Professional Documents

Culture Documents

Capacity

Uploaded by

preeyal0 ratings0% found this document useful (0 votes)

6 views3 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesCapacity

Uploaded by

preeyalCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Capacity is the amount of input resources available

to produce output over a period of time.

Such resources are machinery, man power, capital,

efficiency etc

Maximum rate of output per unit of time: 1000 TV

sets to be delivered within 30mins from one area to

other. We need a specific quantity of vehicles so

that it can delivered within 30mins. We can’t use

only one vehicle as time period can exceed.

Units of resource availability. As on Mondays, there

are many patients as many hosp are closed on

Sundays, so the hosp needs sufficient resource i.e.

beds or etc as there are many patients admitted.

Economies of scales refers to when the capacity of

output produced increases and the cost decreases.

Walmart (WMT) is the largest US supplier of

groceries, and the largest US general retailer. They

can buy in such enormous bulk, and force suppliers

to accept such low prices, so they can sell at low

prices to customers.

Diseconomies of scales refers when the capacity of

output produced increases and the cost increases

too. When the production of a company increases,

the main impact is seen on the machinery involved

in the production process and labor performing the

work. The overproduction might wear machinery

which can cause accidents and damage to

machinery. The insurance cost and installation of

new machinery increase the cost of production and

results in diseconomies of scale.

Theoretical capacity: is the level of manufacturer’s

production if all its equipments and operations are

performed continuously at their optimum

efficiency. It is not realistic due to repairs,

maintenance, holidays, power failures, labor

shortages etc which ll result into downtime.(they

don’t take into account)

Effective capacity/practical: is the level of

manufacturer’s production which is less than

theoretical capacity in terms of machine hours,

pounds etc.

For example, if a manufacturer has theoretical

capacity of 2,080 hours based on 8 hours per day

for 5 days per week for 52 weeks, its practical

capacity might be only 1,860 hours. The 220 hour

difference could be associated with repairs,

maintenance, setups, plant shutdowns for holidays,

and other downtime. Hence, a manufacturer's

practical capacity is more realistic than its

theoretical capacity.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Learn JavaScript - Functions CheatsheetDocument2 pagesLearn JavaScript - Functions CheatsheetpreeyalNo ratings yet

- University of Barishal: Project Report On Impact of Management Information System in Amazon IncDocument49 pagesUniversity of Barishal: Project Report On Impact of Management Information System in Amazon IncpreeyalNo ratings yet

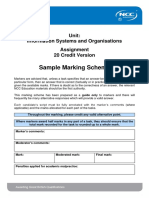

- PBO Assignment QP Spring - Winter 2021 20 Credit FINALDocument5 pagesPBO Assignment QP Spring - Winter 2021 20 Credit FINALpreeyalNo ratings yet

- Skills For Computing 4 September 2018 Marking SchemeDocument9 pagesSkills For Computing 4 September 2018 Marking SchemepreeyalNo ratings yet

- Unit: Skills For Computing Assignment Title: IT System and Creation of Website For A Furniture Retailer September 2018Document3 pagesUnit: Skills For Computing Assignment Title: IT System and Creation of Website For A Furniture Retailer September 2018preeyalNo ratings yet

- SFC Assignment MS September 2018 - FINALDocument4 pagesSFC Assignment MS September 2018 - FINALpreeyalNo ratings yet

- Swot and Pest and Economic, Political, Social, Technological FactorsDocument5 pagesSwot and Pest and Economic, Political, Social, Technological FactorspreeyalNo ratings yet

- Assignment Presentation Requirements1Document1 pageAssignment Presentation Requirements1preeyalNo ratings yet

- OOA, SSADM, Ethics, People and OrganisationDocument5 pagesOOA, SSADM, Ethics, People and OrganisationpreeyalNo ratings yet

- Learn JavaScript - Scope CheatsheetDocument2 pagesLearn JavaScript - Scope CheatsheetpreeyalNo ratings yet

- CATWOE and Stakeholder, Cost Benefit AnalysisDocument7 pagesCATWOE and Stakeholder, Cost Benefit AnalysispreeyalNo ratings yet

- DW Assignment Spring - Winter 2021 20 Credit FINALDocument5 pagesDW Assignment Spring - Winter 2021 20 Credit FINALpreeyalNo ratings yet

- Principles of Business Operations Operations For Business CompetitivenessDocument30 pagesPrinciples of Business Operations Operations For Business CompetitivenesspreeyalNo ratings yet

- Principles of Business Operations Using Technology: Topic 5Document34 pagesPrinciples of Business Operations Using Technology: Topic 5preeyalNo ratings yet

- Unit: Dynamic Websites Assignment Title: Plastic Pollution Autumn 2019Document4 pagesUnit: Dynamic Websites Assignment Title: Plastic Pollution Autumn 2019preeyalNo ratings yet

- 06 L5DB Information Systems and Organisations ISO Sample Assignment MSDocument8 pages06 L5DB Information Systems and Organisations ISO Sample Assignment MSpreeyalNo ratings yet

- Learn JavaScript - Introduction CheatsheetDocument4 pagesLearn JavaScript - Introduction CheatsheetpreeyalNo ratings yet

- Strategic Ict & Ebusiness Implementation: Pharmaceutical Store Management SystemDocument56 pagesStrategic Ict & Ebusiness Implementation: Pharmaceutical Store Management SystempreeyalNo ratings yet