Professional Documents

Culture Documents

Instruction Manual Electronic Brake Units Frenomat®, Frenostat® For AC - Motors (Version: 05/2013)

Uploaded by

radhoinezerellyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual Electronic Brake Units Frenomat®, Frenostat® For AC - Motors (Version: 05/2013)

Uploaded by

radhoinezerellyCopyright:

Available Formats

instruction manual electronic brake units

frenomat® , frenostat® for AC - motors ( version : 05/2013 )

Utilisation

frenomat and frenostat brake units are designed for the power brake of standard 3 phase AC- motors. A rugged current converter produces a

powerful brake torque with a magnetic field inside the 3-phase AC - motor. The brake sequence is automatically initiated after a motor stop

command and is finished after the standstill of the motor rotation. The standstill is detected by the internal electronics.

Safety precautions

Limits in purpose: This brake unit is used for braking 3 phase induction motors in general industrials use.

• DANGER ! PC-board and all terminals are under high voltage !

• Do not connect earth or a PLC-voltage at this terminals ! Earth may only be connected at the earth screw !

• Electrical construction work must be done by a qualified expert.

• Do mount cooling rips vertically.

• Long leads should be avoided, especially between terminal 8 and the choke.

• Use ohmmeters or multimeters for testing.

• Do not use a test lamp, a high voltage generator or electric bell

• Gound must be connected securely with a ground wire

• Wiring must be done after installation only when power is off

Before you switch on power make sure following points :

1. power must be only connected with terminal a and 8 (Choke). Any other power connection will distroy the brake unit !

2. The power supply voltage must not exceed the marked value on the cover label.

3. Make sure that there is no short circuit in the wiring and that ground is connected to ground terminals only. There is no short circuit

protection in the unit !

Selection of fuses

All types of brake units have to be externally provided with 2 branch circuit protection fuses in lead of the choke and terminal 8 and a.

Fuse size : 150 % of the rated motor current

The 2 amp fuse must be provided in terminal n1

Selection of brake contactor

Use the same size as for the motor contactor. The ON and OFF switching of the brake contactor operates without any current-load ! This is

why an AC contactor is sufficiant .

Selection of wires

For the wiring use the same size of wires as you have provided for the motor power and the motor control circuit.

First set in operation :

Currentfree operation

Remove motor fuses. Adjust time potentiometer at its maximum (clockwise) and current potentiometer at its minimum (Counter – clw)

Switchlock check

Check if there is no possibilty that brake contactor and motor contactor could be activated at the same time . Observe the function of the

LED’s on the PC board beside the time potentiometer ( frenomat has no LED’s !) :

• LED „P“ = Power

• LED „M“ = Motorcontactor is ON

• LED „B“ = Brake contactor is ON

Motorcontactor K1 ON: LED „M“ on OFF: LED „M“ off

Brakecontactor K2 OFF: LED „B“ off K1 not activated

K2 + LED „B“ on

Locking check K 2 manually on: K1 manually on:

K1 drops off K2 drops off

Brake current adjustment

Install motor fuses and adjust time potentiometer „T“ clockwise at 1/4.

When the motor is warm activate the brake and turn the current potentiometer „I“ slowly clockwise; observe the amount of current at the bar-

graph-display. One bar-line lights for 10 % of the max. device current. The maximum value should be adjusted to 3 times of the nominal motor

current.

There is no bar-graph display at frenomat 2 . In this case apply a DC-ampmeter at terminal b and observe the current while you turn the

current potentiometer clockwise . The current of type frenomat may not exceed 30 A !

During brake operation the states „brake on“ B and „stoppage detector“ S are indicated by the LED’s B and S. ( frenomat has no LED‘s ) .

When the motorspeed has reduced at 10 % of nominal speed, LED „S“ is off and an internal time process is started. The manually adjusted

time will be added.

LED „O“ Overflow is flashing when the heatsink of the brake unit has become too hot because of a too large number of brakings within a short

time. As long as it is overheated, motorstarting is locked. ( frenomat has no LED „O“ Overload; )

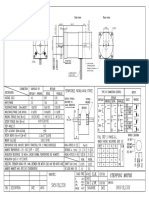

Basic circuit for frenomat and frenostat wiring

You might also like

- Operation Manual NSFC01-02 Lift Door ControllerDocument39 pagesOperation Manual NSFC01-02 Lift Door ControllerHƯNG NGUYỄN THANHNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Generator Output Power Sensor TroubleshootingDocument5 pagesGenerator Output Power Sensor Troubleshootingmuhammad arifNo ratings yet

- GD12A Ignition Controller ManualDocument21 pagesGD12A Ignition Controller ManualMr.Thawatchai hansuwanNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Audi TT 1.8L Camshaft Valve Check P0011Document4 pagesAudi TT 1.8L Camshaft Valve Check P0011Kandy KnNo ratings yet

- Manual 1500 / 2500 Va Corona Treater (Regular Model With Power Control Feature) IndexDocument6 pagesManual 1500 / 2500 Va Corona Treater (Regular Model With Power Control Feature) IndexRaja Pathamuthu.GNo ratings yet

- IRMC Transistor CheckDocument7 pagesIRMC Transistor ChecksebifuenteNo ratings yet

- Fit transponder immobiliser instructionsDocument8 pagesFit transponder immobiliser instructionsLuis Perez17% (6)

- BRAKE FAILURE INDICATOR CIRCUIT GUIDEDocument28 pagesBRAKE FAILURE INDICATOR CIRCUIT GUIDErishika71% (7)

- Interruptor de Parada de Emergencia Motor 3516 MarinoDocument9 pagesInterruptor de Parada de Emergencia Motor 3516 MarinoJoséNo ratings yet

- CT2 Motor Controller Installation - ComNavDocument11 pagesCT2 Motor Controller Installation - ComNavDare DoreNo ratings yet

- Futaba MC30CR FET Speed Controller Futm0932-ManualDocument1 pageFutaba MC30CR FET Speed Controller Futm0932-Manualxlam99No ratings yet

- DYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDocument18 pagesDYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDavid Coronado100% (1)

- 1g Charging Starting System-1Document21 pages1g Charging Starting System-1Anthony DizonNo ratings yet

- CD Application NotesDocument48 pagesCD Application NotesJuan Carlos PiotrovskiNo ratings yet

- Snr. ElectDocument17 pagesSnr. ElectAhmed AbdeltawabNo ratings yet

- Thyrotronic Description EngDocument5 pagesThyrotronic Description EngHillary Mcgowan100% (1)

- PLC Traction Temporary Run Manual PDFDocument13 pagesPLC Traction Temporary Run Manual PDFfreddyjoertyNo ratings yet

- RSS3 InformationDocument6 pagesRSS3 InformationndukNo ratings yet

- DKG-155 Manual Start Unit: Installation and Operating InstructionsDocument2 pagesDKG-155 Manual Start Unit: Installation and Operating InstructionsMazatlanSinaloaNo ratings yet

- Manual Utilizare Sistem Garaj - SPIDODocument78 pagesManual Utilizare Sistem Garaj - SPIDOTheodora GherdanNo ratings yet

- Cursor 13 Iveco CalibracionDocument59 pagesCursor 13 Iveco CalibracionWaliixiitoo Landerxito Thv Xikito AL93% (28)

- Anti-Lock Brake SystemDocument21 pagesAnti-Lock Brake SystemWoong-Sub LeeNo ratings yet

- Electric Switch Over Valve For Boost Pressure ControlDocument2 pagesElectric Switch Over Valve For Boost Pressure ControlPedro BaptistaNo ratings yet

- LTS: Locomotive Testing ShopDocument4 pagesLTS: Locomotive Testing ShoprockeygreatNo ratings yet

- $37KW-Above (Soft Strat 3070)Document12 pages$37KW-Above (Soft Strat 3070)phanhongquanphqNo ratings yet

- Welding Machine AWELCO Repspec125Document13 pagesWelding Machine AWELCO Repspec125thorsharp100% (2)

- Service Manual: XS-G3 XS-G4 XS-G5Document49 pagesService Manual: XS-G3 XS-G4 XS-G5ferdelvastoNo ratings yet

- CC-S3A+Manual Dysplay CNCDocument62 pagesCC-S3A+Manual Dysplay CNCJoseph Arturo Solis100% (2)

- 1079 3Document5 pages1079 3Marco OlivettoNo ratings yet

- Digital Sensor: SupplyDocument6 pagesDigital Sensor: SupplyYUDI WAHYUDI 17249No ratings yet

- A510s Quick Setting Manual V09Document107 pagesA510s Quick Setting Manual V09Canokan DENİZNo ratings yet

- 037 - Diagnostic Information and ProceduresDocument332 pages037 - Diagnostic Information and ProceduresGedas GvildysNo ratings yet

- Volkswagen - New Beetle - Wiring Diagram - 2007 - 2008Document13,861 pagesVolkswagen - New Beetle - Wiring Diagram - 2007 - 2008Harshad NaringrekarNo ratings yet

- QW-MS605D Power SupplyDocument7 pagesQW-MS605D Power SupplydonsterthemonsterNo ratings yet

- Mechatronics Lab ManualDocument55 pagesMechatronics Lab ManualSoumi Bandyopadhyay SB100% (1)

- Akai LCT37Z6TA CMO (11-27-06) LCDDocument135 pagesAkai LCT37Z6TA CMO (11-27-06) LCDRicardo PicassoNo ratings yet

- 641 - 2051B ManualDocument10 pages641 - 2051B ManualPirv Maria AncaNo ratings yet

- Im PK 1603Document32 pagesIm PK 1603James James MorrisonNo ratings yet

- Temperature Controller: User'S ManualDocument32 pagesTemperature Controller: User'S ManualkmpoulosNo ratings yet

- H-Bridge PPDocument16 pagesH-Bridge PPMohammed HediaNo ratings yet

- Fluke - Troubleshooting Auto Electrical SystemsDocument23 pagesFluke - Troubleshooting Auto Electrical SystemsWesley YoungNo ratings yet

- PandarosDocument9 pagesPandarosTempest_LNo ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P281 O Solenoid G ElectricalDocument5 pagesDiagnostic Trouble Codes (DTC) : DTC P281 O Solenoid G Electricalluis eduardo corzo enriquezNo ratings yet

- Fuente Goldstar PDFDocument11 pagesFuente Goldstar PDFdirectNo ratings yet

- ICHG 500 Reference GuideDocument7 pagesICHG 500 Reference GuideShree KiranNo ratings yet

- s1000 Voltage RegulatorDocument36 pagess1000 Voltage RegulatorAnonymous 7PtTlrNo ratings yet

- Charging System: General InformationDocument39 pagesCharging System: General InformationEngine Tuning UPNo ratings yet

- CHGDocument22 pagesCHGDadang Lukmanul Hakim100% (1)

- Diagnostic InstructionsDocument4 pagesDiagnostic Instructionsjosecuellar69100% (1)

- Life Speed Service ManualDocument13 pagesLife Speed Service ManualCxar RodNo ratings yet

- Loco Test Shop: Commissioning Test Requirements and Procedure For Electrical EquipmentDocument3 pagesLoco Test Shop: Commissioning Test Requirements and Procedure For Electrical EquipmentutkarshNo ratings yet

- GARD G6000: Installation Instructions For Swift Road BarriersDocument24 pagesGARD G6000: Installation Instructions For Swift Road BarriersShah JeeNo ratings yet

- D6N XL Differential Steering, Electrohydraulic Implement Troubleshooting GuideDocument5 pagesD6N XL Differential Steering, Electrohydraulic Implement Troubleshooting GuideMarco OlivettoNo ratings yet

- Lucas Generator and Control Box Tests PDFDocument28 pagesLucas Generator and Control Box Tests PDFdkjohnbarjoNo ratings yet

- Manual Icm 450Document8 pagesManual Icm 450CoolSolutions ElSalvadorNo ratings yet

- 001192187GS01Document33 pages001192187GS01radhoinezerellyNo ratings yet

- E Waste PCB Recycling LineDocument19 pagesE Waste PCB Recycling LineradhoinezerellyNo ratings yet

- LT3SM00M: Product Data SheetDocument3 pagesLT3SM00M: Product Data SheetradhoinezerellyNo ratings yet

- Pmu Editor Eng PDFDocument235 pagesPmu Editor Eng PDFMahmoud RummanNo ratings yet

- Teaching PLC Chap3Document39 pagesTeaching PLC Chap3bhagirath kansaraNo ratings yet

- Operation Manual: Ssep148 Twin Screw ExtruderDocument22 pagesOperation Manual: Ssep148 Twin Screw ExtruderradhoinezerellyNo ratings yet

- Data Sheet Ih58mDocument3 pagesData Sheet Ih58mradhoinezerellyNo ratings yet

- C4.4 MSC3 GENERATOR SET Operation and Maintenance Manual GensetDocument164 pagesC4.4 MSC3 GENERATOR SET Operation and Maintenance Manual GensetAnand100% (10)

- Allrounder 470-520 CDocument8 pagesAllrounder 470-520 CradhoinezerellyNo ratings yet

- Keba User Manual (4030) - 27march2006Document100 pagesKeba User Manual (4030) - 27march2006Daniel Pirvu86% (7)

- Twin-Screw Extruder For PVC Profiles: Voithstr. 2 D - 71272 Renningen / GermanyDocument1 pageTwin-Screw Extruder For PVC Profiles: Voithstr. 2 D - 71272 Renningen / GermanyradhoinezerellyNo ratings yet

- Operation Manual: Ssep148 Twin Screw ExtruderDocument22 pagesOperation Manual: Ssep148 Twin Screw ExtruderradhoinezerellyNo ratings yet

- NEED Manual Ver. 1.7 enDocument297 pagesNEED Manual Ver. 1.7 enradhoinezerellyNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Nanotec SH5618L2308 - SpecDocument1 pageNanotec SH5618L2308 - SpecradhoinezerellyNo ratings yet

- Plastic TechnologyDocument171 pagesPlastic Technologyeitan-dalia4971No ratings yet

- Nanotec SH5618L2308 SpecDocument1 pageNanotec SH5618L2308 SpecradhoinezerellyNo ratings yet

- Supplementary Instructions L-BV2, L-BV5: Supplement To Instruction Manual 610.44440.40.000Document10 pagesSupplementary Instructions L-BV2, L-BV5: Supplement To Instruction Manual 610.44440.40.000radhoinezerellyNo ratings yet

- Análisis Del Moldeo Por Inyección .Document90 pagesAnálisis Del Moldeo Por Inyección .Lewis PuelloNo ratings yet

- Mathematical Modeling of Plastic Injection MouldDocument4 pagesMathematical Modeling of Plastic Injection MouldIJSTENo ratings yet

- FM X EN 2015 Manual Web PDFDocument292 pagesFM X EN 2015 Manual Web PDFAnwar Deen100% (1)

- Injection Molding Machine Inspection Manual: APRIL, 2013Document41 pagesInjection Molding Machine Inspection Manual: APRIL, 2013farNo ratings yet

- Injection Molding Machine Inspection Manual: APRIL, 2013Document41 pagesInjection Molding Machine Inspection Manual: APRIL, 2013farNo ratings yet

- LaserCAD User Manual PDFDocument144 pagesLaserCAD User Manual PDFgustavo0% (1)

- Supplementary Instructions L-BV2, L-BV5: Supplement To Instruction Manual 610.44440.40.000Document10 pagesSupplementary Instructions L-BV2, L-BV5: Supplement To Instruction Manual 610.44440.40.000radhoinezerellyNo ratings yet

- 7dko5wfg OpenPasswordFileDocument1 page7dko5wfg OpenPasswordFilefırtNo ratings yet

- Injection Molding Machine Inspection Manual: APRIL, 2013Document41 pagesInjection Molding Machine Inspection Manual: APRIL, 2013farNo ratings yet

- Operating Instructions L-BV2, L-BV5Document32 pagesOperating Instructions L-BV2, L-BV5radhoinezerellyNo ratings yet

- Operation Manual: Ssep148 Twin Screw ExtruderDocument22 pagesOperation Manual: Ssep148 Twin Screw ExtruderradhoinezerellyNo ratings yet

- Operation Manual: Ssep148 Twin Screw ExtruderDocument22 pagesOperation Manual: Ssep148 Twin Screw ExtruderradhoinezerellyNo ratings yet