Professional Documents

Culture Documents

Universal Measuring Device: Brief Instructions See Last Page

Uploaded by

aleksandarlaskovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Universal Measuring Device: Brief Instructions See Last Page

Uploaded by

aleksandarlaskovCopyright:

Available Formats

Universal Measuring Device

UMG 96

Operating instructions

Brief instructions see last page

Mean value

Programming mode

Sum measurement

Phase to phase

L1-N / L1-L2

L2-N / L2-L3

L3-N / L3-L1 Password

Voltage transformer

Current transformer

Output K1

Output K2

Maximum value Minimum value Supply Key 1 Key 2

Janitza electronics GmbH

Vor dem Polstück 1

D-35633 Lahnau

Doc No. 1.021.020.f

Support Tel. (0 64 41) 9642-22

Fax (0 64 41) 9642-30

e-mail: info@janitza.de

Internet: http://www.janitza.de

Table of contents

Receipt control 3 Programming mode 12

Product description 4 Key functions 13

Intended use 4 Table 1, Measured value indications 14

Hints for the user 4 Password 16

Functional description 4 Current transformer 16

Hints for Maintenance 5 Programming 16

Repairs and calibration 5 Voltage transformer 17

Front foil 5 Programming 17

Waste management 5 Outputs K1 and K2 18

Installation 6 Usage as switching output 19

Mounting place 6 Programming as switching output 19

Measurement and supply voltage 6 Usage as pulse output 20

Current measurement 6 Programming as pulse output 20

Sum current measurement 6 Pulse valency 21

Connection diagrams 7 Minimum pulse width 22

Installation and putting into service 8 Programming of minimumpulse width 22

Averaging times (Bimetal function) 23

Program current and voltage transformers 8

Method of taking the mean 23

Connect current transformers 8

Programming of averaging times 23

Check phase assignment 9

Measured value rotation 24

Check current flow 9

Programming of rotation time 24

Removal of errors 10

Measured value selection 25

Service 11

Programming of the measured value

Usage and display 12 selection 25

Indication mode 12 Delete minimum and maximum values 26

Measured values 12 Delete 26

Mean values 12 Delete energy 26

Energying hours meter 12 Delete 26

LCD contrast 27

Programming of LCD contrast 27

Software Release 27

User password 27

Indicating range and accuracy 28

Configuration data 29

Technical data 30

Ambient conditions 30

Measurement 30

Outputs 30

Connectable cables 30

Back side 31

Side wiew 31

Brief instructions 32

Programming of current transformer 32

Call up measured values 32

Page 2 = Peak value = Minimum value = Supply

Receipt control

In order to ensure a perfect and safe use of the device, a proper transport, expert storage, erection and mounting

and careful usage and maintenance are required. When it may be supposed, that a safe operation is no longer

possible, the device has to be put out of service and be protected against unintentional putting into service.

A safe operation can no longer be assumed, when the device

• shows visible damage,

• does not energy in spite of intact net supply,

• has been exposed to disadvantageous conditions for a longer time (e.g. storage out of the allowed climate

without adaption to the room climate, dew etc.) or transport use (e.g. falling from great height, even without

visible damage).

Please test the contents of delivery for completion, before starting the installation of the device. All delivered

options are listed on the delivery papers. The operating instructions also describe those options, which are not

delivered, and, therefore, do not belong to the contents of delivery.

The following items always belong to the contents of delivery:

The UMG96,

A packing (item code 52.07.103) with 2 mounting clamps and

The operating instructions.

A seal is available as an option with item code 2901907.

Issue note

24.11.1999 First edition.

19.09.2000 Supplementings.

17.01.2001 Measuring range, energying hour meter.

All rights reserved. No part of this manual may be 08.02.2001 Power consumption.

reproduced or duplicated without the written 22.02.2001 Energying hour meter.

permission of the author. Any contraventions are 06.04.2001 Delete maximum values of current

punishable and will be prosecuted with all legal average.

means. 06.07.2001 Programmable pulse width 5/5A.

No liability can be taken for the faultless condition 22.10.2001 20mA min. energying current, 60kV,

of the manual or damage caused by the use of it. As Measured value indications.

failures cannot be avoided completely, we shall be 19.11.2001 Operation at frequency inverter not

very grateful for any advice. We will try to remove possible.

any failures as soon as possible. The mentioned 06.05.2002 Logo, setting range for ../1A current

software and hardware descriptions are registered transformers.

trademarks in the most cases and are subjected to the 08.07.2002 Measuring range for power.

regulations by law. All registered trademarks are 03.03.2003 Current transformer inputs.

property of the corresponding companies and are 03.03.2003 Supplementings.

fully recognized by us. 08.06.2004 Accuracy class according.

= Peak value = Minimum value = Supply Page 3

Product description

Intended use

The UMG96 is suited for fixed mounting and the measurement of voltage, current, power etc. in low voltage

switchgear. The measurement is designed for 3 phase systems with neutral conductor (TN and TT-mains).

Measurement and supply voltages (50Hz/60Hz) up to 275VAC against earth and 476VAC phase to phase can

be connected directly. The measurement and supply voltages must be connected to the UMG 96 via a separation

(switch or power switch) and an overcurrent protection fuse (2-10A) in the building installation. The connection

of the measurement and supply voltage is carried out on the back side of the UMG 96 via spring power

clamps, which are all-insulated. To the current measuring inputs, either ../5A or ../1A current transformers can

be connected.

Hints for the user

This device may be installed and used by qualified personnel only, according to the safety regulations. Please

mention the legal and safety regulations for the corresponding application, while using the device.

Qualified personnel are persons, who are familiar to installation, mounting, putting into service and operation

of the product and have qualifications according to their occupation, for example:

• Education or instruction or the right to switch on or off, ground or characterize current circuits or devices

according to the standards of safety techniques.

• Education or instruction in care and use of safety equipment according to the standard safety techniques.

Functional description

The electronical three phase measurement system determines and digitalizes the effective values of voltages

and currents in 50/60 Hz netenergys.

The auxiliary voltage needed for operation of UMG 96 is taken from the measurement voltages L1-N, L2-N

and L3-N. For devices for measurement in 230V/400V netenergys, at least one phase must be within the rated

voltage range. For devices measuring in 58V/100V or 63V/110V netenergys, at least two phases must be in

the rated voltage range.

For each random test one period is scanned. From those sampled values the microprocessor calculates the

electric magnitudes. These measured values are indicated within the programmable display. The programming

data and the minimum and maximum values are saved all 15 minutes in a none volatile storage (EEPROM).

The transistor outputs K1 and K2 can be used as switching or pulse outputs. The scanning frequency is

calculated for all measuring inputs from the net frequency of phase one. For a net frequency of 50Hz the

scanning frequency is 2,5kHz and for 60Hz it is 3,0kHz. If the voltage in L1 is smaller than 50V, the UMG 96

uses the last measured net frequency for the determination of the scanning frequency.

In order to achieve a constant quality while reading the display over the whole temperature range, the inner

temperature is measured and the contrast is changed automatically.

Attention!

There is no possibility for a measurement in systems with pulsed measurement signals, as no continous

scanning of the measurement signals is carried out.

Page 4 = Peak value = Minimum value = Supply

Hints for Maintenance

Before delivery the device is tested in various safety checks and marked with a seal. If the device is opened,

these checks must be repeated.

Attention!

The guarantee is void if the seals are broken.

Repairs and calibration

Repairs and calibration can only be carried out by the manufacturing.

Front foil

The cleaning of the front foil must be done with a soft cloth using a common cleansing agent. Acid or acidic

agents may not be used for cleaning.

Waste management

The UMG96 can be disposed as electronical waste according to the legal regulations and recycled.

= Peak value = Minimum value = Supply Page 5

Installation

Mounting place

The UMG96 is suitable for a fixed installation into low and medium voltage switchgear. Any mounting position

is possible.

Measurement and supply voltage

The measurement is laid out for three phase systems with neutral conductor (TN and TT mains). The measure-

ment and supply voltages must be connected to the UMG 96 via a separation (switch or power switch) and an

overcurrent protection (2-10A) within the building installation.The connection of the measurement and supply

voltages is carried out at the back side of the UMG 96 via shock protected spring clamps.

As the supply voltage is taken from the measurement voltage, at least one measurement input (L-N)

must be in the rated range of voltage for operation.

- Devices with a voltage of 196 .. 275V (L-N) or 98 .. 140V (L-N) need a measurement input in the

rated voltage range.

- Devices with a measurement and supply voltage of 49 .. 76V (L-N) need two inputs at least in the

rated voltage range.

Current measurement

The current measurement is carried out via ../5A or ../1A current Verbraucher

transformers. If the current must be measured additionally to the Consumer

UMG96, with an Amperemeter, it must be connected in series to the l

UMG96. L l

UMG 96

K k

Attention!

k

A

The current transformer inputs of the UMG96 are live. Einspeisung

Supply

Sum current measurement

If the current measurement is carried out via two current transfor- Verbraucher 1 Verbraucher 2

mers, the total transformer ratio must be set to the UMG96. Consumer 1 Consumer 2

L l L l

Example: Sum current transformer

A current measurement is carried out via one current transformer K k K k

AK AL BK Bl

with a ratio of 1000/5A and one with a ratio of 200/5A. The sum

measurement is carried out with a sum transformer 5+5/5A. K l

The UMG96 must be programmed as follows:

k l

Primary current: 1000A + 200A = 1200A

Secondary current: 5A Einspeisung 1 UMG 96 Einspeisung 2

Supply 1 Supply 2

Page 6 = Peak value = Minimum value = Supply

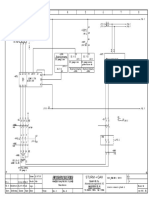

Connection diagrams 10210050ot

10210050ot

UMG 96 UMG 96 Hilfsausgang

Hilfsausgang

Messung Auxiliary

Messung Auxiliary

Measurement Measurement Output

Output

K1 K2 K1 K2

Siehe Siehe

Typenschild 0,01 .. 5A Typenschild 0,01 .. 5A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 2 3 4 5 6 7 8 9 10 11 12 13 14

L1 L2 L3 N 1k 1l 2k 2l 3k 3l L1 L2 L3 N 1k 1l 2k 2l 3k 3l

2 ..10A +

= -

2 ..10A

max. 30V DC max. 30V DC

L1 k l L1 k l

L2 ../5(1)A k l L2 ../5(1)A

Verbraucher Verbraucher

L3 ../5(1)A k l L3 k l

Consumer Consumer

PEN ../5(1)A PEN ../5(1)A

Diagr.: Connection example 1 Diagr: Connection example 2. Four wire measure-

Four wire measurement with three current trans- ment with two current transformers.

formers

10210050ot 10210050ot

UMG 96 Hilfsausgang

UMG 96 Hilfsausgang

Messung Auxiliary Messung Auxiliary

Measurement Output Measurement Output

K1 K2 K1 K2

See type See type

plate 0,01 .. 5A plate 0,01 .. 5A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 2 3 4 5 6 7 8 9 10 11 12 13 14

L1 L2 L3 N 1k 1l 2k 2l 3k 3l L1 L2 L3 N 1k 1l 2k 2l 3k 3l

2 ..10A 2 ..10A

max. 30V DC max. 30V DC

u u u u u u

x x x x x x

X X X X X X

U U U U U U

L1 k l L1 k l

L2 ../5(1)A k l Verbraucher L2 ../5(1)A Verbraucher

L3 ../5(1)A k l Consumer L3 k l Consumer

../5(1)A ../5(1)A

Diagr: Connection 3 Diagr.: Connection example 4

Three wire measurement with voltage transform- Three wire measurement with voltage transform-

ers and three current transformers. ers and two current transformers.

= Peak value = Minimum value = Supply Page 7

Installation and putting into service

The installation and putting into service of the UMG96 should be carried out as follows:

- Mount the device

- Connect measurement and supply voltage

Before connection of the measurement and supply voltage to UMG96, please ensure, that the net conditions

match the information on type plate.

The UMG96 can be delivered in three voltage varieties:

Type plate L-N Voltage range L-L Phases, required for operation

196 .. 275V 340 .. 476V 1 Phase + N

98 .. 140V 170 .. 242V 1 Phase + N

49 .. 76V 85 .. 132V 2 Phases + N

To ensure, that the connected measurement and supply voltage is within the allowed range, this must be

checked with an AC voltmeter before connecting the UMG96.

The connection wires for measurement voltage to the UMG96 must be suitable for voltages up to 300V against

ground and 520V phase to phase.

After switching on the measurement and supply voltage, shown on type plate, all segments on display appear.

If no indication appears, please check, if at least one (two) phase are within the rated voltage range. At devices

for the measurement in 230V/400V mains, at least one phase must be within the rated voltage range.

Program current and voltage transformers

When the device is delivered, a current transformer ratio of 5/5A is entered.

The voltage transformer ratio must be changed, if a voltage transformer is connected only.

While connecting a voltage transformer, please note the measurement and supply voltage of UMG96,

mentioned on type plate.

The program only allows current and voltage transformer ratios, which can lead to sum power of a

maximum of 99.9MW.

Connect current transformers

The current transformers (../5A or ..1A) are connected to the clamps k and l from the corresponding outer

conductors L1, L2 and L3. The current can be measured with an Amperemeter and compared with the indica-

ted current at the UMG96 to check. Please note, that the current transformer ratio is preset with 5/5A and

must be adapted to the used current transformers.

Attention!

Ꮨ The current transformer inputs of the UMG96 are live.

Page 8 = Peak value = Minimum value = Supply

Check phase assignment

The assignment of the outer conductors to the current transformer is correct, if a current transformer is short

circuited on the secondary, and the indicated current in the corresponding phase decreases to 0A at the UMG96.

Check current flow

Short circuit two current transformers on the secondary. The real power in the connected phase must be:

Positive (+) for consumption of real power and

negative (-) for supply of real power (power station service).

If no real power is indicated, the assignment of voltages and currents can be wrong.

10210050ot

UMG 96 Hilfsaus-

gang

Messung Auxiliary

Measurement Output

K1 K2

See type

plate 0,01 .. 5A

1 2 3 4 5 6 7 8 9 10 11 12 13 14

L1 L2 L3 N 1k 1l 2k 2l 3k 3l

2 ..10A

+ = -

max. 30V DC

L1 k l

L2 ../5(1)A k l

Verbraucher

L3 ../5(1)A k l

Consumer

PEN ../5(1)A

Diagr: Connection example, four wire measurement with three

current transformers

Attention!

Voltages, which exceed the allowed voltage range, can damage the device.

Attention!

Current transformer clamps, which are not earthed can be dangerous to touch.

= Peak value = Minimum value = Supply Page 9

Removal of errors

Fault Reason Removal

Display dark. Fuse released. Insert Fuse.

Device defective. Send the device to the manufacturer for repair.

Measured value cannot The indication has been deleted in Add the required measured value indication to

be called up. measured value selection. the measured value selection.

No current indication. Corresponding voltage is not con- Connect corresponding voltage.

nected.

Current too small. Current measurement in wrong Check and correct connection.

phase

Current incorrect. Current measurement in wrong Check and correct connection.

phase

Current transformer programmed Read ratio of current transformer and program

incorrectly. accordingly.

Measuring range exceeded. Insert a current transformer with a higher ra-

tio.

The current peak at measuring Insert a current transformer with a higher ra-

input was exceeded caused by tio.

harmonic waves. Attention! Please ensure, that the measuring

inputs are not overloaded.

Insert a current transformer with a smaller

ratio.

The current at measuring input Check and correct connection.

was exceeded.

Voltage L-N incorrect. Measurement in wrong phase. Check and correct connection.

Attention! Please ensure, that the measuring

inputs are not overloaded.

Voltage L-L too small / Outer conductors exchanged. Check and correct connection.

too high.

N not connected. Check and correct connection.

Page 10 = Peak value = Minimum value = Supply

Fault Reason Removal

Phase shift ind/cap. Current path is assigned to the Check and correct connection.

wrong voltage path.

Programmed data get The device was under electro- Improve external protection measures such as

lost. magnetical disturbance, which protection, f iltering, earthing and local

was higher than those mentioned separation.

in the technical data.

Real power too small / Current transformer ratio is pro- Read current transformer ratio and program

too high. grammed incorrectly. accordingly.

Current path is assigned to the Check and correct connection.

wrong voltage path.

Real power generation / At least one current transformer Check and correct connection.

consumption ex- connection is exchanged.

changed. Current path is assigned to the Check and correct connection.

wrong voltage path.

One output does not The device was programmed Check and correct programming.

react. incorrectly.

The device was connected in- Check and correct connection.

correctly.

The device does not Device defective. Please send the device back to the

operate in spite of the manufacturer with a detailed description of the

above. error.

Service

If there are questions, which are not described in this manual, please contact us directly.

For a better conversation we need the following information:

- Device description (see type plate),

- Serial number (see type plate),

- Software Release,

- Measurement and supply voltage and

- Detailed error description.

You can reach us:Monday until Thursday between 07:00 and 15:00

and Friday between 07:00 and 12:00

Janitza electronics GmbH

Vor dem Polstück 1

D-35633 Lahnau

Support: Tel. (0 64 41) 9642-22

Fax (0 64 41) 9642-30

e-mail: info@janitza.de

= Peak value = Minimum value = Supply Page 11

Usage and display

The usage of the UMG 96 is carried out via the keys one and two. Measured values and programming data are

indicated on the liquid crystal display. You must distinguish between

Indication mode and

Programming mode.

By entering a password, you can avoid unintentional change of programming data.

Indication mode

In indication mode you can scroll through the programmed measured value indications by using the keys 1 and

2. When the device is delivered, you can call up all measured values shown in table 1. For each measured value

indication, up to three measured values are indicated. The measured value rotation allows to indicate all se-

lected measured values one after the other with a selectable changing time.

Measured values

One measurement is carried out each second. The average is build from the detected values and indicated.

By taking the mean of the measured values, a large change of the input signals of the indicated measured

values appears after 4 second, and can be reduced to 95% of the input signal. The indicated measured value for

reactive power can reach 95% of the input signal after 8 seconds at large changes!

Mean values

For currents and power, additional averaging times in the range of 5 to 900 seconds can be set. These measured

value are marked with a horizontal bar above the measured value.

Energying hours meter

The energying hours meter detects the time, which the UMG96 is under operation. The time can be measured

with a resolution of 15 minutes and indicate in hours.

The energying hours meter cannot be deleted.

Programming mode

In programming mode the settings, which are necessary for the operation of the UMG 96, can be indicated and

changed. Pressing the keys 1 and 2 simultaneously for about 1 second, you reach programming mode via the

password indication. If no user password is programmed, you reach the first programming menu directly. The

programming menu is marked with the text „PRG“ in the display.

With key 2 you can change over between the following programming menues:

- Currect transformers,

- Voltage transformers,

- Output K1, switching output / pulse output,

- Output K2, switching output / pulse output,

- Minimum pulse width,

- Averaging times (bimetallic function),

- Rotation time of measured value rotation,

- Measured value rotation and measured value selection,

- Delete minimum and peak values,

- Delete energy,

- LCD contrast,

- Software Release,

- User password.

If you are in the menu programming mode, and no keys are pressed within 60 seconds, or you press the keys 1

or 2 simultaneously for about 1 second, you return to the indication mode.

Page 12 = Peak value = Minimum value = Supply

Key functions

Indication mode Password Programming mode

simultaneous

1 2

Change mode

simultaneous

1 2

long

long

Measured Programming

values menu

2 2

Measured Programming

short

short

Scroll

values menu

Measured Measured Programming

values values menu

1

long short

Programming 1

menu Confirm selection

Programming

2 short number +1

long number -1

2 short value *10

(dec. point to the right)

2 long value/10

flashing (dec. point to the left)

= Peak value = Minimum value = Supply Page 13

Table 1, Measured value indications

Measured values Maximum values Minimum values

L1-N Voltage L1-N V, meas. value L1-N V, meas. value

L2-N Voltage L2-N V, meas. value L2-N V, meas. value

L3-N Voltage L3-N V, meas. value L3-N V, meas. value

Measured values Maximum values Minimum values

L1-L2 Voltage L1-L2 V, meas. value L1-L2 V, meas. value

L2-L3 Voltage L2-L3 V, meas. value L2-L3 V, meas. value

L3-L1 Voltage L3-L1 V, meas. value L3-L1 V, meas. value

Measured values Mean values Maximum values Maximum values

L1 Current L1 Current L1 Current L1 cur. mean values

L2 Current L2 Current L2 Current L2 cur. mean values

L3 Current L3 Current L3 Current L3 cur. mean values

Measured values Mean value Maximum value Maximum values

Σ Current in N Σ Current in N Σ Measured value Σ Mean value

current in N current in N

Measured values Mean values Maximum values

L1 Real power L1 Real power L1 Real power, meas.

L2 Real power L2 Real power L2 Real power, meas.

L3 Real power L3 Real power L3 Real power, meas.

Measured value Mean value Maximum value Maximum value

Sum real power Sum real power (Consumption) (Consumption)

Sum real power meas. Sum real power, mean

Measured values Mean values Maximum values

L1 Apparent power L1 Apparent power L1 App. power, meas.

L2 Apparent power L2 Apparent power L2 App. power, meas.

L3 Apparent power L3 Apparent power L3 App. power, meas.

Measured value Mean value Maximum value

Sum apparent power Sum apparent power Sum App. power, meas.

Page 14 = Peak value = Minimum value = Supply

Measured values Mean values Max. values (ind)

L1 Reactive power L1 Reactive power L1 Reac. power, meas.

L2 Reactive power L2 Reactive power L2 Reac. power, meas.

L3 Reactive power L3 Reactive power L3 Reac. power, meas.

Measured value Mean value Max. value (ind)

Sum reactive power Sum reactive power Sum reac. power, meas.

Measured values

L1 cos(phi)

L2 cos(phi)

L3 cos(phi)

Measured value

Sum cos(phi)

Measured value

L1 Frequency

Measured value

(Consumption)

Sum real energy

Measured value

(ind)

Sum reactive energy

Energying hours

meter

= Peak value = Minimum value = Supply Page 15

Password

To avoid an unintentional change of programming data, a user pass-

word can be entered. If the correct user password is entered, a change

into the following programming menus is possible.

L1

In delivery condition, no user password is given (000). In this case,

the user password is skipped and you reach the current transformer

menu immediately.

L2

If a user password was programmed, the password menu appears in

display with the indication „000“. L3

The first cipher of the user password is flashing and can be changed

with key 2. Pressing key 1, the next cipher is selected and flashes.

After entering the correct cipher combination, you reach the program- Password Password Symbol

ming menu for the current transformer.

Current transformer

Current transformers with a secondary current of 1A or 5A can be Primary current (5.00kA = 5000A)

connected to the UMG 96 by choice.

The presetting is a current transformer ratio of 5A/5A. As the se- PRG

condary current, only 1A or 5A can be set. L1

k A

In programming mode the current transformer setting is marked with

the symbol „CT“.

L2

Programming

CT

In programming mode you scroll to the current transformer ratio by

L3

pressing key 2. Confirm the selection by pressing key 1.

The first cipher of the primary current is flashing and can be chan-

ged by pressing key 2. Pressing key 1, you select the next cipher, Secondary current Cur renttrans-

which is flashing now. former symbol

If the complete number is flashing, the decimal point can be moved.

Press key 2 shortly - The decimal point moves to the right.

Press key 2 longer - The decimal point moves to the left.

If no cipher is flashing anymore, you can go to the indication of the

voltage transformer.

Example: Sum current transformer

A current measurement is carried out via two current transformers,

each with a ratio of 1000/5A and one transformer with a ratio of 200/

5A. The sum measurement is carried out with a sum current

transformer 5+5/5A.

The UMG96 must be programmed with the following values:

Primary current: 1000A + 200A = 1200A

Secondary current: 5A

Attention!

The program only allows current and voltage transformer

ratios, if the single phase power can be 33.3kW maximum

and the sum power 99.9kW maximum.

Page 16 = Peak value = Minimum value = Supply

Voltage transformer

Only voltages with a secondary voltage, which is marked on type Primary voltage

plate of the UMG 96, can be connected.

PRG

L1

V

Type plate Input voltage UMG96

UMG96 L-L (Secondary voltage)

L2 L-L

196 .. 275V 400V (Standard version) VT

98 .. 140V 220V und 200V (Option) L3

49 .. 76V 110V und 100V (Option)

As secondary and primary voltage, the phase to phase voltage (L/L) Secondary voltage

is given in the display of UMG96. When the device leaves our factory, Phase to phase

the primary voltage is set the same as the secondary voltage. This voltage transformer symbol

means a transformer ratio of 1:1.

In programming mode, the voltage transformer is marked with the

symbol „VT“.

Programming

In programming mode, please scroll to the voltage transformer setting Primary voltage in kV

by pressing key 2. Confirm with key 1.

PRG

The first cipher of the primary voltage is flashing and can be chan- L1

kV

ged by pressing key 2. If you confirm with key 1, the next cipher is

flashing and can be changed.

L2

If the complete number is flashing, you can move the decimal point. L-L

If no cipher is flashing anymore, you can go to the programming of

VT

the outputs by pressing key 2. L3

The

Attention! Secondary voltage in Volt

program only allows current and voltage transformer

ratios, if the single phase power can be 33.3kW maximum

and the sum power 99.9kW maximum.

= Peak value = Minimum value = Supply Page 17

Outputs K1 and K2

The UMG96 has got two outputs. Each output can either be used as a

PRG

switching output or pulse output.

L1 Wh

The presetting for the outputs is:

Output 1 = Pulse output for real energy

Output 2 = Pulse output for reactive energy

L2

Outputs, which are assigned to a energy, energy as a pulse output.

Outputs, which are assigned to a measured value, energy as a swit- L3 K1

ching output.

The real energy can only be assigned to output 1 and reactive Output K1

energy can only be assigned to output 2.

One measured value can be assigned to each switching output. If

necessary, you can activate each single phase. A switching output

PRG

switches, when a set limit is exceeded or underscored.

L1

Therefore it is possible to supervise only the current in L1 and L2 VArh

with one threshold, for instance.

L2

The condition of the outputs is marked by a cyclic symbol.

Output is off, no current flowing.

Output is on, a current can flow. L3

K2

Output K2

Page 18 = Peak value = Minimum value = Supply

Usage as switching output

Exceeding Limit

If a measured value, but not energy, is assigned to the outputs K1 or

K2, the output energys as a switching output. The following values

for programming are at your disposal: PRG

Limit L1

A

Decimal point

Measured value

Sign L2

Exceeding / underscoring

Mean value

L3 K1

Phase

The selected measured value is compared to the set limit. If this limit

is exceeded or underscored, depending on your programming, the

corresponding output switches. Phase = L1

In order to avoid a too frequent switching, a minimum connection Measured value = Current

time of one second is fixely programmed. Switching output no. = K1,

Switching output, condition = On

+24V

10210140 +24V

10210290

11

30V 11

12 30V

12

Diagr. Switching output with external relay in Diagr. Switching output with external relay in

minus. plus..

Programming as switching output

In programming mode, scroll to output K1 or K2 by pressing key 2.

Confirm selection with key 1. PRG

The first cipher of the selected limit flashes. L1

A

Scroll to the next symbol or value with key 1. Flashing symbols or

values can be changed using key 2. L2

If the symbol PRG is flashing, a selection of the phases can be

carried out. K1

L3

If the complete number is flashing, the decimal point can be moved.

If the flashing symbols for the sign and mean value are longer on

than off, they are selected and remain on after proceeding with key 1.

If no symbol is flashing anymore, you can change over to the next

menu by using key 2.

Attention! The programmed values for the outputs can only

partially be checked, if they are plausible.

= Peak value = Minimum value = Supply Page 19

Usage as pulse output

Pulse valency=100VArh/pulse

If real energy is assigned to output K1 or reactive energy to K2, the

respective output energys as a pulse output. For each pulse output, a

pulse valency can be defined (Wh/pulse, VArh/pulse). The pulses, PRG

sampled within one second, are given out with a minimum duration L1

VArh

of 50ms and a maximum frequency of 10Hz. The pulse distances are

not proportional to the power.

If the measured energy exceeds the set pulse valency, so that the L2

maximum frequency for the pulse output is exceeded, the remaining

pulses are stored and given out later. Saved pulses get lost in case of

L3

a net breakdown. K2

Attention!

As the real energy meter operates with reverse running stop, there Output K2

will only be pulses given out, when electrical energy is consumed.

As the reactive power meter operates with reverse running stop, there

will only be pulses given out at inductive load.

10210280 +24V

+24V

11

UMG96 30V

10210130 1,5k 12

1,5k

11

30V UMG96

12

Diagr.: Usage as pulse output. Diagr. Usage as pulse output for optic coupling.

Programming as pulse output

In programming mode scroll to output K1 or k2 with key 2. Confirm PRG

selection with key 1. L1

VArh

The first number of the pulse valency flashes and can be changed

with key 2. Confirming with key 1, the next cipher is selected and L2

flashing.

If the whole number is flashing, the decimal point can be moved by

L3

using key 2. K2

If no cipher is flashing anymore, you can change over to the next

programming menu using key 2. Output K2

Page 20 = Peak value = Minimum value = Supply

Pulse valency

The pulse valency is given in Wh per pulse.

Pulse valency = Energy per pulse

The pulse valency may not be confused with the kW-meter-constant. The kW-meter-constant is given in

kW-meter-constant = Rotations per kWh

The context between pulse valency and kW-meter- constant can be seen in the following correlations:

kW-meter-constant = 1/pulse valency

Pulse valency = 1/kW-meter-constant

Example

For an AC mains with connected consumers, which have a real power consumption of 400kW, the pulse valency

must be calculated.

The energy, which can be consumed in one our, is:

Energy = Real power * time

Energy = 400kW * 1h

Energy = 400kWh

The result is a pulse valency of:

Pulse valency = Energy/pulse

Pulse valency = 400kWh/pulse

This means, that the pulse valency must be equivalent or higher than 400kWh/pulse, and must be set at UMG

96. Now one pulse per hour appears at the output at a power of 400kW.

If at a power of 400kW more pulses per time are required, 1 pulse per minute, for instance, the pulse valency

must be set to:

Pulse valency = 400kWh/pulse : 60

Pulse valency = 67kWh/pulse

If at a power of 400kW even more pulses are required, 1 pulse per second, for instance, the pulse valency is:

Pulse valency = 400kWh/pulse : 3600

Pulse valency = 112Wh/pulse

= Peak value = Minimum value = Supply Page 21

Minimum pulse width

If one of the outputs K1 or K2 is used as pulse output, a

programmable minimum pulse width is assigned. The minimum pul- PRG

L1

se width cannot be set separately for the outputs K1 and K2, but is MkWh

valid for both pulse outputs. MkVArh

The minimum pulse width can be set in the range of 0.05 seconds up L2 S

to 2.00 seconds in 0.05 second steps. The presetting of minimum

pulse width is set to 0.05 seconds.

L3

Minimum pulse width Minimum pulse width = 0.05s.

Pulse Pulse pause

0.05s 0.05s

100ms => 10Hz

Diagr. Maximum pulse frequency at minimum pulse width of 0.05

seconds.

At minimum pulse width the maximum pulse frequency is 10Hz.

If less pulses must be sent, the pulse pauses become longer. The

preset pulse width of 0.05, for example, remains constantly.

Minimum pulse width

Pulse Pulse pause

The outputs of UMG96 are equipped with semiconductor switches.

If a pulse appears, the output transistor becomes conductive and a

current can flow.

Programming of minimumpulse width

Go to minimum pulse width in programming mode using key 2.

Confirm selection with key 1. PRG

L1

The minimum pulse width flashes and can be changed with key 2. MkWh

Confirming with key 1, it stops flashing. MkVArh

Using key 2 you can now change to next programming menu. L2 S

L3

Minimum pulse width= 1.00 sec.

Page 22 = Peak value = Minimum value = Supply

Averaging times (Bimetal function)

For the most current and power values, a mean value is built. You can

Symbol for mean value

program a common averaging time for the current measured values

L1, L2, L3 and N , and one for power measured values, real power,

apparent power and reactive power is programmable.

L1

A

Presettings:

Averaging time of currents = 900 seconds

Averaging time power = 900 seconds L2

The following averaging times are selectable: K1

L3

5, 10, 30, 60, 300, 480, 900 seconds K2

Diagr: Indication of the mean

Method of taking the mean

values for the currents in L1, L2

The used exponential method reaches at least 95% of the measured

and L3.

value after the set averaging time.

MEn = MEn-1 + (MA-MEn-1) / N

MEn = indicated mean value

MA = measured value

n = running number

N = number of measured values, whose mean

values shall be built.

Mean value=real power

Programming of averaging times

Real power PRG

In programming mode scroll to the averaging time of power with key L1 W

2. Confirm using key 1.

The averaging time flashes and can be changed by pressing key 2. L2 S

Confirming with key 1, the averaging time stops flashing. Using key

2 you can now change to programming menu „Averaging time for

current“. L3

Averaging time= 5 seconds

Currents Mean value= Current

In programming menu scroll to the averaging time for currents with

key 2. Confirm selection with key 1. PRG

L1

A

The averaging time is flashing and can be changed using key 2.

Confirming with key 1, the averaging time stops flashing. Using key

2 you can now change to programming menu „Rotation time“. L2 S

L3

Averaging time = 5 seconds

= Peak value = Minimum value = Supply Page 23

Measured value rotation

Once in a second all measured values are calculated and can be shown Rotation time in seconds

on the display. For calling up the measured value indications, two

methods are available: PRG

- The automatic rotating indications of selected measured value L1

indications, in the following called measured value rotation.

- The selection of measured value indications via the keys 1 and 2.

L2 S

Both methods are available simultaneously. The rotation is program-

med, when at least one measured value indication and one rotation

time bigger than 0 seconds are programmed. If no key was pressed L3

for about 60 seconds, an automatic change over to rotation, and all

programmed measured values are indicated one after the other.

Symbol rotation time

Setting range of rotation time: 0 .. 250 seconds

If 0 seconds have been programmed, no rotation is carried out.

Measured value indications, which are not programmed in the measu-

red value selection, can nevertheless be user for rotation.

Programming of rotation time

In programming mode scroll to the menu measured value rotation,

using key 2. Confirm selection with key 1.

The first cipher of the rotation time is flashing and can be changed

by pressing key2. Confirming with key 1, the next cipher is selected

and flashes.

If no cipher is flashing anymore, you can change to programming

menu „Measured value selection“ pressing key 2.

Page 24 = Peak value = Minimum value = Supply

Measured value selection

In programming menu „measured value selection“, the measured

PRG

value indications can be selected via the two keys for automatic rota-

L1

tion.

All listed measured values from table 1 can be called up via the keys

1 and 2, when the device is delivered. The selection for automatic

L2

rotation is programmed together with the value selection.

The condition of the choice is indicated by the output symbols. Those

symbols have the following meaning: L3

Measured value selection

K1 This indication can be reached via the two keys.

K1 This indication cannot be reached via the two keys.

Measured value rotation

K2 This indication is in automatic rotation.

K2 This indication is not in automatic rotation.

Programming of the measured value selection

With key 1 you change to measured value selection. The first indica- Measured value indication of cur-

ted measured value indication is the current in the outer conductors. rents

In the example, the measured value indication of currents is program- PRG

med for the measured value selection and for the automatic rotation. L1

The selection of a measured value indication is carried out by a short A

pressing of the keys.

Key 1 - Scroll to the right within the measured value indications. L2

Key 2 - Scroll downwards within the measured value indications.

L3 K1

For the selected measured value indication, you can fix, if it is K2

available for measured value selection or automatic rotation.

The selection is carried out by a long press of the buttons 1 or 2.

Measured value

Key 1 - Change over the measured value selection.

selection

Key 2 - Change over the automatic rotation.

Measured value selection

If the programming is finished, you return to indication mode by

pressing key 1 and 2 simultaneously.

= Peak value = Minimum value = Supply Page 25

Delete minimum and maximum values

In programming mode, the menu „delete minimum and maximum

PRG

values“ is marked with an arrow up- and downwards. All minimum

L1

and maximum values can only be deleted simultaneously.

One exception is the maximum value of current mean value. The

maximum value of current mean value can be deleted directly in in-

L2

dication menu by pressing key 2 for a long time.

L3

Delete

In programming mode go to deletion of minimum and maximum va-

lues by pressing key 2.

With key 1 you can change over between the indicated numbers 0

and 1. These numbers have the following meaning:

PRG

0 = Do not delete the minimum and maximum values. L1

1 = Delete all minimum and maximum values.

After selection, you leave the menu by pressing key 2 and the mini- L2

mum and maximum values are deleted, if the number 1 was selected.

L3

Delete energy

The real and reactive energy can only be deleted simultaneously via PRG

the keys. L1 Wh

L2

L3

Symbol for the deletion of energy

Delete

In programming mode you scroll to the menu delete energy by using

PRG

key 2. Wh

L1

Pressing key 1 you can change over between the numbers 0 and 1.

These numbers have the following meaning:

0 = Do not delete real and reactive energy. L2

1 = Delete real and reactive energy.

After selection, you leave the menu by pressing key 2, and real and L3

reactive energy are deleted, if the number 1 was selected.

Page 26 = Peak value = Minimum value = Supply

LCD contrast

The favoured view for the LCD display is from below. This favoured

PRG

view can be adapted by the user. The contrast setting is possible in

L1

steps from 0 to 15.

0 = Very light

15 = Very dark

L2

In order to achieve an optimum contrast over the whole temperature

range, the inner temperature of the device is measured and the

contrast setting is corrected automatically. This correction is not in- L3

dicated in the display contrast setting.

Programming of LCD contrast PRG

In programming mode go to LCD contrast by pressing key 2. Con- L1

firm with key 1.

The first cipher of the contrast setting is flashing. Go to the right L2

cipher with key 1.

Now you can change the cipher with key 2. You can move to pro-

gramming menue „user password“ by pressing key 2 afterwards. L3

Software Release

The software for the UMG 96 is improved and expanded continously. PRG

The software release is marked with a number. The software release L1

cannot be changed by the user.

L2

L3

Example: Software Rel. 1.23

User password

With a three digit user password you can protect the device from

PRG

unintentional changing of the programming. In delivery condition, L1

the user password is "000".

If a changed user password is not known anymore, the user password

can only be reset by the master password „758“. L2

L3

User password

= Peak value = Minimum value = Supply Page 27

Indicating range and accuracy

Quantity Indicating range Measuring range1) Accuracy 5)

Meas. and supply voltage 196 .. 275V

Voltage L-N 0 .. 34kV 196 .. 275V +-1,0% rng

Voltage L-L 0 .. 60kV 340 .. 476V +-2,0% rng

Current 0,00 .. 9,99kA 0,02 .. 5,00A +-1,0% rng

Current in N 0,00 .. 9,99kA 0,03 .. 15,00A +-3,0% rng

Real power consumption, sum 0,00W .. 99,9MW 3,2W .. 1,375kW +-1,5% rng

Real power, supply, sum -0,00W .. -99,9MW -3,2W .. -1,375kW +-1,5% rng

Apparent power, sum 0,00VA .. 99,9MVA 3,2VA ..1,375kVA +-1,5% rng

Reactive power (Q0), sum 0,00var .. 99,9Mvar 3,2var..1,375kvar +-1,5% rng

Meas. and auxiliary voltage 98 .. 140V

Voltage L-N 0 .. 34kV 98 .. 140V +-1,0% rng

Voltage L-L 0 .. 60kV 170 .. 242V +-2,0% rng

Current 0,00 .. 9,99kA 0,02 .. 5,00A +-1,0% rng

Current in N 0,00 .. 9,99kA 0,03 .. 15,00A +-3,0% rng

Real power, consumption, sum 0,00W .. 99,9MW 1,6W .. 700W +-1,5% rng

Real power, supply, sum -0,00W .. -99,9MW -1,6W .. -700W +-1,5% rng

Apparent power, sum 0,00VA .. 99,9MVA 1,6VA .. 700VA +-1,5% rng

Reactive power (Q0), sum 0,00var .. 99,9Mvar 1,6var .. 700var +-1,5% rng

Meas. and auxiliary voltage 49 .. 76V

Voltage L-N 0 .. 34kV 49 .. 76V +-1,0% rng

Voltage L-L 0 .. 60kV 85 .. 132V +-2,0% rng

Current 0,00 .. 9,99kA 0,02 .. 5,00A +-1,0% rng

Current in N 0,00 .. 9,99kA 0,03 .. 15,00A +-3,0% rng

Real power, consumption, sum 0,00W .. 99,9MW 0,8W .. 380W +-1,5% rng

Real power, supply, sum -0,00W .. -99,9MW -0,8W .. -380W +-1,5% rng

Apparent power, sum 0,00VA .. 99,9MVA 0,8VA .. 380VA +-1,5% rng

Reactive power (Q0), sum 0,00var .. 99,9Mvar 0,8var .. 380var +-1,5% rng

cos(phi) 0,00i .. 1.00 .. 0,00k 2)

Frequency (voltage) 45,0 .. 65,0Hz +-1,5% rdg

Reactive energy, inductive

v4) < 10 0..999 999 9.99kvarh class 2 3)

v4) < 100 0..999 999 99.9kvarh class 2 3)

v4) >= 100 0..999 999 999kvarh class 2 3)

Real energy, consumption

v4) < 10 0..999 999 9.99kWh class 2 3)

v4) < 100 0..999 999 99.9kWh class 2 3)

v4) >= 100 0..999 999 999kWh class 2 3)

Energying hours counter 0..999 999 999h +-2minutes/day

1) Measuring range with scale factor = 1, (Current transformer = 5/5A, 1/1A)

2) If the measured apparent power is in the range of 1% .. 100% of the measuring range, the cos(phi) is displayed with an accuracy of +/- 3%.

3) Accuracy class according to DIN EN61036:2001-01, VDE0418part 7, IEC61036:1996 + A1:2000

4) v = vi * vu, vi = Current transformer ration. Example: 200/5A -> vi = 40

vu = Voltage transformer ratio. Example: 1000/100V -> vu = 10

5) In the range of -10..18°C and 28..55°C an additional inaccuracy of +-0,5‰ omv per K must be mentioned.

Page 28 = Peak value = Minimum value = Supply

Configuration data

Description Display Setting range Presettings

Current transformer, primary CT 1A .. 10,0kA (../5A) 5A

1A .. 2,0kA (../1A)

Current transformer, secondary CT 1A, 5A 5A

Voltage transformer, primary

Type plate, 196 .. 275V VT 100V .. 60,0kV 400V

Typeplate, 98 .. 140V VT 100V .. 60,0kV 200V

Type plate, 49 .. 76V VT 100V .. 60,0kV 100V

Current transformer secondary

Type plate, 196 .. 275V VT 400V (cannot be changed) 400V

Type plate, 98 .. 140V VT 200V, 220V 200V

Type plate, 49 .. 76V VT 100V, 110V 100V

Outputs (by choice) Kx

Pulse output K1, K2 K1, K2

Measured values Reactive and real energy K1=Real., K2=React.

Pulse valency 0,00(W/var)h .. 99,9k(W/var)h K1=1,00Wh, K2=1,00varh

Switching output K1, K2 -

Measured value All values except energy -

Exceeding 0,01 .. 20,0M -

Underscoring 0,01 .. 20,0M -

Minimum pulse width 0.05...2.00 sec. 0.05 sec.

Averaging time current 5, 10, .. 900 sec. 900 sec.

Averaging time power 5, 10, .. 900 sec. 900 sec.

Rotation time 0 .. 255 0=no rotation

Measured value rotation see table No measured value rotation

Measured value selection see table All measured value indicat.

LCD contrast 0 .. 15 7

Software Release x.xx x.xx

User password 000 .. 999 „000“ = no password

These specifications presuppose a yearly calibration and a warm up time of 10 minutes.

Used abbreviations:

rng = of measuring range

rdg = of measured value

= Peak value = Minimum value = Supply Page 29

Technical data

Weight : 250g

Calorific value : 2,2MJ (610Wh)

Ambient conditions

Overvoltage class : CATIII

Pollution degree :2

Ambient temperature : -10°C .. +55°C

Storage temperature : -20°C .. +70°C

Humidity : 15% up to 95% without dew

Protection class

Front : IP50 according to IEC529

Front with seal (option) : IP65 according to IEC529

Back side : IP20 according to IEC529

Protection class : II = without protective wire

Installation place : any

Height : 0 .. 2000m over NN

Resistance against interf. (Industr. areas) : EN50082-2:1995; IEC1000-4-,3, 10V/m

: IEC1000-4-4, 2kV; IEC1000-4-2, 8kV

Interference radiation (residential areas) : EN55011 10.1997

Safety guidelines : EN61010-1 03.1994 + A2 05.1996; IEC1010-1

Measurement

Measurement and supply voltage : see type plate

Measuring inputs

Scanning frequency : 1 Measurement/sec.

Rated pulse voltage : 4kV

Signal frequency : 45Hz .. 1000Hz

Current measurement : max. 300VAC against earth

Power consumption : about 0,2 VA

Rated current at ../5A (../1A) : 5A (1A)

Min. energying current : 20mA

Current limit at ../1A : 1,2A (sinus shape)

Current limit at ../5A : 6A (sinus shape)

Overload : 180A for 2 Sek.

Voltage measurement : max. 300VAC against earth

Power consumption

196 .. 275V (see type plate) : max. 13,4VA / Phase

98 .. 140V (see type plate) : max. 7,4VA / Phase

49 .. 76V (see type plate) : max. 2,6VA / Phase

Fuse : 2A..6A (medium time-lag type)

Frequency of fundamental : 45Hz .. 65Hz

Outputs

Type : NPN-Transistor

Switching frequency : max. 10Hz (50ms pulse width)

Operating current : max. 50 mA (not short-circuit-proof)

Permissible rest current : < 1mA

Operating voltage : 5.. 24VDC, max. 30VDC

Connectable cables

One wire, multiple-wire, fine wire : 0,08 - 2,5mm2

Pin contacts : 1,5mm2

Only one wire may be connected at one clamp!

Page 30 = Peak value = Minimum value = Supply

Back side

Cut out: 92+0,8 x 92+0,8 mm

10210060b

Side wiew

42 6

96

90

10210060a

Dimensions in mm

= Peak value = Minimum value = Supply Page 31

Brief instructions

Pressing the keys 1 and 2 for about 1 second, you reach programming

mode.

If you are in programming mode, you return to indicating mode by

pressing keys 1 and 2 for about 1 second.

Programming mode

Programming of current transformer

Select current transformer menu: PRG

Press both keys simultaneously for about 1 second. The symbols for L1

k A

programming mode PRG and the current transformer CT appears.

Confirm with key 1.

L2

The first cipher of primary current is flashing.

CT

L3

Current transformer 1 2

symbol

Change primary current:

Primary current

Change the flashing cipher with key 2.

Select the next cipher to be changed with key 1.

PRG

The selected cipher is flashing. L1

If the whole number is flashing, the decimal point can be moved. k A

Change secondary current: L2

Only 1A or 5A can be set as secondary current.

Select secondary current with key 1. CT

Change cipher with key 2. L3

Leave programming mode:

Secondary current 1 2

Press both keys for about 1 second.

The current transformer setting is saved and you return to indication

menu.

Call up measured values

The measured values indications can only be called up, when the

symbol PRG for programming mode is not in the display.

With the keys 1 and 2 you can leave through the measured values. L1

V

When the device is delivered, all measured values you find in table 1

can be called up.

L2

If you are in programming mode and do not press a key within 60

seconds, the device returns to indication mode automatically. L3 K1

K2

1 2

Page 32 = Peak value = Minimum value = Supply

You might also like

- Universal Measuring Device: Brief Instructions See Last PageDocument32 pagesUniversal Measuring Device: Brief Instructions See Last PageStefanitaNo ratings yet

- Janitza Manual UMG96 All Versions en PDFDocument32 pagesJanitza Manual UMG96 All Versions en PDFxuyen tranNo ratings yet

- Janitza BHB Umg96 All Versions en PDFDocument32 pagesJanitza BHB Umg96 All Versions en PDFStefan BusoiNo ratings yet

- Janitza Manual UMG510 enDocument44 pagesJanitza Manual UMG510 enMike MtzNo ratings yet

- QL355, QL355P, QL564 & QL564P: Instruction ManualDocument169 pagesQL355, QL355P, QL564 & QL564P: Instruction ManualluisNo ratings yet

- Janitza UMG503Document87 pagesJanitza UMG503razvansasu100% (1)

- 8kW Power-Meter H M 8 1 1 5 - 2: ManualDocument18 pages8kW Power-Meter H M 8 1 1 5 - 2: ManualErick NarváezNo ratings yet

- Dpi 610 Is Portable Pressure Calibrator/Indicator User Guide K239Document52 pagesDpi 610 Is Portable Pressure Calibrator/Indicator User Guide K239Michael Adu-boahenNo ratings yet

- LA10C ManualDocument39 pagesLA10C ManualenticoNo ratings yet

- Operating Manual UMG503Document96 pagesOperating Manual UMG503voltus88No ratings yet

- Thurlby Thandar Instruments TTI QL Series II User ID4754Document42 pagesThurlby Thandar Instruments TTI QL Series II User ID4754luisNo ratings yet

- Compact Display User ManualDocument17 pagesCompact Display User Manualabhi kannanNo ratings yet

- 16Document220 pages16indrajeetNo ratings yet

- Operating Instructions: ETS 132 Net Temperature Controller ModuleDocument90 pagesOperating Instructions: ETS 132 Net Temperature Controller ModuleJuan Carlos HernandezNo ratings yet

- Janitza BHB Umg96rme enDocument132 pagesJanitza BHB Umg96rme enjeremy.vfeNo ratings yet

- QL Series II: Instruction ManualDocument42 pagesQL Series II: Instruction ManualluisNo ratings yet

- BP SartoriuspdfDocument93 pagesBP Sartoriuspdfrendy widayatNo ratings yet

- 3 B6 LM I Service Manual For Frannacranes: Revisione 23/01/2002Document36 pages3 B6 LM I Service Manual For Frannacranes: Revisione 23/01/2002M RefaiNo ratings yet

- Manual MCDocument64 pagesManual MCclaus.skjoethNo ratings yet

- Technical Catalog ABB ACS1000Document94 pagesTechnical Catalog ABB ACS1000Huan VoNo ratings yet

- Brewery Automation: BREE 495 Ian Burelle 260 472 128Document41 pagesBrewery Automation: BREE 495 Ian Burelle 260 472 128Fotonika ITSNo ratings yet

- MG33M102 - Programming InstructionDocument175 pagesMG33M102 - Programming InstructiondarrenghallNo ratings yet

- 8400 Protec Handbook-Daimler - en - V4Document73 pages8400 Protec Handbook-Daimler - en - V4Venypierre ParraNo ratings yet

- DAS APM Catalogue v1.0 ENDocument5 pagesDAS APM Catalogue v1.0 ENJan SebastianNo ratings yet

- Parker Installationsanleitung PCM Modul Ep2 Ep3 MSG30 2902 INST EN 2019Document66 pagesParker Installationsanleitung PCM Modul Ep2 Ep3 MSG30 2902 INST EN 2019nime fuziNo ratings yet

- Universal Measuring Instruments: TNM 34XxDocument6 pagesUniversal Measuring Instruments: TNM 34XxAngel RuizNo ratings yet

- Documento PDFDocument49 pagesDocumento PDFRuben De La RosaNo ratings yet

- Danfoss VLT2800 VFD Manual PDFDocument124 pagesDanfoss VLT2800 VFD Manual PDFRamon Eduardo Castillo AbreuNo ratings yet

- Static Trip ManualDocument52 pagesStatic Trip ManualRavijoisNo ratings yet

- Elplek PDFDocument246 pagesElplek PDFvnunes01No ratings yet

- ENG SS MP2000 Operation Manual ADocument30 pagesENG SS MP2000 Operation Manual Anik.lukoyanov.91No ratings yet

- SWC-32 Controller: Belt Scale User ManualDocument24 pagesSWC-32 Controller: Belt Scale User ManualDhananjay MahakudNo ratings yet

- Tense Electronic Product CatalogDocument36 pagesTense Electronic Product CatalogJuan Carlos Gonzales PreiraNo ratings yet

- Basic PLCDocument45 pagesBasic PLCisilpii4No ratings yet

- Models 18C 19C and 25C Panel Mount ControllerDocument54 pagesModels 18C 19C and 25C Panel Mount Controllerjdjsj jfjedNo ratings yet

- Janitza Manual UMG96RM E 20 250V enDocument124 pagesJanitza Manual UMG96RM E 20 250V enAnonymous N13JdnNo ratings yet

- Ar 4201 PDFDocument22 pagesAr 4201 PDFRiyanPratomuSiregarNo ratings yet

- The Moog Source Owner's Manual PDFDocument81 pagesThe Moog Source Owner's Manual PDFkevin8gerzevitzNo ratings yet

- Technical Overview: Functions Ea Ea MFD-... CP8/CP10... Counter FunctionsDocument1 pageTechnical Overview: Functions Ea Ea MFD-... CP8/CP10... Counter FunctionsVirgil DamianNo ratings yet

- M Series Mass Flow MetersDocument38 pagesM Series Mass Flow MetersÉric DeRepentignyNo ratings yet

- 6inch HD E-Paper SpecificationDocument26 pages6inch HD E-Paper SpecificationfirsttenorNo ratings yet

- Vacuum MeasurementDocument18 pagesVacuum MeasurementSamuel GillilandNo ratings yet

- Selecpricelist 2022 2023 Electrical Doc V1R12 250422Document36 pagesSelecpricelist 2022 2023 Electrical Doc V1R12 250422DeepakNo ratings yet

- Mass Volum Gas MeterDocument38 pagesMass Volum Gas MeterDANTE BAYONA MENESESNo ratings yet

- RWD 62Document10 pagesRWD 62Piee SyafieNo ratings yet

- Technical Document W10Document116 pagesTechnical Document W10namNo ratings yet

- GUI m-etr132II-$2001 INDocument86 pagesGUI m-etr132II-$2001 INRoberto linaresNo ratings yet

- Kimray BK2800 PDFDocument12 pagesKimray BK2800 PDFjhonattan covelliNo ratings yet

- SDX30 UM 10082280 enDocument209 pagesSDX30 UM 10082280 enBerny777No ratings yet

- Janitza BHB Umg96rmpn enDocument128 pagesJanitza BHB Umg96rmpn enRafael PeÑaNo ratings yet

- Ut 321Document37 pagesUt 321Arnaldo AbadNo ratings yet

- Amkasyn Parameter Description KW-R25: Part No.: 2019/45 205909 Translation of The "Original Dokumentation"Document250 pagesAmkasyn Parameter Description KW-R25: Part No.: 2019/45 205909 Translation of The "Original Dokumentation"joseNo ratings yet

- PDK 205904 Parameter Description kw-r06 enDocument278 pagesPDK 205904 Parameter Description kw-r06 enIsao TomitaNo ratings yet

- dcs800 s02 0820 05+s171 - TCDocument40 pagesdcs800 s02 0820 05+s171 - TCSergio ArredondoNo ratings yet

- DCP-20 Genset Control ManualDocument65 pagesDCP-20 Genset Control Manualandy habibiNo ratings yet

- Instructions and Advices To Use The Electronic Controller Logik 9Document27 pagesInstructions and Advices To Use The Electronic Controller Logik 9Muhammad Zeeshan Saeed100% (1)

- Model Sr620: Universal Time Interval CounterDocument124 pagesModel Sr620: Universal Time Interval CounterFrancisco Javier GalindoNo ratings yet

- Newnes Electronics Engineers Pocket BookFrom EverandNewnes Electronics Engineers Pocket BookRating: 4.5 out of 5 stars4.5/5 (4)

- SVERKER 750 - 780 Relay Test Unit. User S ManualDocument76 pagesSVERKER 750 - 780 Relay Test Unit. User S ManualaleksandarlaskovNo ratings yet

- A Guide To Preventive MaintenanceDocument15 pagesA Guide To Preventive MaintenancealeksandarlaskovNo ratings yet

- Soft Starter SiemensDocument1 pageSoft Starter SiemensaleksandarlaskovNo ratings yet

- Installation and Operation: On Tanks and VesselsDocument24 pagesInstallation and Operation: On Tanks and VesselsaleksandarlaskovNo ratings yet

- Installation and Operation: EKL/EMK For Containers and SurfacesDocument23 pagesInstallation and Operation: EKL/EMK For Containers and SurfacesaleksandarlaskovNo ratings yet

- 03 - HS131087E Treatment and Storage InstructionDocument14 pages03 - HS131087E Treatment and Storage InstructionaleksandarlaskovNo ratings yet

- 04 - 1HC0022379 Instruction For Transport, Packaging and State of Delivery HECSDocument3 pages04 - 1HC0022379 Instruction For Transport, Packaging and State of Delivery HECSaleksandarlaskovNo ratings yet

- Katalog Dimnjaka 2015 SRBDocument8 pagesKatalog Dimnjaka 2015 SRBaleksandarlaskovNo ratings yet

- Dvostijeni Izolirani Dimovodni Sistemi Za Kamine I Kotlove: Inoxterm 50 Peleterm 25 Alternativ 25Document4 pagesDvostijeni Izolirani Dimovodni Sistemi Za Kamine I Kotlove: Inoxterm 50 Peleterm 25 Alternativ 25aleksandarlaskovNo ratings yet

- White Paper Electrical Ground Rules Pt2 020Document7 pagesWhite Paper Electrical Ground Rules Pt2 020aleksandarlaskovNo ratings yet

- Altistart 22 ATS22C14Q PDFDocument9 pagesAltistart 22 ATS22C14Q PDFaleksandarlaskovNo ratings yet

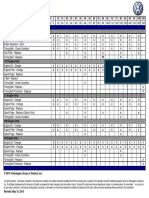

- Kilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersDocument2 pagesKilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersaleksandarlaskovNo ratings yet

- Altistart 22 ATS22C14QDocument26 pagesAltistart 22 ATS22C14QaleksandarlaskovNo ratings yet

- Corsa FuseDocument1 pageCorsa FusealeksandarlaskovNo ratings yet

- Solution To Bypass The ATV61Document2 pagesSolution To Bypass The ATV61aleksandarlaskovNo ratings yet

- 2016 CIGRE SC ScopeofWorkDocument36 pages2016 CIGRE SC ScopeofWorkaleksandarlaskovNo ratings yet

- 1ybhn9z7 1xub9llf 1y3yikea Ehgst5Document42 pages1ybhn9z7 1xub9llf 1y3yikea Ehgst5aleksandarlaskovNo ratings yet

- 3161 9711 1 SMDocument3 pages3161 9711 1 SMpuskesmas sidosermoNo ratings yet

- Test Bank For Anatomy and Physiology: An Integrative Approach 3Rd Edition, by Mckinley DR., Michael, Valerie Oâ ™loughlin, Theresa BidleDocument36 pagesTest Bank For Anatomy and Physiology: An Integrative Approach 3Rd Edition, by Mckinley DR., Michael, Valerie Oâ ™loughlin, Theresa Bidlesublunardisbench.2jz85100% (19)

- Life of Celwenkosini by Nomfundo MbheleDocument792 pagesLife of Celwenkosini by Nomfundo Mbheleanelelerato70No ratings yet

- Woking Priciple in DCDocument7 pagesWoking Priciple in DCRohit Kumar DasNo ratings yet

- Shannon Entropy Based On The S-Transform Spectrogram Applied On The Classification of Heart SoundsDocument6 pagesShannon Entropy Based On The S-Transform Spectrogram Applied On The Classification of Heart SoundsdenyspestanaNo ratings yet

- Hygiene and Healthy Habits For TeensDocument15 pagesHygiene and Healthy Habits For Teensdibose8563No ratings yet

- Effect of Probiotics On Growth, Feed Utilization and Whole Body Proximate Composition of Pabda (Ompok Pabda) JuvenileDocument5 pagesEffect of Probiotics On Growth, Feed Utilization and Whole Body Proximate Composition of Pabda (Ompok Pabda) Juvenilemasuma akter jiniaNo ratings yet

- BaeS RG-35 6x6Document2 pagesBaeS RG-35 6x6engelbrechtwjNo ratings yet

- 4th Grade - Lesson Overview-Organisms in Their EnvironmentDocument1 page4th Grade - Lesson Overview-Organisms in Their EnvironmentlchamblessNo ratings yet

- Static and Thermal Analysis of Piston and Piston RingsDocument8 pagesStatic and Thermal Analysis of Piston and Piston RingsNguyenNo ratings yet

- Tobler - MWO Raum Und Zeit Final - English - FinalDocument6 pagesTobler - MWO Raum Und Zeit Final - English - Finalheinz_toblerNo ratings yet

- Holiday Gift Ideas 2013Document0 pagesHoliday Gift Ideas 2013Lillie NewspapersNo ratings yet

- Jeannerod (2001) Neural Simulation of Action. A Unifying Mechanism For Motor CognitionDocument7 pagesJeannerod (2001) Neural Simulation of Action. A Unifying Mechanism For Motor CognitionPaul Wood100% (2)

- Test About Good Citizen - CorrectionDocument2 pagesTest About Good Citizen - CorrectionDjaouida BoucedraNo ratings yet

- Peli Overview 2015Document31 pagesPeli Overview 2015api-300615472No ratings yet

- Corrosion Prevention During Acid Cleaning of Pulping EquipmentDocument22 pagesCorrosion Prevention During Acid Cleaning of Pulping EquipmentlyoufNo ratings yet

- Exam Year Questions and AnswersDocument8 pagesExam Year Questions and AnswersArdianto SuhendarNo ratings yet

- EDS-64UD Single Point Borehole ExtensometerDocument3 pagesEDS-64UD Single Point Borehole ExtensometerdavzuluetaNo ratings yet

- Bladder Accumulators High Pressure: 1. DescriptionDocument4 pagesBladder Accumulators High Pressure: 1. DescriptionNasajonNo ratings yet

- Covid-19 Expose (Unmask)Document2 pagesCovid-19 Expose (Unmask)Eduardo CasesNo ratings yet

- Chapter 1, Unit 2, Human Anatomy and Physiology 1, B Pharmacy 1st Sem, Carewell PharmaDocument5 pagesChapter 1, Unit 2, Human Anatomy and Physiology 1, B Pharmacy 1st Sem, Carewell Pharmatambreen18No ratings yet

- LECTURE 2 Urinary System - Histology HB II 2023Document79 pagesLECTURE 2 Urinary System - Histology HB II 2023Emmanuel AssopiahNo ratings yet

- 06 The Technical Framework of Truffle CultivationDocument19 pages06 The Technical Framework of Truffle CultivationMate CroNo ratings yet

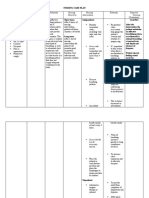

- NCP ScribdDocument3 pagesNCP ScribdAngela AyalaNo ratings yet

- Four Year Plan StandardDocument4 pagesFour Year Plan Standardapi-336266844No ratings yet

- Fluid & Electrolite Management in Surgical WardsDocument97 pagesFluid & Electrolite Management in Surgical WardsBishwanath PrasadNo ratings yet

- The Gaudapada Karika Quotes 2Document1 pageThe Gaudapada Karika Quotes 2goldenlion1No ratings yet

- E Locking Cessna 172Document3 pagesE Locking Cessna 172RAJ MOHANNo ratings yet

- Acei and ArbDocument6 pagesAcei and ArbNurulrezki AtikaNo ratings yet

- Coach Bud WinterDocument4 pagesCoach Bud WinterPasquale Belluscifotografo100% (1)