Professional Documents

Culture Documents

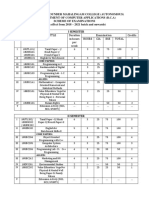

IJERT Performance Analysis of Shell and

Uploaded by

Mr sfeanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJERT Performance Analysis of Shell and

Uploaded by

Mr sfeanCopyright:

Available Formats

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 10, October-2016

Performance Analysis of Shell and Tube Heat

Exchanger using Nano Fluid

Mrs. D Swetha1 Mr. K. Srinivasa Chalapathi2 Mrs. P. Saritha3

Assistant Professor Associate Professor Assistant Professor

Dept of Mechanical Engineering Dept of Mechanical Engineering Dept of Mechanical Engineering

Anurag Group of Institutions Anurag Group of Institutions Anurag Group of Institutions

(CVSR), (CVSR), (CVSR),

Hyderabad, India. Hyderabad, India. Hyderabad, India.

Abstract—Nanofluids are suspensions of nanoparticles in fluids 9. Spiral heat exchangers.

that show significant enhancement of their properties at modest 10. Air cooled: coolers and condensers

nanoparticle concentrations. Nano fluids are found to be having 11. Direct contact: cooling and quenching

the best thermal transport property in the recent years many 12. Agitated vessels

investigations are took place to improve the thermal efficiency by

using the nano fluids which might become the revolutionary

solutions to the heat transfer problems and the nano fluid can in II. NANO FLUIDS PREPARATION

future over take the places of the conventional fluids.

The proposed analysis is carried out whether the method can

help in the extraction of heat and to That to what extent we can

use this for the better results in the thermal efficiency. The

analysis is carried out by using B L method and kern method and

graphs are plotted, compared with water to water results.

Keywords—Nano Fluids, Heat Exchanger, Thermal Efficiency

I. INTRODUCTION

The natural laws of physics always allow the driving energy in

a system to flow until equilibrium is reached. Heat leaves the

warmer body or the hottest fluid, as long as there is a

temperature difference, and will be transferred to the cold

medium. A heat exchanger follows this principle in its

endeavour to reach equalisation. With a plate type heat

exchanger, the heat penetrates the surface, which separates the

hot medium from the cold one very easily. It is therefore

possible to heat or cool fluids or gases which have minimal

energy levels. The theory of heat transfer from one media to

another, or from one fluid to another, is determined by several

basic rules.

Heat will always be transferred from a hot medium to a cold

medium.

There must always be a temperature difference between the

media.

The heat lost by the hot medium is equal to the amount of

heat gained by the cold medium, except for losses to the

Fig 1. Two step process for Nano fluid Preparation

surroundings.

Types of heat exchanger: III. SHELL AND TUBE HEAT EXCHANGER

1. Double-pipe exchanger: the simplest type, used for cooling Shell and tube heat exchanger consisting of a calming section,

and heating. test section, rot meters, overhead water tank for supplying cold

2. Shell and tube heat exchanger water & a constant temperature bath for supplying hot water

3. Plate heat exchanger with in-built heater, pump & the control system. The test

4. Plate and shell heat exchanger section is a smooth stainless tube with dimensions of 800mm

5. Rotating wheel heat exchanger length, Inner diameter of tube- 16mm ID, and Outer diameter

6. Plate fin heat exchanger of tube-19mm OD. These tubes are arranged in triangular pitch

7. Pillow plate heat exchanger in the shell. Two calibrated rot meters, with the flow ranges,

8. Fluid heat exchangers

IJERTV5IS100251 www.ijert.org 320

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 10, October-2016

are used to measure the flow of cold water. The water, at room The values are noted down through the computer

temperature is drawn from an overhead tank using gravity connected to the experimental set up.

flow. Similarly a rot meter is provided to control the flow rate Values are logged in for every reading using the

of hot water from the inlet hot water tank. Four thermo-couples software interface.

are used measure the inlet & outlet temperature of hot water & Graphs are generated for every flow and temperatures

cold water (T1 –T4) through a multipoint digital temperature in the excel sheets.

indicator. Sensors are inserted to measure the mass flow rate in Properties of fluids used is to be enter if different fluid

shell and as well tubes sides. is used other than water as water’s properties are

already been induced in the software provided.

But for nano fluid the thermal conductivity value is

separately fed into the software

After completion of logging many readings, the log

sheet of results is generated which is to be saved for

calibration

Standardization of the set-up:Before starting the

experimental study on friction & heat transfer in heat

exchanger, standardization of the experimental setup

is done by obtaining the friction factor & heat transfer

results for the smooth tube & comparing them with

the standard equations available.

Pressure drop is measured for each flow rate with the

help log sheet.

Over all heat transfer rate is measured.

Discuss your results, by

Commenting on the results and possible reasons for

discrepancies,

Fig 2. Line Diagram of Shell And Tube Heat Exchanger.

Reporting on the possible sources of errors in the

IV. EXPERIMENTAL PROCEDURE AND experiment, and

CALCULATIONS Analyzing the assumptions made during the

Water is collected upto some volume in the tanks experiment and their effects on the results in detail.

provided in the experimental set up of shell and tube

heat exchanger. V. KERN’S DESIGN PROCEDURE

All the rotameters & RTD are calibrated. Shell and tube heat exchanger is designed by trial and error

Shell and tube heat exchanger set up is made ON and calculations. The procedure for calculating the shell-side heat-

heater provided is connected to the red water tank. transfer coefficient and pressure drop for a single shell pass

Temperature is taken into consideration as water is exchanger is given below The main steps of design following

started to heat. the Kern method are summarized as follows:

Pumps of shell side and tube side are started and flow STEP 1: Calculating the area of cross flow As, for hypothetical

takes place. Hot water at about 60°C is allowed to row of tubes at the shell Equator, given by

pass through the shell side of heat exchanger for water As = {(Pt – Do)*Ds*Lb} /Pt

to water method. STEP 2: Calculate shell side mass velocity Gs and linear

In the red tank side nano fluid is introduced for water- velocity Us.

nano fluid method and passed to the shell side of the Gs = ms / As or Us = Gs / ρs

heat exchanger STEP 3: Calculate the shell side equivalent diameter De.

Cold water is now allowed to pass through the tube For square pitch:

side of heat exchanger in counter current direction at a De = [4*(Pt2 – {(π/4)* Do2}] / (π* Do)

desired flow rate. For triangular pitch:

The water inlet and outlet temperatures for both hot De = [4*{(Pt2*√3)/4} – {(π* Do2)/8}] / [(π*Do)/2]

water & cold water (T1-T4) are recorded only after STEP 4: Calculate shell side Reynolds number Res.

temperature of both the fluids attains a constant value. Res = (Gs* De) / μs Or Res = (Us* De* ρs) / μs

The procedure was repeated for different cold water STEP 5: Calculate shell side Prandtl number Prs.

flow rates Prs = (Cps*μs) / Ks

Temperatures are noted through the display. STEP 6: Calculate the shell side heat transfer coefficient hs

Temperatures for shell inlet and out let and tube side hs = 0.36*( Ks / De)* (Re^0.55)*(Pr^0.33)*{(μs / μw)^0.14}

inlet and outlet are calibrated using thermocouples Note: The value of (μs / μw) ^0.14 = 1, for water.

connected at every inlets and outlets. CALCULATION OF SHELL SIDE PRESSURE DROP

Minimum three readings are taken for every flow and STEP 7: Calculate the number of baffles on shell side Nb.

average is considered. Nb = {Ls / (Lb + tb)} – 1

STEP 8: Calculate the friction factor f.

IJERTV5IS100251 www.ijert.org 321

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 10, October-2016

f = exp {0.576 – (0.19*Ln Res)} Table 4: Fluid Properties of Water

STEP 9: Calculate the shell side pressure drop ΔPs. S. Property Unit Cold Hot Silver Silicon

ΔPs = [4* f* Gs2* Ds*( Nb+1)] / [2* ρ*De*×{(μs / μw)^0.14}] no water water Nano Dioxide

Or shell side tube fluid Nano

ΔPs = [f* Gs2* Ds*( Nb+1)] / [2* ρs* De*{(μs / μw)^0.14}] side Fluid

1 Specific Heat KJ/kg. 4.187 4.187 4.485 4.278

CALCULATION OF TUBE SIDE HEAT TRANSFER (Cp) K

COEFFICIENT 2 Thermal W/m. 0.00098 0.00098 0.0020 0.0016

STEP 1: Calculate the tube side cross flow section area At. conductivity K

At = {(π* Di2) / 4}*(Nt / 2) (k)

STEP 2: Calculate the tube side mass velocity Gt and linear

velocity Ut. VI. RESULTS AND GRAPHS

Gt = mt / At Or Ut = Gt / ρt

STEP 3: Calculate the tube side Reynolds number Ret. Table 5. RESULTS (SHELL SIDE HOT FLUID) BY KERN

Res = (Gt* Di) / μt Or Ret = (Ut* Di* ρt) / μt METHOD

Sl.n Shell side R1 R2 R3 R4 R5

STEP 4: Calculate the tube side Prandtl number Prt. o

Prt = (Cpt*μt) / Kt

STEP 5: Calculate the friction factor f. 1 Mass flow 0.0255 0.0314 0.0343 0.041 0.0446

f = {(1.58*Ln Ret) – 3.28} ^ (-2) rate

STEP 6: Calculate the tube side Nusselt number Nut. (Kg/sec)

2 Temperature 55.5 55.8 56.2 56.3 56.3

Nut = {(f /2)*(Ret -1000)* Prt} / {1+ (12.7*√(f /2)*(Prt ^ at inlet

(2/3))-1)} (oc)

STEP 7: Calculate the tube side heat transfer coefficient hi. 3 Temperature 44.5 44.7 44.7 45 45.3

hi = (Nut * Kt) / Di at

outlet (oc)

CALCULATION OF TUBE SIDE PRESSURE DROP 4 Reynolds 65.644 80.832 88.297 105.802 114.81

STEP 8: Calculate the pressure drop on the tube side ΔPt. number 2

ΔPt = [{(4* f* Lt* np) / Di} + (4* np)]*[(ρt*Ut2) / 2

5 Prandtl 1.228 1.228 1.228 1.228 1.228

number

Table2: Heat Exchanger data at the shell side 6 Heat transfer 0.355 0.398 0.418 0.462 0.483

coefficient

S.No Quantity Symbol Value (W/

1 Shell side fluid Water m2’K).

7 Pressure drop 0.031 0.045 0.053 0.074 0.085

2 Shell side Mass flow Mt 0.060 (Pa)

rate(Kg/sec) 8 Over all heat 0.431 0.547 0.66 0.924 1.385

transfer

3 Shell ID(m) Ds 0.2

coefficient

4 Shell length(m) Ls 0.800

5 Tube pitch(m) Pt 0.03 Sl.n Tube side R1 R2 R3 R4 R5

6 No. of passes n 1 o

7 Baffle cut(m) Lb 0.2 1 Mass flow 0.0199 0.0251 0.0301 0.035 0.0406

rate

8 No. of baffles N 4

(Kg/sec)

2 Temperature 35.8 36.1 36.3 36.7 36.8

Table3: Heat Exchanger data at the tube side at inlet

(oc)

Sl.no Quantity Symbol Value 3 Temperature 40.1 40 39.8 40.1 40

at

1 Tube side fluid Water+ nano outlet (oc)

fluids 4 Reynolds 205.65 259.432 311.11 361.75 419.638

Tube side Mass flow Mt 0.060 number 8 7

2 rate (Kg/sec)

3 Tube OD (m) Do 0.019 5 Prandtl 3.674 3.674 3.674 3.674 3.674

4 Tube ID(m) Di 0.016 number

5 Tube thickness(m) Tp 0.0162

6 Number of Tubes N 18 6 Heat transfer -1.11 -0.944 -0.82 -0.719 -0.62

7 Tube length(m) Lt 0.825 coefficient

(W/

m2’K).

7 Pressure drop 1.445 2.102 2.839 3.659 4.711

(Pa)

IJERTV5IS100251 www.ijert.org 322

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 10, October-2016

Table 6. RESULTS (TUBE SIDE HOT FLUID) BY KERN

METHOD

Sl.n Shell side R1 R2 R3 R4 R5

o

1 Mass flow 0.0253 0.030 0.035 0.040 0.04

rate (Kg/sec) 4

2 Temperature 32.4 34.7 34.7 34.7 34.7

at inlet (°c)

3 Temperature 32.4 32.8 32.9 33.1 33.2

at outlet (°c)

4 Reynolds 65.129 77.228 90.099 102.97 113.

number 267

5 Prandtl 3.67 3.67 3.67 3.67 3.67

number

6 Heat transfer 0.167 0.184 0.2 0.215 0.22 Fig 3. Mass Flow Rate V/S Heat Transfer Coefficient

coefficient 7

(W/m2K)

7 Pressure drop 1.503 2.13 2.983 3.748 4.73

(Pa) 1

8 Over all heat 0.146 0.162 0.18 0.199 0.21

transfer 9

coefficient

Sl.n Tube side R1 R2 R3 R4 R5

o

1 Mass flow 0.0204 0.0253 0.031 0.0355 0.04

rate (Kg/sec) 07

2 Temperature 49 50.3 50.8 51.1 51.5

at inlet (°c)

3 Temperature 42.4 42.9 43.4 44.3 44.7 Fig 4. Pressure Drop V/S Heat transfer Coefficient

at outlet (°c)

4 Reynolds 210.85 261.49 320.41 366.92 420.

number 3 9 3 5 672

5 Prandtl 2.401 2.401 2.401 2.401 2.40

number 1

6 Heat transfer -1.303 -1.116 -0.948 -0.839 -0.73

coefficient

(W/m2K)

7 Pressure drop 1.503 2.13 2.98 3.748 4.73

(Pa) 1

Fig 5. Over all Heat Transfer coefficient V/S Reynolds Number

Fig 2. Reynolds Number V/S Mass Flow rate

IJERTV5IS100251 www.ijert.org 323

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 10, October-2016

Fig 9. Heat transfer coefficient V/S Pressure Drop

Fig 6. Pressure Drop V/S Mass flow rate on tube side

Fig 10. Mass Flow rate V/S Over all Heat transfer coefficient on shell and tube

side

VII. CONCLUSION

Fig 7. Reynolds number V/S Mass Flow rate on Tube side This method of analyzing the heat exchanger using the Nano

fluid gives the satisfactory result even though the analysis is

not conducted in full labrotical conditions.

The results obtained shows the better thermal conductivity than

the conventional fluids when used the nano fluids and simpler.

The nano fluids produced by using the neem leaf and guava

leaf shows a stable nano fluids And they are stable for about 6

months and the process is simpler.

In future it is desired to experiment with the compact smaller

heat exchangers as the results might be better than the proposed

one. And the experiment needs to be conducted with the other

nano fluids to know how they will effect in improving the

thermal efficiency .

VIII. REFERENCES

[1] Deshpande raghunandan.bedre d Mahesh. S baswaraja. S d balaji.

S y manjunath. A venkatraman; “microwave –assisted rapid

Fig 8. Reynolds number V/S Over all Heat transfer coefficient on shell and tube extracellular synthesis of bio-functionalized silver nanoparticles

side from guava leaf extract” ; hke’s college of pharmacy sedum road,

Gulbarga, Karnataka, india .

[2] Sandeep K. Patel, Professor Alkesh M. Mavani “shell & tube

heat exchanger thermal design with optimization of mass flow

rate and baffle Spacing” .d.r.p – i.t.r, gandhinagar, Gujarat., india

[3] B.V. Babu, Professor S.A. Munawar: Differential evolution

strategies for optimal design of shell-and-tube heat exchangers.

Department of Chemical Engineering Birla Institute of

Technology and Science PILANI-333 031 . Rajasthan, India.

[4] Rajiv Mukherjee: Effectively Design Shell-and-Tube Heat

Exchangers February 1998 • Chemical Engineering Progress

Copyright 1997 American Institute of Chemical Engineers.

IJERTV5IS100251 www.ijert.org 324

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 10, October-2016

[5] L.B. Mapa, Sana Mazhar “Heat transfer in mini heat exchanger

using nanofluids “American Society for Engineering Education

April 1-2, 2005 –Northern Illinois University, DeKalb, Illinois.

2005 IL/IN Sectional Conference.

[6] Mohammad Hadi Pirahmadian, Azadeh Ebrahimi; Theoretical

Investigation Heat Transfer Mechanisms in Nanofluids and the

Effects of Clustering on Thermal Conductivity International

Journal of Bioscience, Biochemistry and Bioinformatics, Vol. 2,

No. 2, March 2012

IJERTV5IS100251 www.ijert.org 325

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- M.H. Sloboda - 1961 - Design and Strength of Brazed JointsDocument16 pagesM.H. Sloboda - 1961 - Design and Strength of Brazed JointsPieter van der MeerNo ratings yet

- Heat Loss Insulated Pipe SpreadsheetDocument14 pagesHeat Loss Insulated Pipe SpreadsheetHernan RodriguezNo ratings yet

- Design of Bolted ConnectionsDocument7 pagesDesign of Bolted ConnectionsEngineerNo ratings yet

- Engine Zna RichDocument40 pagesEngine Zna RichEMILIO “ER NEGRO MECANICO” GONZALEZ100% (9)

- University of Duhok College of Engineering Mechanical DepartmentDocument3 pagesUniversity of Duhok College of Engineering Mechanical DepartmentMr sfeanNo ratings yet

- (5-1) Economical Comparison of Engineering Projects:-: 1-Present Worth Methods (P.W.M)Document7 pages(5-1) Economical Comparison of Engineering Projects:-: 1-Present Worth Methods (P.W.M)Mr sfeanNo ratings yet

- Engineering Economic 2020-1Document5 pagesEngineering Economic 2020-1Mr sfeanNo ratings yet

- Economy 2021 3Document4 pagesEconomy 2021 3Mr sfeanNo ratings yet

- (1-4) Factors That Affect The Economic Growth of A CountryDocument3 pages(1-4) Factors That Affect The Economic Growth of A CountryMr sfeanNo ratings yet

- (3-3) Interest:: Is Payment From A Borrower or Deposit-Taking Financial Institution To A Lender orDocument4 pages(3-3) Interest:: Is Payment From A Borrower or Deposit-Taking Financial Institution To A Lender orMr sfeanNo ratings yet

- (4-5) Uniform Series With Middle of Period Cash FlowsDocument8 pages(4-5) Uniform Series With Middle of Period Cash FlowsMr sfeanNo ratings yet

- I C Engines Chapter - 10 - Supercharging PartDocument7 pagesI C Engines Chapter - 10 - Supercharging PartMr sfean100% (1)

- (4-1) Future Value (FV) Single-Payment Compound Amount FormulaDocument6 pages(4-1) Future Value (FV) Single-Payment Compound Amount FormulaMr sfeanNo ratings yet

- Study The Convective Heat Transfer of Tio /water Nanofluid in Heat Exchanger SystemDocument11 pagesStudy The Convective Heat Transfer of Tio /water Nanofluid in Heat Exchanger SystemMr sfeanNo ratings yet

- Investigation of Shell and Tube Heat ExcDocument7 pagesInvestigation of Shell and Tube Heat ExcMr sfeanNo ratings yet

- Qip Ice 16 Ignition - SystemsDocument60 pagesQip Ice 16 Ignition - SystemsAjay KumarNo ratings yet

- Principles of Programming Languages Lecture Notes Unit 1Document7 pagesPrinciples of Programming Languages Lecture Notes Unit 1LaraibZafarKhan100% (1)

- Dougherty Valley HS Chemistry - Solutions Packet Name - Per - DateDocument4 pagesDougherty Valley HS Chemistry - Solutions Packet Name - Per - Date2413ramesh_snehaNo ratings yet

- 1468-Article Text-26836-2-10-20220428Document6 pages1468-Article Text-26836-2-10-20220428Rommel AnastacioNo ratings yet

- VMC Advance 1 Paper 1Document11 pagesVMC Advance 1 Paper 1amogh kumarNo ratings yet

- Generalised Butterworth-Van Dyke Equivalent Circuit For Thin-Film Bulk Acoustic ResonatorDocument2 pagesGeneralised Butterworth-Van Dyke Equivalent Circuit For Thin-Film Bulk Acoustic ResonatorByron FischerNo ratings yet

- S N Ne C Las Es L: Quantitative AptitudeDocument33 pagesS N Ne C Las Es L: Quantitative AptitudeanuragNo ratings yet

- Seminar in Seminar in Translation Informatics. InformaticsDocument3 pagesSeminar in Seminar in Translation Informatics. InformaticsMohammed Sabri BatainehNo ratings yet

- D2LU6C04Document34 pagesD2LU6C04Sani PoulouNo ratings yet

- Electric PotentialDocument20 pagesElectric PotentialAllan Gabriel LariosaNo ratings yet

- No of BerthsDocument16 pagesNo of BerthsSamer ElabdNo ratings yet

- CATALOGO PRODOTTI 2013 Per Sito WEB TEDDocument52 pagesCATALOGO PRODOTTI 2013 Per Sito WEB TEDmuhammad abidin100% (1)

- MU 4080 English Version 1.0.0Document43 pagesMU 4080 English Version 1.0.0Matz100% (1)

- Frictional Properties of Textile FiberDocument8 pagesFrictional Properties of Textile FiberMD Nazrul IslamNo ratings yet

- Quantitative Analysis 1Document20 pagesQuantitative Analysis 1FirdoseNo ratings yet

- Shivani Mehan - ResumeDocument1 pageShivani Mehan - ResumeShivani MehanNo ratings yet

- Worksheet On Carboxylic AcidsDocument3 pagesWorksheet On Carboxylic AcidsmalisnotokNo ratings yet

- Instructions:: Question Paper Booklet CodeDocument20 pagesInstructions:: Question Paper Booklet CodeadiNo ratings yet

- PROBABILITY It Is A Numerical Measure Which Indicates The ChanceDocument20 pagesPROBABILITY It Is A Numerical Measure Which Indicates The ChancePolice stationNo ratings yet

- Business Research Methods: Session 6 To 7Document109 pagesBusiness Research Methods: Session 6 To 7Contact InfoNo ratings yet

- Model 5Document4 pagesModel 5m hNo ratings yet

- Bca 2018 2021 PDFDocument94 pagesBca 2018 2021 PDFBala SivaramNo ratings yet

- T G 1653646560 Time Zones Powerpoint Ver 1Document8 pagesT G 1653646560 Time Zones Powerpoint Ver 1Malvika BalchandaniNo ratings yet

- PHUL Sheet TemplateDocument3 pagesPHUL Sheet TemplatetiandalfaNo ratings yet

- 6.metabolism in FungiDocument67 pages6.metabolism in FungiWahyuni Irmal100% (2)