Professional Documents

Culture Documents

Food

Food

Uploaded by

sourav0 ratings0% found this document useful (0 votes)

23 views12 pagesOriginal Title

food

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views12 pagesFood

Food

Uploaded by

souravCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

freezing nnd slow freeeing

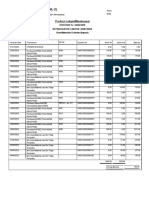

Fables Difference between Quick freezing or

Z Slow te

= 4%

Large ice crystals nie jo

— eran Pare formed!

To] Snail ice erystats ae forme : an

| inbekwor sippress Meaboiiom Meakdrati of meta

cA TEST = to ailverse or injutlous | Longer exposite tn wily Ot

a | mel eee | factors oe

pes of Freezing Methuds

1. Direct contact freezing (Alt Blast, Tunnel, Fluidized fed)

‘i the oles nl least expensive method of Receny py

his

Still air blast freezi

feecring carried out in home freezers, In this method, food packs are

an circulate between the packapes. The freezer i 5

such a way thal

of 23° to -28%

In tunnel Freezing, food packages are carried on an open mesh-belt through a oy

ocities of 10 10 15 aay, be,

which air at temperature -20° to -46°C is forced at vel

through the product, Under these conditions, a food packet that tkes 72 re

still-air can be frozen ii

Tunnel Freezer

A drawback or disadvantage of air-blast freezing is the dehydration of fi

unwrapped condition, which is known as freezer burn. This occurs dus 1 ie &

directly to water vapor molecules without going through the liquid state, Faces bx

changes in texture and off-flavor. Freezer burn can he minins!t

at about - 4°C and the pre-chilled food isthert

in discoloration,

chilling food with air at high humidity

into the colder zone where it is quickly frozen,

2. Indirect Contaet Freezing (Plate freezing)

Flat packets are placed on hallow metal plates chilled b:

foods in the direct contact with cold metal wall but in indineet contact with i

The efficiency of freezing depends upon the extent of contact between the pe!

y circulating eft

ace

Scanned with CamScanner

ine packages Should be Well fied ge Wey ovectitea

ca es =

te

. igus a0 HFCs by indict Freeing

nso

is cutie

ile of which the reltigerant hows, ty Out

NOUR appro

1 this en;

poe sil

peli o

pn!

joa is serapped 10 Keep the mass in moti

y f0 F food into contact with cold w,

Pt hs enablin

es All Un this method

y nls

Freezing

enersion : :

i has enter Of AMAR." i admmg

aly import

HIME irtepulaely a

7 Y shaped

on ee nizes the contacto loud with Ait dus freer,

sirable for foods sensitive to oxidation anes

ith 867 percent giycerol-

4. Cryogenic: Uses liquid vaporization to rapidly freeze Wroduct. Cryogenic lieuids ave

liquefied gases of extremely low boiling point, such as liquid nitopen (BP-196°C),liguid

carbon dioxide (BP-79°C) and freon 12 (BP-30°C),

Lewd

nor

\

Iravatedeatret

quid is liquid nitrogen.

The most Commonly used cryogenic liquid is Tiquid nitrope

Page|

Scanned with CamScanner

aa

« spailage Of the product when It thaws.

piv at ene ny frozen prowlucts which have seen

refit oor eezer door Neing left open,

oa eth

vat of 0

Por this reason its necessary to

Hemally thawed by the freezer

content | Prewsieig pot

or) ne

pehydration

Dehydration is the removal of moisture from

produced heat under controlled condition of ter

flow.

«In dehydration, sufficient: moisture is removed

spoilage; hut this must be done in such a way to pr we as faras possible

+ Rate of dehydration is so done in hygienic condition to have Products of uniform

colour than sun dried. Dehydration reduces the bull. Fequites less storage space and

usually cheaper that the other methods of preservation

+ The suitable fruits and vegetables for detiydration are Frape, date, fig, raw mango,

anola, ber, litchi, apricot, banana, apple, carrot, leafy vegetables, ete. ERO

ation for dehydrated fruits and vegetables are:

Truits and vepeiables hy anificially

nperature, relative humidity and ait

so that the product

Is free from

reserve food val

rinciple of Preservation Dehydration

* The principle behind drying is that sufficient moistuee is remov

for growth of microorganisms and for enzyme activity

* Removal of moisture increases the st

activity. If the moisture content is r

stored for more than a year.

‘The processing should be done in such a way that the food value, natural Qavour and

characteristic cooking quality of the fresh material ae retained after drying A geo

Gried product on reconstitution with water should resernble the original product

ed, which is essential

‘rage life of the product due to reduced water

tduced to 1 (0 5 per cent then the product can he

Paateeth

>=

Loa

Geese mevernent

Food Drying

Page [1

Scanned with CamScanner

7. Sulphiting/ sulphuring: It involves dipping, the material in 1-2 per cent potassium

metabisulphate (KMS) or exposing the product to sulphur fumes (done in a closed

room), respectively. Sulphur prevents mould growth ond preserves colour of light

coloured vegetables, repels insects anil conserves vitamins A and C. Carotenoids are

Preserved by coating with starch. Food is exposed to sulphur fumes in such a way that

1000-3000 ppm of it is absorbed. Sulphuring of the fruit is done at the rte of 1.8 —

3.6 kg of sulphur per tonne of fruit. After sulphuring, the trays ate kept in tke sun with

‘occasional turing of the fruit tll itis dried.

8. Drying: Product is kept for drying.

9. Sweating: Dried product is kept in heaps in a room for few weeks for moisture

equilibrium,

10. Packing: Plastic or polythene covers can be used. Aluminum foils, cardboard (wax

lining, is necessary for card board and wooden containets) etc. can also he used. Tin 3s

such is not suitable as it becomes rusty but can be used after coating with inert ¢25

like N2.

11, Some fruits and vegetables, in particular, banana, apples and potatoes go brown very

quickly when left in air after peeling and slicing; this discolouration is due to phe

oxidase, To prevent slices from going brown, they must be kept under

drying can be started. For certain fruits like geapes, figs etc. alkali (Iye)

done to help quicker drying due to appearance of cracks using O.1-1.5 per cent

Na2CO3 solution. Acid dipping for apples and pears is done to prevent browning

Using | per cent ascorbic acid and 1.25 per cent malic acid.

Page | 195

Scanned with CamScanner

ees

ey

ae arying uses desipned|

MIEWCHte, WO

* 19 coltect ang

16 enka

sets generate Nida LeMPeFauTE and joy Mutiny whichce SO tahation Solar

‘edict 4 Faster than yun ae NU also reais jean ge tes WW faver dyin

° sedton clously days, MIEN Tess day

Me Ate. Wat teary be

Mai ayy

Invader

Diagram of Sotsy Diyigg Mt Aberin

+ Generally. dae ype of sola dre wed, wae Some

driers im Which the product is direetly heated by sun, (2 ee mian Ot het be type

Uses in hich the pods expat oe Biwi ae ise

absorber or heat exchanger aed te ster, which ic come

yr

Serine

S89 Using this method. Tie in

nof mango flakes, ange flakes, baby fools ite al

of edible stsech and then heb

Poured litle by tittle o dan th

valy

a lead is

5 to heated drum wh

Svalving ata slow speed, umm Which ate

=

Ce) a

* The pulp of fruitis blended with

Adjusted for acidity. The mixture is

ade of stainless steel. Daums ase jy

Lid has to be placed imm €5 ae highly hygroscopic, Drum

drying is one of the mast energy efficient Arylng methods and is pasticwlarly effective

for drying high viscous liquid or puteed foods

4.Tunnel belt drier:

J consists of several parallel sloping and nastow chanbets above a furnace morn.

“Trays are passed on a conveyor belt at upper end and removed. it the lower end. Air

for drying is circulated by a fan, Ihumidiy is contcalled by ovcasionally letting in ai.

Page | 107

Scanned with CamScanner

flow VAPOUE PressHte, water can, Pvapate fro,

jnions of

il

oot

tod

ete ying genera wed

nega vine it Wiahly hyprose

pe Te nvoperty of frit ju

"econ ofthe ‘i combination ‘thai {08 seaman

“eer A Sample: Yegetables pieces MAY be nit dried No aber 46

* deine Mize dried down in 2-4 Pet Cent tnoistune

ul

"0 (ee withent the jem

Y Sensitive

Vpn Value Nguid ef

Hes, shicken dices eninge Meee

opie and sie ve

ice cone Is era

MN ae sotie

Feconit

eID

ices ete

UY. Taste, flay

out and

ellen. Mery,

1 Ay cmtty

teducing cont of

pe

ant

Per Cent alse

neentration

co

U

oncentration

pineipte of ce ration process increases the

«Concent

the temperature of its boiling p

fe wapéur pressure rites ‘and bes

* Rat enpehantion supplied by

:

ing, mediuny (

‘int during evaporation

bles Of vapour in the hed are

Vapour is the

and volume

SEAM) to the foead to

the steam. ‘The

surface of the boiling liquid.

railks, fruits and vegetable j

Sweetened cond

and jellies, tomato paste ete.

82° Syrups and flay,

sat

ured syrups, jams

Methods of Concentration

nis en ing water with solar energy. This process

Pe Ses the simplest method of evaporating w a : ie every (Dares

i ii i c in salt from sea water and st

*as used in earlier times to obtain sal sciitaing sal sehaione

wrocess is very slow and is suitable only for concentrating salt si

2 Concentration by Nash evaporation

Zoncenty

shtin direct

i waterial is brought in direct

Hon process is markedly speeded when sub sized food mater

ration e

ntact with heating medium,

Clean steam supetheatsd at

This is done in flash evaporators. a on suet fatal

i ration

150°C is injected into food and then is pumped into an evn ue ser ban

oe The bai ‘ nixtue then enters a separator vessel a et TS evacasiol tyough 8

"8. The boiling mi 5 Ml a

Off at the bottont an the steam plus water vapour Halen ‘of high temperature

constituent

“arate outlet. Foods lose volatile flavour

Page | At

Scanned with CamScanner

Fatt

he ——————

- J J =I

Wettncis Truck piegieti in Bsa deecton

aot

on

Schematic of a counter current-fow tunnel Atyer

+ Heating can be diteet or by radiation Indirect Iweating Heat iy py

and it is sufficient, but there is tisk of overheating, PILE oy

+ By radiation

heated over pipes carrying bot g

may also be ws

5. Spray drying:

Spray drier is used to dry purces, low:

atomized. The material is sprayed in a rapidly moving currern of hot ai.

* The dried produet drops to the bottom of the drying charnber ang

‘Aomization into minute droplets results in dying in w none oe 7

common inlet air temperature Of about 200°C andl properly Aesipned syn

removes the dried particles from heated zones. E

Osity pastes and liquids, yp,

|

Shay Dryer |

Hoenn

|

Powe

+ This method of dehydration ean prodice exceptionally high qusliy wih smgytit

heat sensitive materials including milk and coffee.

6, Freeze drying:

* Foods in the pieces and lig

manufactured using freez:

under vacuum,

aids are dried by this method. Fruit juice epee

© drying. The material is frozen on trays and tha ¢e

Scanned with CamScanner

LY

Ly

Concentration by thin film evaporation

In thin film evaperstors foo! s pumped ito a venical exter hig

avthin layer 4 eylinder Wall, The eyig yi Ato,

ed by steam, Water is quickly evaporite frei! Of nh

taneously wiped From the eylindey ening?

food and water vapour are continuously discharged to an externa le hee!

product is removed al the bottom and water vapour passes fo heat

temperature may teach 85°C or higher but since resitence tin of thay.)

the heated cylinder may be less than a minute, heat damage is mining

that spreads the food

construction usually is he:

and the concenteated food is simul

4. Concentration by vacuum evaporation

This metiod is suitable for heat sensitive foes ss this rtd Hote,

Evaporation uniler vacuuen cnn be done by operating thin tlm evaporite

Connecting a vacuum pump or steam ejector to the condenser Several ne eet

attached in sercs so thatthe food prot tnoves from one vacwun dng a Se

thereby becomes more awl more conceatited at cach scp. The seen ek

tmaintained at progressively higher degrees of vac and hot water ven,

step is used to heat the second vessel and so on. In this way heat energy iv ellie 1s

5. Freeze concentration

Initially formed ice crystals during freezing process sre rernoved wih the hp ce

force resulting in a concentrated unfrozen food which passes through fine met cn

process is repeated many limes to reach final concentration of food

6. Ultrafiltration and reverse osmosis

These are the two methods of concentrating foods employing presure

Separation process. In ultrafiltration large solute particles ate selectively remove! wh

reverse osmosis smaller solutes are separated out.

diver mt

Thermal processing

Thermal processing is defined as the combination of tempersture and tine f

eliminate a desired number of microorganisms from a food product

The term "thermal" refers to processes involving heat.

* Heating food is an effective way of preserving,

‘The basic purpose for the thermal processing of foods is,

© to reduce or destroy microbial activity,

0 reduce or destroy enzyme activity,

ft

ad

Scanned with CamScanner

ce pysient or chemical chan

nicet a certain quality stan

pro

Mine fool

proces ang

“Hn. cemperauure eatepories employed in

Manching is to destroy enzytie

activi

fea as a sole methord of preservation Haulers

Irying. and canning,

inf

Hine ascot

au

plat ary pure

pre 0 nite ;

° tye arcaument prior to Hees

© Jor bianchi

yc!

yp nce

ctf aucins UES microbial contamination

0 Rerening veretable tissties 16 facilitate Filling, into conta

Removing air (rom intercellular spaces prior to canning, iners

cof Blanching

{ out at up to 100°C using hot water

wet ° planching is carried

ing. is carried Out steam

Blanchi

a wae anes |

iva a Narous designs which Hold the fool in hot wee (7

lca e, ten moves a devaterinycofing section CRO a 200°C) fees

__ Bpis wpe the food enters a slowly rotating

water ig drum, partially submerged in the hee

Steam Blanchers

this is the preferred method for foods with large cut surface areas 25 love leach

losses.

na mesh belt or rotatory cylinder through a steam

© Normally food material carried o

almosphere, residence time controlled by speed of the conveyor oF rotation

Je layers of food, so attaining, the

© Often poor uniformity of heating in the multip

centre results jn overheating of ‘outside layers.

tequired time-temperature at the

Page |}

Scanned with CamScanner

Pasteurization

Introduction

‘The word pasteurization Is derived from the name of g

Pasteur (1860), who found that heating certain tiquids ‘pee CHinent

improved their keeping, quality. Pasteurization enn ints wn ites

se om

dairy industry shortly after 1880 in Germany andl Denman

in all branches of dairy industry, Heat treatment destroye yes PE

Further, a more or less complete imetivation of enzymes occa

and treatment time. In order to retain as many Sensory and yi PEM

Inaterials as possible, different heating, methods hive been deve’ Pm

Grganisms (pasteurization) or destroy ll mictoorganigmns

(sterilization), .

tn

FS, depey

Definition

Accoriling to International Dairy Federation (IDF), pasteurization ¢

process applied 10 a product with the object of minimizing possibte

from pathogenic microorganisms associated with milk by heat trestineny

with minimal chemical, physical and sensory changes in the product’,

be

ath hina

Which

thy

In general, the term pasteurization as appticd to market milk refers 1p

every particle of milk to at least 63°C for 30 min or 72°C for 155 ero ant

combination which is equally efficient, in a_ properly operated a

pasteurization, the milk is immediately cooled to 5°C or below. ‘Wipe:

Principle of Pasteurization

All pathogenic organisms are destroyed by pasteurization, except spore formiy

‘The thermal death point of tuberculosis. germs (Mycobacterium tubercut

hhigher than that for inactivation of phosphatase enzyme. Pasteurization is carey

treatment temperature above that for phosphatase inactivation and yet below thy

line reduction, The pasteurization ensures complete destruction of pathogens,

alkaline phosphatase test and least damage to the crear lin :

unten Pasteurization Process 4.4.

CIELEL PYEEE CeEEEET]

a

Enrymes the pipe va

rk in full working

condition

nme coronas

tatdeceotey

Uuenment eae

tunablerolareren |

Nia

‘When the entymes go Uheough heat B

treatment they are denatured and epg bacecats

become unable to function properly

yo"

Scanned with CamScanner

cess involves heating fon if

ocess a

en “Cand hen Predetinge,

ean aty petaweet ‘WO ated 85 °C aad hen eo MAN eapicty ap

“ie “a chemical int rity of eran inpreiticnts MY beatfectey

ac tHe sesh” prexhuce, (nen Pasteutization Naga ed. 1

cee ot $A Tr foots mt be tetiperted a “Ct te patget

va 6 any bacteria Not desteayed Foolstuepaventiged thy wa eset the

inte tk cider, jam ete, like beet,

wk

ees

h

Pusteurization

nee Tate Cor eran consumption ty

”

enter

Hesttoying all the Hathopenic

1 ce Keeping quality of milk by killing

1

coe

i

aln

gin Pasteurization

11 of Pas

hos

Seaman (HH gy

etry.

‘Treatment

en

HTST) pasteurization

ature short time (|

Temper

caligh temperature (UITT) pasteurization >|

{Thr igh tempers ne

—_—

ature long.time (L-U1-T)Uatch pasteurization

Low teed, held and cooled in the inner vessel. The gp;

Ah ae ajackel, through which ihe heating or cooling

casing, forms ater oF low: pressine. snes is circulated y

aa Ht eated [or rapid and uniform heating. The t

sa eally controlled. The rai heated to a mi

Sapertuce Cor minimum 30 min,

ace between Vessel and the outer

Medium is eitculited. To hese

Wnroweh the jacket and mite. is

Neating WeOCeSS could be manly

urn Of 627°C and, held at thas

the

Actwrncy tsi

rotting Themen

leet une i

ie Reigns tbemnaneie

[Ne Space Hosier hetering Merman

rch Heating

Medium

loved Couple

i inthe jacket

is circulated i "

rea uo surface cooler ete a

sloeked tubes. A cooling

Sc ting, medi

Is then cooled as rapidly as possle oC Aon distal \

i : the hes ce at ite

i gf ok te ik, but more often ed metal plates or series of som

fm of milk flows down the cornugat

Scanned with CamScanner

Unevtiann sets ay baie or chilled watery

the tubes st SHH hy oy ‘

Advantages 1 Mle

Rel elf" Sm ants, ten Volume products “Ye

volt ening testuets can De hnnted

{Well suited for cultye

‘Simplecoutioty

Low instaty

POM ete

tO cost

Disadvontanes

Batch iyye

Slow process

SAV the contol are mostly mmanial, ih requires constang Alten

“Hotl beating ant cooling me telaively expenaion (Web nth ey

ve hey

High-Temperature Short-Time (EST) Pasteurization

This was first developed by AVY. Co. in the nie Kinptonn

Inethionl of pasteurizing milk aul is invativly used weet large yo 2

‘The HIST pastenrizer paves a contiauois flow of gal Which

then promptly cooled to $°C or below,

Resiicing ounce

Advantages

J. Capacity to heat treat milk quickly and adequately, while maintaining rg gat.

over both the raw and finished product

2. Less floor space required

3. Lower initial cost

4. Milk packaging, can start as soon as milk is pasteurized

5. Easily cleaned and sanitized (system adapts ilself to CIP)

6. Lower Operating cost (due lo regeneration system)

7. Reduced milk los

Disadvantapes a

1, The system is not well-adapted to handling small quantiti ss of liquid milk pro!

2. Gaskels require constant attention for possi

3. Complete drainage is not possible (without

ble damage and lack fs a

losses exceeding those fromthe ht

N

ath

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sonargaon (Tiil-2) : Product Ledger (Warehouse)Document1 pageSonargaon (Tiil-2) : Product Ledger (Warehouse)souravNo ratings yet

- Sonargaon (Tiil-2) : Product Ledger (Warehouse)Document1 pageSonargaon (Tiil-2) : Product Ledger (Warehouse)souravNo ratings yet

- Communication Hacks Online Edition PDFDocument127 pagesCommunication Hacks Online Edition PDFsouravNo ratings yet

- Trade International Industries LTD Unit 2 Sonargaon Injection Mold Items Transfer SlipDocument3 pagesTrade International Industries LTD Unit 2 Sonargaon Injection Mold Items Transfer SlipsouravNo ratings yet

- Sonargaon, Narayanganj: Finished Goods Transfer Slip (Refrigerator & Freezer)Document1 pageSonargaon, Narayanganj: Finished Goods Transfer Slip (Refrigerator & Freezer)souravNo ratings yet