Professional Documents

Culture Documents

Appendix 2: Manual Handling Risk Assessment Worksheet (Completed)

Uploaded by

Mohammed HamzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix 2: Manual Handling Risk Assessment Worksheet (Completed)

Uploaded by

Mohammed HamzaCopyright:

Available Formats

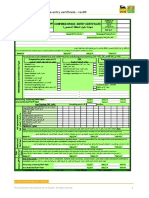

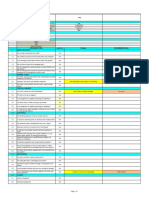

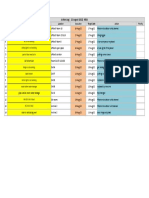

APPENDIX 2: MANUAL HANDLING RISK ASSESSMENT WORKSHEET

(COMPLETED)

STAGE 1: TASK DESCRIPTION

The employee is working at a packing station which is at the

end of the production process. The employee is required to

transfer boxes weighing 15 kg from the workbench to the

pallet on the floor.

STAGE 2: COLLECT ALL TECHNICAL DETAILS

• The boxes weigh 15 kg

• The employee has to lift a number of boxes into position on a pallet

• The employee has to work below knee height when positioning some boxes on the pallet

• The pallet is very close to the employee, which results in the employee engaging in an upper body twist when

transferring the boxes to the pallet

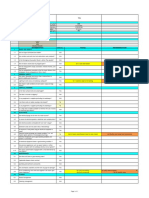

STAGE 3: IDENTIFY THE RISK FACTORS

• The physical effort can involve a twisting movement of the trunk

• The load is positioned in a manner requiring it to be held with a bending of the trunk

• The work environment prevents the handling of loads at a safe height

• The activity requires over-frequent or over-prolonged physical effort involving the spine

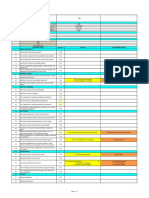

STAGE 4: IDENTIFY THE IMPROVEMENTS TO BE PUT IN PLACE

• A high lift or variable height pallet truck is used and can be adjusted to optimum height as the pallet is being

packed

• The staff are trained in the correct use of the pallet truck, including the benefits of setting the equipment to

optimum height

• A job rotation system is introduced so that staff are not

involved in this activity for long periods of time

• A conveyor table which is adjustable in height is sourced

to allow the boxes to be rolled along the conveyor

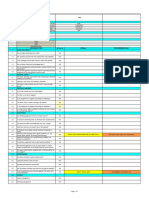

STAGE 5: REVIEW EFFECTIVENESS OF THE SOLUTION

Guidance on the prevention and management of musculoskeletal disorders (MSDs) in the workplace 35

You might also like

- Manual Handling Risk Assessment WorksheetDocument1 pageManual Handling Risk Assessment WorksheetMohammed HamzaNo ratings yet

- Order PickingDocument4 pagesOrder PickingPJCNo ratings yet

- ScaffoldsDocument38 pagesScaffoldsSaru ArjunanNo ratings yet

- Material HandlingDocument47 pagesMaterial HandlingmrugeshjNo ratings yet

- Work Health and Safety Policy SamplesDocument16 pagesWork Health and Safety Policy SamplesCyril Bayuga100% (1)

- Flat Bed Reactor Loading& UnloadingDocument12 pagesFlat Bed Reactor Loading& Unloadingabdulgafoor54No ratings yet

- BOSH5Document30 pagesBOSH5SHAIRA PALMANo ratings yet

- MMH Manual Materials HandlingDocument43 pagesMMH Manual Materials Handlingshobhit singhNo ratings yet

- 2006 US Army LessonPlans B06 Load 18pDocument18 pages2006 US Army LessonPlans B06 Load 18pLo Shun FatNo ratings yet

- Lifting and Rigging Training Session 1 - 2021 01 22Document25 pagesLifting and Rigging Training Session 1 - 2021 01 22ELMLEMROZINo ratings yet

- OSHA Warehouse Safety Guide: Hazards & SolutionsDocument15 pagesOSHA Warehouse Safety Guide: Hazards & SolutionsCaleb ConnerNo ratings yet

- Reviewer in ErgoDocument10 pagesReviewer in ErgoLyka RamosNo ratings yet

- Offloading Solar Panels with TelehandlerDocument11 pagesOffloading Solar Panels with TelehandlerBabel THIAMNo ratings yet

- Ei0Pz71R3efC3jFh - rYavs5iKWZl6SQiL-Pallet Jack Safe Operating Procedure v1Document2 pagesEi0Pz71R3efC3jFh - rYavs5iKWZl6SQiL-Pallet Jack Safe Operating Procedure v1robinNo ratings yet

- Safe Lifting OperationDocument16 pagesSafe Lifting OperationsureshNo ratings yet

- Powered Industrial Truck Operator Training TrainingDocument75 pagesPowered Industrial Truck Operator Training TrainingiqjreynaNo ratings yet

- Warehousing SafetyDocument15 pagesWarehousing SafetyDin JamalNo ratings yet

- Worker Safety Series - Warehousing PDFDocument15 pagesWorker Safety Series - Warehousing PDFAndi WahyudinNo ratings yet

- Working at Heights DirectiveDocument11 pagesWorking at Heights DirectiveMyolwinooNo ratings yet

- Material Handling ObjectivesDocument15 pagesMaterial Handling ObjectivesSavanPatelNo ratings yet

- Element 3: Musculoskeletal Hazards and Risk ControlDocument6 pagesElement 3: Musculoskeletal Hazards and Risk ControlUMAR FAROOQNo ratings yet

- Risk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0Document7 pagesRisk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0NirmalKumarSelvarajNo ratings yet

- Safe Material Storage and Handling TechniquesDocument2 pagesSafe Material Storage and Handling TechniquesMuhammad TohirNo ratings yet

- Tool Box Talk # 20 Hydraulic Excavators: Lifting With SlingsDocument1 pageTool Box Talk # 20 Hydraulic Excavators: Lifting With Slingssudeesh kumarNo ratings yet

- MELAB1 - Exp 3 DraftDocument3 pagesMELAB1 - Exp 3 DraftShawn TaladhayNo ratings yet

- Chapter 11 - Handling LoadsDocument43 pagesChapter 11 - Handling Loadsoracel dataNo ratings yet

- Aerial Lifts Forklifts Aerial Lifts Safe Work PracticesDocument1 pageAerial Lifts Forklifts Aerial Lifts Safe Work PracticesWaqas KhanNo ratings yet

- Crane/lifting Operations Supervisor: Planning and Regulatory RequirementsDocument5 pagesCrane/lifting Operations Supervisor: Planning and Regulatory RequirementssurendraNo ratings yet

- BOSH - Lecture 5 - Material Handling and StorageDocument25 pagesBOSH - Lecture 5 - Material Handling and StorageAlfonso Martin AngelesNo ratings yet

- SOP of ForkDocument15 pagesSOP of ForkGyanendra Narayan NayakNo ratings yet

- Stairways and Ladders A Guide To OSHA Rules: Drs. Sahuri, SST.K3.,Msi (K3) Drs. Sahuri, SST.K3.,Msi (K3)Document7 pagesStairways and Ladders A Guide To OSHA Rules: Drs. Sahuri, SST.K3.,Msi (K3) Drs. Sahuri, SST.K3.,Msi (K3)Bobby PrawiraNo ratings yet

- Lifting EquepmentsDocument31 pagesLifting Equepmentslina.darwish14No ratings yet

- Lifting and Rigging Safety FundamentalsDocument65 pagesLifting and Rigging Safety FundamentalsMuhamad arifNo ratings yet

- Optimize material handling costsDocument7 pagesOptimize material handling costsDennis Tee NdareraNo ratings yet

- Materi Safety Talk 1Document3 pagesMateri Safety Talk 1temter gandaNo ratings yet

- Jsa For Pre-Cast Column ErectionDocument19 pagesJsa For Pre-Cast Column ErectionKhuda BukshNo ratings yet

- Suspended Loads Safety Tips (39Document3 pagesSuspended Loads Safety Tips (39my_agautamNo ratings yet

- FPE - 1 - Working at Heights PDFDocument7 pagesFPE - 1 - Working at Heights PDFKaruppuswamy PalanisamyNo ratings yet

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Rigging & Lifting HandbookDocument7 pagesRigging & Lifting HandbookRachmadKurniadi20% (5)

- Hydraulic Excavators: Lifting With Slings: (Refer To Manufacturer's Manual)Document1 pageHydraulic Excavators: Lifting With Slings: (Refer To Manufacturer's Manual)Nathan ThillaiNo ratings yet

- A Health and Safety Guideline For Your Workplace - Manual Materials HandlingDocument6 pagesA Health and Safety Guideline For Your Workplace - Manual Materials HandlingJames UgoNo ratings yet

- Sample: Manual Handling Risk Assessment Reference SheetDocument1 pageSample: Manual Handling Risk Assessment Reference Sheetvinu7171100% (1)

- Erecting and Dismantling ScaffoldsDocument11 pagesErecting and Dismantling ScaffoldsN P SrinivasaraoNo ratings yet

- Technical Advisory For ForkliftDocument5 pagesTechnical Advisory For ForkliftErica LindseyNo ratings yet

- Lifting PlanDocument3 pagesLifting PlanBibin JohnNo ratings yet

- 11-Lifting OperationsDocument73 pages11-Lifting OperationsElavarasan Pavan100% (1)

- Overhead Crane Safety GuideDocument11 pagesOverhead Crane Safety GuideAhsan Farooq100% (1)

- Using Mobile Cranes in Pick Carry Operations Safety Alert 3919Document2 pagesUsing Mobile Cranes in Pick Carry Operations Safety Alert 3919talabiraNo ratings yet

- Csuci Heavy Equipment ProgramDocument23 pagesCsuci Heavy Equipment ProgramrichardNo ratings yet

- OSU CFAES Skid Loader Operator Training 2014Document29 pagesOSU CFAES Skid Loader Operator Training 2014Rolando CostaNo ratings yet

- Rigging and LiftingDocument19 pagesRigging and Liftingnitesh dayamaNo ratings yet

- Upper Mast Section Lifting PlanDocument7 pagesUpper Mast Section Lifting PlanDurgham Adel EscanderNo ratings yet

- My Training Academy by SamyDocument173 pagesMy Training Academy by Samydoreena764No ratings yet

- Materials HandlingDocument34 pagesMaterials HandlingPrachi SinghNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined SpacesDocument31 pagesPro Hse 024 Eni Iraq r00 - Working in Confined SpacesMohammed Hamza100% (1)

- Techno Gym - Gym Equipment Maintenance Report ReportDocument1 pageTechno Gym - Gym Equipment Maintenance Report ReportMohammed HamzaNo ratings yet

- 04 - Accomdation Room Iso Corner MSKU 938908 0 - CompressedDocument1 page04 - Accomdation Room Iso Corner MSKU 938908 0 - CompressedMohammed HamzaNo ratings yet

- Annex C Confined Space LogsheetDocument1 pageAnnex C Confined Space LogsheetMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex BDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex BMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex FDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex FMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex GDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex GMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex ADocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex AMohammed HamzaNo ratings yet

- Eni Iraq BV Mechanical Isolation Cert Annex DDocument1 pageEni Iraq BV Mechanical Isolation Cert Annex DMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex EDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex EMohammed HamzaNo ratings yet

- Smoke Alarms Disability Safety TipsDocument1 pageSmoke Alarms Disability Safety TipsBarkat UllahNo ratings yet

- Office 7 InspectionDocument1 pageOffice 7 InspectionMohammed HamzaNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex HDocument1 pagePro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex HMohammed HamzaNo ratings yet

- M InspectionDocument1 pageM InspectionMohammed HamzaNo ratings yet

- Action Log For 22 of JulyDocument1 pageAction Log For 22 of JulyMohammed HamzaNo ratings yet

- EI InspectionDocument1 pageEI InspectionMohammed HamzaNo ratings yet

- Required Equimpent For Ro Station and Blackwater TreatmentDocument2 pagesRequired Equimpent For Ro Station and Blackwater TreatmentMohammed HamzaNo ratings yet

- CA InspectionDocument1 pageCA InspectionMohammed HamzaNo ratings yet

- CA InspectionDocument1 pageCA InspectionMohammed HamzaNo ratings yet

- Grilling SafetyDocument1 pageGrilling SafetyShaikJeelanBashaNo ratings yet

- Smoking SafetyDocument1 pageSmoking SafetyBinoy GopinathanNo ratings yet

- Office 8 InspectionDocument1 pageOffice 8 InspectionMohammed HamzaNo ratings yet

- Action Log For 22 of AugDocument1 pageAction Log For 22 of AugMohammed HamzaNo ratings yet

- Smoke AlarmsDocument1 pageSmoke AlarmscristoferNo ratings yet

- Generator Safety TipsDocument1 pageGenerator Safety TipsMohammed HamzaNo ratings yet

- Gel Fuel Safety TipsDocument1 pageGel Fuel Safety TipsMohammed HamzaNo ratings yet

- Electrical SafetyDocument1 pageElectrical SafetyDougNewNo ratings yet

- Security Bar SafetyDocument1 pageSecurity Bar SafetyMohammed HamzaNo ratings yet

- Halloween Fire Safety Tips: Did You Know?Document1 pageHalloween Fire Safety Tips: Did You Know?Mohammed HamzaNo ratings yet