Professional Documents

Culture Documents

Blast Audits and Compliance

Blast Audits and Compliance

Uploaded by

Mohamed Badian Traore0 ratings0% found this document useful (0 votes)

8 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views10 pagesBlast Audits and Compliance

Blast Audits and Compliance

Uploaded by

Mohamed Badian TraoreCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Blast Audits and Design Compliance

Need for blast audits

‘Audits are the to! that provides the method to reconcile what we

‘esign with what actualy gots done

“You get what you inspect, not what you expect

* you don't measure , you cant manage

Audits

Uncover diferences between what is set out in procedures and

what ls done in practice

«Provide feedback on changes to processes

* Are informative, not punitive

Blast Audit Design

Purpose of bias aut

improve fagmtaton and cast

* Reauce damage

* Redvee alton and cal oss

* Reduce ground vrations and atiast

Level ofthe prob

* Ute contol over implementaton

2 Okcasnay rs rata pecs ant rmsts wn

| eau are OK btther isan opportunity to improve

Existing Resources and their reliablty

"iil monitorngsystoms

+ Mine repocing systems

+ Fragmentaton measurement systams

Audit Procedure

last Audts

view SWPs and blast designs thon aust for compan with hese

+ ust fequeney should st compance requirements

tal equoney maybe igh ur rca ure

‘tormamaes ono

“Determine immediate and basic causes of any nan-complance

+ Assn espanseiion

+ Seton eto any tanga rege

Audit Procedure

Aut fotlow-up

Track ogress of rues work

Raju venone oS conpians sched

1 era progres agin compton dase rake

“+ Reviow outcomes of remedial actions whan work complete

il emecn son wat compaans?

“ Updato SWPs avd bast sig pocodures to rtect changes

todd cart SWPs toatl beac change werk pacions

* Now prods andor poceauosegure lomo senso arvana

ewes naw SPS

Blast Design Implementation and Compliance}

Systems to capture & contro variations

"Nothina beats Ori and Blast Engineer witha

clipbeard anda tape measure!

Wiite coat effect

Just being hee wit part and tape wlndue sgnifeant

improvementsin performance

+ Rogulr aus are a good tot for making thie change permanant

Feedback ote diane bast crows citeal t ovrcoing thir

loqutatthe aut

Blast Audits Checklist

Diling Records

Pre-Loading Hole Checks

Explosives Loading

Patten Tiesns

‘Bast Clearance and Firing

Misfire Handling

Bast Reporting

Sata aon.

Blast Audits.

Blas

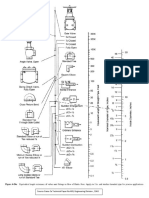

Pattern Implementation

a

eee

Sioa nvenzeam Eo

Pattern Implementation

In aitnaceenteses,,

de ewan a

Pattern Implementation

Blast Implementation: Column Length

* Tager ee

Blast Implementation: Stemming Lenaths

Fngvney

eves

Poo ee vee

ELLE EE EOL OES

Blast Design Implementation - Variation

Assume a blast pattorn as follows

Burden = 7m

“Spacing =m

nich Height = 150.

© Hole Diameter= 70mm

Now assume the following allowable tolerances:

+ Burden = 7m +0.5m (Le. apprex 2 hole dlameters)

* Spacing = 8m +0.

5 Hole Dopth = 18m 4.0m

Blast Design Implementation - Variation

Burden =7m-+/-0.8m This ie +/-7% variation

Spacing =m ¥.5m This tsa ¢/-6% variation

Hole Depth = 18m 1.0m This is 2-3 variation

NB: Those variations are within the normally accoptable range for

This fs thesort of variability you wil get in an acceptatle

patter

+ This error in eriing is large enough to mask most of he gains

you wouldespect frm any blast improvement progr andor

{e produce substantial false positives

Blast Design Implementation - Variation

‘Gurdon =7m4¥-05m This +/-7% variation

‘Spacing =m 0.5m Thisis 9 4/-6% variation

Hole Dapth= 8m +-1.0m This a sf 6% variation

“This means variations between two adjacent of up to 15% in

[burdens = up to 12% In spacings + upto 11% In hole depth are

‘considered accoptatle

Now add an “acceptble” 05m variation in charge column tength

* Assume an 1Om charge column with + 05m variation

+ This 25% variation in enarge

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flexiroc D65: Surface Drill Rig For Quarrying and MiningDocument5 pagesFlexiroc D65: Surface Drill Rig For Quarrying and MiningMohamed Badian TraoreNo ratings yet

- Smartroc D65: DTH Surface Drill Rig For Quarrying and MiningDocument5 pagesSmartroc D65: DTH Surface Drill Rig For Quarrying and MiningMohamed Badian TraoreNo ratings yet

- O-Pitblast Manual v.3.0Document178 pagesO-Pitblast Manual v.3.0Mohamed Badian TraoreNo ratings yet

- Cat 980H Wheel Loader: Fuel BurnDocument2 pagesCat 980H Wheel Loader: Fuel BurnMohamed Badian TraoreNo ratings yet

- Caterpillar D9T DozerDocument1 pageCaterpillar D9T DozerMohamed Badian TraoreNo ratings yet

- Liebherr R9100 Ilovepdf CompressedDocument22 pagesLiebherr R9100 Ilovepdf CompressedMohamed Badian TraoreNo ratings yet

- Yanfolila Project - Mali: Fastest Growing Gold District in The WorldDocument18 pagesYanfolila Project - Mali: Fastest Growing Gold District in The WorldMohamed Badian TraoreNo ratings yet

- Flow Calculation From A Nozzle Nozzle DischargeDocument1 pageFlow Calculation From A Nozzle Nozzle DischargeMohamed Badian TraoreNo ratings yet

- Aeci Mining Explosives Product Catalogue Surface Bulk Emulsions 2019 OctoberDocument14 pagesAeci Mining Explosives Product Catalogue Surface Bulk Emulsions 2019 OctoberMohamed Badian Traore0% (1)

- Liebherr R9100 Ilovepdf CompressedDocument22 pagesLiebherr R9100 Ilovepdf CompressedMohamed Badian TraoreNo ratings yet

- Flow Calculation by Measuring Horizontal Pipe DischargeDocument2 pagesFlow Calculation by Measuring Horizontal Pipe DischargeMohamed Badian TraoreNo ratings yet

- Analyse Économique Du Développement Du Secteur Minier Au Mali - FINAL PDFDocument87 pagesAnalyse Économique Du Développement Du Secteur Minier Au Mali - FINAL PDFMohamed Badian TraoreNo ratings yet

- DR17 HDPE Friction Loss Table PDFDocument1 pageDR17 HDPE Friction Loss Table PDFMohamed Badian TraoreNo ratings yet

- Source Crane Co Technical Paper No 409, Engineering Division., 1942Document1 pageSource Crane Co Technical Paper No 409, Engineering Division., 1942Mohamed Badian TraoreNo ratings yet