Professional Documents

Culture Documents

Emergency Shutdown Valves Safety Features: Flow Control Daeju Control Co., LTD

Emergency Shutdown Valves Safety Features: Flow Control Daeju Control Co., LTD

Uploaded by

EnamulKhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emergency Shutdown Valves Safety Features: Flow Control Daeju Control Co., LTD

Emergency Shutdown Valves Safety Features: Flow Control Daeju Control Co., LTD

Uploaded by

EnamulKhanCopyright:

Available Formats

Emergency Shut Down Valve

The Emergency Shutdown Valve (ESDV) controls process media flow and is responsible for isolating

the supply of hazardous gasses and fluids within the pipeline in the event of an emergency. As a

result, these valves provide more reliable performance than standard on-off valves.

Emergency Shutdown Valves Safety Features

■ Tight Shut Off

With a double-seated design, ESDV’s are rated up to

ANSI Class VI shutoff providing bubble tight shutoff.

■ Fire Safe

In the event of an emergency, your assets may be

exposed to fire, all ESDV’s are rated to API 607 Fire

Safe.

■ Fast-Acting

Quick response is critical to reducing escalation of

hazards, ESDV’s can go from full-open to full close

in less than a second.

■ Manual and Automatic Release Options

Users have flexibility on resumption of system

operation after shutdown.

■ Rugged Design

Designed to withstand shocks and vibrations that could cause false trips, ensuring your systems is up

and running when it needs to be

■ Customizable Configurations

Several unique configurations can be engineered to meet your specific application’s needs

■ Certified Safety Integrity Level (SIL) per IEC 61508

The ESDV has been evaluated by an independent third party, those that have not been evaluated are

relying solely on manufacturers’ product claims

■ Capable of Both Local and Remote Partial Stroke Test

Users can minimize system disturbances to prevent and diagnose potential operational problems

FLOW CONTROL DAEJU CONTROL CO., LTD.

Emergency Shut Down Valve

ESDV features are designed

g for accuracy

y and dependability

p y

■ Trunnion-mounted ball valve

■ Fail-safe spring return actuator

■ Low emissions design

■ Anti-blow out stem configuration

■ Fast response time

■ Suitable for use in SIL 3 applications

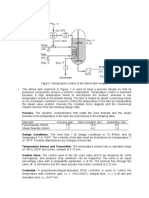

Emergency Shutdown Valve

A full port ball valve’s (FPBV) quarter-turn operation allows the valve to

close in less than a second when an emergency situation arises.

Full Open Position – Normal Operation Full Closed Position – Emergency Situation

The ESDV provides minimal pressure Set point pressure has been exceeded and

Differential when the valve is in full

full-open

open the ESDV has fully closed providing tight

position. shutoff with its double-seated design.

The full bore ball valve virtually acts like a

pipe minimizing process fluid turbulence .

FLOW CONTROL DAEJU CONTROL CO., LTD.

Emergency Shut Down Valve

The Emergency Shutdown Valve is engineered, built and tested with the industry’s international

standards to ensure product quality.

Product Specifications

■ Valve Type : Trunnion mounted full port ball valve ■ Pressure Ratings : ANSI Class 150 - 2500

■ Body Style : Side entry, forged body ■ Shut Off : Soft seat - tested up to Class VI

■ Actuator Type : Single-acting, spring return Metal seat - tested up to Class V

■ Instrumentation : Pneumatic ■ End Connections : RFFE, RTJ, weld end

■ Size Range : 6 – 36” ■ Closing Time < 2 second (depending on size)

Standard Code

■ ASME B16.5 -Valve flange dimensions ■ API 607- Fire test for soft-seated quarter-turn

■ ASME B16.10 -Valve face-to-face/end-to-end valves

dimensions ■ NACE MR0175- Petroleum and natural gas

■ ASME B16.25 -Valve butt weld ends Industries -materials for use in

■ ASME B16.34 -Valve design,g , test & p

performance H2S containing g environments in

■ API6D -Specification for pipeline valves oil and gas production

■ SIL - Up to SIL 3 per IEC 61508

Partial Stroke Test Assures Reliability

Since the Emergency Shutdown Valve remains open and not in use for prolonged periods, the system’s

performance and reliability should be checked periodically but without interrupting the operation. Without

proper testing, the probability of this component failing when called upon increases over time. Our

technology offers test procedures, such as partial stroke testing, an effective and practical method for

testing device functionality.

A device that does not have this option is at risk for false trips and potential failure to react when require.

Additionally using devices without this capability may required complete shutdown and potentially

removing equipment from the line. These types of methods are labor intensive and therefore prone to

human error.

Emergency Shutdown Valve is capable of both local and remote partial stroke testing through pneumatic

configurations. Using a device that can perform partial stroke testing provides the following benefits

■ No operation disruptions

■ Eliminates need for bypass line

■ Improved SIL rating

■ Prevention and diagnoses potential problems

■ Even while testing, the valve will still shut if emergency signal received

FLOW CONTROL DAEJU CONTROL CO., LTD.

Emergency Shut Down Valve

Partial Stroke Schematic Diagram

DAEJU CONTROL

ADRESS

Rm. 905, New T Castle, 429-1, Gasan-Dong.

Geumcheon-Gu, Seoul, Korea

TEL. +82-2-2626-9791

FAX. +82-2-2626-9792

Website : http://aov

http://aov.kr

kr

Email : djc@aov.kr

FLOW CONTROL DAEJU CONTROL CO., LTD.

You might also like

- 2018 - 814 - Eng Granskingsrapport Hammerfest LNGDocument21 pages2018 - 814 - Eng Granskingsrapport Hammerfest LNGrieza_fNo ratings yet

- Aquestia OCV AVIATIONDocument16 pagesAquestia OCV AVIATIONSony Nd AshaNo ratings yet

- Vdocuments - MX Limitorque Actuation MX Series Electric Actuator and WTR Series Worm Gear OperatorDocument35 pagesVdocuments - MX Limitorque Actuation MX Series Electric Actuator and WTR Series Worm Gear OperatorJulián Jair Cadena SánchezNo ratings yet

- Instrumentation CoursesDocument2 pagesInstrumentation CoursesAbdul LateefNo ratings yet

- 2009-Rational Coaching A Cognitive Behavioural Approach.Document8 pages2009-Rational Coaching A Cognitive Behavioural Approach.huerfanitovanidosoNo ratings yet

- Globe Valve: Fundamental of Engineering DataDocument16 pagesGlobe Valve: Fundamental of Engineering Datarieza_fNo ratings yet

- Va18 Va19Document59 pagesVa18 Va19joymotiNo ratings yet

- Experience List For Gas Compressor PackagesDocument15 pagesExperience List For Gas Compressor Packagesrieza_fNo ratings yet

- Process Control NotesDocument30 pagesProcess Control NotesRyle ArbonNo ratings yet

- Mov Specification PDFDocument27 pagesMov Specification PDFpl_arunachalam79100% (1)

- IQ IQT Catalogue E110EDocument32 pagesIQ IQT Catalogue E110Emani_208eeNo ratings yet

- ME508Document8 pagesME508bariNo ratings yet

- Displacer Type Level Transmitter Fisher FIELDVUE™ DLC3010 Digital Level Calibration - Kishore KaruppaswamyDocument7 pagesDisplacer Type Level Transmitter Fisher FIELDVUE™ DLC3010 Digital Level Calibration - Kishore KaruppaswamymanikandanNo ratings yet

- Handbook of Ship Calculations PDFDocument776 pagesHandbook of Ship Calculations PDFrieza_fNo ratings yet

- Shut Down ValveDocument3 pagesShut Down ValveMsKarolyNo ratings yet

- CCC Controllers: Recycle TripDocument1 pageCCC Controllers: Recycle TripBalasubramanianNo ratings yet

- Critical Discourse Analysis of Obama's Political DiscourseDocument12 pagesCritical Discourse Analysis of Obama's Political DiscourseSlava S-n100% (5)

- HandBook Pressure Transmitter-En PDFDocument32 pagesHandBook Pressure Transmitter-En PDFcarloscieza100% (2)

- Surge Relief Valve PDFDocument2 pagesSurge Relief Valve PDFMuhammadImaduddienSalamNo ratings yet

- Haiwell Industry Application CaseDocument38 pagesHaiwell Industry Application CaseAlexander Diaz AlvarezNo ratings yet

- Twido Programming GuideDocument604 pagesTwido Programming GuideDavid ParraNo ratings yet

- Tdoct1551b Eng PDFDocument738 pagesTdoct1551b Eng PDFzikhail93No ratings yet

- Fisher ET and EAT Easy-E Valves CL125 Through CL600 PDFDocument48 pagesFisher ET and EAT Easy-E Valves CL125 Through CL600 PDFARMANDONo ratings yet

- Esd PPT PDFDocument31 pagesEsd PPT PDFSameer Kapare100% (1)

- Haiwell Cloud SCADA CatalogDocument2 pagesHaiwell Cloud SCADA Catalogkhulalah chusniatiNo ratings yet

- Instrument Overview: For Yaman LNG On The Job TrainingDocument86 pagesInstrument Overview: For Yaman LNG On The Job TrainingQhismu AdjieNo ratings yet

- Teori Dasar Gas ChromatographDocument52 pagesTeori Dasar Gas Chromatographnoor hidayatiNo ratings yet

- Akshar: Make ConnectionDocument39 pagesAkshar: Make ConnectionsubramanyaNo ratings yet

- Instrumentation and P&ID - QuestionDocument6 pagesInstrumentation and P&ID - QuestionSharath Kota100% (1)

- Sop SDV-R3Document11 pagesSop SDV-R3Budbud YuaNo ratings yet

- Tri Sen Surge ControlDocument4 pagesTri Sen Surge ControlJimmy RumlusNo ratings yet

- Handbook of RefractoryDocument331 pagesHandbook of RefractoryAamirMalikNo ratings yet

- Fisher Fieldvue DVC 6200 Instruction Manual Instruktionsmanual Valve Positioner Ventil Lägesställare Reglerventil AskalonDocument152 pagesFisher Fieldvue DVC 6200 Instruction Manual Instruktionsmanual Valve Positioner Ventil Lägesställare Reglerventil AskalonEver SucoNo ratings yet

- Control Valve SourcebookDocument218 pagesControl Valve SourcebookJuanita JitomateNo ratings yet

- BASICS of Process ControlDocument31 pagesBASICS of Process ControlMallikarjun ManjunathNo ratings yet

- 2.seguridad Intrinseca PDFDocument104 pages2.seguridad Intrinseca PDFerstendrainNo ratings yet

- Close Loop Control Sys IntroDocument7 pagesClose Loop Control Sys IntroDwi Mulyanti DwimulyantishopNo ratings yet

- Yoke Keep Still - October2017Document4 pagesYoke Keep Still - October2017rieza_fNo ratings yet

- PIASEREpppDocument28 pagesPIASEREppprieza_fNo ratings yet

- Day 1 Session 1-Training Experiences in Nanyang Polytechnic and RemarksDocument6 pagesDay 1 Session 1-Training Experiences in Nanyang Polytechnic and RemarksFerdy FernandoNo ratings yet

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituNo ratings yet

- Final Control ElementsDocument33 pagesFinal Control ElementsMor DepRzNo ratings yet

- Control ValveDocument2 pagesControl ValveNadia KamaNo ratings yet

- Fisher Volume BoosterDocument16 pagesFisher Volume Boosterpawank_kswnNo ratings yet

- How To Tune PID Controllers On Self-Regulating ProcessesDocument6 pagesHow To Tune PID Controllers On Self-Regulating ProcessestennesseefarmerNo ratings yet

- 1.1. Process Measurement and Industrial InstrumrntationDocument34 pages1.1. Process Measurement and Industrial InstrumrntationKemal GetisoNo ratings yet

- Part 5: Advanced Control + Case StudiesDocument52 pagesPart 5: Advanced Control + Case StudiestahermohNo ratings yet

- Density Measurement - System OverviewDocument20 pagesDensity Measurement - System OverviewLuis MayorgaNo ratings yet

- Fisher l2 Liquid Level Controllers en 135074Document16 pagesFisher l2 Liquid Level Controllers en 135074GOKUL PRASADNo ratings yet

- Rittal Assem Purge Type Z y 0000 0000Document16 pagesRittal Assem Purge Type Z y 0000 0000Ashish GuptaNo ratings yet

- 9720081-010 Triconex SOE Recorder Users Guide 4.5.0Document130 pages9720081-010 Triconex SOE Recorder Users Guide 4.5.0jorisanNo ratings yet

- Asco Series 314 Exida Sil Certificate 2016Document2 pagesAsco Series 314 Exida Sil Certificate 2016AkoKhalediNo ratings yet

- Control SystemsDocument27 pagesControl SystemskakiksNo ratings yet

- Sistema de Control 2Document98 pagesSistema de Control 2Esteban CastellanoNo ratings yet

- 1.topic 1 - Ind ControlDocument52 pages1.topic 1 - Ind ControlLoga HSNo ratings yet

- Chen4352 PDC Lab ManualDocument26 pagesChen4352 PDC Lab ManualmohammedNo ratings yet

- Sapag PDFDocument4 pagesSapag PDFMargaret Daugherty100% (1)

- Quotation Request Form For BALL VALVESDocument2 pagesQuotation Request Form For BALL VALVESSreekumar Nair100% (1)

- DP Level Configuration AssistantDocument2 pagesDP Level Configuration AssistantibharNo ratings yet

- 2240s PDFDocument100 pages2240s PDFHenry MoralesNo ratings yet

- Electronic Instrumentation & Control SystemsDocument76 pagesElectronic Instrumentation & Control SystemsshahnawazuddinNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- Leeden SYDocument8 pagesLeeden SYSandra Viviana Rodriguez Muñoz100% (1)

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- Becker EmergShtdwnValve BrochureDocument8 pagesBecker EmergShtdwnValve BrochureAnonymous b9ylgFXNo ratings yet

- Ts0708 6 ShutdownDocument45 pagesTs0708 6 Shutdownuserscribd2011No ratings yet

- Surface Safety Valve (SSV)Document7 pagesSurface Safety Valve (SSV)Huda Basim100% (1)

- Control Reliable Hydraulic Safety ValvesDocument6 pagesControl Reliable Hydraulic Safety ValvesJOHN HARVEY LOPEZ A.No ratings yet

- Series: Actuators General CatalogDocument10 pagesSeries: Actuators General Catalogrieza_fNo ratings yet

- A Comparison Transnav 1 2019Document9 pagesA Comparison Transnav 1 2019rieza_fNo ratings yet

- Comparison of BS and BSEN For Steel Simplified Version PDFDocument25 pagesComparison of BS and BSEN For Steel Simplified Version PDFrieza_fNo ratings yet

- Active and Passive Control Auto-Switching Research Based On Heartbeat Protocol For Long-Distance Natural Gas Pipeline SCADA SystemDocument4 pagesActive and Passive Control Auto-Switching Research Based On Heartbeat Protocol For Long-Distance Natural Gas Pipeline SCADA Systemrieza_fNo ratings yet

- Orifice Calculation Program For Windows: Control EngineeringDocument39 pagesOrifice Calculation Program For Windows: Control Engineeringrieza_fNo ratings yet

- Lab 4 Tank DischargeDocument5 pagesLab 4 Tank Dischargerieza_fNo ratings yet

- 16 MAN MDT Turbo 02 2017 SPDocument48 pages16 MAN MDT Turbo 02 2017 SPrieza_fNo ratings yet

- FSO Gagak Rimang Tower Yoke: Banyu Urip Field, IndonesiaDocument1 pageFSO Gagak Rimang Tower Yoke: Banyu Urip Field, Indonesiarieza_fNo ratings yet

- Cabling Solutions For Industrial Applications PDFDocument268 pagesCabling Solutions For Industrial Applications PDFIrfan AshrafNo ratings yet

- Vijeo Citect Programming With Cicode v7.30 Exam Study GuideDocument16 pagesVijeo Citect Programming With Cicode v7.30 Exam Study GuideRelativity81No ratings yet

- PEMA-Scalable Data AnalysisDocument49 pagesPEMA-Scalable Data AnalysisSelcuk CanNo ratings yet

- Tooth-Size Discrepancy: A Comparison Between Manual and Digital MethodsDocument7 pagesTooth-Size Discrepancy: A Comparison Between Manual and Digital MethodsSoe San KyawNo ratings yet

- Application Note: Primer For Cepstrum Analysis - A Powerful Tool For Simpler Diagnosis of REB and Gear VibrationsDocument3 pagesApplication Note: Primer For Cepstrum Analysis - A Powerful Tool For Simpler Diagnosis of REB and Gear VibrationspradeepNo ratings yet

- Python CurriculumDocument3 pagesPython CurriculumUjwal TickooNo ratings yet

- Advanced Vehicle Security System: Key To The Programmable WorldDocument40 pagesAdvanced Vehicle Security System: Key To The Programmable WorldTajinder SinghNo ratings yet

- Compact Quad-Mode Planar Phased Array With Wideband For 5G Mobile TerminalsDocument11 pagesCompact Quad-Mode Planar Phased Array With Wideband For 5G Mobile TerminalsDJNo ratings yet

- Lactobacillus Pneumococcus Plasmodium: MCQ Unit 6Document4 pagesLactobacillus Pneumococcus Plasmodium: MCQ Unit 6Anand100% (1)

- Arduino TutorialDocument85 pagesArduino Tutorial이종호No ratings yet

- Scan Converting CircleDocument36 pagesScan Converting CircleKashish KansalNo ratings yet

- Midwifery Program Catalogue PDFDocument20 pagesMidwifery Program Catalogue PDFdummy damnNo ratings yet

- Satsearch Uqkij4 Honeywell Aero S Band TT C Transceiver STC ms03Document2 pagesSatsearch Uqkij4 Honeywell Aero S Band TT C Transceiver STC ms03LêTiếnDungNo ratings yet

- PCTH 400 - T2 SyllabusDocument2 pagesPCTH 400 - T2 SyllabusAliseyNo ratings yet

- Notes Methods of PhilosophizingDocument2 pagesNotes Methods of PhilosophizingChristy YcongNo ratings yet

- Albanese2019 PDFDocument31 pagesAlbanese2019 PDFSorayda Hancco HuisaNo ratings yet

- Where Forest Is God - Lessons in Conservation From Western Ghats Tribes - Technology News, The Indian ExpressDocument4 pagesWhere Forest Is God - Lessons in Conservation From Western Ghats Tribes - Technology News, The Indian Expressvibha bNo ratings yet

- Effectiveness of Digital Music Platforms ' Social Media Interaction On Advertising Trust Using Cognitive AspectsDocument16 pagesEffectiveness of Digital Music Platforms ' Social Media Interaction On Advertising Trust Using Cognitive Aspectsceria Pro 02No ratings yet

- Dwnload Full Chemistry 10th Edition Zumdahl Solutions Manual PDFDocument35 pagesDwnload Full Chemistry 10th Edition Zumdahl Solutions Manual PDFlifelike.anenstkq2h100% (13)

- Combined Cycle Nandi Pur Power PlantDocument57 pagesCombined Cycle Nandi Pur Power PlantHassan FarazNo ratings yet

- Sideshow Alley BookletDocument8 pagesSideshow Alley Bookletapi-548309479No ratings yet

- Community GovernanceDocument17 pagesCommunity GovernanceJustin TayabanNo ratings yet

- CGV Lab Manual by Chandrashekar M ADocument34 pagesCGV Lab Manual by Chandrashekar M Anaquash1983No ratings yet

- Coaching in Hotel Management 2010Document52 pagesCoaching in Hotel Management 2010Tebebe SolomonNo ratings yet

- Dsi Suspa Systems Eta 07 0186 Suspa Wire Ex enDocument48 pagesDsi Suspa Systems Eta 07 0186 Suspa Wire Ex enAnonymous TxhyGfNo ratings yet

- The Future of Commerce Payme 441515Document12 pagesThe Future of Commerce Payme 441515HungNo ratings yet

- Watercolor Tapes Scrapbook For CollegeDocument65 pagesWatercolor Tapes Scrapbook For Collegejazmin cuestasNo ratings yet

- 10.13 Master Position ListDocument13 pages10.13 Master Position ListDangolNo ratings yet

- Special Relationships Between Organisms: ParasitismDocument2 pagesSpecial Relationships Between Organisms: Parasitismsmartkid167No ratings yet