Professional Documents

Culture Documents

Norma ASTM B 233-97 - Vergalhão de Alumínio para Fins Elétricos

Norma ASTM B 233-97 - Vergalhão de Alumínio para Fins Elétricos

Uploaded by

Anonymous w13t9b0 ratings0% found this document useful (0 votes)

7 views4 pagesOriginal Title

Norma ASTM B 233-97 - vergalhão de alumínio para fins elétricos

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesNorma ASTM B 233-97 - Vergalhão de Alumínio para Fins Elétricos

Norma ASTM B 233-97 - Vergalhão de Alumínio para Fins Elétricos

Uploaded by

Anonymous w13t9bCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Aly Designation: B 233 - 97

tit

Standard Specification for

Aluminum 1350 Drawing

1. Scope

1.1 This specification covers aluminum 1350 drawing stock

'9.52 mm) to 1.000 in, (25.40 mm) in diameter, in the

tempers shown in Table I. for drawing into wire for electrical

‘conductors (Explanatory Note | and Note 2).

1.2 The SI values of density and resistivity are to be

farded as the standard. For all other properties the inch-

cgarded as standard and the SI units

pound values are to be

may be

proximate.

Non 1—Prioe to 1975, aluminum fed a EC alumi

‘Nor 2-—The alumioum and temper designations conform to ANSE

Has 1 Aluminum 1380 corresponds to unified numbering system A91350

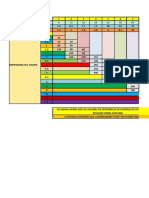

in accontance with Practice E 527 Table !Table 2Table STable 4Table 5

2. Referenced Documents

2.1 The following documents of the issue in effect on date

of material purchase form a part of this specification to the

extent re herein:

2.2 ASTM Standards:

B 193 Test Method for Resistivity of Electrical Conductor

Materials?

B 354 Terminology Relating to Uninsulated Metallic Elec

trical Conductors

B 557 Test Methods of Tension Testing Wrought and Cast

Aluminum- and Magnesium-Alloy Products”

B 830 Specification for Uniform Test Methods and Fre

quency

EM Test Methods for Chemical Analysis of Aluminum and

Aluminum-Base Alloys*

E 55 Practice for Sampling Wrought Nonferrous Metals and

Alloys for Determination of Chemical Composition*

Test Method for Optical Emission Spectrometric

Analysis of Aluminum and Aluminum Alloys by the

Point-to-Plane Technique*

E

eral Condotos ais the dst responsibilty of Subcommitee 801.07 on

igh Metal,

publinicd a5 B288 48 Last previous eton B233~92

ws i of ASTM Standards Nol 0202

Stock for Electrical Purposes'

tned designation 233: the mumber immediatly following the designation infcates the yar of

ot revioon, A pmber in parentheses indicates the year of last reapproval A

on etna change since the lst revision Or eappONa

‘TABLE 1 Tensile Property Limits

Tenate Sven

1509 30-97

1350-812 and 422 enr

35014 and HOF 103-138

{250H16 and 126 7-152

" appcabo to atoak sizes Brough 0.S0Din (T27O-mm) damete. The abe

acon’ briarper zee nese tempers shal be nego ate of Quy

E527 Practice for Numbering Metals and Alloys (UNS

23. American National Standard:

‘ANSI H35.1 Alloy and Temper Designation Systems

Aluminum®

24 National Bureau of Standards:

ook of ASTM Standards. V8 01.01

‘American Navona Standard Isat, 11 W. 2nd S.

‘TABLE 2 Chemical Requirements

lovee

‘icon, mae

Copper max

Manganese, max

(Chromium, max

Boron, max

Galturn, max

nasa plus ari, ttl, max

(ther elements, each. max

‘tne eamorts, otal, max

‘Numiewm in

7 peal hal egal be made ol for he eemens spectig ee

ti nowever he presence of oer elements is suspected rindcated in 8

[renee man tne spect lt, further anaes shal be made 10 ders

{Fe semonts ae not present in aunts excess ofthe spectig

‘TABLE 3 Electrical Resistivity Limits

Resitty Equator vou

Temper . ‘Conductty

ee SMCS. mt

i009. 027600 ee

1250-12 ana n> 28035 615

1350-Hi4 and Hos n2s080 ea

850-116 and H26 ooast26 613

130

TABLE 4 Equivalent Resistivity Values at 20°C

ne Resist Constants

Metered Conary, Votre:

BUCS “Rawtim tent yim pew

Cexper 100 ours t0a71 avers n.7281

Mmmm 619 aaei28 © Ne s19" 410792828

814 9028080 © reas1 1058 28080

815 .zecas © 8864 tour 08S

618 00z7e99 16762 0006 27000

“The equivalent resubvly values for 100 %

emouted rom the Andaman IEC value (1

‘etre each accurate to at east seven signa

feather conductivities (alumina) were dered

"proce fhe conduct aoe accurate

TAGS conductvay were each

58 Sunni) using conversion

rt gues. Crespenang valves

to thes by mating bythe

atest seven igliant tours

TABLE 5 Diameter Tolerances

Taesace, (om), Pus & nae

Seectiea ameter, in. Deviton of Waar Ben a aay

(oom) Diameter tem Point rom

‘Spectied Diameter spactied Dametar

Tare-aswo wSETaT ones} ‘0.00 (0.76)

9501-100(1273-2540) 0025 1068) 2.035 (0.89),

“Fer this specication, mean damete the average of he maximum damier

nd he minimum damter measured the same ansrere pane’ ly tee

legn,

Handbook 100, Copper Wire Tables?

3. Ordering Information

3.1 Orders for material under this specification shall include

the following information

3.1.1 Quantity,

3.1.2 Diameter (see 11.1),

3.1.3 Temper (see Table 1 and Explanatory Note 1 and Note

2,

3.1.4 Whether joints are permitted (see 8.1),

3.1.5 Whether tests of joints are required and number of

specimens (see 8.2),

4 31.6 Coil size and weight (see 14.2),

3.1.7 Whether wrapping of coils is required (see 14.3),

3.1.8 Special marking on tags, if required (see 14.4), and

3.1.9 Whether inspection or witness of inspection and tests

by purchaser's representative is required prior to shipment (see

Section 13),

4. Manufacture

4.1 Unless otherwise agreed upon at the time of placing the

order, the manufacturer shall have the option of producing the

Sock from either individually cast ingots or continuously cast

tars. Only one method of production shall be used on any

siven order,

4.2 Unless otherwise specified, the manufacturer shall have

the option of supplying stock in the H2X temper when H1X is

specified, and of supplying stock in the HIX temper when H2X

' specified. Only one temper shall be supplied in any given

ender (see Explanatory Note 1 and ANSI 1135.1).

§ Chemical Composition

|, 5:1 The stock shall conform to the requirements of Table 2

* avaiable fom the National Tesh

eal Infomation Service, 5285 Port Royal

4M, Springieit VA 22161

i

13

—— es

Ay 8 233

V2 boxe keallls

ron 416.333 ew ts

sane

Ue

06

28 to chemical composition. Conformance shall be determined

by the manufacturer by analyzing samples taken tthe tine the

ingots or continuously cast bars are poured, or samples taken

from the finished or semifinished product. If the manufacturer

hhas determined the chemical composition of the material

during the course of manufacture, he shall not be required to

sample and analyze the finished product.

5.2 Number of Samples—The number of samples taken for

‘determination of chemical composition shall be as follows:

5.2.1 When samples are taken at the time the ingots are

Poured, at least one sample shall be taken to represent each

‘group of ingots poured simultaneously from the same source of

‘molten metal

5.2.2 When samples are taken at the time continuously cast

bars are poured, at least one sample shall be taken to represent

the continuously cast length poured from each furnace load of

‘molten me

5.2.3 When samples are taken from the finished or semifin-

ished product, a sample shall be taken to represent each 5000

1 (2300. kg) or fraction thereof of material in the shipment,

except that no more than one sample shall be required per

continuous unjointed coil.

5.3 Methods of Sampling—Samples for determination of

‘chemical composition shall be taken in accordance with one of

the following methods:

5.3.1 Samples for chemical analysis shall be taken from the

material by drilling, sawing, milling, turning, or clipping

‘representative piece or pieces to obtain a weight of prepared

sample not less than 75 g. Sampling shall be in accordance

with Practice E 55.

5.3.2 Samples for spectrochemical and other methods of

analysis shall be suitable for the form of material being

analyzed and the type of analytical method used,

3a Methods of Analysis—The determination of chemical

composition shall be made in accordance with suitable chemi-

cal (Test Methods E 34), spectrochemical (Test Method E 227),

‘or other methods.

6. Workmanship

6.1 The stock shall be uniform in quality and temper and

shall be suitable for drawing into wire.

6.2 The stock shall be clean, sound, smooth, and free of

pipes, laps, cracks, kinks, twists, seams, damaged ends, exces-

sive oil, and other injurious defects within the limits of good

‘commercial practice.

7, Tensile Requirements

7A Limits:

7A The

shall confor

tensile test,

712 The

ensile strength of the respective tempers of stock

to the requirements specified in Table 1. All

sults shall be reported.

sile strength of joints made in the finished

stock shall be not less than 8500 psi (59 MPa) for 1350-0 and

not less than 11 000 psi (76 MPa) for the other tempers.

7.2 Number of Specimens—One specimen shall be taken

from each 5000-Ib (2300-kg) coil.

7.2.1 Tests to demonstrate conformance with 7.1.2 are not

required unl agreed upon at time of ordering. The number of.

specimens shall be as negotiated (see 8.2),

iy 8 233

7.3 Type of Specimens—Tension test specimens shall be the

full section of the stock, or specimens machined from it

Machined specimens shall conform to Fig. 8 of Test Methods

B 557. In case of dispute, tension test specimens shall be full

section.

7.4 Test Method— Tension tests shall be made in accor-

dance with Test Methods B 557. When tested in full section,

the free length between jaws of the testing machine shall be at

least 10 in, (250 mm) (Explanatory Note 2)

8. Joints é

8.1 The stock shall be furnished in continuous-length coils,

without joints, unless otherwise agreed upon between the

‘manufacturer and purchaser at the time of ordering. When

joints are permitted, the joints shall be made by electric-butt

welding, by cold-pressure welding, or by electric-butt, cold-

upset welding,

8.2 When requested by the purchaser and agreed to by the

‘manufacturer at the time of ordering, the tensile strength of

joints in finished stock shall be determined (see 7.2.1).

9. Resi

9.1 The electrical resistivity of the stock in the temper

supplied shall conform to the requirements specified in Table 3

(Explanatory Note 3).

9.2 Number of Specimens—One specimen is required per

30.000 Ib (14 000 kg) lot

9.3 Test Method— The resistivity tests shall be made on

full-section samples of the stock in accordance with Test

Method B 193.

ity

10. Density

10.1 For the purpose of calculating mass per unit length,

Weight, cross section, etc., the density of aluminum 1350 shall

be taken as 0.0975 Ib/in. (2705 kg/m’) at 20°C.

11, Diameter and Permissible Variations

11.1 The diameter of the stock shall be specified in decimal

fractions of an inch using three places of decimals or in

millimetres using two places of decimals.

11.2 The diameter of the stock shall be determined on at

least 10 % of the coils in alot. The diameter shall not vary from

that specified by more than the permissible variations specified

in Table 5,

12. Number of Tests and Retests

12.1 If a sample fails to conform to the requirements of

Sections Tand 9, two additional samples from the same coil

shall be tested. If either of these samples fails to conform, that

coil and the lot represented by the sample is subject to

132

rejection, However, the lot may be resubmitted for inspection

by testing every coil for the failed characteristic and sorting out

the defective coils.

12.2 If a coil fails to conform to the permissible diameter

variations specified in Table 5, each coil in the lot shall be

gaged and the nonconforming coils shall be rejected.

13, Inspection

13.1 Unless otherwise specified in the contract or purchase

corder, the manufacturer shall be responsible for the perfor

mance of all inspection and test requirements specified.

13.2 All inspections and tests shall be made at the place of

manufacture unless otherwise especially agreed to between the

manufacturer and the purchaser atthe time of the purchase.

13.3 The manufacturer shall afford the inspector represent

ing the purchaser all reasonable manufacturer's facilities to

satisfy him that the material is being furnished in accordance

with this specification.

134 An inspection lot shall consist of an identifiable quan-

tty of stock subjected to inspection at one time. Each lot shall

consist of stock of the same size and temper manufactured

under essentially the same conditions at essentially the same

time.

14, Packaging and Marking

14.1 The material shall be shipped in coils.

142 Coil size and mass shall be agreed upon by the

manufacturer and the purchaser at the time of placing the order.

14.3 Coils will be wrapped for shipment only when speci-

fied in the contractor order. The quality and application ofthe

‘wrapping material shall be adequate to protect rods from

damage incident to normal handling and shipment.

144 Each coil shall bear a tag showing the manufacturer's

name of trademark, size, aluminum number, and temper of

material. If additional information isto be required on the tags,

it shall be arranged with the manufacturer at the time of

purchase,

15. Statistical Process Control

15.1 When statistical process control (SPC) is used, the

statistical sampling of each lot shall comply with Specification

B 830. The process control ratio (CPK) shall not be less than

1.3. Control charts following the form and style of ASTM

“Manual 7 shall be provided, if requested, to the customer with

‘each order that is representative of the processes used in the

‘manufacture of the product.

16. Keywords

16.1 aluminum; aluminum drawing stock; aluminum wire;

drawing stock; wire

Aly B 233

EXPLANATORY NOTES

Nore 1—The selection of the proper temper of stock will depend onthe

ti of wire to he drawn, the wire properties desired, and the wire deawing

pes employed

‘Noe 2—For definitions of terms relating to conductors, reference

thuld be made fo Terminology B 354,

Nore 3—The HIX tempers (strain-hardened only) and the HOX tem-

ps (sminardened and partially annealed) of stock are considered

spay suitable for electrical purposes. ‘i

Nae 4 In tension tess, the values obtained may be affected by testing

‘pet It is recommended that for conformance criteria the testing speed

Shui ot exceed 015 infin. (05 mm/mm) of gage length or distance

Teveen grips per minute

Nort SRelationships that may be useful in connection with the

tof electrical resistivity presribed in Table 3 are shown in Table 4

Resistivity units are based on the Intemational Annealed Copper Standard

(ACS) adopted by TEC in 1913, which is Vax O-mm/m at 20°C for 100

conductivity. The value of 0.017241 Omm"/m at 20°C isthe international

‘equivalent of volume resistivity of annealed copper equal 10 100%

conductivity. A complete discussion of this subject is contained in NBS

“Handbook 100, Copper Wire Tables. The use of five significant figues in

expressing resistivity does not imply the need for greater accuracy of

measurement than that specified in Test Method B 193. The use of five

significant figures is required for reasonably accurate reversible conver

sion from one set of resistivity units to another. The equivalent resistivity

values in the table were derived from the functional IEC value (és

‘Q-mm*im) computed to seven significant figures and then rounded to five

significant gues,

The American Society fr Tesing an Matera takes no poston regpectng the vakay of any patent ightsassertedin connection

‘sth any tem mentoned in is standard Users of is standard are expressly advised tat termination ofthe vay f any such

patent nights andthe rk of inngement of such igs are entirely ther own responstaly

This standard is subject to revision at anytime bythe responsible tetrical committee and st be rviowed avery Wve years and

itporrevced otha reaporove or wiharan. Your comment are nv eter revision oft slansardorforadatonal andra

and shout be adressed to ASTM Headquartars. Your comments wl Yeceive cre consieraton ata meeting othe esponaiNe

{echnical conmitee, whch you may afen. Mf you fea that your comments have rot recaved afar hearng you SNOU Make Your

views known the ASTM Commies on Stadars.atthe addres shown belo.

‘Thi standard is copynghtedby ASTM. 100 Bar Harbor Drive, PO Box C700, West Conshohocken, PA 18428-2069, Unted States.

mata! reprints (ePgle oF matple copes) of bis standard may be obtained ty contacting ASTM a the above agcrss Or at

£6104882-9585 (phorw), 810-8329855 (ay, or senice@ asin og e-mal): or @wough te ASTM wobsto (wir. asin 7).

133,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Bs en Iso 16092 1 2018 PDF DownloadDocument57 pagesBs en Iso 16092 1 2018 PDF DownloadAnonymous w13t9b80% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Bs en Iso 16092 3 2018 PDF DownloadDocument49 pagesBs en Iso 16092 3 2018 PDF DownloadAnonymous w13t9b100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Duroline Catalogo 2009 enDocument12 pagesDuroline Catalogo 2009 enAnonymous w13t9bNo ratings yet

- Tabela DobradeiraDocument4 pagesTabela DobradeiraAnonymous w13t9bNo ratings yet

- PF - MM - Pan - PH - Din - 7985Document1 pagePF - MM - Pan - PH - Din - 7985Anonymous w13t9bNo ratings yet

- Fieiras PDFDocument1 pageFieiras PDFAnonymous w13t9bNo ratings yet

- Cronograma Do Seminário de Qualificação Do Estágio IIDocument4 pagesCronograma Do Seminário de Qualificação Do Estágio IIAnonymous w13t9bNo ratings yet

- Cronograma One by CoralDocument2 pagesCronograma One by CoralAnonymous w13t9bNo ratings yet

- Exemplo Laudo PDFDocument7 pagesExemplo Laudo PDFAnonymous w13t9bNo ratings yet

- Adequação de Uma Prensa Excêntrica de Engate Por Chaveta As Normas de Segurança BrasileiraDocument4 pagesAdequação de Uma Prensa Excêntrica de Engate Por Chaveta As Normas de Segurança BrasileiraAnonymous w13t9bNo ratings yet