Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsHose Discharge Capacity Graphs

Hose Discharge Capacity Graphs

Uploaded by

William DaslerCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Monitoring Findings Inspection SPOB PUTRA PASIFIC 01Document2 pagesMonitoring Findings Inspection SPOB PUTRA PASIFIC 01William DaslerNo ratings yet

- Marine Emergency Communication Flow Chart: MasterDocument1 pageMarine Emergency Communication Flow Chart: MasterWilliam DaslerNo ratings yet

- Fotonya Sesuaikan Dengan Ketentuan Dari Web Nya Ga Kurang N Ga Lebih Tanggal Stay Dimnulai Dari KedatanganDocument11 pagesFotonya Sesuaikan Dengan Ketentuan Dari Web Nya Ga Kurang N Ga Lebih Tanggal Stay Dimnulai Dari KedatanganWilliam DaslerNo ratings yet

- Surat Hasil Rafid AntigenDocument2 pagesSurat Hasil Rafid AntigenWilliam DaslerNo ratings yet

- No.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10Document9 pagesNo.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10William DaslerNo ratings yet

- Tender Jack Up Rig PHKTDocument1 pageTender Jack Up Rig PHKTWilliam DaslerNo ratings yet

- AR 2019 PT Sillomaritime Perdana TBK FA HRDocument258 pagesAR 2019 PT Sillomaritime Perdana TBK FA HRWilliam DaslerNo ratings yet

- Approved Steel Pipe Mills061016Document89 pagesApproved Steel Pipe Mills061016William DaslerNo ratings yet

- Ships' Piping: A Master'S Guide ToDocument32 pagesShips' Piping: A Master'S Guide ToWilliam DaslerNo ratings yet

- Pengawasan K3 Kebakaran-AK3 UmumDocument197 pagesPengawasan K3 Kebakaran-AK3 UmumWilliam DaslerNo ratings yet

- PQ Invitation PQPS000639-THWDocument11 pagesPQ Invitation PQPS000639-THWWilliam DaslerNo ratings yet

- p2k3 Dinar Lokakarya 2019Document20 pagesp2k3 Dinar Lokakarya 2019William DaslerNo ratings yet

- Checklist For Company Audit: Form DOC CHKDocument13 pagesChecklist For Company Audit: Form DOC CHKWilliam DaslerNo ratings yet

- 01 Tips Menyusun Kebijakan Keselamatan Pertambangan R02 1Document3 pages01 Tips Menyusun Kebijakan Keselamatan Pertambangan R02 1William DaslerNo ratings yet

Hose Discharge Capacity Graphs

Hose Discharge Capacity Graphs

Uploaded by

William Dasler0 ratings0% found this document useful (0 votes)

4 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesHose Discharge Capacity Graphs

Hose Discharge Capacity Graphs

Uploaded by

William DaslerCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

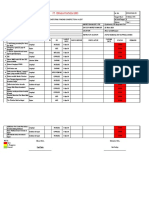

Loading Rate and Flow Veloci

Wie.

tse mon Ue

SSCS | ih

SEEN

Nt +A -+— _\ + \F

Seeee Sane See eas

KOEN AY

L _ N NI 4

I i

L_| it iS | Lo roar

{ _| || | _ A

{ l i |

— St a = = i

ore SN

| Ti |

PT Ereeeryeryeeer

lS

_ $+ L | Py i

l it l

ee es ee 7

i i: | i |

AHO AM/dtk (Guns 200 204) aa ONIGVOT

70 Fusee.

0

FLOW VELOCITY M/eoo. Fusee.

Pressure Loss in Hose String

The pressure toss in hose string or steel pipe line is calculated as follows:

ap eA XLXV? x 7x 10%

ZxqxD

where;

oP: Pressure Loss, (Kg/cm?)

A: Friction Factor. (—)

L: Length of Hose String. (m)

V: Flaw Vetocity. (m/sec.)

Y: Specific Weight of Oil. (Ka/m?) = 1000 x Specific Gravity.

Acceleration of Gravity. (m/sec*)

Inside Diameter of Hose. (m)

ve

Ais calculated by using the following Mises’ experimentat formula:

A= 0.0096 + 5.7.x VKID + 1.7 x VURE

where;

K: Coefficient of Wall-roughness by Mises’ experiment. (m}

K =0,3x 10° for Rubber Hose.

K = 0.5 x 10 for Welded Stee! Pipe.

Re: Reynolds Number.

Re is calculated as follows: Re =

where;

v: Kinematic Viscosity. (m? /sec.)

BawcesTone 137

LINE CAPACITY AND

PRESSURE LOSS

Pressure loss through a hose needs to be determined so The flow capacity or throughput can be expressed using &

that a hose size and type may be specified to yield the numberof units as shown in Figure 1.below which displays

novessary flow capacity capaci agains Now veloly fr each bore size,

FIGURE 1.

| -~ FLOW CONVERSION CHART - 42"

a

a

a4 do

Pe

Ea.

Ee

ee

B 2

Z

2 o

”

o be

Flow Velocity Gai/s)

Flow velocity in anol hose i usually limited to 21 mis.” hose and the physical propries ofthe transported fd

Such weloclesoweverare rarely Used because of the ‘To provide aval guile forthe selection of ose, the

Overall pressure and capectyimils of he system tolowng Figure 2 provides an estimate of the pressure

loss for a range of flow velocities for each of the bore sizes

alculating the pressure loss in a hose i 4

Calculating the pressure ossin ahoseis dependant upon (Sr foy anna ot Tow

many factors including the surface characteristics of the

FIGURE 2.

PRESSURE LOSS CHART -

70 | Theory : Fannin a"

S Fluid’: Light O1

5 oo S.G.: 0.85

= Viscosity : 100 cpoise |

& 50 | Roughness : 0.25mm

Bao | o |

2

Eo a

8 10"

2 20 5

é ce

Z - |

° “42 ~«63°~«84 10S 16 AO

Flow Rate (m/s)

For more specific calculations, details of the transported fluid and flow requirements along with relevant

system details should be forwarded to Dunlop.

@ DUNLOP OILE MARINE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Monitoring Findings Inspection SPOB PUTRA PASIFIC 01Document2 pagesMonitoring Findings Inspection SPOB PUTRA PASIFIC 01William DaslerNo ratings yet

- Marine Emergency Communication Flow Chart: MasterDocument1 pageMarine Emergency Communication Flow Chart: MasterWilliam DaslerNo ratings yet

- Fotonya Sesuaikan Dengan Ketentuan Dari Web Nya Ga Kurang N Ga Lebih Tanggal Stay Dimnulai Dari KedatanganDocument11 pagesFotonya Sesuaikan Dengan Ketentuan Dari Web Nya Ga Kurang N Ga Lebih Tanggal Stay Dimnulai Dari KedatanganWilliam DaslerNo ratings yet

- Surat Hasil Rafid AntigenDocument2 pagesSurat Hasil Rafid AntigenWilliam DaslerNo ratings yet

- No.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10Document9 pagesNo.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10William DaslerNo ratings yet

- Tender Jack Up Rig PHKTDocument1 pageTender Jack Up Rig PHKTWilliam DaslerNo ratings yet

- AR 2019 PT Sillomaritime Perdana TBK FA HRDocument258 pagesAR 2019 PT Sillomaritime Perdana TBK FA HRWilliam DaslerNo ratings yet

- Approved Steel Pipe Mills061016Document89 pagesApproved Steel Pipe Mills061016William DaslerNo ratings yet

- Ships' Piping: A Master'S Guide ToDocument32 pagesShips' Piping: A Master'S Guide ToWilliam DaslerNo ratings yet

- Pengawasan K3 Kebakaran-AK3 UmumDocument197 pagesPengawasan K3 Kebakaran-AK3 UmumWilliam DaslerNo ratings yet

- PQ Invitation PQPS000639-THWDocument11 pagesPQ Invitation PQPS000639-THWWilliam DaslerNo ratings yet

- p2k3 Dinar Lokakarya 2019Document20 pagesp2k3 Dinar Lokakarya 2019William DaslerNo ratings yet

- Checklist For Company Audit: Form DOC CHKDocument13 pagesChecklist For Company Audit: Form DOC CHKWilliam DaslerNo ratings yet

- 01 Tips Menyusun Kebijakan Keselamatan Pertambangan R02 1Document3 pages01 Tips Menyusun Kebijakan Keselamatan Pertambangan R02 1William DaslerNo ratings yet