Professional Documents

Culture Documents

Figlist

Uploaded by

oblex990 ratings0% found this document useful (0 votes)

8 views4 pagesThis document contains a list of figures from a book on polymer science and engineering. It includes the figure number, title, and page number for 39 total figures spread throughout chapters 2 through 5 of the book. The figures cover topics related to polymer chain dimensions, molecular weight distributions, transitions temperatures, rheology, processing techniques like extrusion, injection molding, and film blowing.

Original Description:

Original Title

57261_figlist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a list of figures from a book on polymer science and engineering. It includes the figure number, title, and page number for 39 total figures spread throughout chapters 2 through 5 of the book. The figures cover topics related to polymer chain dimensions, molecular weight distributions, transitions temperatures, rheology, processing techniques like extrusion, injection molding, and film blowing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pagesFiglist

Uploaded by

oblex99This document contains a list of figures from a book on polymer science and engineering. It includes the figure number, title, and page number for 39 total figures spread throughout chapters 2 through 5 of the book. The figures cover topics related to polymer chain dimensions, molecular weight distributions, transitions temperatures, rheology, processing techniques like extrusion, injection molding, and film blowing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

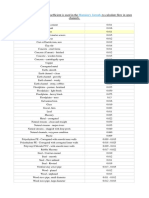

List of Figures

FIGURE

NUMBER TITLE PAGE

2-1 Equilibrium curve for copolymerization 26

3-1 Polymer chain dimensions 35

3-2 Steric structure of chains 35

3-3 A zigzag structure of PE 36

3-4 A differential MWD curve 39

3-5 Osmotic pressure of polymer solutions 42

3-6 Separation in GPC columns 43

3-7 Universal calibration curve for GPC measurements 44

3-8 Transition temperatures 45

3-9 Multiple transitions 46

3-10 Changes in modulus around Tg 46

3-11 Morphology of polymer chains 50

3-12 Morphology of crystallites from polymer melts 51

3-13 Kinetics of crystallization 52

[ xviii ] List of Figures

FIGURE

NUMBER TITLE PAGE

4- 1 Shear stresses and deformation 59

4-2 Flow curves of various liquids 60

4-3 Apparent viscosity of various liquids 61

4-4 Dependence of melt viscosity on MW 61

4-5 Ferry’s equation 63

4-6 Carreau’s equation 63

4-7 Mechanical models for solids (spring)and liquids

(dash-pot) 65

4-8 Deformation of an elastic solid (at constant stress) 65

4-9 Deformation of a Newtonian liquid

(at constant stress) 65

4-10 A Maxwell model 66

4-11 Deformation of the Maxwell model 66

4-12 Stress relaxation of a Maxwell model 67

4-13 A Voigt (Kelvin)model 68

4-14 Deformation of a Voigt body 68

4-15 The Burger model 69

4-16 Deformation of Burger body 70

4-17 Time (or temperature) dependence of relaxation

modulus 70

4-18 A master curve (at 25OC) for generalized

amorphous polymer 71

4-19 The complex modulus 72

4-20 Frequency dependence of storage modulus 73

4-21 The electronic Maxwell body 74

4-22 The electronic Voigt body 74

4-23 A stress-strain curve 75

4-24 Stress-strain curves at various temperatures 76

4-25 A stress testing dumbbell 77

4-26 Necking of a dumbbell 77

List of Figures [ xix ]

FIGURE

NUMBER TITLE PAGE

4-27 Stress-strain graph of a rigid and brittle material 78

4-28 Stress-strain graph of a rigid and strong material 78

4-29 Stress-strain graph of a rigid and tough material 79

4-30 Stress-strain graph of a soft and tough material 79

4-31 Performance of elastomers 80

4-32 Effect of orientation on tensile strength 80

4-33 Flexure test 82

4-34 Decrease of tensile strength with time 83

4-35 A specimen for impact test 84

4-36 Creep tests 86

4-37 Creep and stress relaxation profiles

(three-dimensional) 87

4-38 Fatigue test 88

4-39 Complex dielectric constant in alternating current 92

5-1 A single screw extruder (schematic) 111

5-2 Various types of screws 113

5-3 A scheme of the channel 114

5-4 Velocity profile of drag flow 117

5-5 Velocity profile of pressure flow 117

5-6 Velocity profile for a = 1 118

5-7 Velocity profile for a = 1/3 118

5-8 Operating lines of the screw 119

5-9 Operating lines for the screw and the die 120

5-10 Dependence of output on velocity at isothermal

conditions 121

5-11 Operating lines at various temperatures 121

5-12 Operating curves for non-Newtonian liquids 123

5-13 The layout of an injection molding apparatus 126

5-14 History of pressure in the mold cycle 130

[ xx ] List of Figures

FIGURE

NUMBER TITLE PAGE

5-15 Field of workability in injection molding 132

5-16 The principle of blow molding 135

5-17 The process of extrusion film blowing 135

5-18 Scheme of vacuum forming operation 137

5-19 Principle of calendering 138

You might also like

- Elasticity: Theory and Applications: Pergamon Unified Engineering SeriesFrom EverandElasticity: Theory and Applications: Pergamon Unified Engineering SeriesRating: 3 out of 5 stars3/5 (1)

- Viscous Fluid Flow Frank M White Third EditionDocument4 pagesViscous Fluid Flow Frank M White Third EditionPaulo Souza50% (2)

- Viscous Fluid Flow: Second EditionDocument4 pagesViscous Fluid Flow: Second EditionAnonymous ObsY3S7OtqNo ratings yet

- Centrifugal and Axial Compressor ControlDocument13 pagesCentrifugal and Axial Compressor ControlMomentum Press0% (3)

- EOR Larry W. LakeDocument577 pagesEOR Larry W. LakeVictor fonsecaNo ratings yet

- A. I. Leonov, A. N. Prokunin (Auth.) - Nonlinear Phenomena in Flows of Viscoelastic Polymer Fluids-Springer Netherlands (1994) - 1 PDFDocument491 pagesA. I. Leonov, A. N. Prokunin (Auth.) - Nonlinear Phenomena in Flows of Viscoelastic Polymer Fluids-Springer Netherlands (1994) - 1 PDFEdgar SharapovaNo ratings yet

- Maan H. Jawad (Auth.) - Theory and Design of Plate and Shell Structures-Springer US (1994)Document434 pagesMaan H. Jawad (Auth.) - Theory and Design of Plate and Shell Structures-Springer US (1994)ascanioba100% (5)

- D Lovett (Author) - Tensor Properties of Crystals-CRC Press (1989)Document181 pagesD Lovett (Author) - Tensor Properties of Crystals-CRC Press (1989)林丗育No ratings yet

- (Arthur S. Nowick) Crystal Properties Via Group THDocument244 pages(Arthur S. Nowick) Crystal Properties Via Group TH142520No ratings yet

- Introduction To Naval Architecture GillmerDocument338 pagesIntroduction To Naval Architecture GillmerRenato Ramos100% (3)

- Chapter 01Document20 pagesChapter 01Charlene KronstedtNo ratings yet

- U. C. Jindal - Machine Design-Pearson Education India (2013)Document872 pagesU. C. Jindal - Machine Design-Pearson Education India (2013)otromaasNo ratings yet

- CentrifugalandAxialCompressorControlInstructorsGuide 1Document133 pagesCentrifugalandAxialCompressorControlInstructorsGuide 1Abelio TavaresNo ratings yet

- FiguresDocument3 pagesFiguresantonio PierceNo ratings yet

- Jom Module IIDocument138 pagesJom Module IIPrinceNo ratings yet

- Instant Download Ebook PDF Fluid Mechanics Fundamentals and Applications 4th Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Fluid Mechanics Fundamentals and Applications 4th Edition PDF Scribdanne.scally474100% (41)

- Methods of Seismic Data Processing PDFDocument410 pagesMethods of Seismic Data Processing PDFMamani Callisaya GabrielNo ratings yet

- Installation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterDocument78 pagesInstallation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterevgenyNo ratings yet

- Space Groups Solid State Scientists: Second EditionDocument4 pagesSpace Groups Solid State Scientists: Second EditionKevin BritoNo ratings yet

- Installation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterDocument80 pagesInstallation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterassiaNo ratings yet

- Devraj Singh Part 2Document255 pagesDevraj Singh Part 2Akshat GoyalNo ratings yet

- BasicElectronics BernardGrob PDFDocument786 pagesBasicElectronics BernardGrob PDFMike100% (2)

- 103106158Document815 pages103106158Khushii NaamdeoNo ratings yet

- Shigleys Mechanical Engineering Design PDFDocument6 pagesShigleys Mechanical Engineering Design PDFPhemi258040% (5)

- Libro Excelente 2Document586 pagesLibro Excelente 2JavierChavezPalomino100% (1)

- Kamaraj2003 Article RaftingInSingleCrystalNickel-bDocument14 pagesKamaraj2003 Article RaftingInSingleCrystalNickel-bMITUSHI AGRAWALNo ratings yet

- Turbo Gener AdoresDocument141 pagesTurbo Gener AdoresMario AndradeNo ratings yet

- NOVAFEM-PUC Solver: Theoretical Manual, Non-Linear FormulationsDocument62 pagesNOVAFEM-PUC Solver: Theoretical Manual, Non-Linear FormulationsMohammedNo ratings yet

- (Daniel J. Amit) Field Theory, The Renormalization GroupDocument412 pages(Daniel J. Amit) Field Theory, The Renormalization Grouptjny699100% (1)

- Electronic Devices and CircuitsDocument525 pagesElectronic Devices and CircuitsSibasankar Padhy100% (4)

- Sime, Anthony P. (1998) Stress Analysis of Overlapped Crankshafts. PHD Thesis, University of NottinghamDocument281 pagesSime, Anthony P. (1998) Stress Analysis of Overlapped Crankshafts. PHD Thesis, University of Nottinghamimran5705074No ratings yet

- Debashis de - Basic Electronics - For BPUT Subject Code BE-2101-Pearson Education (2011)Document457 pagesDebashis de - Basic Electronics - For BPUT Subject Code BE-2101-Pearson Education (2011)Suraj MateNo ratings yet

- Zlib - Pub Basic ElectronicsDocument629 pagesZlib - Pub Basic ElectronicsJean GoujonNo ratings yet

- Microwave Devices and Circuits (LIAO)Document545 pagesMicrowave Devices and Circuits (LIAO)DHEERAJ KAMALNo ratings yet

- Mathematical Elements For Computer Graphics by David F Rogers J Alan Adams PDFDocument260 pagesMathematical Elements For Computer Graphics by David F Rogers J Alan Adams PDFraaspoy2007No ratings yet

- Roald K. Wangsness - Electromagnetic Fields-Wiley (1986)Document598 pagesRoald K. Wangsness - Electromagnetic Fields-Wiley (1986)jujujaga86No ratings yet

- Microwave Devices and Circuits Samual LiaoDocument545 pagesMicrowave Devices and Circuits Samual LiaoOnkar JadhavNo ratings yet

- Modern Fracturing by UHDocument536 pagesModern Fracturing by UHEvence Chen75% (4)

- m300-III Shop ManualDocument6 pagesm300-III Shop ManualFawzi AlzubairyNo ratings yet

- M300-Iii Shop ManualDocument6 pagesM300-Iii Shop ManualGeorge MikropoulosNo ratings yet

- FULL Download Ebook PDF Introduction To Electric Circuits 10th Edition PDF EbookDocument41 pagesFULL Download Ebook PDF Introduction To Electric Circuits 10th Edition PDF Ebookpablo.timlin339100% (32)

- BS Pani Fluid MechDocument362 pagesBS Pani Fluid MechAnukool VikramNo ratings yet

- Eng CS Epp-1376 1401-1Document2 pagesEng CS Epp-1376 1401-1Siniša VučinićNo ratings yet

- Sliding Contact Bearings Sliding Contact Bearings: r c μ n p r c μ n pDocument4 pagesSliding Contact Bearings Sliding Contact Bearings: r c μ n p r c μ n pAditya Varma YalamanchiliNo ratings yet

- D3W Old CatalogDocument25 pagesD3W Old CatalogElias80No ratings yet

- CH16: Adsorption and Ion ExchangeDocument5 pagesCH16: Adsorption and Ion Exchangeangel matienzoNo ratings yet

- 51 Sdms 01rev022 For Distribution TransformerDocument20 pages51 Sdms 01rev022 For Distribution Transformernadeem UddinNo ratings yet

- Itm - Codigos SiemensDocument234 pagesItm - Codigos SiemensSantiago FarfanNo ratings yet

- The SMP Concept-Based 3D Constitutive Models For Geomaterials - Hajime Matsuoka (Author) - 1, 2006 - CRC Press - 9780415395045 - Anna's ArchiveDocument154 pagesThe SMP Concept-Based 3D Constitutive Models For Geomaterials - Hajime Matsuoka (Author) - 1, 2006 - CRC Press - 9780415395045 - Anna's ArchiveElias Santos SouzaNo ratings yet

- General Information, Safety and ToolsDocument8 pagesGeneral Information, Safety and ToolsAdriel ComelatoNo ratings yet

- NabeelAbed MastersdissertaionDocument141 pagesNabeelAbed MastersdissertaionMark Oliver YonsonNo ratings yet

- B. K. Sarkar - Strength of MaterialsDocument406 pagesB. K. Sarkar - Strength of MaterialsMechpec Mech100% (3)

- Ahmad Fitri Zainal AbidinDocument24 pagesAhmad Fitri Zainal AbidinsureshgraphicsNo ratings yet

- Zapomel Orel OGU 2018aDocument58 pagesZapomel Orel OGU 2018aalexander fetisovNo ratings yet

- Shop Manual M300-III PDFDocument277 pagesShop Manual M300-III PDFBer Honza100% (5)

- HCH-MaintenanceManual2 4Document171 pagesHCH-MaintenanceManual2 4Jonathan Lara FandiñoNo ratings yet

- Kompendium TurbDocument49 pagesKompendium TurbSantiago Del Rio OliveiraNo ratings yet

- 13 1108 PDFDocument14 pages13 1108 PDFMohan KumarNo ratings yet

- Skrabek Strength ReliabilityDocument339 pagesSkrabek Strength Reliabilityfahmi aballiNo ratings yet

- Okara Oils: HistoryDocument1 pageOkara Oils: Historyoblex99No ratings yet

- Final 2019Document84 pagesFinal 2019oblex99No ratings yet

- Behavior PolymersDocument17 pagesBehavior Polymersoblex99No ratings yet

- Structure Ara Eriza Tion PolymersDocument25 pagesStructure Ara Eriza Tion Polymersoblex99No ratings yet

- Chap 3Document15 pagesChap 3oblex99No ratings yet

- SymlistDocument5 pagesSymlistoblex99No ratings yet

- Polymer Engineering: FundamentalsDocument4 pagesPolymer Engineering: Fundamentalsoblex99No ratings yet

- Lastback MatterDocument11 pagesLastback Matteroblex99No ratings yet

- Type The Document SubtitleDocument2 pagesType The Document Subtitleoblex99No ratings yet

- Monomers Derived From Ethylene Monomers Derived From Propylene Phenol and Other AromaticsDocument5 pagesMonomers Derived From Ethylene Monomers Derived From Propylene Phenol and Other Aromaticsoblex99No ratings yet

- Minitab Manual 05Document2 pagesMinitab Manual 05oblex99No ratings yet

- Minitab Manual GraphsDocument8 pagesMinitab Manual Graphsoblex99No ratings yet

- Introduction To The World PolymersDocument4 pagesIntroduction To The World Polymersoblex99No ratings yet

- Idiotic Newton Published By: Martin Publishers Find On ScribedDocument1 pageIdiotic Newton Published By: Martin Publishers Find On Scribedoblex99No ratings yet

- Minitab Manual 06Document3 pagesMinitab Manual 06oblex99No ratings yet

- Minitab Manual 04Document4 pagesMinitab Manual 04oblex99No ratings yet

- Proposal by Asfaw ADocument34 pagesProposal by Asfaw ABelachew ZelekeNo ratings yet

- Ultima Pro 450Document1 pageUltima Pro 450Aman PunjabiNo ratings yet

- CSE30310 Lecture 6Document17 pagesCSE30310 Lecture 6iversonszeNo ratings yet

- Em Sor 2022Document253 pagesEm Sor 2022swarna rawatNo ratings yet

- G-CAST Catalogue (U-Drain Standard 0300-3600)Document5 pagesG-CAST Catalogue (U-Drain Standard 0300-3600)Adib KhairNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- Pds - Sunshades Instrument CoverDocument2 pagesPds - Sunshades Instrument CoverAntonio LantiguaNo ratings yet

- 7K-L, Second & Third Floor, Jalan Ban Hock, 93100, Kuching, Sarawak. Tel: +6082 7877 123 Fax: +6082 7877 234 Method StatementDocument4 pages7K-L, Second & Third Floor, Jalan Ban Hock, 93100, Kuching, Sarawak. Tel: +6082 7877 123 Fax: +6082 7877 234 Method StatementmadinaNo ratings yet

- RC-2200 Rubber Compound Specification SheetDocument1 pageRC-2200 Rubber Compound Specification SheetRoosta_ManNo ratings yet

- Fip SferopolDocument16 pagesFip SferopolMarco BenedettiNo ratings yet

- Scheda Tecnica Spray Zincato 0893114113ztd02Document2 pagesScheda Tecnica Spray Zincato 0893114113ztd02Samuel Chiappara100% (1)

- Methods For Diffusion Welding The Superalloy Udimet 700Document9 pagesMethods For Diffusion Welding The Superalloy Udimet 700Enary SalernoNo ratings yet

- BT4 Guardhouse Specifications PDFDocument4 pagesBT4 Guardhouse Specifications PDFFrancis Anne DoradoNo ratings yet

- Checklist Experimental TextileDocument2 pagesChecklist Experimental TextileVinay GuptaNo ratings yet

- Manning's Roughness CoefficientDocument2 pagesManning's Roughness Coefficientdjuka15No ratings yet

- 2 Review Paper On Strength and Durability Evaluation of Recycled Aggregate ConcreteDocument4 pages2 Review Paper On Strength and Durability Evaluation of Recycled Aggregate ConcreteVishal NagpureNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofAshish SontakkeNo ratings yet

- TRANSPORTATION MATERIALS SPESIFICATION Part 3Document10 pagesTRANSPORTATION MATERIALS SPESIFICATION Part 3Dedi NurpadilahNo ratings yet

- Flooring QtyDocument2 pagesFlooring QtyJyoti SarkarNo ratings yet

- Brittle Analysis of Steel Structure in Extremely Cold EnvironmentDocument6 pagesBrittle Analysis of Steel Structure in Extremely Cold EnvironmentabelNo ratings yet

- 'TDS ONDULINE TILE (Asia) 2018-03 PDFDocument2 pages'TDS ONDULINE TILE (Asia) 2018-03 PDFIwan SetiawanNo ratings yet

- WDE - Anganwadi Building - PasthalaDocument52 pagesWDE - Anganwadi Building - PasthalaGurram Lakshmi NavakanthNo ratings yet

- Lectures 2Document3 pagesLectures 2Muhammad AhmedNo ratings yet

- Vulkanox BKF (20140210)Document4 pagesVulkanox BKF (20140210)simbua72No ratings yet

- YDPN-641: Phenol Novolac EpoxyDocument2 pagesYDPN-641: Phenol Novolac Epoxysriatul2006No ratings yet

- PP Copolimero - Lloyndellbasell Purell RP373RDocument1 pagePP Copolimero - Lloyndellbasell Purell RP373RarmandoNo ratings yet

- Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing For Pressure Application at High TemperaturesDocument6 pagesCentrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing For Pressure Application at High TemperaturesHoem ITNo ratings yet

- BOQ of WaterproofingDocument7 pagesBOQ of WaterproofingmohnishNo ratings yet

- 4A. Simona CatalogueDocument6 pages4A. Simona CatalogueMEAGAN CHNGNo ratings yet