Professional Documents

Culture Documents

Terminal Blocks: Notes For The Installation of Terminal Blocks From Phoenix Contact

Uploaded by

PezhmandmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terminal Blocks: Notes For The Installation of Terminal Blocks From Phoenix Contact

Uploaded by

PezhmandmCopyright:

Available Formats

Terminal blocks

Notes for the installation of terminal blocks from

Phoenix Contact

Application note

108769_en_02 © PHOENIX CONTACT 2020-05-19

1 Description Table of contents

This document provides an overview of the installation of 1 Description .................................................................. 1

terminal blocks from Phoenix Contact. 2 Personnel requirements .............................................. 2

It describes how to connect copper wires. 3 Mounting terminal blocks............................................. 2

Please also observe the notes printed on the product and 4 Installing terminal blocks.............................................. 2

the instructions supplied.

4.1 Screw connection ................................................ 3

4.2 Spring-cage connection....................................... 3

4.3 Push-in connection .............................................. 4

4.4 Fast connection ................................................... 4

4.5 Bolt connection.................................................... 5

4.6 Barrier connection ............................................... 5

5 Distributor terminal block ............................................. 6

6 Accessories ................................................................. 7

6.1 Bridges ................................................................ 7

6.1.1 Plug-in bridges (FBS...) ............................ 7

6.1.2 Insertion bridges (EB...)............................ 7

6.1.3 Chain bridge (KB...).................................. 8

6.1.4 Fixed bridge (FBI...).................................. 8

6.1.5 Step bracket (STL...) ................................ 8

6.2 Disconnect points and connectors....................... 8

6.3 Test adapters....................................................... 8

Make sure you always use the latest documentation.

It can be downloaded at phoenixcontact.net/products.

Terminal blocks

2 Personnel requirements 4 Installing terminal blocks

Only electrically qualified personnel may install and operate Only use accessories and tools recommended by

terminal blocks. Phoenix Contact.

The qualified persons have to be familiar with the basics of Observe the corresponding technical data.

electrical engineering. They must be able to recognize and You will find information:

prevent danger.

– On the product

This symbol on the packaging indicates that only – On the packing label

personnel familiar with electrical engineering is al-

– In the supplied documentation

lowed to install and operate terminal blocks.

– On the web at phoenixcontact.net/products under the

product

3 Mounting terminal blocks – Packing slips and application notes for the Ex area can

be found in the product download area at

• When mounting terminal blocks side by side, ensure

phoenixcontact.net/products.

that the required air clearances and creepage distanc-

es are observed. This is particularly important if differ- – In the catalog

ent sizes or series are mounted side by side.

Defective terminal blocks

• Install terminal blocks and accessories in suitable hous-

ings. Observe the specifications for touch protection. • Only operate properly working terminal blocks.

• Immediately take defective terminal blocks out of ser-

DIN rail mounting vice.

• Mount an end bracket onto the DIN rail. • Replace damaged terminal blocks. Repairs are not

• Snap on the terminal blocks. possible.

• Place terminal blocks with clamp foots onto the DIN rail

with the tensioning screw loosened. Tighten the screw

to the specified torque.

• For optical or electrical separation, partition plates or

covers can be snapped on between the terminal blocks.

• When the terminal blocks are mounted side by side, fit

the corresponding cover to the end terminal block with

the open half of the housing.

• Finally, snap on another end bracket.

Direct mounting

Some terminal block ranges can be directly screwed to a

mounting surface via flanges or securing pins.

• Use suitable screws to secure terminal blocks with

flanges on the intended mounting surface.

• For terminal blocks with an open half of the housing, fit

the corresponding cover and flange to the end terminal

block.

108769_en_02 PHOENIX CONTACT 2/8

Terminal blocks

4.1 Screw connection 4.2 Spring-cage connection

Series Series

DIK... SSK... UKH... UT... MSB... MZFK... STIO... ZDIK...

MUT... STU... UK... UTI... MSBV... ST... STME... ZVIOK...

UTME... MSDB... STI... STU...

Example Example

Figure 1 Screw connection Figure 2 Spring-cage connection

Connecting the conductor Connecting the conductor

• Strip the specified length off the conductors. • Strip the specified length off the conductors.

• Flexible conductors can be fitted with ferrules. • Flexible conductors can be fitted with ferrules.

Crimp the ferrules using crimping pliers. Ensure that the Crimp the ferrules using crimping pliers. Ensure that the

test requirements in accordance with DIN 46228-4 are test requirements in accordance with DIN 46228-4 are

met. met.

The length of the ferrule corresponds to the stripping The length of the ferrule corresponds to the stripping

length of the conductor. length of the conductor.

• Insert the conductors into the terminal points as far as • Push a screwdriver into the angular actuation shaft to

they will go. open the terminal point.

• Tighten the screws of all terminal points. Observe the Use a suitable bladed screwdriver. For tool recommen-

specified torque. dations, please refer to the accessories.

We recommend to also tighten the terminal points of • Insert the conductor into the round connection opening

terminal blocks that are not used. as far as it will go.

• If you want to connect more than one conductor per ter- • Remove the screwdriver to establish the conductor

minal point, check the specifications regarding the con- connection.

nection capacity. The specifications apply to the • Reinsert the screwdriver into the actuation shaft to

connection of two conductors of the same cross section release the conductor.

and the same conductor type.

• Loosen the terminal screw to open the terminal point

and remove the conductor.

108769_en_02 PHOENIX CONTACT 3/8

Terminal blocks

4.3 Push-in connection 4.4 Fast connection

Series Series

MP... PT... PTIO... PTRV... QT...

MPT... PTCB... PTMC... PTU... QTC...

PTI... PTME... PTV... QTCU...

Example

Example Figure 4 Fast connection

Figure 3 Push-in connection

Connecting the conductor

Connecting the conductor Fast connection is suitable for conductors with PVC and PE

insulation. Fast connection terminal blocks have an orange

• Strip the specified length off the conductors.

swiveling lever.

• Flexible conductors can be fitted with ferrules.

• Insert the stripped conductor into the round conductor

Crimp the ferrules using crimping pliers. Ensure that the guide from the rotary connection to the stop.

test requirements in accordance with DIN 46228-4 are

• Insert a bladed screwdriver into the angular orange-col-

met.

ored actuation shaft.

The length of the ferrule corresponds to the stripping

length of the conductor. • Rotate the conductor connection to the middle of the

terminal block until it snaps into place.

• Rigid conductors and flexible conductors with ferrules

can be inserted directly into the round opening of the Reconnection

terminal block without using tools.

• For small conductor cross sections and flexible conduc- • Before reconnecting the conductor, cut off the wired

tors without ferrules, you first have to open the terminal point of the conductor at an adequate distance.

point.

For this purpose, push the push button down using a

bladed screwdriver.

Releasing the conductor

• Push down the push button using a bladed screwdriver

to release the conductor.

108769_en_02 PHOENIX CONTACT 4/8

Terminal blocks

4.5 Bolt connection 4.6 Barrier connection

Series Series

HV... RT... UHV... BT...

OTTA... RBO... BTO...

BTH...

Example

Figure 5 Bolt connection Example

Figure 6 Barrier connection

• Strip off the conductor. Provide the conductor with a

ring cable lug in accordance with DIN 46234, • Strip off the conductors. Provide the conductor with a

DIN 46235, or DIN 46237. The stripping length de- ring cable lug in accordance with DIN 46234,

pends on the ring cable lug. DIN 46235, or DIN 46237. The stripping length de-

If you connect two conductors, only use cable lugs for pends on the ring cable lug.

crimp connections in accordance with DIN 46235. If you connect two conductors, only use cable lugs for

• Crimp the ring cable lugs using suitable crimping pliers. crimp connections in accordance with DIN 46235.

Ensure that the test requirements are met. • Crimp the ring cable lugs using suitable crimping pliers.

• Use insulated cable lugs or insulate the cable lugs using Ensure that the test requirements are met.

a shrink sleeve. • Insert the ring cable lug into the connection point.

• Insert the ring cable lug, the washer, and the hex nut • Tighten the screw to the specified torque.

into the connection point in this order. • Use a maximum of two cable lugs per bolt.

• Tighten the hex nut to the specified torque using a sock-

et wrench. For tool recommendations, please refer to

the accessories.

• Use a maximum of two cable lugs per bolt.

108769_en_02 PHOENIX CONTACT 5/8

Terminal blocks

5 Distributor terminal block

Series

PTU... UDB...

STU... UKH...

Example

Figure 7 Distributor terminal blocks (example)

If you use distributor terminal blocks for power distribution,

observe the conditions for reducing the conductor cross

sections within a circuit.

Here, the requirements of IEC 60364-4-43

(DIN VDE 0100-430) apply, for example.

108769_en_02 PHOENIX CONTACT 6/8

Terminal blocks

6 Accessories

6.1 Bridges Bridging between non-adjacent terminal blocks

Connect the desired number of positions to form terminal • Disconnect the contact tab of the bridge for the terminal

block groups with the same potential. Different bridges can to be skipped.

be used for this purpose.

– Plug-in bridge (FBS...) Cut-to-length bridges

– Insertion bridge (EB...) • If you use cut-to-length bridges, the rated voltage is re-

– Chain bridges (KB...) duced.

– Fixed bridges (FBI...) • To maintain the required air clearances and creepage

– Step brackets (STL...) distances, install the intended covers and partition

plates.

If neighbored bridges are located directly opposite of each

• If cut-to-length bridges are located directly opposite of

other, you have to fit an insulation plate, a cover, or a parti-

each other, you have to fit an insulation plate, a cover,

tion plate in between. This is necessary to maintain the re-

or a partition plate in between.

quired air clearances and creepage distances.

From a certain voltage onwards, you have to insert an insu- Reducing bridge

lation plate or a cover at the ends of the bridge rail.

A reducing bridge enables terminal blocks with different

If the bridges are used for bridging between non-adjacent rated cross sections to be connected easily. Power blocks

terminal blocks, the rated voltage is reduced. can be created using the reducing bridge.

Observe the maximum rated currents when using bridges.

6.1.2 Insertion bridges (EB...)

6.1.1 Plug-in bridges (FBS...)

Figure 9 Insertion bridges

Figure 8 Plug-in bridges

• Connect the desired number of positions to form termi-

nal block groups with the same potential. • Insert the bridge into the open terminal points of the ter-

• To do so, push a plug-in bridge into the function shaft of minal blocks as far as it will go.

the terminal block as far as it will go. • Close the terminal point to fasten the bridge in the ter-

• Terminal blocks with a double function shaft can be minal block.

used in the same way to implement flexible chain bridg- • Depending on the terminal block type, insert the con-

ing or bridging between non-adjacent terminal blocks. ductor into the terminal point above or below the bridge

• When mounting plug-in bridges with more than 20 posi- metal.

tions, you must mount the bridge from the outside in- • Note that the maximum connection cross section is

wards. First insert the two outer contact tabs into the generally reduced by one level.

bridge shaft. Then mount the bridge inwards from both

sides.

108769_en_02 PHOENIX CONTACT 7/8

Terminal blocks

6.1.3 Chain bridge (KB...) 6.1.5 Step bracket (STL...)

Figure 10 Chain bridges Figure 12 Step bracket

• Remove the flap on the first chain bridge so that you ob-

tain a support bracket for laying the subsequent bridge.

• After inserting the support bracket into the bridge shaft,

mount the other chain bridge.

The step bracket enables bridging of terminal blocks of dif-

6.1.4 Fixed bridge (FBI...)

ferent sizes.

Figure 11 Fixed bridge • Mount the step bracket into the bridge shaft of the termi-

nal blocks. Screw tight the step bracket.

6.2 Disconnect points and connectors

• Only operate the disconnect points of test disconnect

terminal blocks and connections when the system is at

no load and switched off. Exceptions are specified in

the documentation.

The maximum current carrying capacity of test disconnect

terminal blocks and terminal blocks with connections are

often reduced compared to equivalent feed-through termi-

nal blocks.

6.3 Test adapters

• In the case of hazardous voltages, create the test circuit

using our test adapters only after the circuit was discon-

• Insert the fixed bridges into the bridge shaft of the termi- nected.

nal blocks. Tighten the bridge screws to the specified

• After measurement, only dismantle the test circuit when

torque.

the system is at no load and switched off.

• You can separate any number of positions from the

multi-position bridge strips.

108769_en_02 PHOENIX CONTACT GmbH & Co. KG • Flachsmarktstraße 8 • 32825 Blomberg • Germany 8/8

phoenixcontact.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Gen V LT1 and LT4 Installation GuideDocument11 pagesGen V LT1 and LT4 Installation Guideavi youthNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4a-W24 - SimpleIntegrations - Student - Guide (1) - EIBDocument157 pages4a-W24 - SimpleIntegrations - Student - Guide (1) - EIBmaruthi63100% (1)

- Invisible Hands The Businessmen's Crusade Against The New Deal by Kim Phillips-FeinDocument349 pagesInvisible Hands The Businessmen's Crusade Against The New Deal by Kim Phillips-Feinfr33bookspleaseNo ratings yet

- Ocampo v. EnriquezDocument5 pagesOcampo v. EnriquezSerena RogerNo ratings yet

- HS 350 Home Cinema System: Owner'S ManualDocument36 pagesHS 350 Home Cinema System: Owner'S ManualPezhmandmNo ratings yet

- SimplIQ Software Manual - MAN-SIMSWDocument226 pagesSimplIQ Software Manual - MAN-SIMSWPezhmandm100% (1)

- Simatic ET 200SP Digital Output Module F-DQ 8x24VDC/0.5A PP HF (6ES7136-6DC00-0CA0)Document53 pagesSimatic ET 200SP Digital Output Module F-DQ 8x24VDC/0.5A PP HF (6ES7136-6DC00-0CA0)PezhmandmNo ratings yet

- Lynx L210-F2G-EX: Industrial Ethernet 10-Port SwitchDocument28 pagesLynx L210-F2G-EX: Industrial Ethernet 10-Port SwitchPezhmandmNo ratings yet

- Micro Drives pdc1000 Manual en-US en-USDocument36 pagesMicro Drives pdc1000 Manual en-US en-USPezhmandmNo ratings yet

- Operation Management CHP 1 5Document82 pagesOperation Management CHP 1 5Games FunNo ratings yet

- Progress Test 2Document13 pagesProgress Test 2Enrique GarciaNo ratings yet

- Syllabus For I - Viii Semesters: Department of Electronics and Instrumentation EngineeringDocument188 pagesSyllabus For I - Viii Semesters: Department of Electronics and Instrumentation EngineeringRavindra VankinaNo ratings yet

- Suchitwa Mission - YP - Modified FinalDocument3 pagesSuchitwa Mission - YP - Modified Finalsandeep pNo ratings yet

- Empowering Leadership and Innovative Work Behavior: A Moderated Mediation ExaminationDocument16 pagesEmpowering Leadership and Innovative Work Behavior: A Moderated Mediation ExaminationMuhammad SarfrazNo ratings yet

- MGT3102 Case StudyDocument2 pagesMGT3102 Case StudyMon LuffyNo ratings yet

- Corp CommrevDocument39 pagesCorp CommrevMary Charlene ValmonteNo ratings yet

- TurboTalk Vol11Document12 pagesTurboTalk Vol11Prastowo PriyatmokoNo ratings yet

- Codal Practices For RCC Design Part A General by VKMehtaDocument22 pagesCodal Practices For RCC Design Part A General by VKMehtavijaymehta3450% (1)

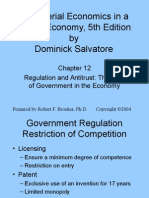

- Managerial Economics in A Global Economy, 5th Edition by Dominick SalvatoreDocument22 pagesManagerial Economics in A Global Economy, 5th Edition by Dominick SalvatoreYentl Rose Bico RomeroNo ratings yet

- Case Method 1Document8 pagesCase Method 1Abcid BlancaNo ratings yet

- Tanzania Mzumbe llb1 2020 ConspincyDocument3 pagesTanzania Mzumbe llb1 2020 ConspincyabdulNo ratings yet

- Interrupts in Atmega16Document3 pagesInterrupts in Atmega16Anoop S PillaiNo ratings yet

- Av RemoveDocument616 pagesAv RemoveSlobodan VujnicNo ratings yet

- Proposal NewDocument17 pagesProposal NewbaseNo ratings yet

- Optimization of Suspension DesignDocument9 pagesOptimization of Suspension Designmult69No ratings yet

- Tea Production in Sri LankaDocument14 pagesTea Production in Sri LankaМаркоСмиљанићNo ratings yet

- Assignment 3 AmazonDocument6 pagesAssignment 3 AmazonSangeeta Bansal0% (2)

- Jalosjos v. COMELECDocument9 pagesJalosjos v. COMELECshhhgNo ratings yet

- Abelardo Rodríguez, Ann Kendall (2001)Document14 pagesAbelardo Rodríguez, Ann Kendall (2001)Alexander J. SicosNo ratings yet

- Byron v. Boone and Audray S. Boone v. United States, 470 F.2d 232, 10th Cir. (1972)Document8 pagesByron v. Boone and Audray S. Boone v. United States, 470 F.2d 232, 10th Cir. (1972)Scribd Government DocsNo ratings yet

- Trans-Asia Shipping Lines, Inc. vs. Court of AppealsDocument19 pagesTrans-Asia Shipping Lines, Inc. vs. Court of AppealsYeu GihNo ratings yet

- Print Server Scalability and Sizing Technical Overview WhiteDocument14 pagesPrint Server Scalability and Sizing Technical Overview Whiteapi-3734769No ratings yet

- (Term Paper) The Rationale of Shari'ah Supporting Contracts - A Case of MPODocument22 pages(Term Paper) The Rationale of Shari'ah Supporting Contracts - A Case of MPOHaziyah HalimNo ratings yet

- 1 - Aguirre, Maria Lourdes CDocument11 pages1 - Aguirre, Maria Lourdes CSanka ReaNo ratings yet

- Minutes AircraftSafetySubcom 03242015Document19 pagesMinutes AircraftSafetySubcom 03242015Elmer VillegasNo ratings yet