4" LBTB: - Mud Lubricated Bearing PackGina Vanessa Quintero CruzNo ratings yet

- K3VL Series: Swash Plate Type Axial Piston Pump Used For Open Circuit' ApplicationsDocument11 pagesK3VL Series: Swash Plate Type Axial Piston Pump Used For Open Circuit' ApplicationsHamza LashinNo ratings yet

- Sandvik DD321Document4 pagesSandvik DD321Anonymous Dm7iMmt0% (2)

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- Breaker Bretec BrochureDocument8 pagesBreaker Bretec BrochureSonny SaputraNo ratings yet

- Frontonero SANDVIK DD311Document4 pagesFrontonero SANDVIK DD311Arturo And100% (1)

- Hsro-390-Ff & Hsro-4040-FfDocument2 pagesHsro-390-Ff & Hsro-4040-FfYasser Mahmoud ZiadaNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNo ratings yet

- SANDVIK DD321-40C Development Drill: Technical SpecificationDocument4 pagesSANDVIK DD321-40C Development Drill: Technical SpecificationLuis AmayaNo ratings yet

- Sandvik DD2710Document4 pagesSandvik DD2710lorenzo henerNo ratings yet

- HR E577tDocument6 pagesHR E577tSite EngineeringtiaNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Manual LZQJXCPHBE340Document119 pagesManual LZQJXCPHBE340Kenneth Thoft AndersenNo ratings yet

- Adams Car Training Guide Mechanical EngineeringDocument6 pagesAdams Car Training Guide Mechanical EngineeringFebrian JhaNo ratings yet

- Instructions For The Use of Fixture Group - Parts ReusabilityDocument7 pagesInstructions For The Use of Fixture Group - Parts ReusabilityRASOUL KHADIBINo ratings yet

- Rudolph Ganz Piano ExercisesDocument1 pageRudolph Ganz Piano ExercisesChristopher DanielNo ratings yet

- EV3 Motor GuidefdDocument6 pagesEV3 Motor GuidefdBob LobbyNo ratings yet

- Project Report MBADocument100 pagesProject Report MBAAnonymous kb5szUqWuNo ratings yet

- LB 0 0 vp2 tp5 - enDocument176 pagesLB 0 0 vp2 tp5 - enVladimír Rapčan100% (1)

- Intake StructuresDocument14 pagesIntake Structuresnimm1962100% (1)

- Compro PT Mitra Sistematika GlobalDocument10 pagesCompro PT Mitra Sistematika GlobalbenyNo ratings yet

- Mathcad MatrixDocument18 pagesMathcad MatrixZokiNo ratings yet

- Zealous Brick Making Machine Main Model Parameters PDFDocument13 pagesZealous Brick Making Machine Main Model Parameters PDFdajl100% (1)

- Standard Operating Procedure: Vehicle and Equipment MaintenanceDocument3 pagesStandard Operating Procedure: Vehicle and Equipment MaintenanceLian Mae SanchezNo ratings yet

- 10 1561@2900000005Document119 pages10 1561@2900000005Farid StiflerNo ratings yet

- Lecture 6 - Ware House ManagementDocument16 pagesLecture 6 - Ware House ManagementThapaa LilaNo ratings yet

- Husqvarna DXRDocument24 pagesHusqvarna DXRSafrin SangiaNo ratings yet

- As 2473.3-2007 Valves For Compressed Gas Cylinders Outlet Connections For Medical Gases (Including Pin-IndexeDocument7 pagesAs 2473.3-2007 Valves For Compressed Gas Cylinders Outlet Connections For Medical Gases (Including Pin-IndexeSAI Global - APACNo ratings yet

- Iec 60287 Grouping TableDocument2 pagesIec 60287 Grouping TableAnas Yousuf100% (1)

- GurujiDocument12 pagesGurujiAnkur SinghNo ratings yet

- fm3 01x15Document128 pagesfm3 01x15mai100100% (1)

- Intelligence Failures: Competitive Intelligence and Strategic SurprisesDocument7 pagesIntelligence Failures: Competitive Intelligence and Strategic SurprisesDr. Avner Barnea100% (1)

- Chesterton Si150 enDocument8 pagesChesterton Si150 ennjsmith5No ratings yet

- Accepted Papers PDFDocument61 pagesAccepted Papers PDFmaheshnagarkar100% (1)

- E SDK D Sail Drive Mechanical RotatableDocument2 pagesE SDK D Sail Drive Mechanical RotatablePCNo ratings yet

- 3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetDocument2 pages3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetAlejandro coronelNo ratings yet

- Mechanical CAD DesignerDocument3 pagesMechanical CAD Designerapi-78142539No ratings yet

- Text For RBA Drilling and CompletionsDocument47 pagesText For RBA Drilling and Completionsfahrain2012No ratings yet

- CSD SPR 2013 PDFDocument3 pagesCSD SPR 2013 PDFHabibAmouriNo ratings yet

- Developing Business ModelDocument31 pagesDeveloping Business ModelCheska LimsonNo ratings yet